Permanent magnet adsorption wheel used for magnetic conductive wall surface and capable of realizing rapid magnet unloading

A permanent magnetic adsorption and wheel technology, applied in the direction of wheels, motor vehicles, pneumatic tires, etc., can solve the problems that the magnetism cannot be fully utilized, the robot's motion performance is reduced, and the performance of the magnet module is poor, so as to improve the distribution of magnetic induction lines, Effects of improving stability and safety and increasing coefficient of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings, so as to help understand the content of the present invention.

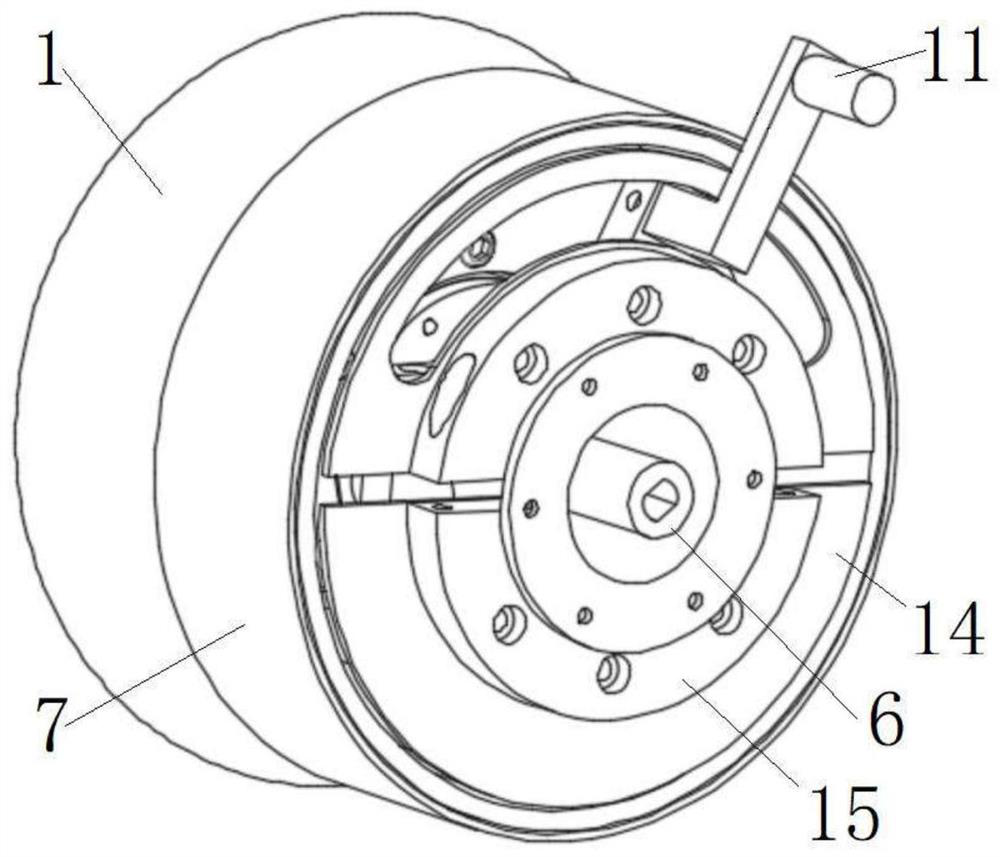

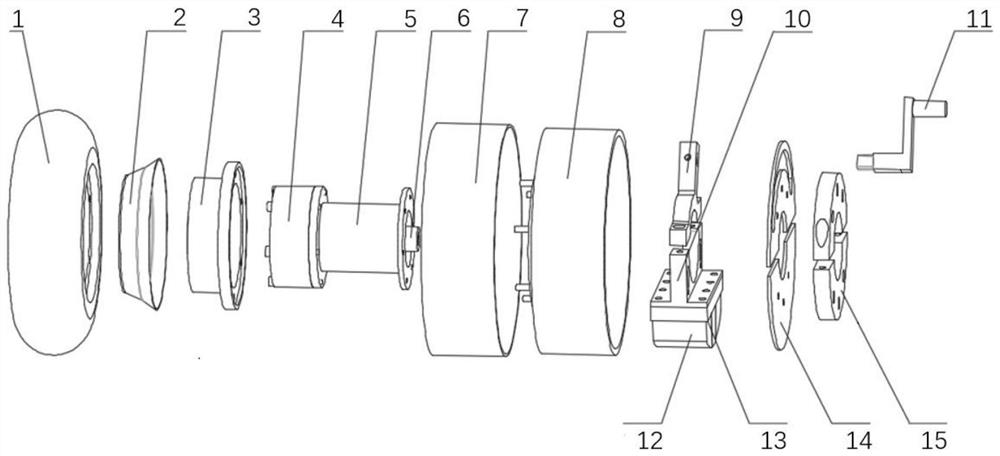

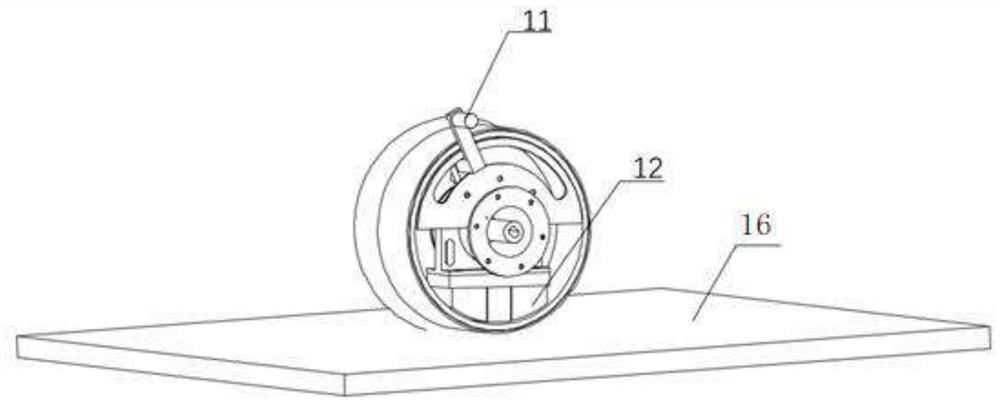

[0026] Such as Figure 1-2 As shown in FIG. 1 and 2 , respectively, are a structural schematic diagram and an exploded view of a permanent magnet adsorption wheel for a magnetically permeable wall surface that can realize rapid demagnetization provided by the present invention. The permanent magnetic adsorption wheel used for magnetically permeable walls that can realize rapid demagnetization includes a pneumatic tire 1, a wheel hub 2, a tire fixing piece 3, a harmonic reducer 4, a bearing sleeve 5, a motor connecting shaft 6, and a synchronous belt 7. Synchronous pulley 8, magnet fixing part 9, magnet connecting plate 10, unloading magnetic handle 11, magnet 12, yoke iron 13, magnet retaining ring 14, magnet limiter 15 and unloading magnetic sleeve. Through the above components, the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com