Magnetic grinding material and preparation method thereof

A magnetic abrasive and abrasive particle technology, applied in chemical instruments and methods, and other chemical processes, can solve problems such as poor temperature measurement accuracy, uneven temperature, and difficulty in mass production, and achieve good grinding performance, improved compatibility, Avoid the effect of oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

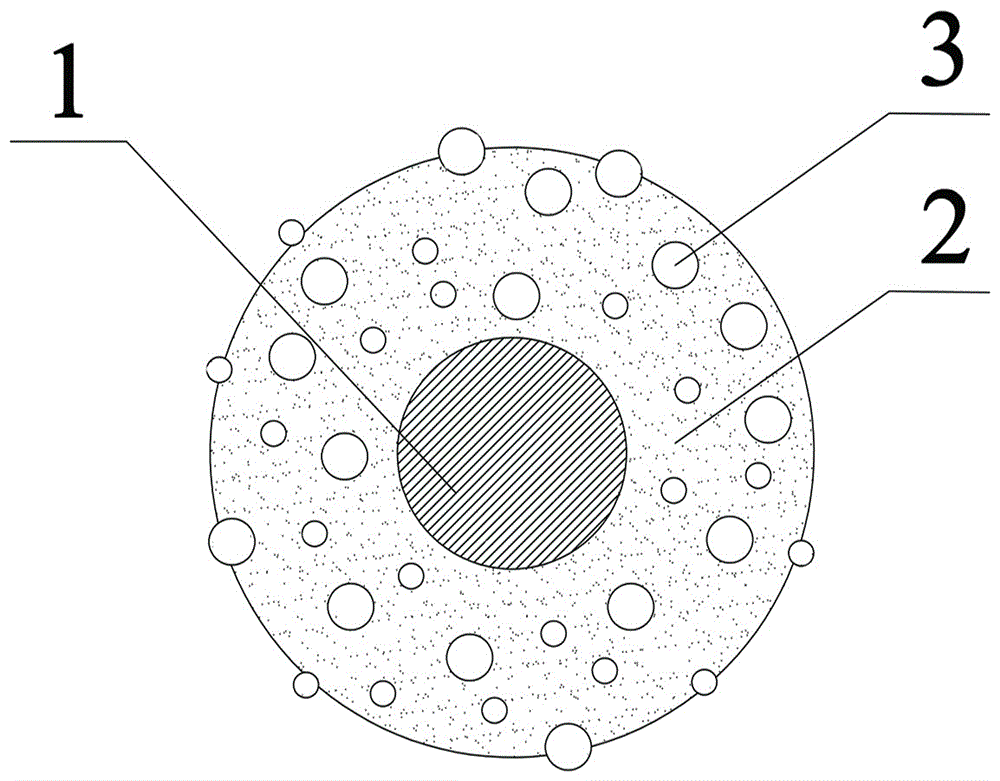

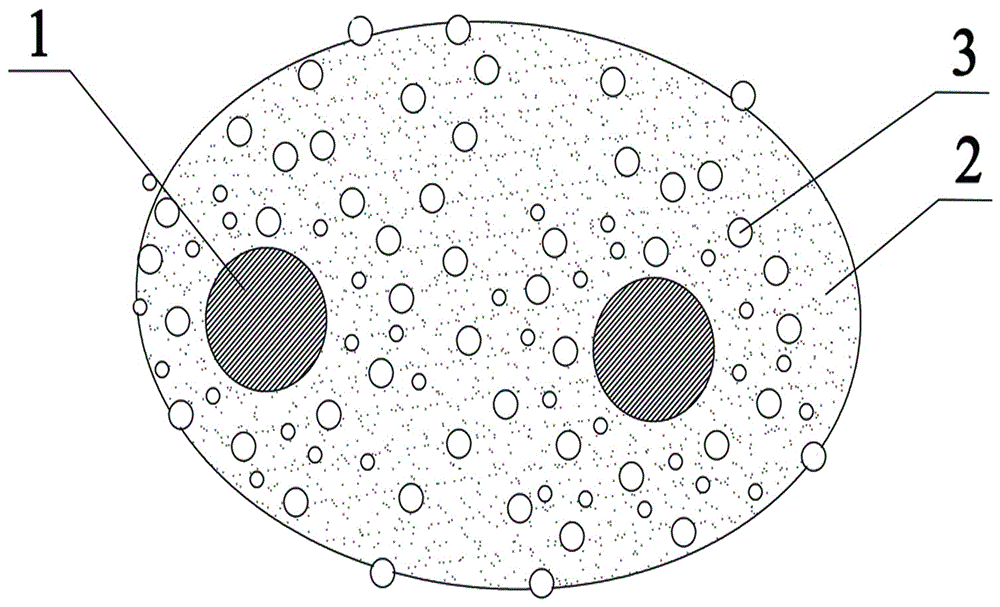

[0030] This embodiment provides a magnetic abrasive, and the specific structure diagram is shown in figure 1 and figure 2 , the magnetic abrasive is a spherical or elliptical magnetic abrasive with a core-shell structure and a particle size of about 150 meshes. It specifically includes a magnetic induction core 1 and a grinding shell bonded to the surface of the magnetic induction core 1 by sintering, wherein the grinding casing is prepared by mixing the bonding agent 2 and the abrasive particles 3 through heating, melting and cooling. Thus, the abrasive particles 3 are bonded to the magnetically sensitive core 1 by the melted and solidified binder 2 .

