Patents

Literature

58results about How to "Good effect of entraining air" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

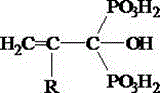

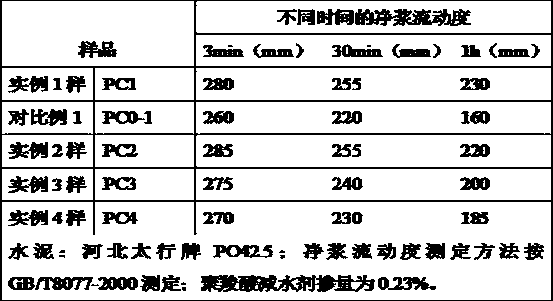

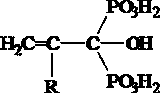

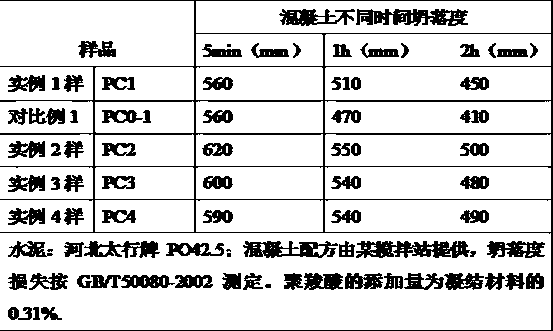

Preparation method of polycarboxylic acid water reducing agent containing phosphate group

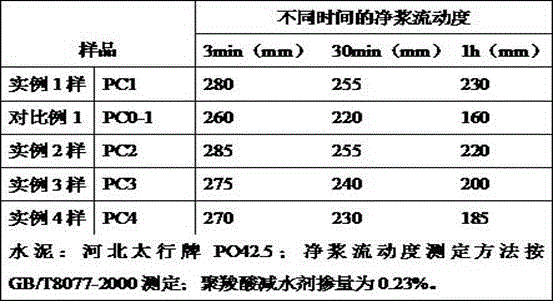

The invention provides a preparation method of a polycarboxylic acid water reducing agent containing a phosphate group. The preparation method comprises the following steps: firstly, preparing a terminal alkenyl unsaturated phosphonic acid monomer; secondly, mixing acrylic acid, the unsaturated phosphonic acid monomer, a chain transferring agent and de-ionized water to prepare a mixed monomer solution; by taking an alkenyl polyoxyethylene ether macro-monomer solution as a base material, dropwise adding an initiator water solution and the mixed monomer solution respectively under a room-temperature polymerization condition; uniformly stirring, dropwise adding and reacting; and finally neutralizing with a sodium hydroxide solution to obtain the polycarboxylic acid water reducing agent. According to the water reducing agent, the terminal alkenyl unsaturated phosphonic acid monomer is introduced into a structure and primary adsorption is facilitated; the initial dispersity is improved, and hydration and agglomeration of cement are delayed; the slump retaining property is effectively improved and the sensitivity to concrete is reduced; and the stress resistance and adaptability on different aggregate are enhanced.

