Permanent magnet rotary motor

A technology of rotating electrical machines and permanent magnets, applied to synchronous motors with stationary armatures and rotating magnets, magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc. It can increase the reluctance torque, reduce the material cost, and improve the demagnetization resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

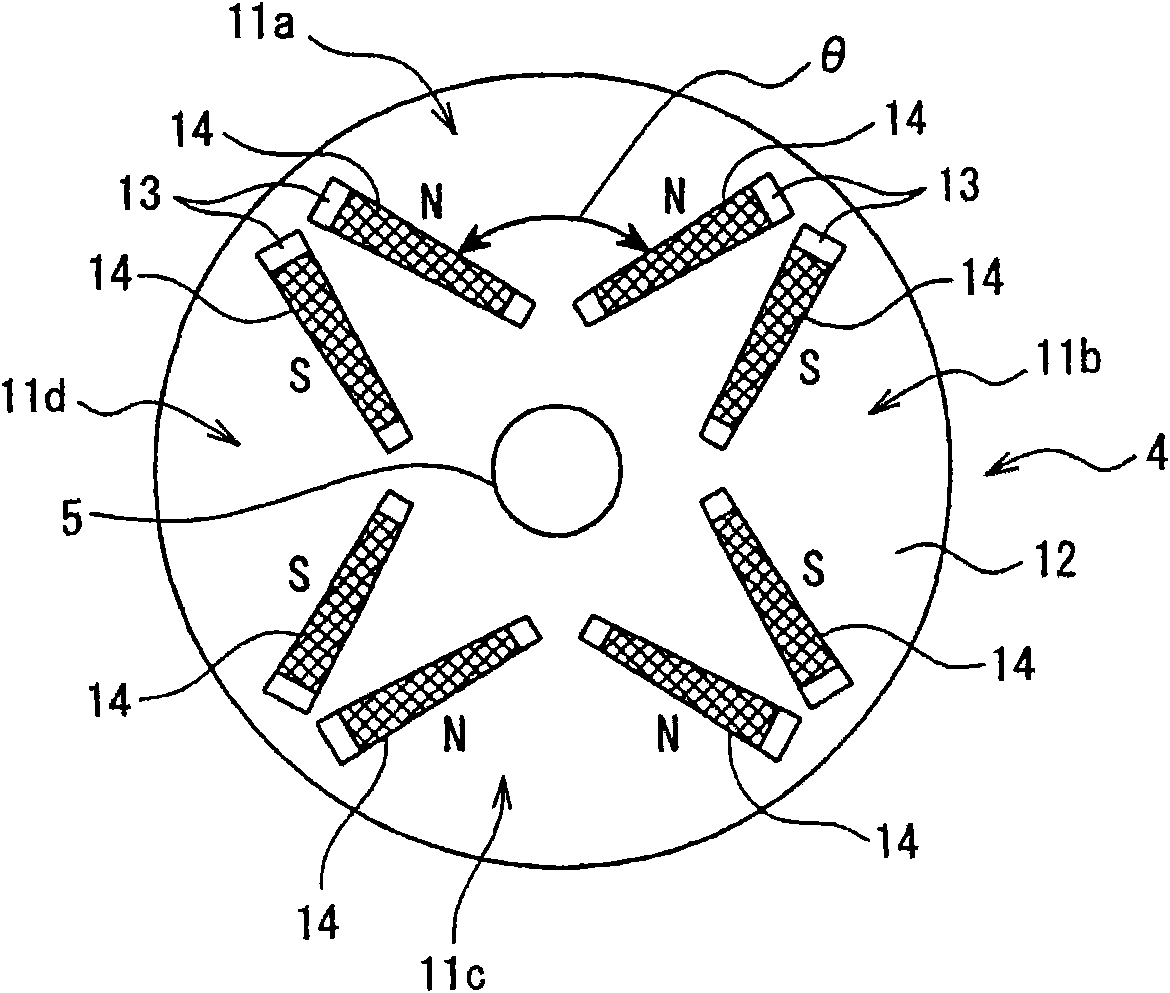

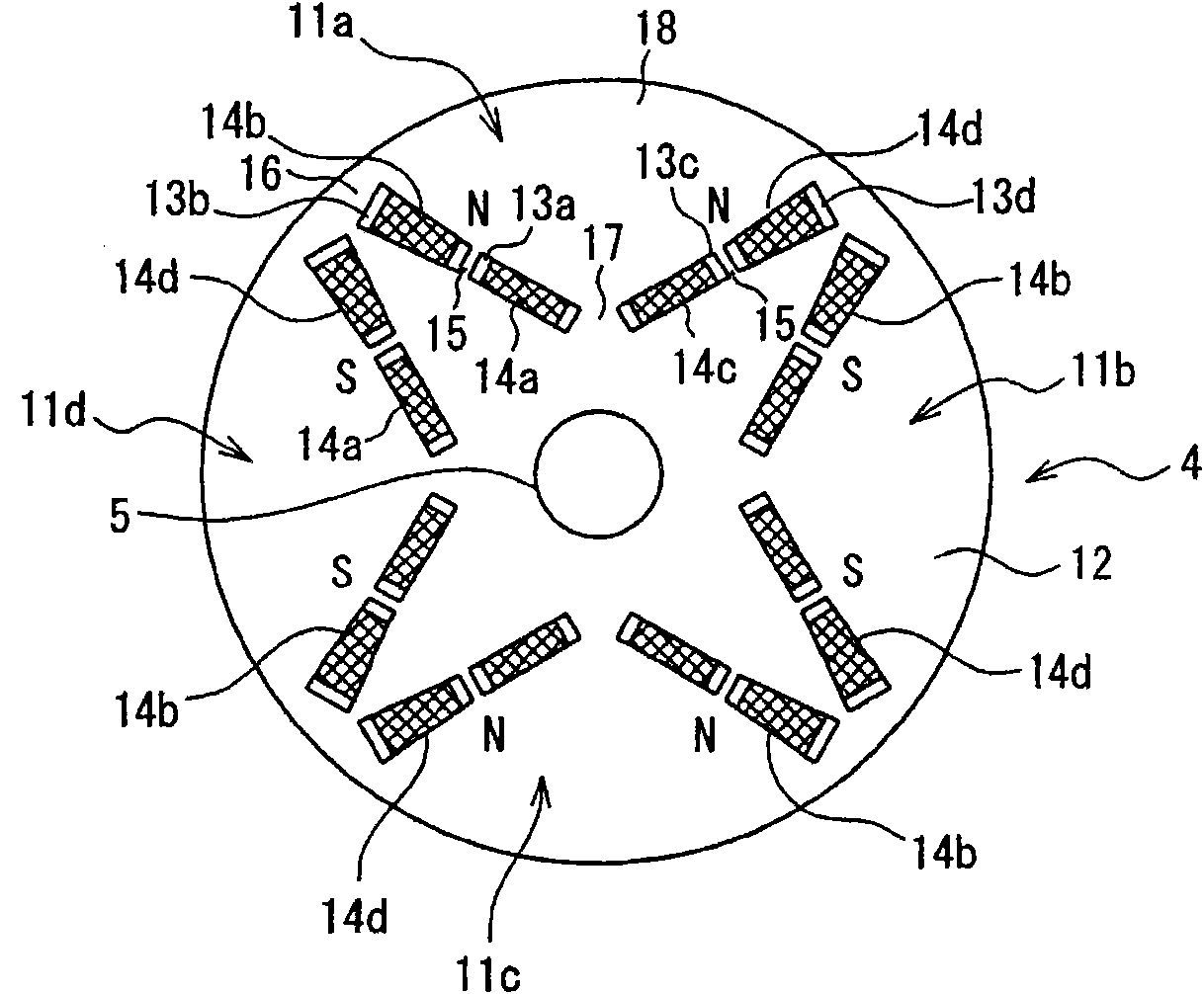

[0043] Hereinafter, embodiments of the present invention will be described based on the drawings.

