Air floatation rotor heat dissipation structure and motor

A technology of heat dissipation structure and rotor, applied in the direction of magnetic circuit shape/style/structure, mechanical equipment, electric components, etc., can solve the problems of increasing the volume and cost of the motor cooling system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

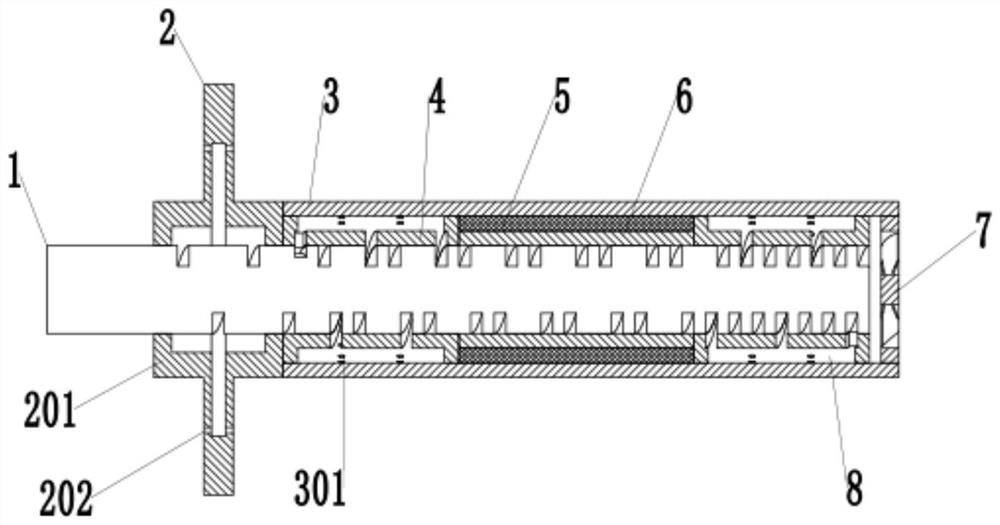

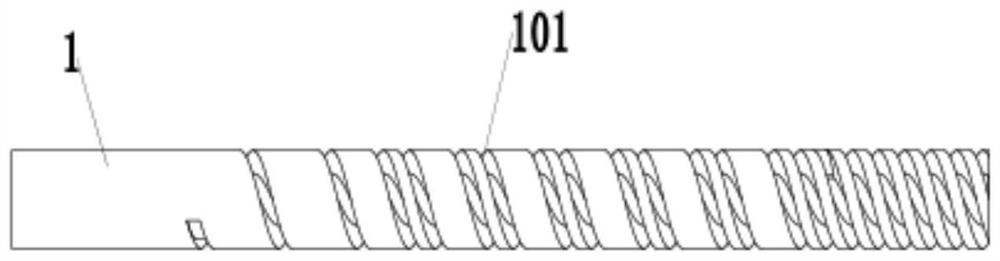

[0025] like Figure 2-5 As shown, an air-floating rotor heat dissipation structure includes a shaft center 1, a thrust plate 2, a sheath 3, a gas delivery device 4 and an impeller 7, and the thrust plate 2 and the sheath 3 are set on the outside of the shaft center 1 , the thrust plate 2 is docked with the sheath 3, and the end of the sheath 3 away from the thrust plate 2 is provided with an impeller 7, and the inside of the sheath 3 is provided with a magnetically conductive ring 6 that is sleeved on the outside of the shaft center 1. The outside of the magnetic ring 6 is covered with a magnetic steel 5, and the two sides of the magnetic steel 5 are provided with a gas delivery device 4 sleeved outside the shaft 1, and the side wall of the shaft 1 is provided with a spiral air channel 101, The side wall of the thrust plate 2 is provided with an orifice 202 communicating with the spiral air passage 101 , and the side wall of the sheath 3 is provided with an air hole 301 commun...

Embodiment 2

[0027] like Figure 2-5 As shown, an air-floating rotor heat dissipation structure includes a shaft center 1, a thrust plate 2, a sheath 3, a gas delivery device 4 and an impeller 7, and the thrust plate 2 and the sheath 3 are set on the outside of the shaft center 1 , the thrust plate 2 is docked with the sheath 3, and the end of the sheath 3 away from the thrust plate 2 is provided with an impeller 7, and the inside of the sheath 3 is provided with a magnetically conductive ring 6 that is sleeved on the outside of the shaft center 1. The outside of the magnetic ring 6 is covered with a magnetic steel 5, and the two sides of the magnetic steel 5 are provided with a gas delivery device 4 sleeved outside the shaft 1, and the side wall of the shaft 1 is provided with a spiral air channel 101, The side wall of the thrust plate 2 is provided with an orifice 202 communicating with the spiral air passage 101 , and the side wall of the sheath 3 is provided with an air hole 301 commun...

Embodiment 3

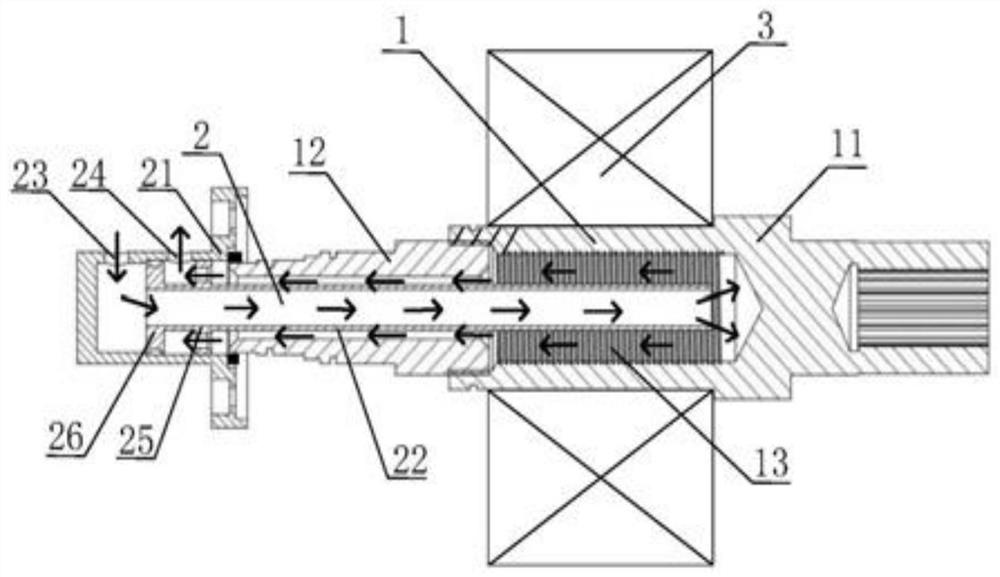

[0036] like Figure 2-5 As shown, a motor includes the heat dissipation structure of the air-floating rotor. The impeller 7 is in interference fit with the sheath 3. The impeller 7 and the sheath 3 can also be fixed together by welding. When the rotor rotates, it can move toward the rotor. High-pressure gas is pumped inside.

[0037] The high-pressure gas pumped by the impeller 7 is transported to each part through the spiral flow channel of the shaft center 1, and at least two flow channels flow through the motor rotor to take away the heat generated in the motor rotor.

[0038] The rear radial bearing gas output device is located between the sheath 3 and the shaft center 1, corresponding to the air hole 301. The part has at least one spiral groove, which can correspond to the spiral flow channel on the shaft center 1, and form an air flow with the corresponding spiral flow channel Channel, this part has an interference fit with the axis 1 to ensure that only the gas in the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com