Owner:山西科腾环保新材料股份有限公司

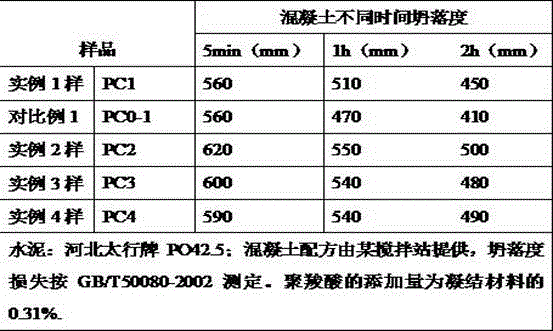

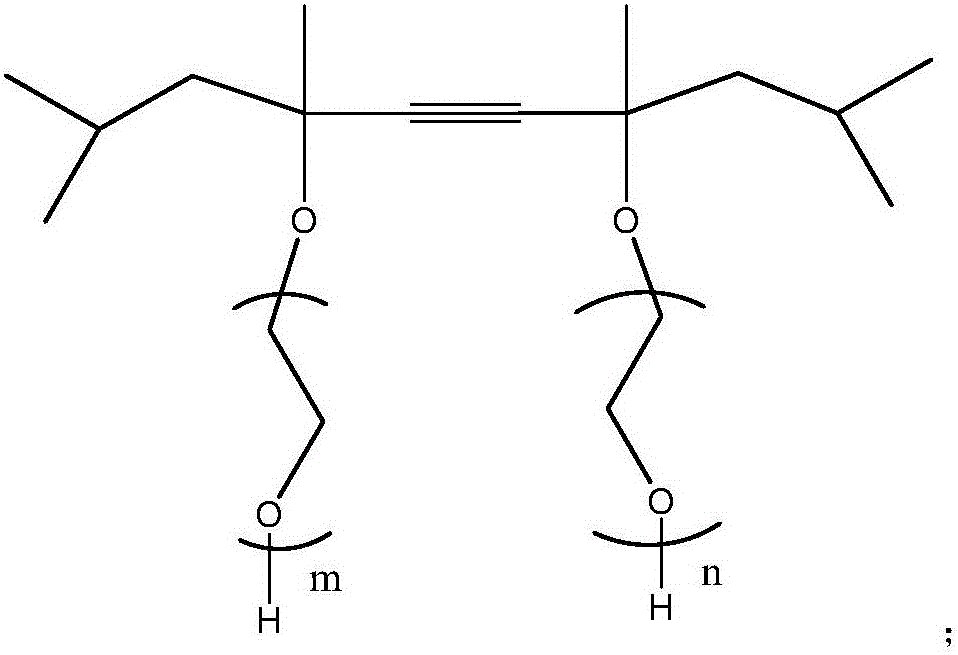

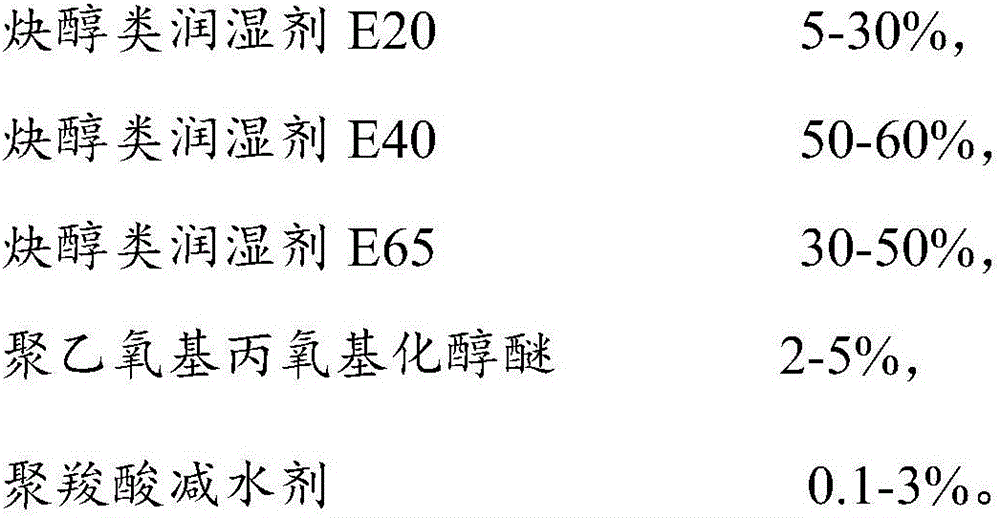

Foam control agent and air-entraining water reducing compounding agent and concrete prepared thereof

