A Radial Integrated Measuring Method of Rotor Axial Displacement, Rotational Speed and Inclination Angle

A technology of axial displacement and inclination angle, applied in the direction of using optical devices to transmit sensing components, etc., can solve the problems of poor anti-interference ability of eddy current sensors, sensitive material installation structure, complex use, etc., to achieve good anti-electromagnetic interference ability, Extended application range and good linearity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to make a clearer and clearer definition of the protection scope of the present invention.

[0048] A radial integrated measurement method of rotor axial displacement, rotation speed and tilt angle includes the following steps:

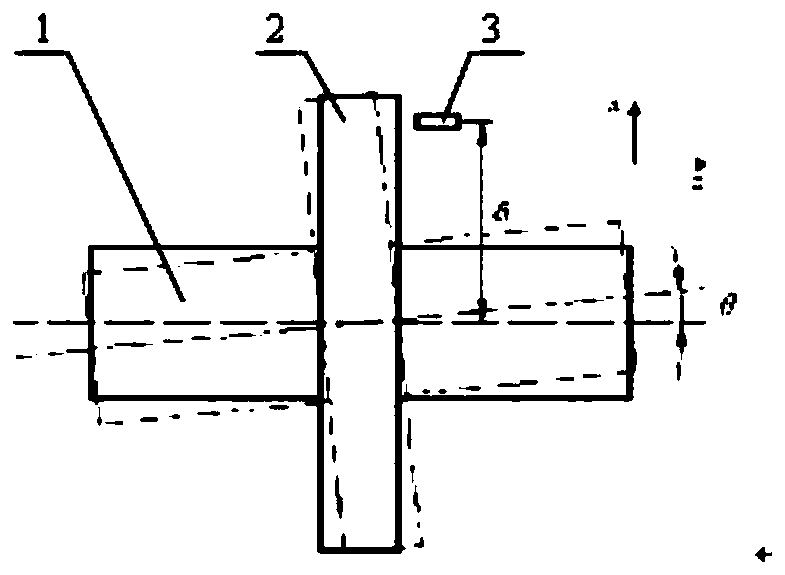

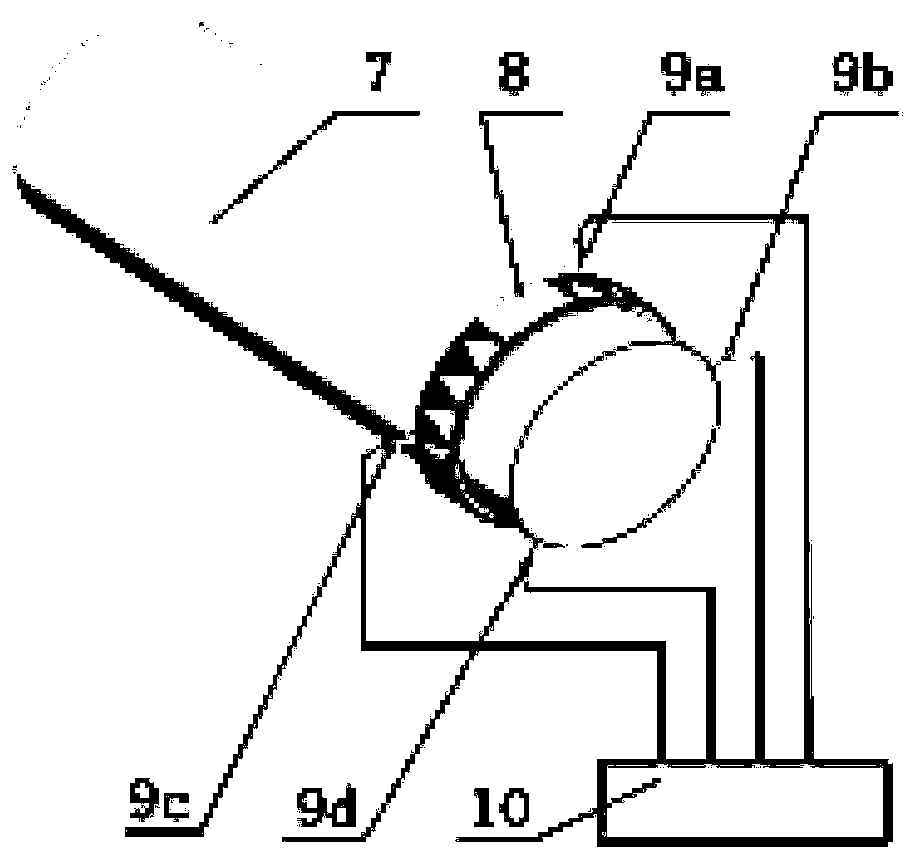

[0049] (1) Reference image 3 , Paste the standard measurement barcode 8 on the rotor 7 to be tested, and move with the rotor 7 to be tested. The surface development of the standard measurement barcode 8 shows that two materials with different reflectivity (8a, 8b) appear alternately The isosceles triangle, the interface of the standard measurement bar code is a rectangular bar code;

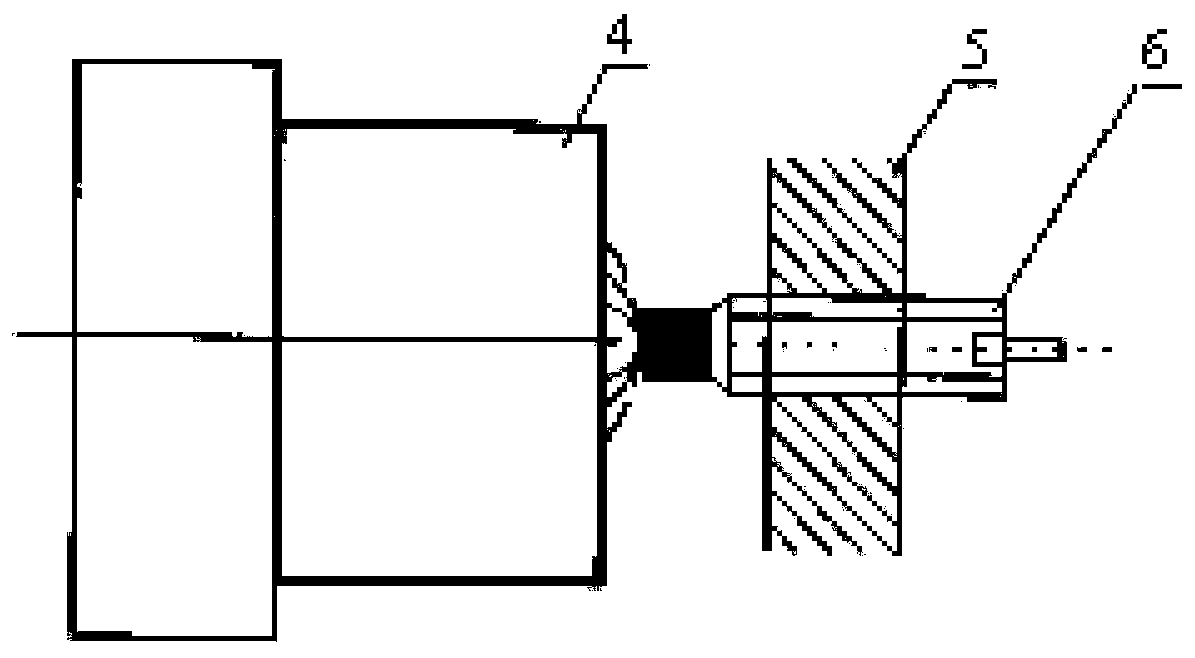

[0050] Specific reference Figure 4 , Figure 5 , The surface of the standard measurement barcode 8 is composed of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com