High-temperature-resistant electric control hoisting electro permanent magnet

A permanent magnet and high temperature resistant technology, applied in the direction of load hanging components, transportation and packaging, etc., can solve the problems of insufficient electromagnet suction, falling of the attracted object, limitation of permanent magnet steel Curie point, etc., and achieve insulation performance and durability Excellent thermal performance, good moisture resistance, low temperature coefficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

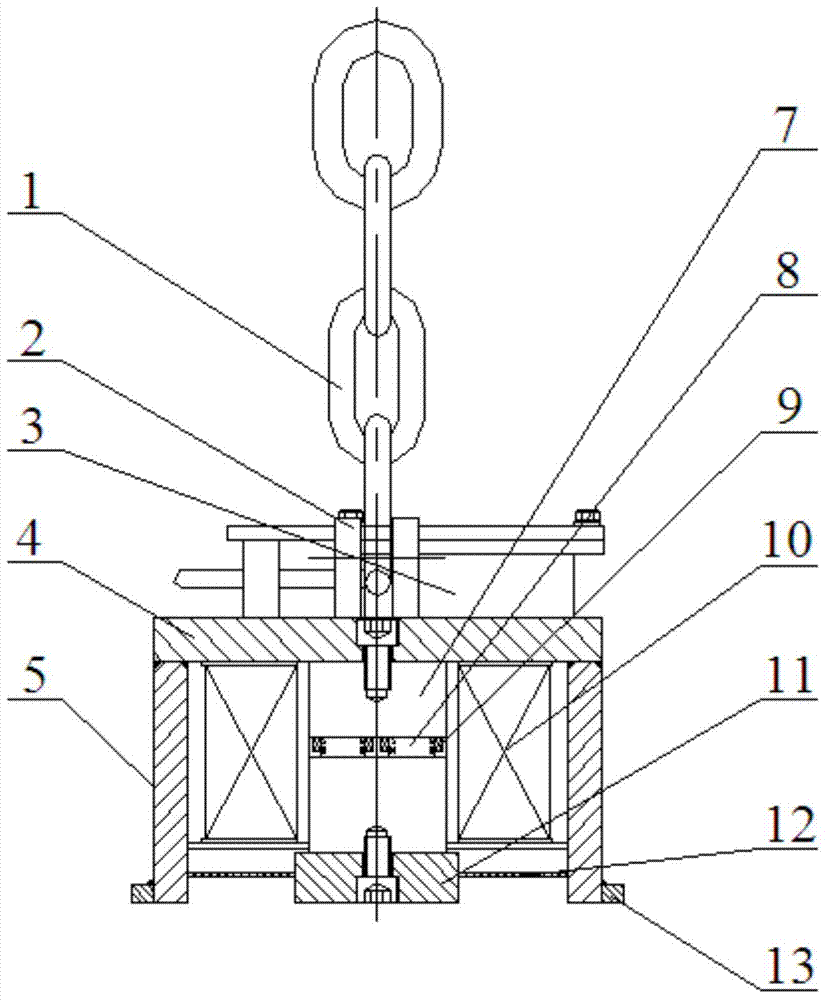

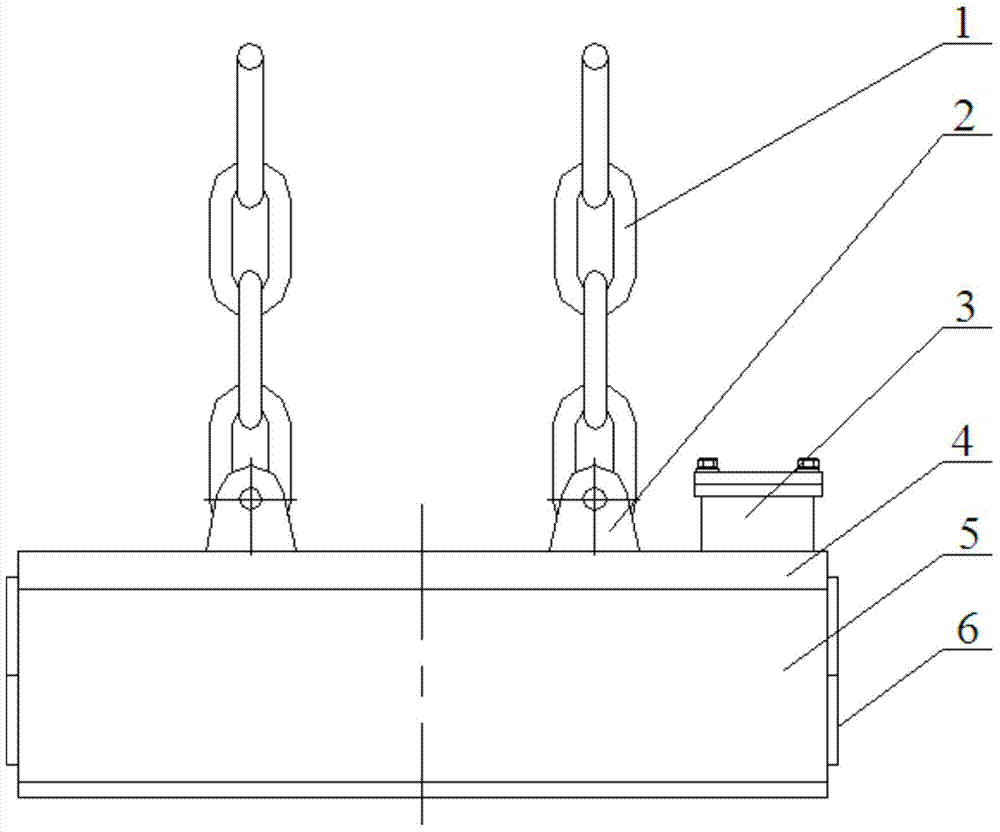

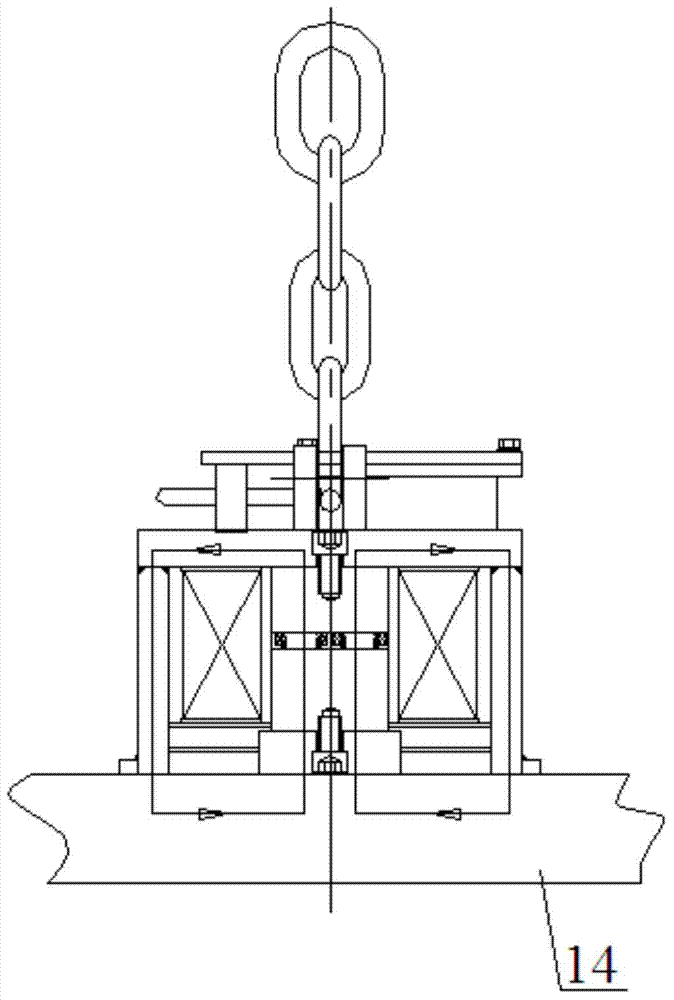

[0021] Referring to the accompanying drawings, a high-temperature-resistant electronically controlled lifting electro-permanent magnet includes a chain 1 connected to a hoisting device, a lifting lug 2 arranged at the bottom of the chain 1 and an electro-permanent magnet fixedly connected to the bottom of the lifting lug 2, the electro-permanent The magnet is a sealed overall structure consisting of top plate 4, side plate 5, end plate 6, inner magnetic plate 11 and heat insulation plate 12. An iron core 7 is arranged in the middle of the inside of the electro-permanent magnet, and the outer cover of the iron core 7 is provided with a main The excitation coil 10, the middle part of the iron core 7 are respectively provided with multiple groups of magnetic steel 8, the multiple groups of magnetic steel 8 are respectively covered with degaussing coils 9, and the bottom end of the electro-permanent magnet is provided with an outer magnetic pole 13;

[0022] The top plate 4, the si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com