Hybrid permanent magnet rotor assembly and corresponding motor

A permanent magnet, rare earth permanent magnet technology, applied in the direction of magnetic circuit rotating parts, magnetic circuit shape/style/structure, etc., can solve the problems of low motor magnetic flux, power drop, low surface magnetic flux density, etc., and prolong the service life , The effect of reducing material cost and reducing manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following description of preferred embodiments is exemplary only and in no way restricts the invention and its application or usage.

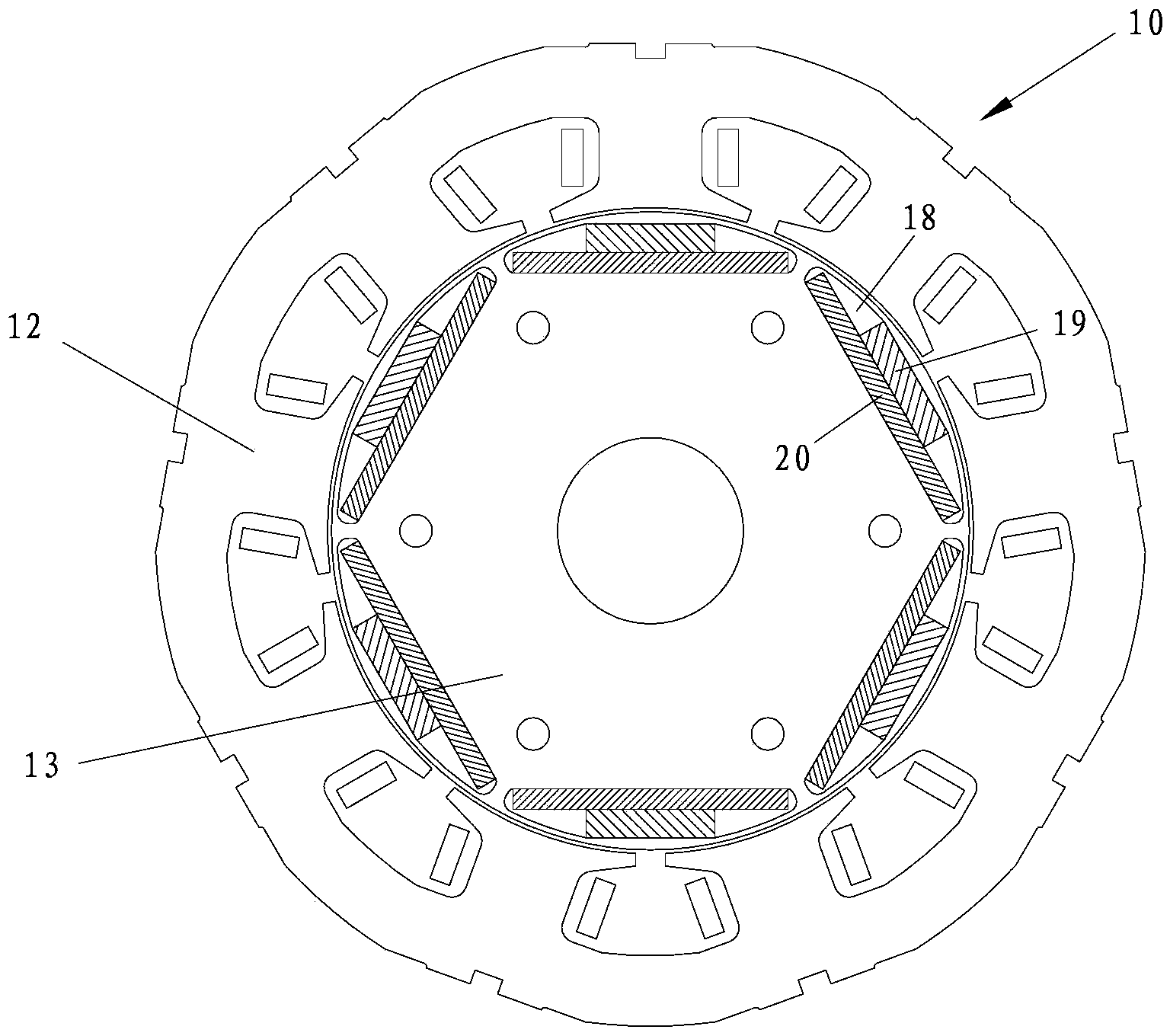

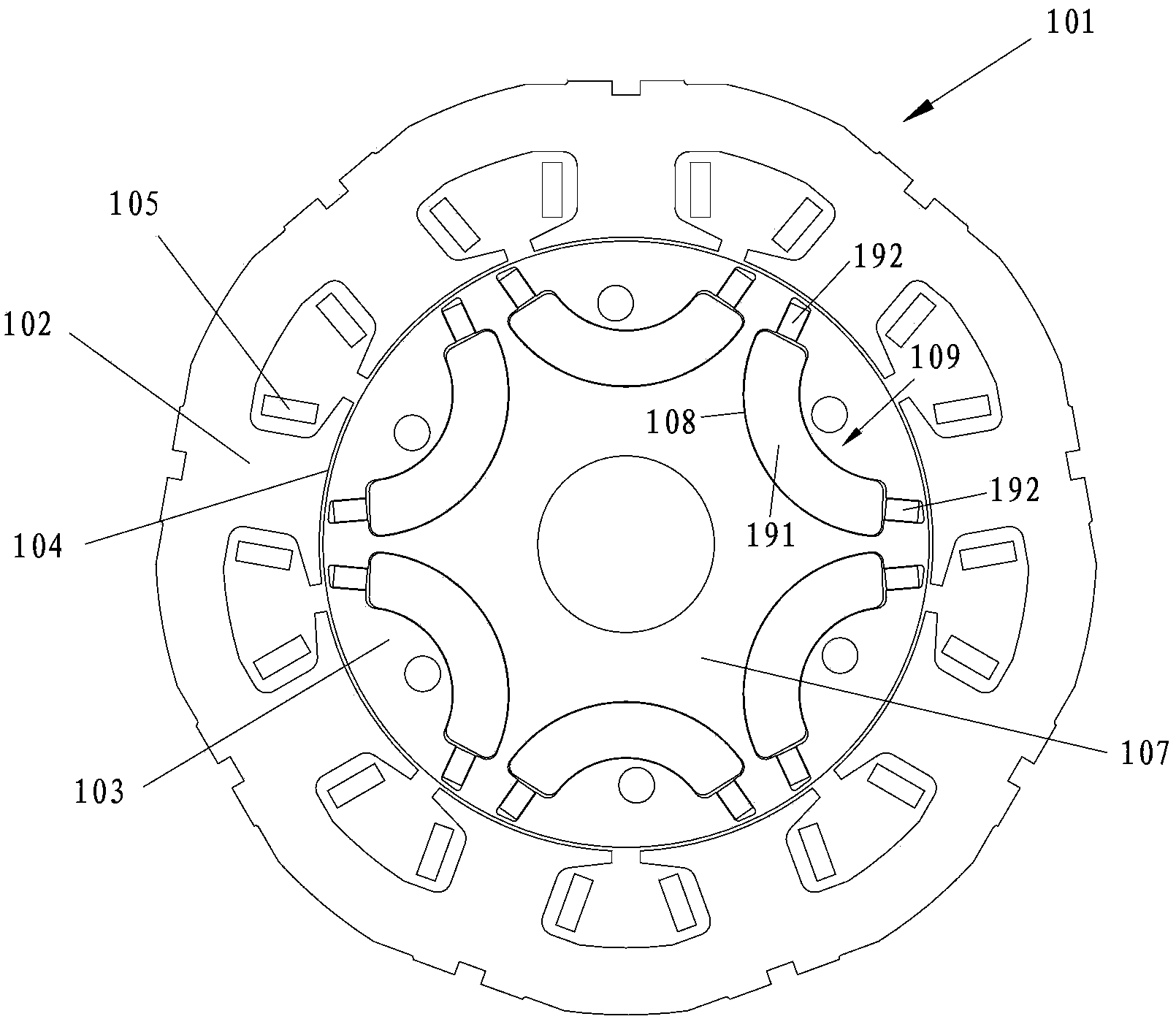

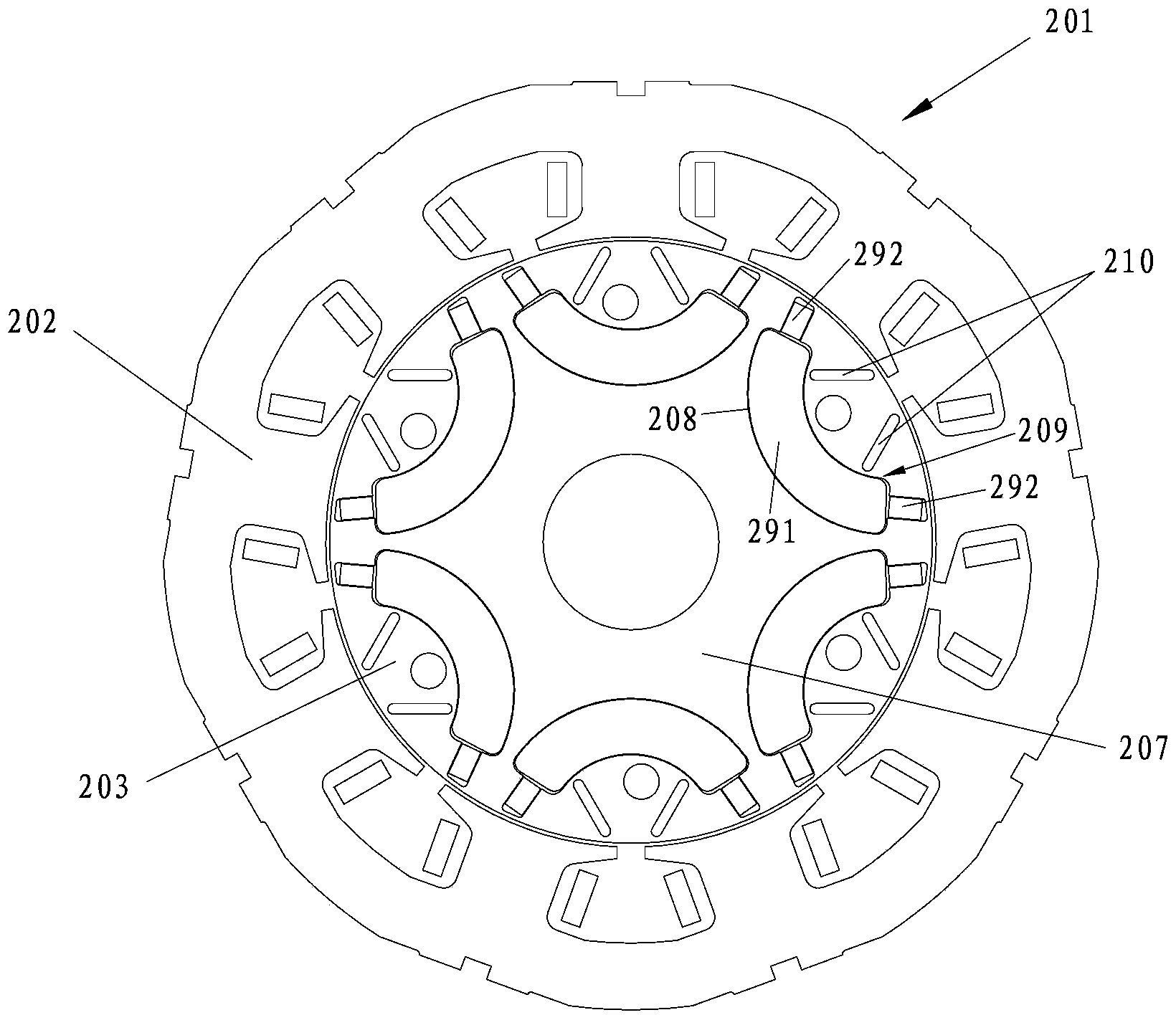

[0020] With reference to the accompanying drawings, figure 2 An interior hybrid permanent magnet motor 101 according to a preferred embodiment of the present invention is shown. The interior hybrid permanent magnet electric machine 101 includes a stator assembly 102 and a rotor assembly 103 within a cavity of the stator assembly 102 . According to known techniques for constructing rotating electrical machines, by using the rotor shaft, rotor bearings and end shields ( figure 1 not shown in ) to position the rotor assembly 103 within the lumen of the stator assembly 102 . The stator assembly 102 defines a plurality of stator teeth 104 extending in a radial direction thereof toward the interior cavity of the stator assembly 102, at figure 1 In the illustrated embodiment, there are 9 stator teeth 104, of course, the number of stator...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com