Preparation method of rare-earth permanent magnet material

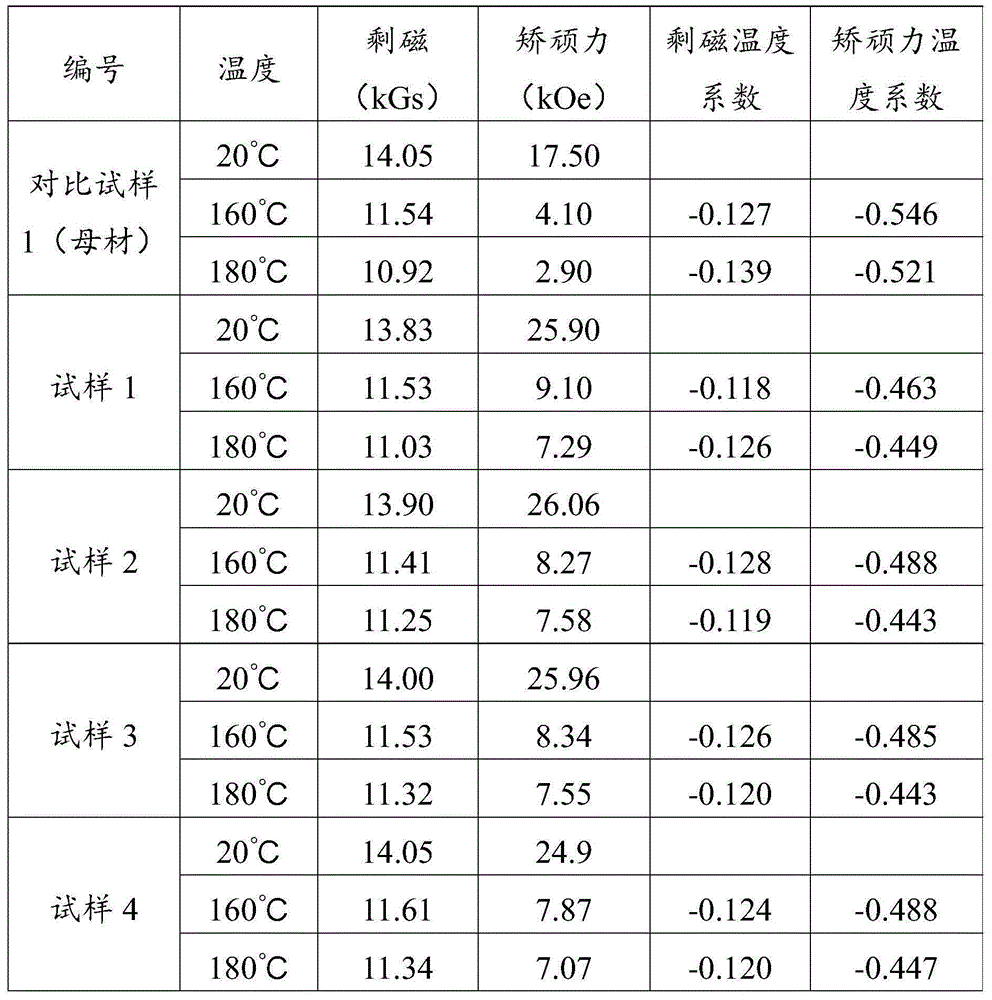

一种制造方法、稀土永磁的技术,应用在磁性材料、电感/变压器/磁铁制造、磁性物体等方向,能够解决中重稀土化合物浪费、无法充分地利用中重稀土、渗透效果差等问题,达到降低剩磁温度系数和矫顽力温度系数、抗退磁能力改善、提高矫顽力的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0091] The manufacture method of the rare earth permanent magnet material of embodiment 1, its technological process is as follows:

[0092] S1) Magnet manufacturing process:

[0093] S1-1) Smelting process: in terms of atomic percentage, according to 13.8% of Nd, 0.2% of Dy, 0.15% of Cu, 1.2% of Co, 0.3% of Al, 5.85% of B, 0.1% of Ga and the balance Prepare raw materials with Fe, put the raw materials into a vacuum intermediate frequency quick-setting induction furnace, vacuumize to less than 1Pa, fill with argon protection for heating and melting, pour the melted alloy liquid on the rotating cooling copper roller, and prepare a thickness of 0.3 mm alloy sheet;

[0094] S1-2) Powder making process: In the hydrogen crushing furnace, the alloy flakes obtained from the smelting process S1-1) are subjected to low-temperature hydrogen absorption and high-temperature dehydrogenation to form coarse magnetic powder, and then the coarse magnetic powder is used as a medium in the jet ...

Embodiment 2

[0104] The manufacture method of the rare earth permanent magnet material of embodiment 2, its technological process is as follows:

[0105]S1) Magnet manufacturing process: Same as the magnet manufacturing process S1) of Example 1.

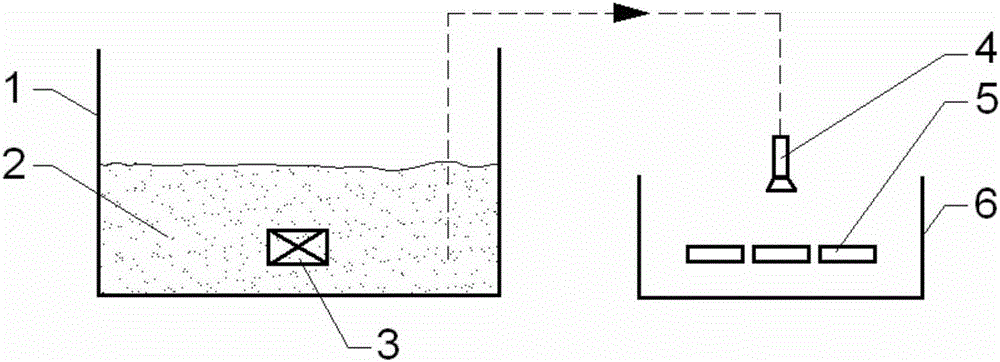

[0106] S2) Atomization and spraying process: the sintered rare earth magnet sample obtained by the magnet manufacturing process S1) without aging treatment is put into the sample as attached figure 1 In the atomized spraying device shown, anhydrous ethanol + terbium oxide (TbO 3 ) solution (containing 0.5 g of terbium oxide per milliliter of absolute ethanol) atomized and sprayed on the sintered rare earth magnet sample, and then put the sample into an oven and bake it at 130°C for 2 hours;

[0107] S3) Infiltration process: put the sample obtained by the atomization spraying process S2) into a stainless steel airtight container, and put the stainless steel airtight container into a vacuum infiltration furnace, and evacuate until the absolute va...

Embodiment 3

[0111] The manufacturing method of the rare earth permanent magnet material of embodiment 3, its process flow is as follows: S1) magnet manufacturing process: same as the magnet manufacturing process S1) of embodiment 1.

[0112] S2) Atomization and spraying process: the sintered rare earth magnet sample obtained by the magnet manufacturing process S1) without aging treatment is put into the sample as attached figure 1 In the shown device, gasoline + terbium fluoride (TbF 3 ) solution (0.5 grams of terbium fluoride per milliliter of gasoline) was sprayed on the sintered rare earth magnet sample after atomization, and then the sample was put into an oven and baked at 130°C for 2 hours;

[0113] S3) Infiltration process: put the sample obtained by the atomization spraying process S2) into a stainless steel airtight container, and put the stainless steel airtight container into a vacuum infiltration furnace, and evacuate until the absolute vacuum degree is less than 5.0×10 -5 At...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| sintering temperature | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com