Terminating electrode head structure for assemble cell

A battery and pole technology, applied in the field of terminal pole structure of assembled batteries, can solve problems such as inapplicability, complex series or parallel connection points, etc., and achieve the effect of reducing the risk of short circuit and safe isolation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

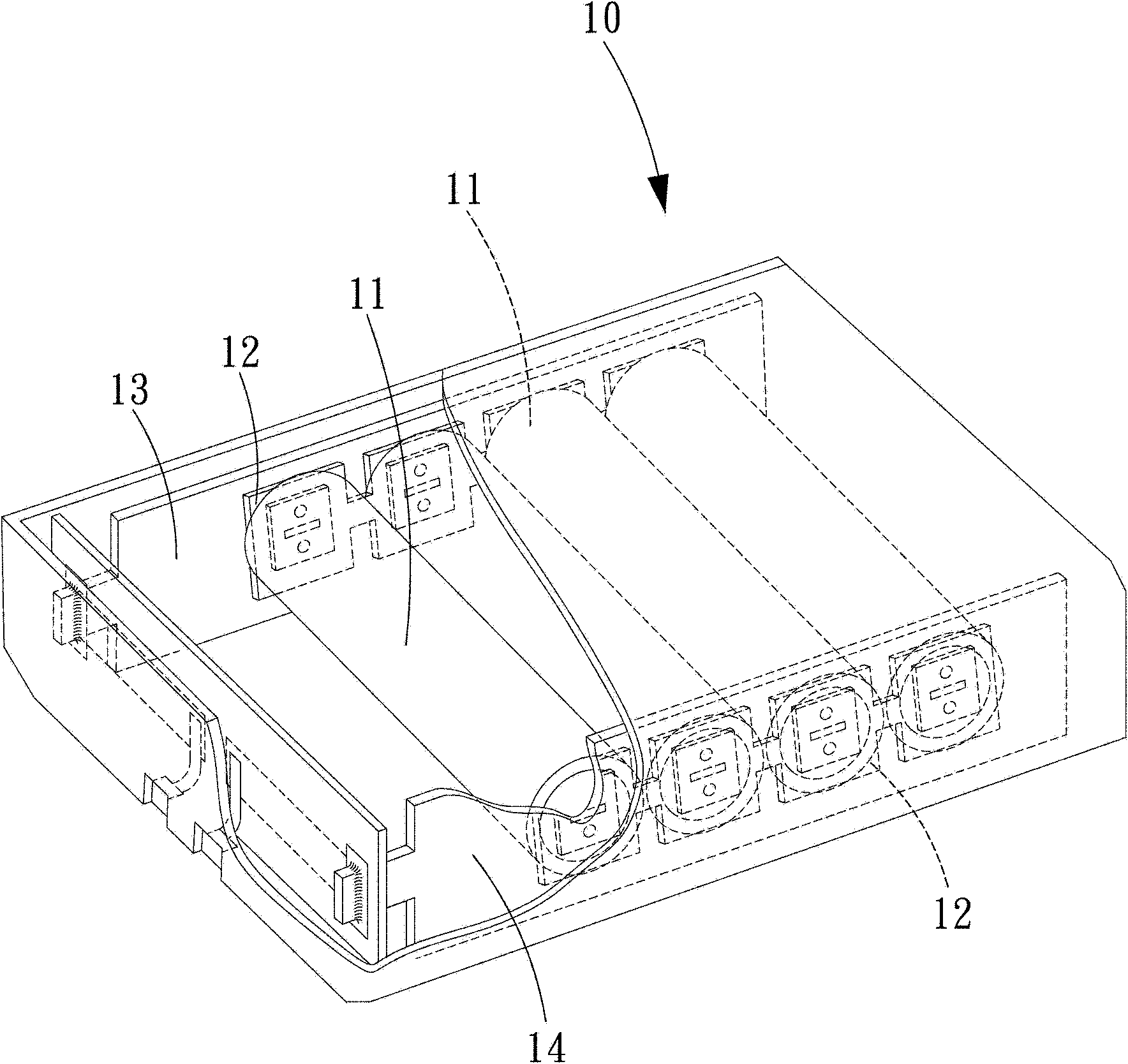

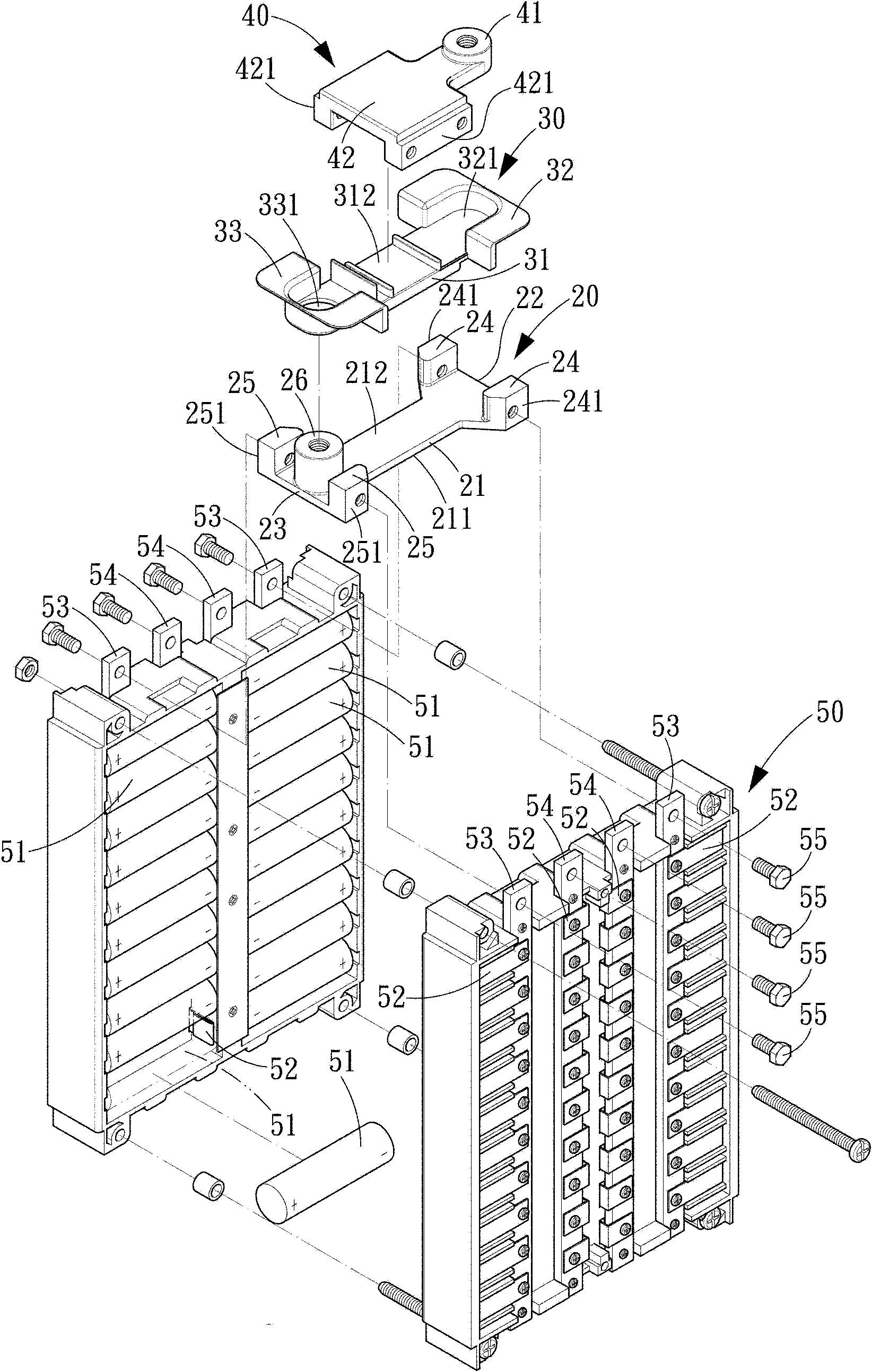

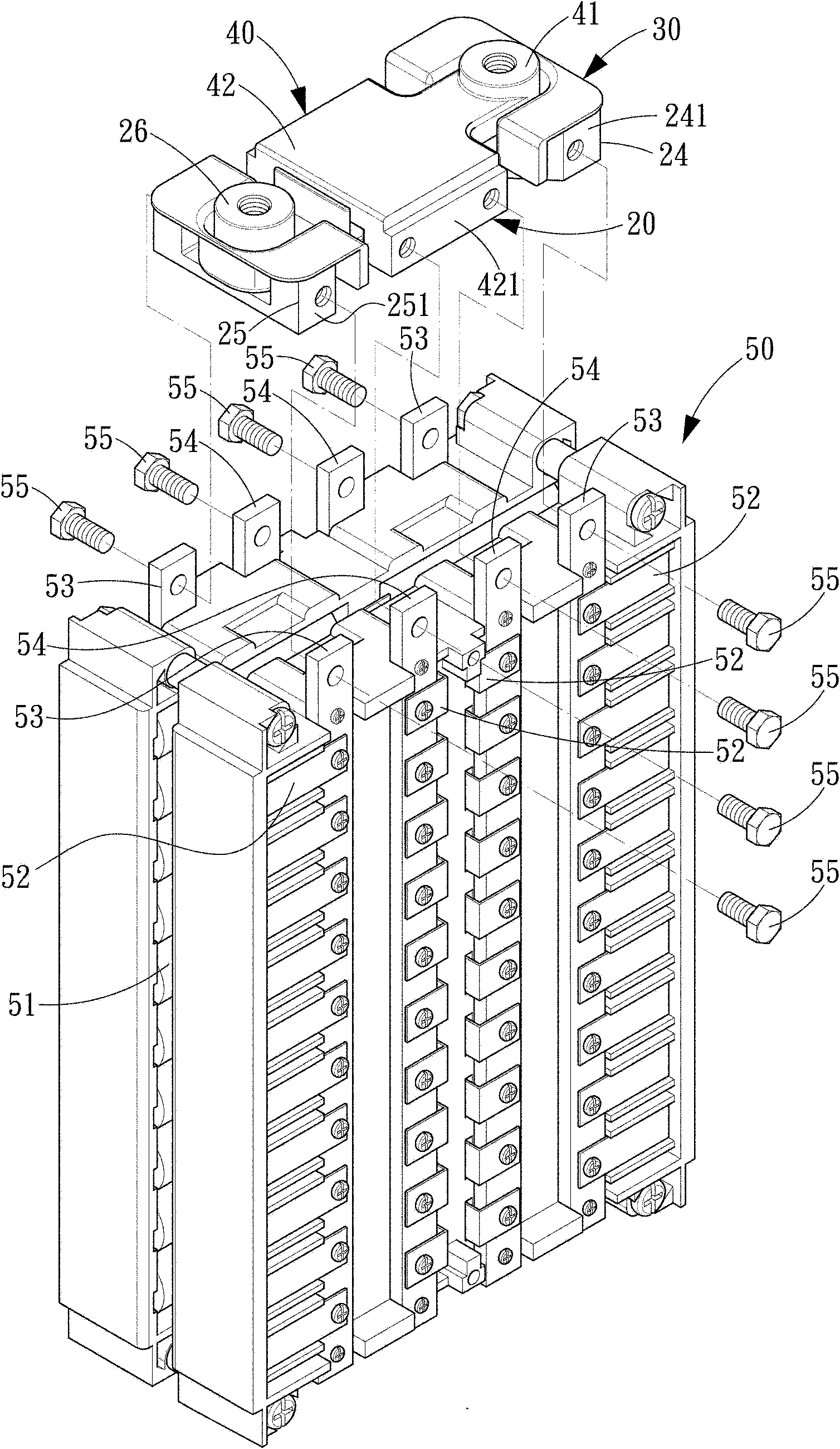

[0036] First, if Figure 2-6 As shown in the figure, the terminal head structure of the assembled battery provided by the embodiment of the present invention, the assembled battery 50 is electrically connected by a plurality of individual batteries 51 through a conductive sheet 52 to form a common positive output terminal 53 and a negative electrode. The output end 54 is formed, and the terminal head structure is composed of a base part 20 , an insulating part 30 and a top part 40 .

[0037] The base part 20 is a conductive member and has a main board 21. Two corresponding surfaces of the main board 21 are respectively defined as a bottom surface 211 and a top surface 212, and two corresponding ends of the main board 21 are respectively formed with an assembly end 22 and An output terminal 23 . The assembly end 22 is located on the two corresponding sides of the top surface 212, and each of the two corresponding sides of the top surface 212 is vertically formed with a first t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com