Sealing structure, sealing assembly for air conditioner and metro vehicle air conditioning unit

A technology of sealing structure and sealing ring, applied in the field of air-conditioning system of rail transit vehicles, can solve the problems of difficult air tightness, wrinkled sealing ring, poor sealing performance, etc., and achieve the effect of strengthening sealing performance, preventing distortion and deformation, and easy assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

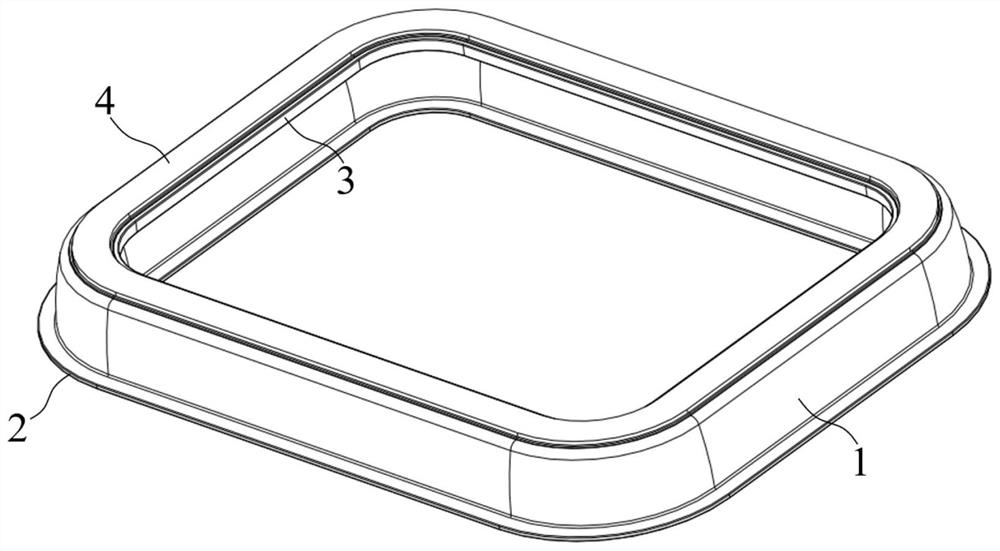

[0059] The sealing structure of the present embodiment includes:

[0060] a main body 1, which is a strip structure, and a hollow cavity 10 is formed in the main body 1;

[0061] a flange surface 2 formed on the bottom of the main body 1;

[0062] a sealing contact surface 3, which is formed on the top of the main body 1, and the sealing contact surface 3 is parallel to the flange surface 2;

[0063] The rubber strip 4 is fixed on the top surface of the sealing contact surface 3 .

[0064] For the end-supply and end-return air-conditioning unit structure, when installed in the urban rail vehicle body, the sealing strips at the air supply port and the air return port mainly play a sealing role through crimping. From the test verification of the existing sealing structure, The existing sealing structure and sealing method have partial air leakage, and the airtightness cannot meet the requirements. The main reasons are as follows: Due to the structural characteristics of the ai...

Embodiment 2

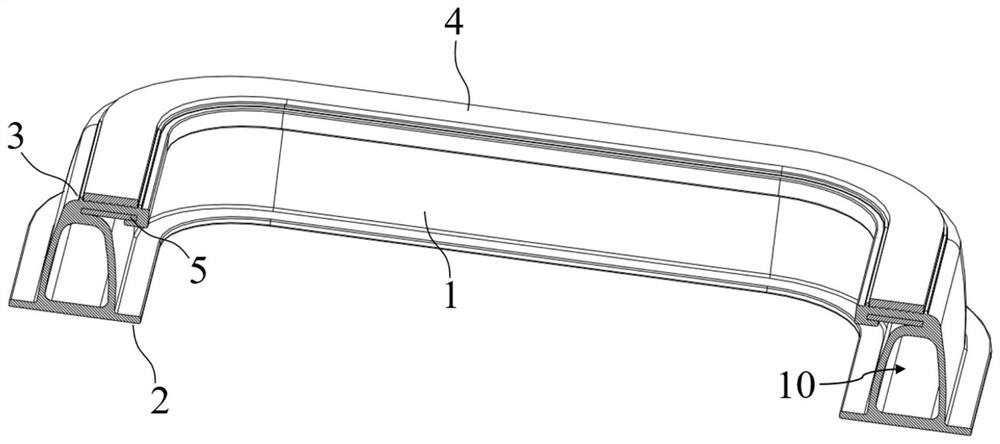

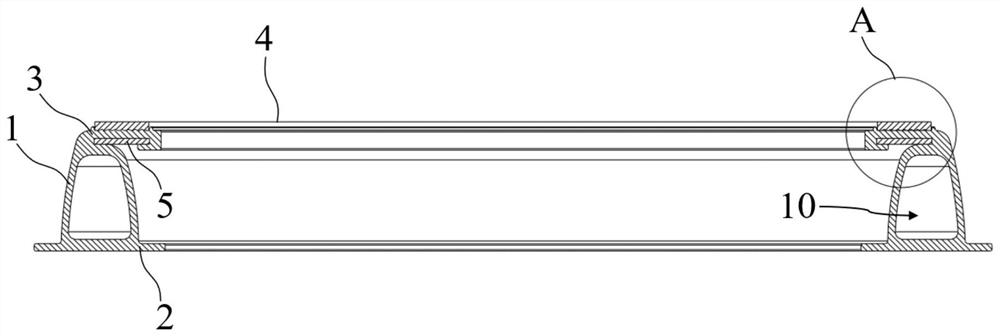

[0068] The sealing structure of this embodiment is further improved on the basis of Embodiment 1, and further includes a rigid plate 5 which is fixedly connected to the bottom surface of the sealing contact surface 3 .

[0069] like figure 2 and image 3 As shown, the rigid plate 5 of this embodiment can be made of rigid materials such as steel plates, and the rigid plate 5 is fixed on the bottom surface of the sealing contact surface 3, so as to ensure the flatness of the sealing contact surface 3 and effectively prevent wrinkles on the sealing contact surface 3 pleats, thereby ensuring that the rubber strip 4 is in effective contact with the vehicle body.

Embodiment 3

[0071] The sealing structure of this embodiment is further improved on the basis of Embodiment 2. The cross-sectional shape of the cavity 10 of the main body 1 is a tower structure with a width at the bottom greater than a width at the top.

[0072] like image 3 As shown, the cavity 10 of the main body 1 in this embodiment has a tower structure, which can effectively prevent the sealing end surface from twisting and deforming when it is installed with the vehicle body. The deformation can continuously increase the reverse supporting force of the end plane, so that the sealing surface in contact with the vehicle body can effectively achieve the sealing function.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com