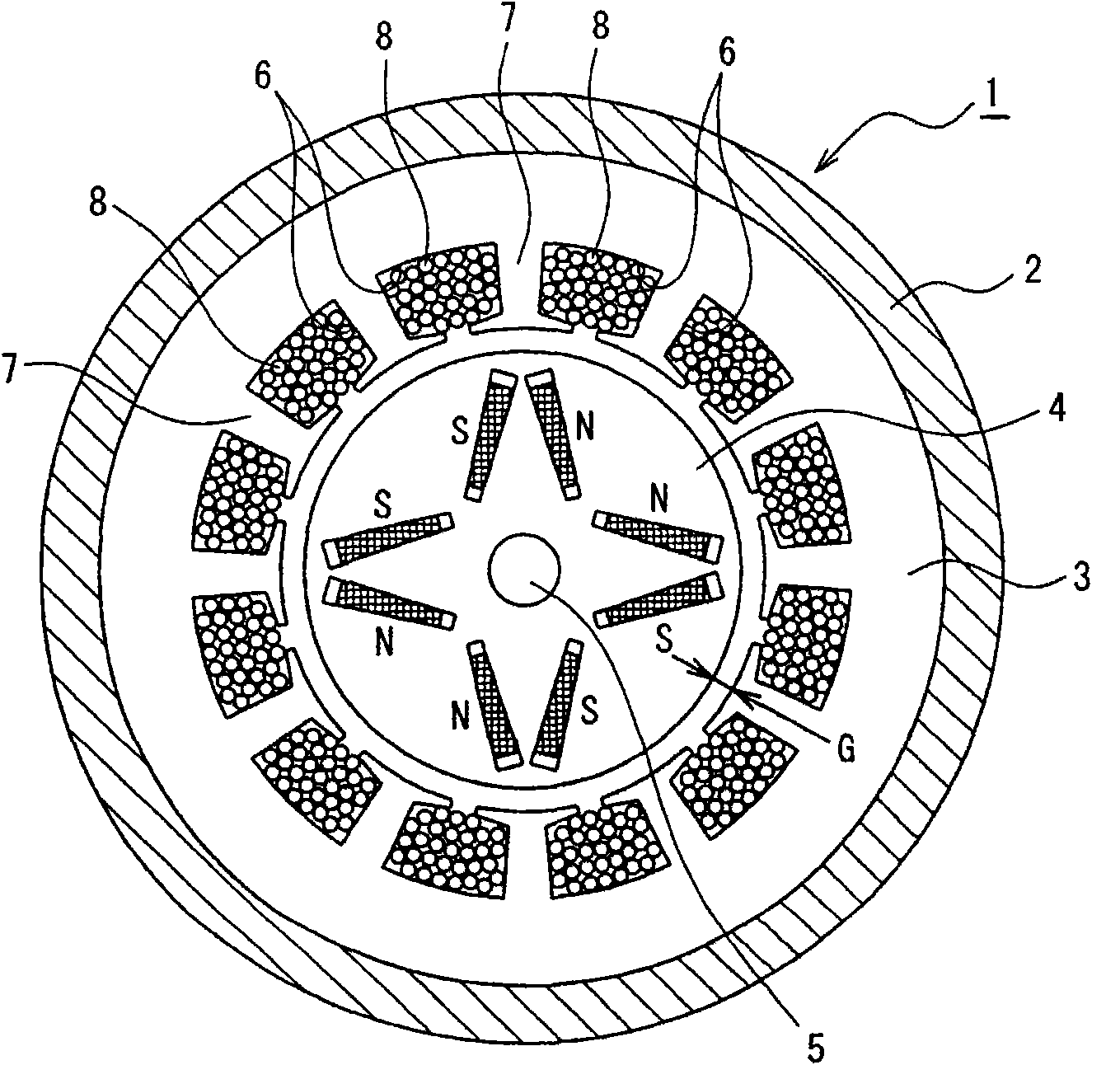

[0044] figure 1 It is a sectional view showing the first embodiment of the present invention. in the figure 1 Among them, the permanent magnet type rotating electrical machine 1 is constituted by an inner rotor type inner magnet type synchronous rotating electrical machine. This permanent magnet type rotating electrical machine 1 has a cylindrical frame 2 . On the inner peripheral side of the cylindrical frame 2, a cylindrical stator 3 is arranged, and on the inner peripheral side of the stator 3, a rotor 4 facing across a predetermined air gap G is arranged. The rotor 4 is supported by a rotating shaft 5 fitted in its center, and is rotatably arranged.

[0045] The stator 3 has, for example, 12 slots 6 and 12 teeth 7 formed at equal intervals in the circumferential direction on the inner peripheral surface side. An exciting coil 8 wound around each tooth 7 and fitted in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com