Novel sintered ndfeb permanent magnet and preparation method thereof

A technology of NdFeB and permanent magnets, which is applied in the fields of magnetic objects, inductors/transformers/magnets, magnetic materials, etc. It can solve the problems of high production cost of sintered NdFeB permanent magnets, unbalanced use of rare earth resources, and high equipment performance requirements , to achieve the effect of improving the particle size distribution of magnetic powder, reducing material costs, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

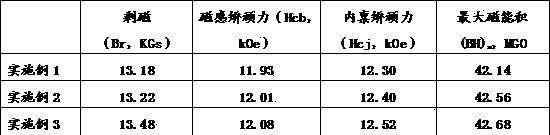

Examples

Embodiment 1

[0028] A novel sintered NdFeB permanent magnet, the composition expression of the sintered NdFeB permanent magnet is: (Ce 0.05 ,Nd 0.95 ) 0.4 -Co 0.2 -Gd 0.3 -Fe 99.1 B 0.95 .

[0029] The preparation method of the above-mentioned sintered NdFeB permanent magnet is carried out as follows:

[0030] (1) Melt the prepared NdFeB materials, cerium, gadolinium iron and cobalt under argon protection at a temperature of 1400-1450°C using a vacuum induction quick-setting furnace, and cast the molten steel into a rotating cooling copper On the stick, prepare a NdFeB alloy sheet with a thickness of 0.2-0.4mm, the purity of the cerium used is 99.5%, and the mass fraction of gadolinium in the gadolinium iron used is 71%;

[0031] (2) Use hydrogen to break the furnace, absorb hydrogen under the hydrogen pressure of 0.1Mpa, dehydrogenate at 550°C, and crush the NdFeB alloy flakes into 100-150μm NdFeB alloy powder;

[0032] (3) The powder obtained in step (2) is further crushed into 2...

Embodiment 2

[0036] A novel sintered NdFeB permanent magnet, the composition expression of the sintered NdFeB permanent magnet is: (Ce 0.1 ,Nd 0.9 ) 0.9 -Cu 1.0 -Gd 2.0 -Zr 2.0 -Fe 94.1 B 1.05 .

[0037] The preparation method of the above-mentioned sintered NdFeB permanent magnet is carried out as follows:

[0038] (1) Melt the prepared NdFeB material, cerium, gadolinium iron, copper and zirconium under the protection of argon at a temperature of 1550-1600°C using a vacuum induction quick-setting furnace, and cast the molten steel into a rotating On the cooling copper rod, a NdFeB alloy sheet with a thickness of 0.6-0.8mm is prepared, the purity of the cerium used is 99.5%, and the mass fraction of gadolinium in the gadolinium iron used is 72%;

[0039] (2) Using hydrogen breaking furnace, absorb hydrogen under 0.1Mpa hydrogen pressure, dehydrogenate at 550°C, and crush NdFeB alloy flakes into 180-200μm NdFeB alloy powder;

[0040] (3) The powder obtained in step (2) is further c...

Embodiment 3

[0044] A novel sintered NdFeB permanent magnet, the composition expression of the sintered NdFeB permanent magnet is: (Ce 0.075 ,Nd 0.925 ) 0.5 -Gd 0.5 -Al 2.0 -Fe 97 B 1.0 .

[0045] The preparation method of the above-mentioned sintered NdFeB permanent magnet is carried out as follows:

[0046](1) Melt the prepared NdFeB materials, cerium and gadolinium iron under the protection of argon at a temperature of 1500-1550°C using a vacuum induction quick-setting furnace, and cast the molten steel onto a rotating cooling copper rod , the NdFeB alloy flakes with a thickness of 0.4-0.6mm are prepared, the purity of the cerium used is 99.5%, and the mass fraction of gadolinium in the gadolinium iron used is 71%;

[0047] (2) Utilize the hydrogen breaking furnace, absorb hydrogen under the hydrogen pressure of 0.1Mpa, dehydrogenate at 550°C, and crush the NdFeB alloy flakes into 120-160μm NdFeB alloy powder;

[0048] (3) The powder obtained in step (2) is further crushed into...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com