Gradient neodymium iron boron magnet and manufacturing method thereof

A production method, NdFeB technology, applied in the direction of magnets, magnetic objects, inductors/transformers/magnets, etc., can solve the problems of poor controllability and large usage of heavy rare earth elements, and achieve strong controllability and effective performance The effect of high utilization rate and outstanding substantive features

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

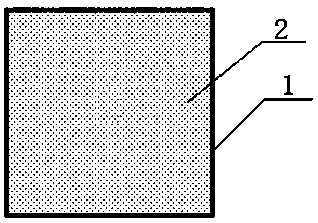

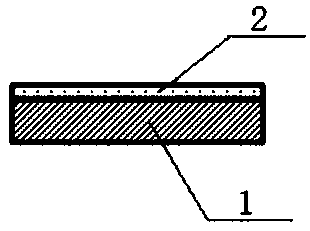

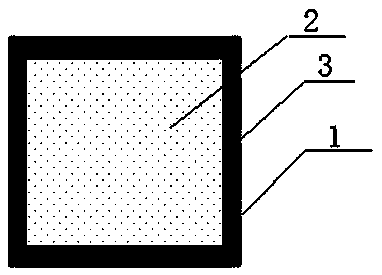

[0033] Example 1, see figure 1 , 2 , 3, 4, 5, 6, the production method of the gradient NdFeB magnet is as follows:

[0034] Place a plurality of NdFeB magnet sheets 1 with a size of 20mm*20mm*5mm (T) tightly and evenly in the argon chamber in a vertical manner according to the magnetization direction, and put the terbium powder with an average particle size of 5 microns, uniformly Cover the surface of the NdFeB magnet sheet, the weight of terbium powder is 0.5% of the weight of the NdFeB magnet sheet, and then move the NdFeB magnet sheet 1 covered with the terbium powder layer 2 to the laser, and use the laser to clean the NdFeB magnet. The surface of the sheet 1 is irradiated within 2mm from the edge (the irradiation area accounts for about 36% of the coverage area of the heavy rare earth powder), so that the terbium powder in this area is rapidly heated and solidified into a heavy rare earth film layer 3 and combined with the NdFeB magnet sheet 1 If adhesion occurs on th...

Embodiment 2

[0036] Example 2, see figure 1 , 2 , 3, 4, 5, 6, the production method of the gradient NdFeB magnet is as follows:

[0037] Place a plurality of NdFeB magnet sheets 1 with a size of 40mm*40mm*10mm (T) tightly and evenly in the argon chamber in a vertical manner according to the magnetization direction, and put the terbium powder with an average particle size of 100 microns, uniformly Cover the surface of the NdFeB magnet sheet, the weight of terbium powder is 2.0% of the weight of the NdFeB magnet sheet, and then move the NdFeB magnet sheet 1 covered with the terbium powder layer 2 to the laser, and use the laser to clean the NdFeB magnet. The area within 3mm from the edge of the sheet surface is irradiated (the irradiation area accounts for about 28% of the coverage area of the heavy rare earth powder), so that the terbium powder in this area is rapidly heated and solidified into a heavy rare earth film layer 3 and adheres to the NdFeB magnet sheet 1 After cleaning the un...

Embodiment 3

[0039] Example 3, see figure 1 , 2 , 3, 4, 5, 6, the production method of the gradient NdFeB magnet is as follows:

[0040] Place a plurality of NdFeB magnet sheets 1 with a size of 80mm*20mm*5mm (T) tightly and evenly in the argon gas chamber in a vertical manner according to the magnetization direction, and evenly cover the dysprosium powder with an average particle size of 200 microns On the surface of the NdFeB magnet sheet, the weight of dysprosium powder is 0.5% of the weight of the NdFeB magnet sheet, and then the NdFeB magnet sheet 1 covered with the dysprosium powder layer 2 is moved under the laser, and the NdFeB magnet sheet is processed by the laser. The area within 2mm from the surface to the edge is irradiated (the irradiation area accounts for about 24% of the coverage area of the heavy rare earth powder), so that the dysprosium powder in this area is rapidly heated and solidified into a heavy rare earth film layer 3 and combined with the NdFeB magnet sheet 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com