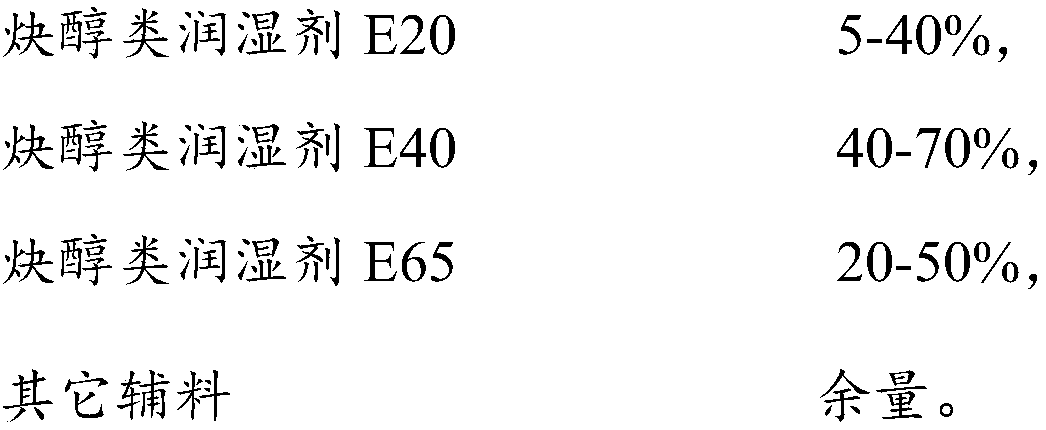

The invention provides a foam control agent and an air-entraining water reducing compounding agent and concrete prepared thereof. The foam control agent is mainly formed by compounding the following components by weight: 5-40% of an alkynol wetting agent E20, 40-70% of an alkynol wetting agent E40, 20-50% of an alkynol wetting agent E65, and the balance other accessories. The foam control agent has double technical effects of air entraining and foam control, can control the foam density and the foam size of a system, makes foams more uniform, eliminates big harmful foams, and makes the cement strength, stability and other properties improved.

Owner:岳阳凯门水性助剂有限公司

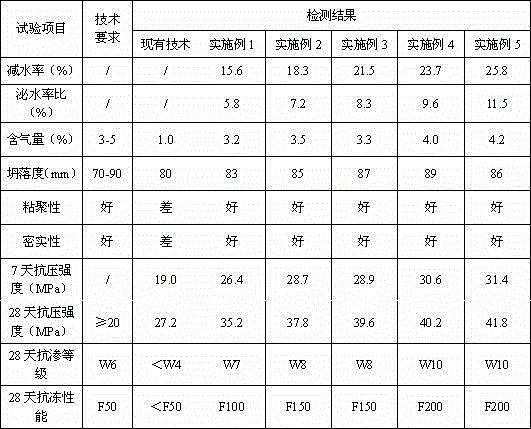

Composite concrete air entraining agent, and preparation method and application thereof

