Machine tool lead screw pre-stretching installation mechanism

A mounting mechanism and pre-stretching technology, which is applied in the direction of feeding device, maintenance and safety accessories, metal processing machinery parts, etc., can solve the problem that the service life cannot meet the design requirements, lubricating oil leakage, oil seal seals and screw rod seals Easy to produce gaps and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to facilitate the understanding of those skilled in the art, the structure of the present invention will be further described in detail with the embodiments in conjunction with the accompanying drawings:

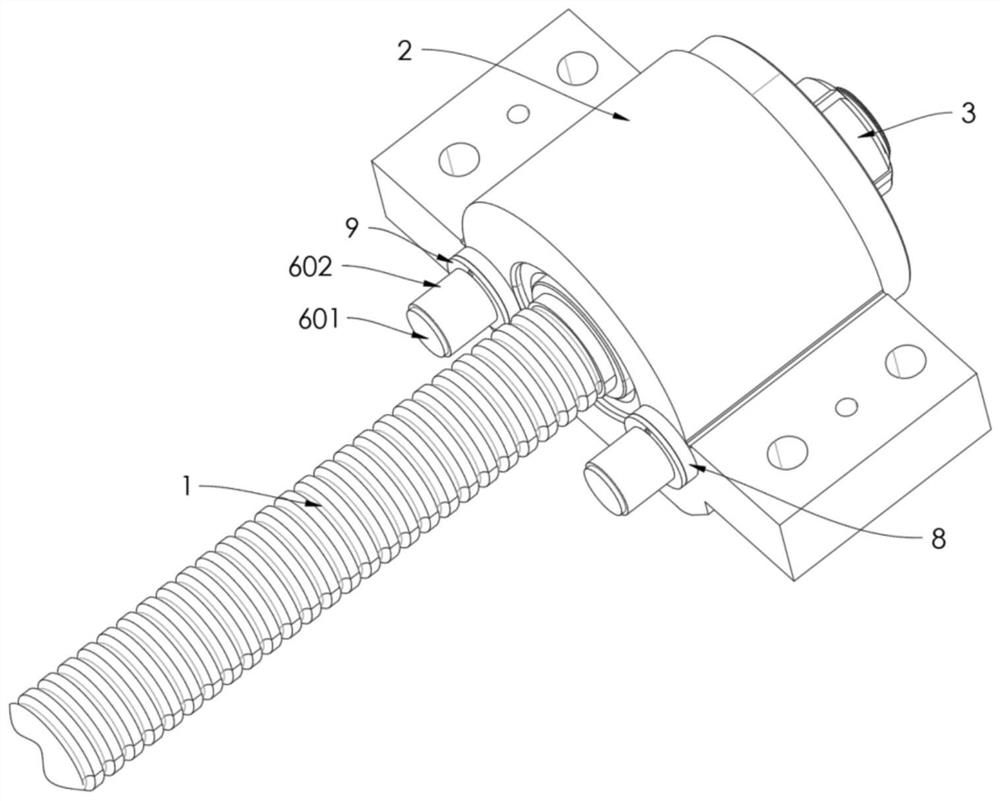

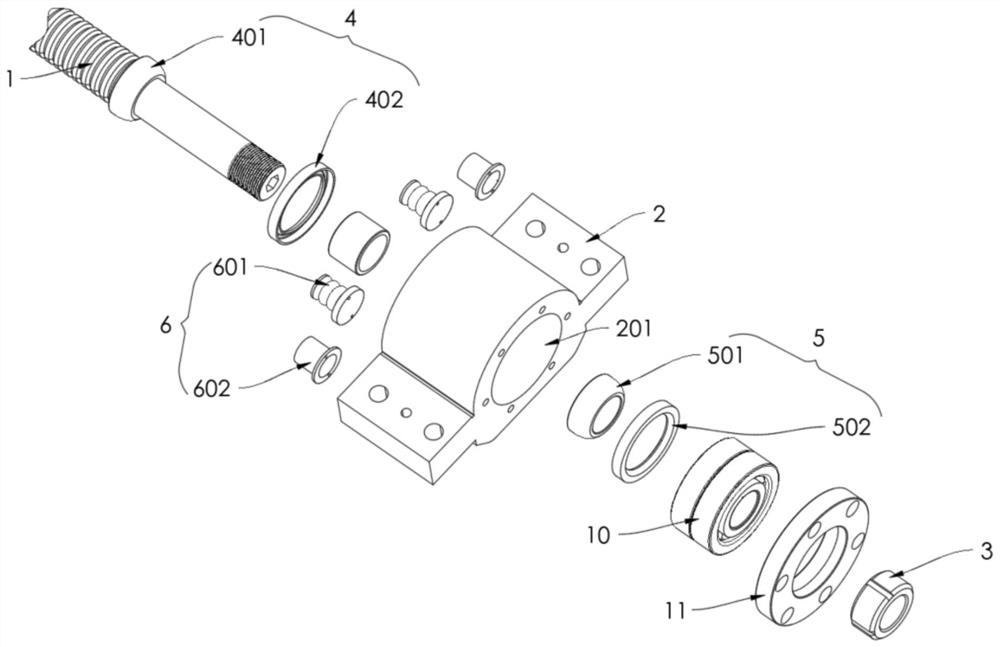

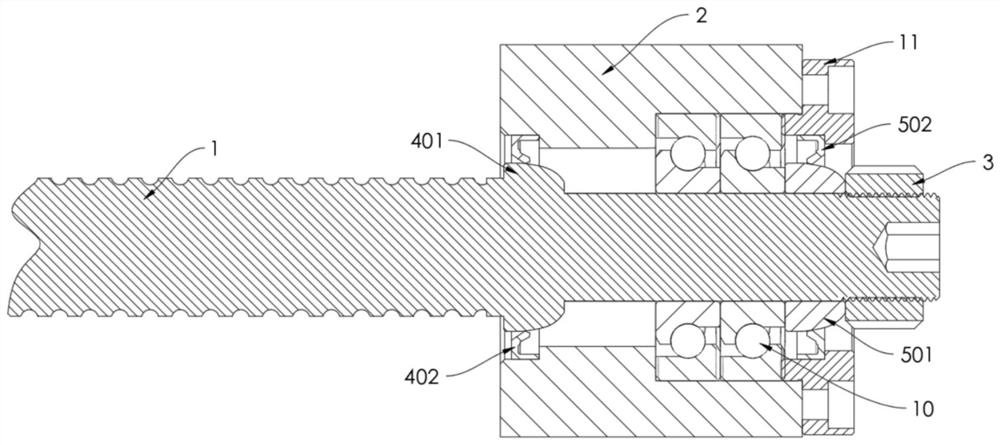

[0033] refer to Figure 1-7 , a screw pre-stretching installation mechanism for a machine tool, comprising a screw 1, a mounting base 2 with a mounting hole 201, the mounting end of the screw 1 is rotatably installed in the mounting hole 201, the front end of the screw 1 A lock nut 3 that can pre-stretch the screw rod 1 is connected through a threaded connection; it also includes

[0034] The first sealing mechanism 4 includes a fixed ring 401 fixedly connected to the rear side of the installation end of the screw rod 1. The outer wall of the fixed ring 401 is in the shape of an arc with a narrow front and a wide rear. A first gasket 402 is installed between the installation hole 201 of the installation seat 2, and the first sealing gasket 402 includes a fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com