Lithium-ion power battery

A power battery and lithium-ion technology, which is applied in the direction of secondary batteries, battery pack components, circuits, etc., can solve the problems of low electrolyte holding rate of insulating diaphragm, heat generation of lithium-ion power battery, shortened battery cycle life, etc., to achieve High performance-to-price ratio, sufficient amount of adsorbed electrolyte, and ingenious design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

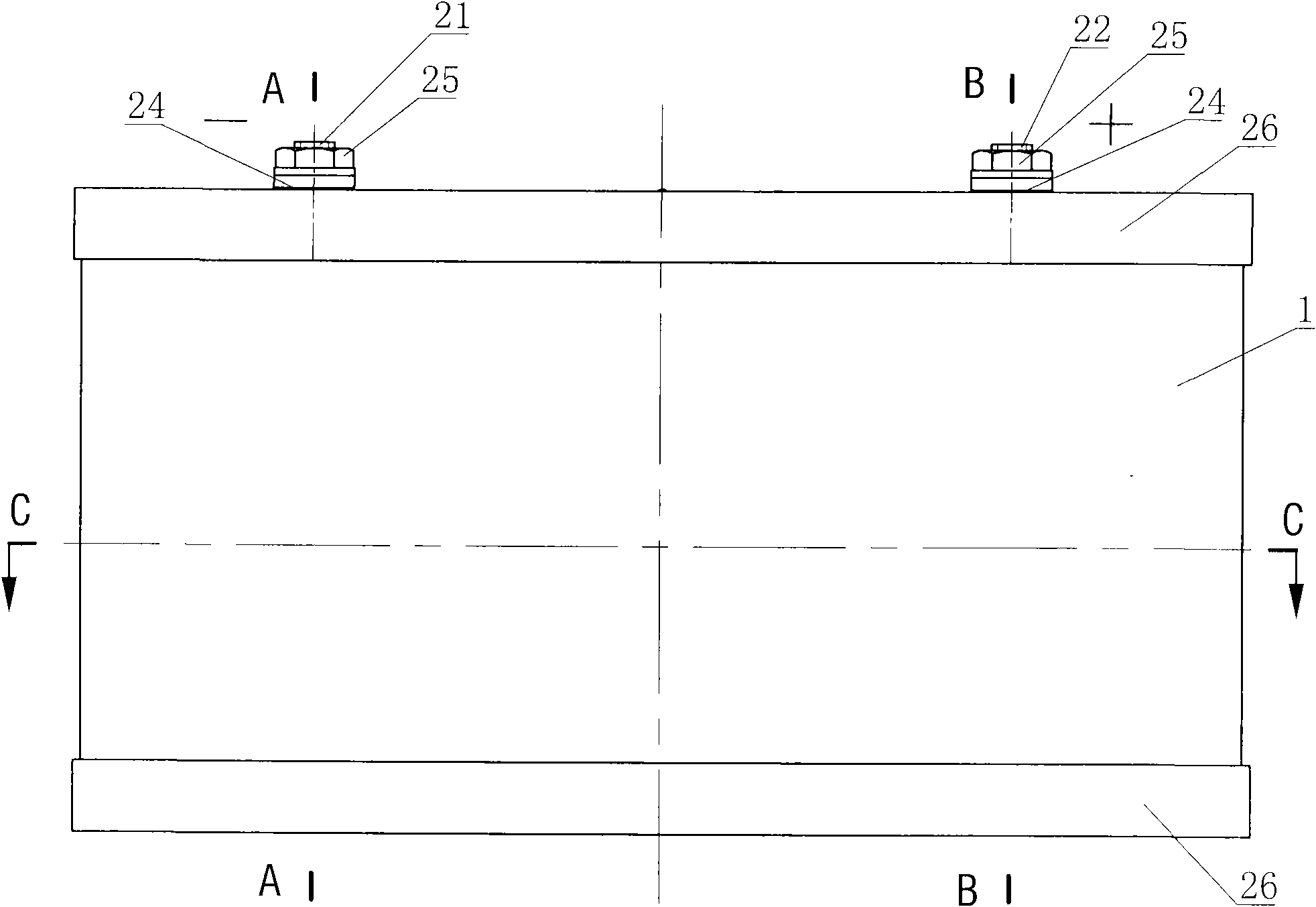

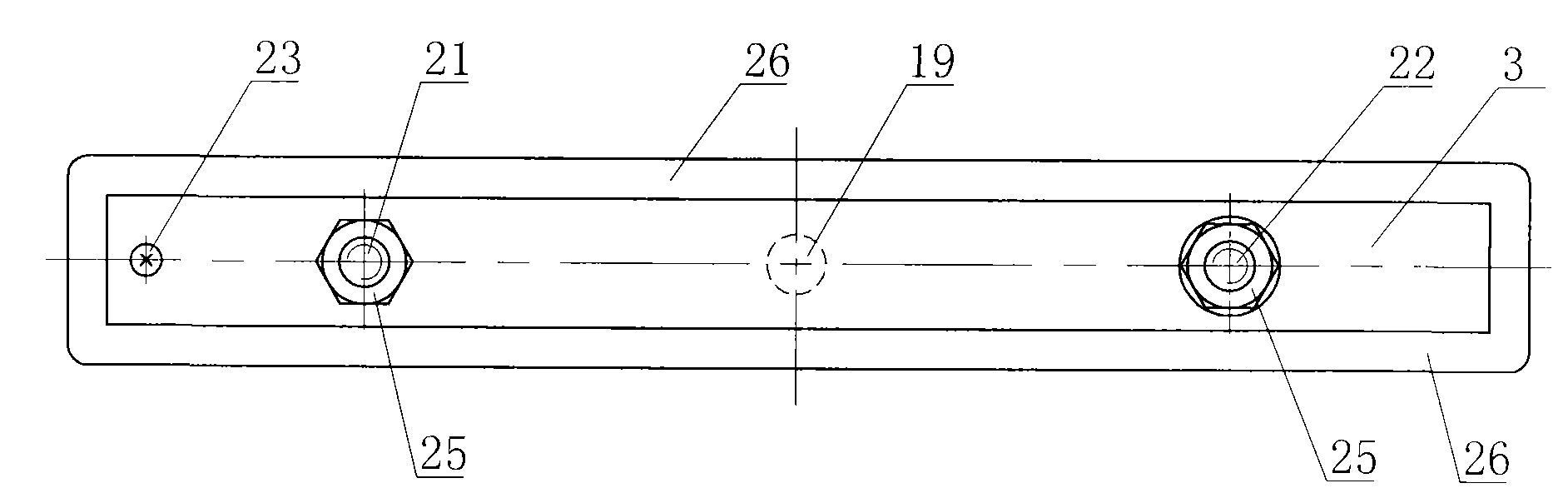

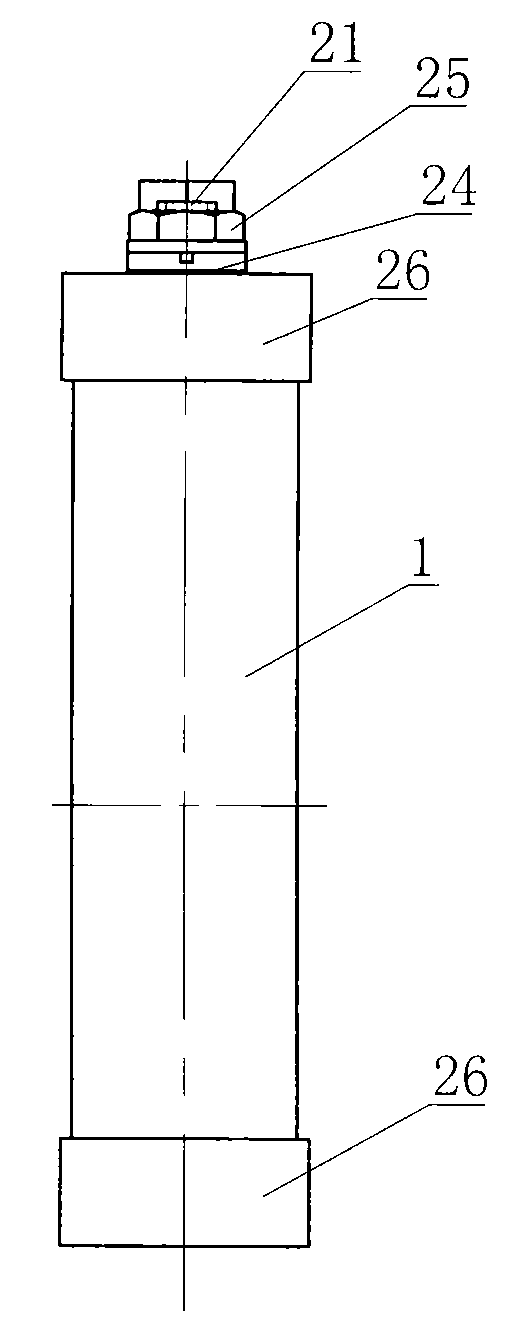

[0033] Such as Figure 1 to Figure 18As shown, a lithium-ion power battery includes a casing 1, an electronic mounting board 4 and a laminated cell 16, and also includes a negative tab joint 21 made of copper and a positive tab joint 22 made of aluminum. The shell 1 is made of stainless steel, so that the heat dissipation and corrosion resistance are better. The shell 1 is packaged on the outside of the electronic mounting board 4 and the laminated battery 16. The shell 1 includes a box body 2 and a cover plate 3. There is an electronic installation board 4, and the electronic installation board 4 is made of insulating material. The shell 1 is provided with a gap 17, the gap 17 is opened on the cover plate 3, the gap 17 includes two installation ports 17-1, a liquid injection port 17-2 and an explosion-proof port 17-3, on the explosion-proof ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com