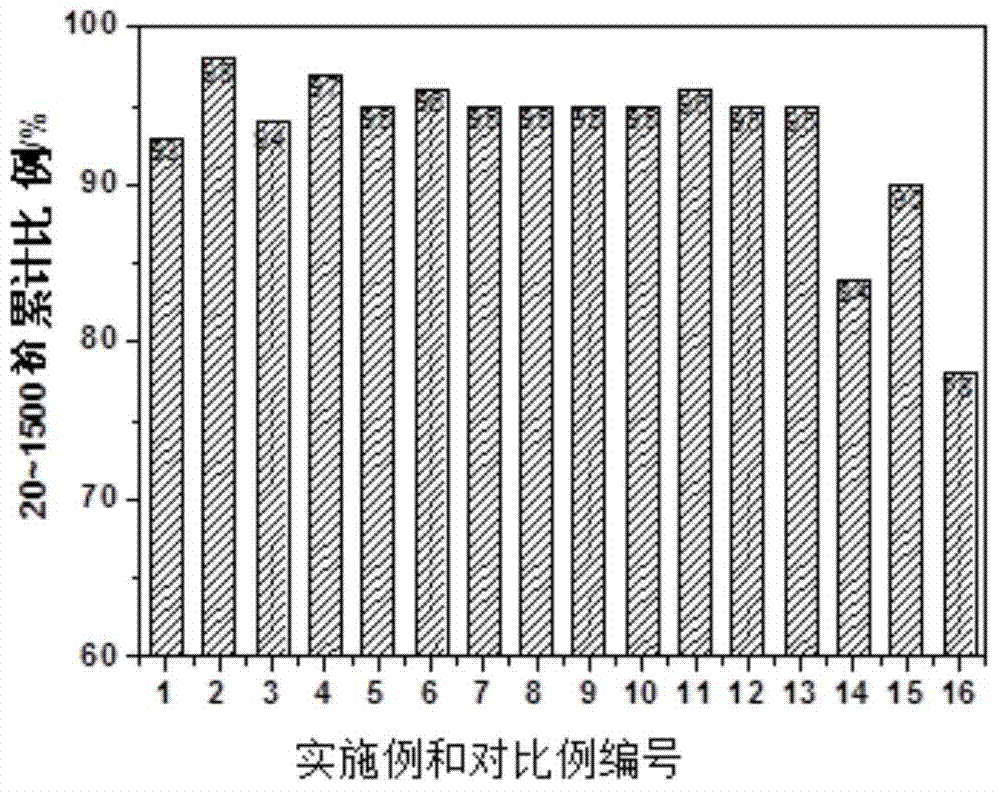

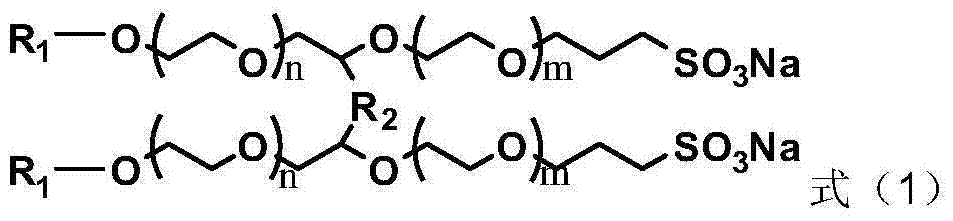

ActiveCN104496525ARemarkable foaming effectGood low temperature stabilityTransportation and packagingMixingNonionic surfactantAir content

The invention provides a composite concrete air entraining agent, and a preparation method and application thereof. The invention is characterized in that the composite concrete air entraining agent is composed of a sulfonate Gemini surfactant, a betaine amphoteric surfactant, an alkanolamide nonionic surfactant and water; and the solid content of the composite concrete air entraining agent is 20+ / -1%. The composite concrete air entraining agent has excellent air-entraining effect in concrete; and sufficient 20-150-mu m stable small bubbles can be introduced to improve the workability of the concrete (mortar), reduce the bleeding rate and sedimentation and avoid lowering the later strength of the concrete on the premise of enhancing the air content.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

Concrete composite air entraining agent and method of preparing the same

InactiveCN101549972AOvercome limitationsOvercome deficienciesCoconut oilSodium dodecylbenzenesulfonate

The present invention disclose a concrete composite air entraining agent and method of preparing the same, the composite air entraining agent is made by 20-30% malay rosin soap, 10-20% sodium dodecyl benzene sulfonate, 8-10% coconut oil diethanolamide and 10-62% water in mass ratio; the specific preparation method is adding the malay rosin soap into water and mixing uniformly, adding the sodium dodecyl benzene sulfonate and the coconut oil diethanolamide at the temperature of 70-150 DEG, and mixing uniformly abundantly to get the concrete composite air entraining agent. The concrete composite air entraining agent of the invention is provided with good air entraining impression, which can improving concrete capability evidently.