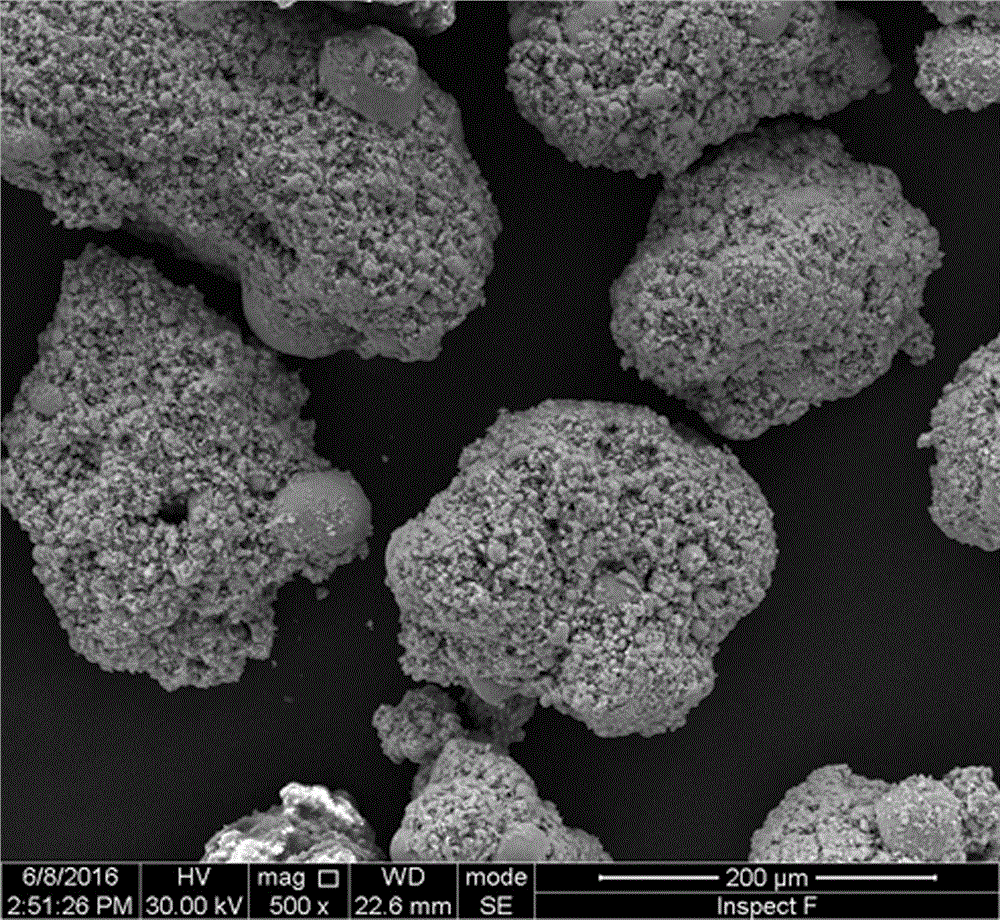

[0031] The magnetic material provided in this embodiment is detected by a scanning electron microscope, and the structure is as follows image 3 and Figure 4 and Figure 5As can be seen from the figure, the external shape of the magnetic abrasive is spherical or elliptical, and there are a plurality of magnetic induction...

Embodiment 2

[0042] This embodiment provides a magnetic abrasive, and the structure of the magnetic abrasive is substantially the same as that of the magnetic abrasive in Embodiment 1, except that the particle size of the magnetic abrasive provided in this embodiment is about 100 meshes. The binding agent is prepared by the following steps: Calculated in parts by mass, firstly SiO 2 18 parts, α-Al 2 O 3 30 copies, B 2 O 3 18, K 2 O 1 part, Li 2 10 parts of O, 5 parts of ZnO, 0.5 parts of MgO, La 2 O 3 1.1 copies, Y 2 O 3 0.2 part is mixed, ground and crushed, and sieved to obtain a mixed powder with a particle size of less than 200 meshes, then the mixed powder is smelted at a temperature of 1200 ° C for 1 hour, and after cooling, it is ground and crushed, and air-selected to obtain the combination with a particle size of less than 4000 meshes. agent particles.

[0043] The abrasive particles 2 are superhard materials, preferably, the superhard materials are polycrystalline ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com