Polycarboxylic acid water reducing agent suitable for machine-made sand and preparation method of water reducing agent

A technology of polycarboxylic acid and water-reducing agent, applied in the field of construction engineering materials, can solve the problems of poor pumpability, excessive viscosity, corrosion, etc., to reduce slump loss, improve early strength, and speed up construction progress. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

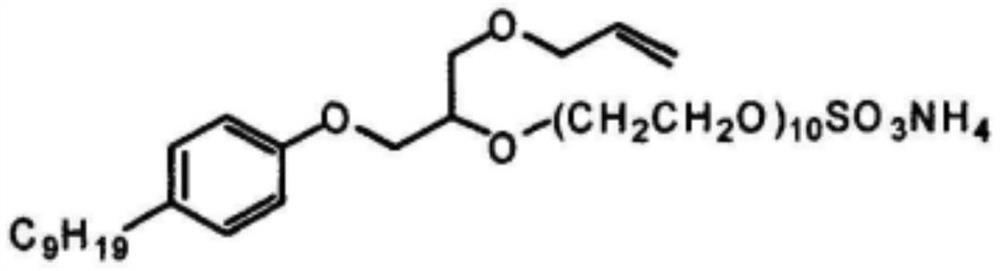

Method used

Image

Examples

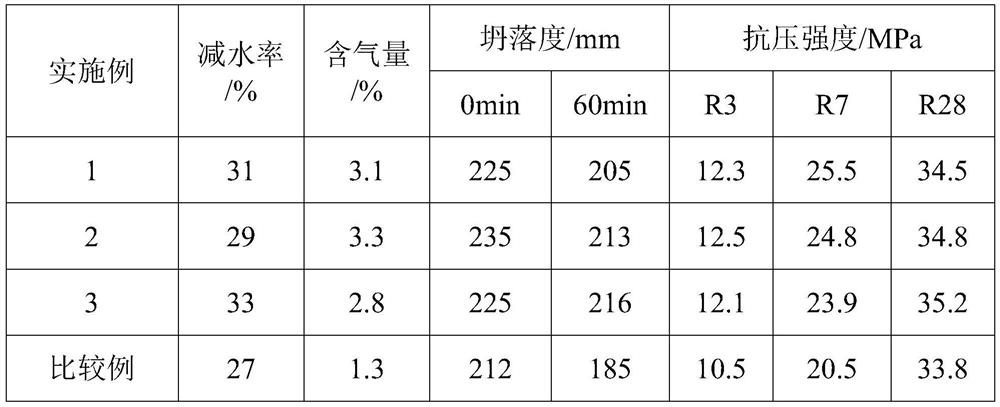

Embodiment 1

[0028] Add 200g of prenol polyoxyethylene ether TPEG-2400 to the reaction vessel equipped with a stirrer, add 200mL of distilled water, stir to dissolve, then dissolve 18g of hydrogen peroxide, control the temperature at 10°C, and start adding the components dropwise at the same time I (after adding 4g DNS-86 to 200mL distilled water for deamination treatment for 30min, then add 30mL distilled water and 20g acrylic acid and stir evenly) and dropwise add component II (dissolve initiator 6g Vc in 50mL distilled water and stir evenly); drop Add for 2.0 hours, keep warm for 3 hours, wait for the reactant to cool to room temperature, adjust the pH value to between 6 and 7 with triethanolamine, and obtain a polycarboxylate water reducer suitable for machine-made sand.

Embodiment 2

[0030] Add 200g of isobutenyl alcohol polyoxyethylene ether TPEG-2400 to the reaction vessel equipped with a stirrer, add 200mL of distilled water, stir to dissolve, then dissolve 35g of hydrogen peroxide, wait until the temperature rises to 15°C, and start adding component I ( Add 6g DNS-86 to 20mL distilled water for deamination treatment for 30min, then add 30mL distilled water and 35g acrylic acid and stir well) and dropwise add component II (dissolve Vc 12g in 50mL distilled water and stir well); add dropwise for 3.0h, keep warm for 2.0 h. After the reactant is cooled to room temperature, adjust the pH value to between 6 and 7 with triethanolamine to obtain a polycarboxylate water reducer suitable for machine-made sand.

Embodiment 3

[0032] Add 200g of prenol polyoxyethylene ether TPEG-2400 to the reaction vessel equipped with a stirrer, add 200mL of distilled water, stir to dissolve, then add 15g of hydrogen peroxide, control the temperature at 20°C, and start adding component I dropwise at the same time (Add 10g DNS-86 to 20mL distilled water for deamination treatment for 30min, then add 30mL distilled water and 23g acrylic acid and stir well) and dropwise add component II (dissolve initiator Vc 8.5g in 50mL distilled water and stir well); add 2.5 h, keep warm at 20°C for 2 hours, wait for the reactant to cool to room temperature, adjust the pH value to between 6 and 7 with triethanolamine, and obtain a polycarboxylate water reducer suitable for machine-made sand.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com