Owner:HUNAN JIANGHAI TECH DEV

Method for improving anti-penetrability of recycled concrete

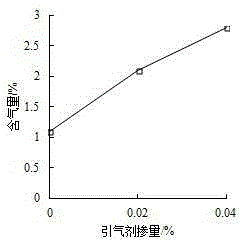

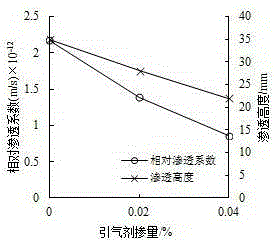

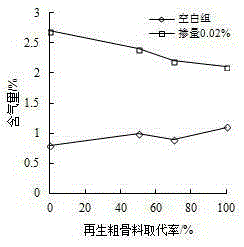

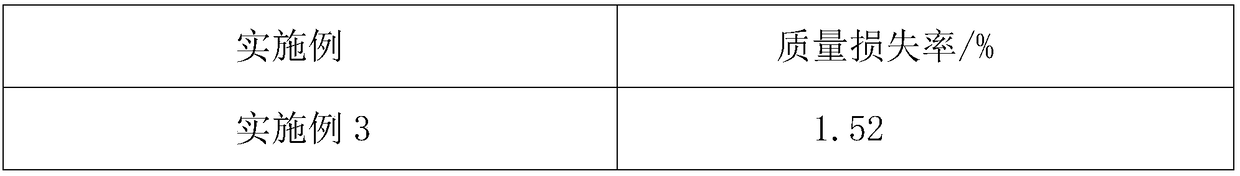

The invention provides a method for improving anti-penetrability of recycled concrete. The method comprises 1, partly replacing cement in cementing material by fly ash and slag powder, 2, limiting a recycled coarse aggregate replacement rate use range, 3, adding a proper amount of an entraining-type additive into a recycled concrete mixture, and 4, carrying out complete recycled concrete preparation. The method provides appropriate fly ash, ore powder and tea saponin mixing amounts, a recycled coarse aggregate replacement rate and difference of the recycled concrete from common concrete in preparation. The method is used for improving anti-penetrability and endurance performances of recycled concrete and promotes recycled concrete popularization and application.

Owner:SHANGHAI URBAN CONSTR MATERIAL CO LTD

Anti-freeze and anti-cracking concrete

The invention discloses anti-freeze and anti-cracking concrete. The anti-freeze and anti-cracking concrete comprises Portland cement, limestone powder, steel slag powder, sand, fine stones, modified rubber powder, potassium water glass, expanded perlite, natural zeolite ultrafine powder, polypropylene fibers, glass fibers, water reducing agents and water. The anti-freeze and anti-cracking concretehas the advantages of high workability, frost resistance and crack resistance, and effectively prolonged service life in a harsh environment.

Owner:蚌埠市方阵商品混凝土有限公司

Concrete air-entraining agent

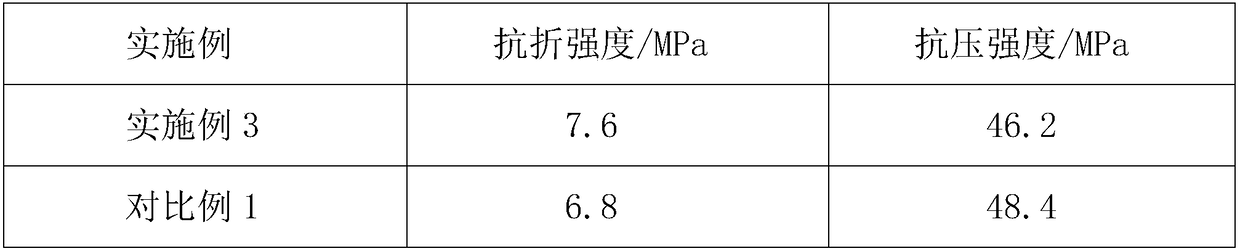

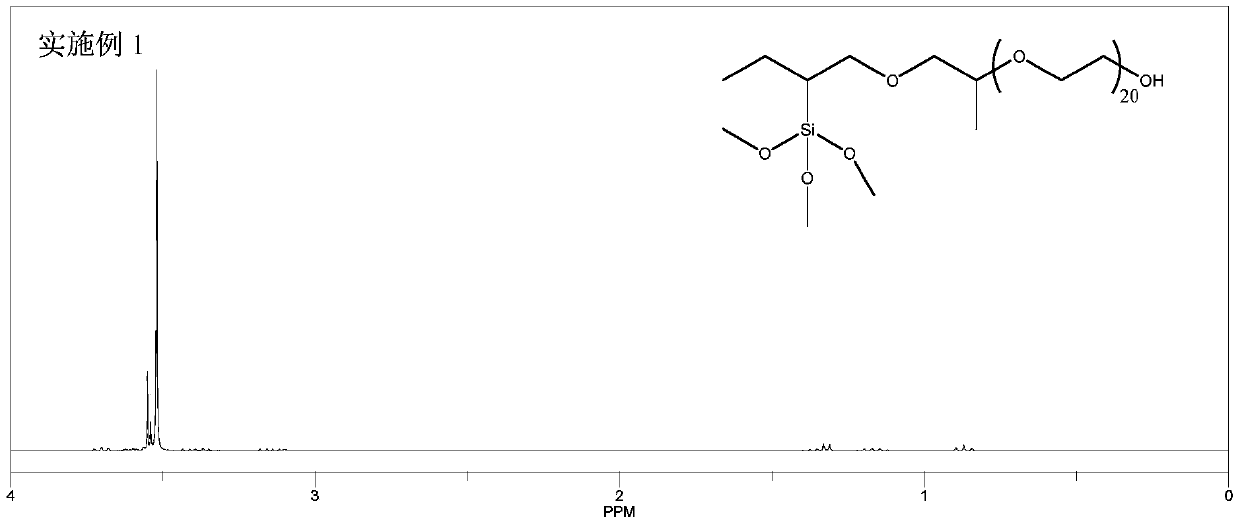

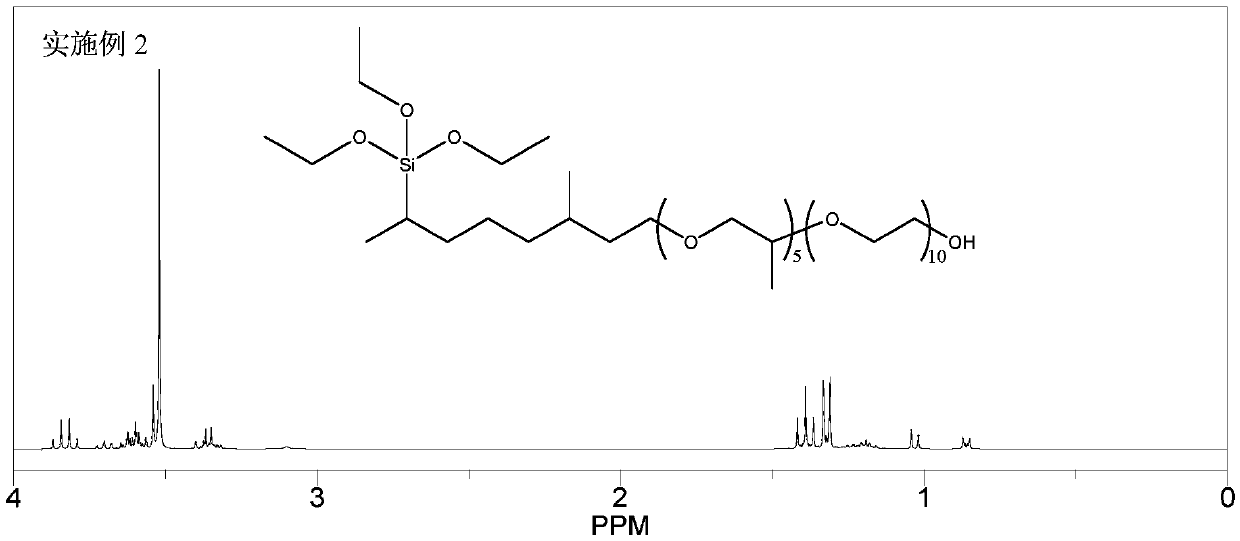

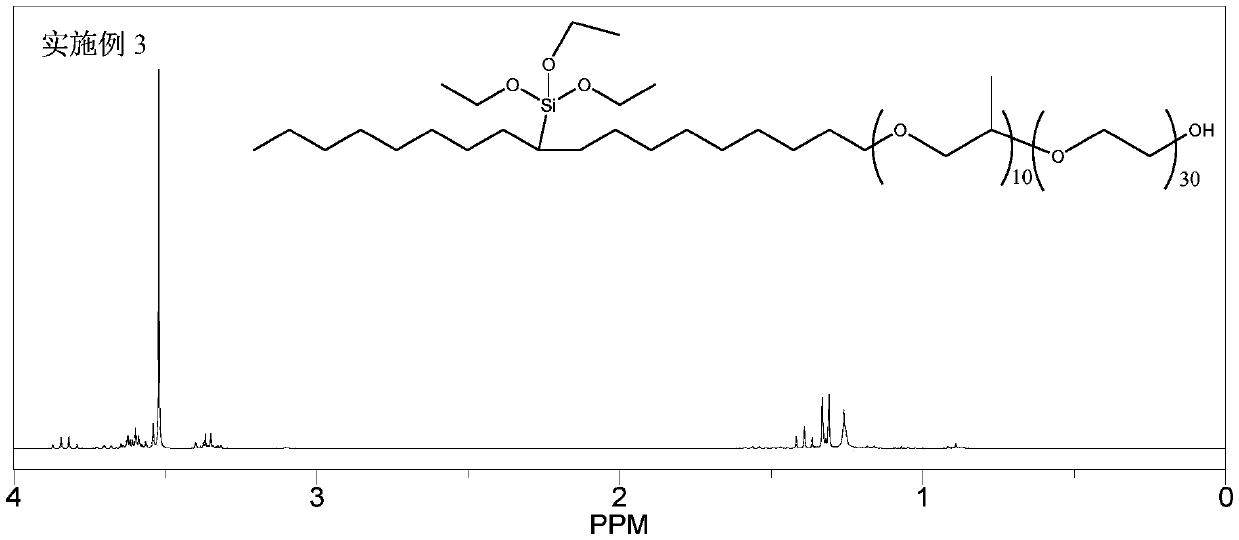

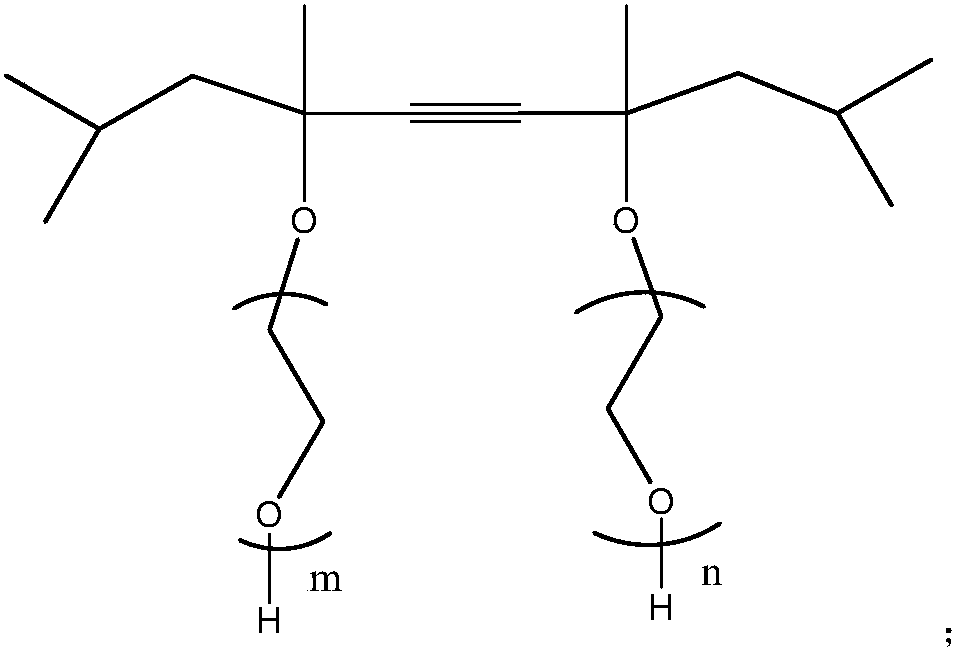

ActiveCN105503029AImprove surface activityReduced impact strengthAliphatic hydrocarbonBlock structure

The invention provides a concrete air-entraining agent molecule with a polyether hydrophilic chain segment and an aliphatic hydrocarbon hydrophobic chain segment modified through an alkyloxysilane group. The concrete air-entraining agent molecule has a structure shown in the formula (I). The invention also provides a preparation method of the compound and a use of the compound as the concrete air-entraining agent. The compound has a three-block structure, good surface activity and molecule reaction activity. The concrete air-entraining agent has excellent performances: 1, good air entraining effects at a low doping amount and reasonable size distribution of entrained bubbles, 2, good bubble stabilization effects and a high gas content level, and 3, small influence on concrete strength.

Owner:JIANGSU SOBUTE NEW MATERIALS +3

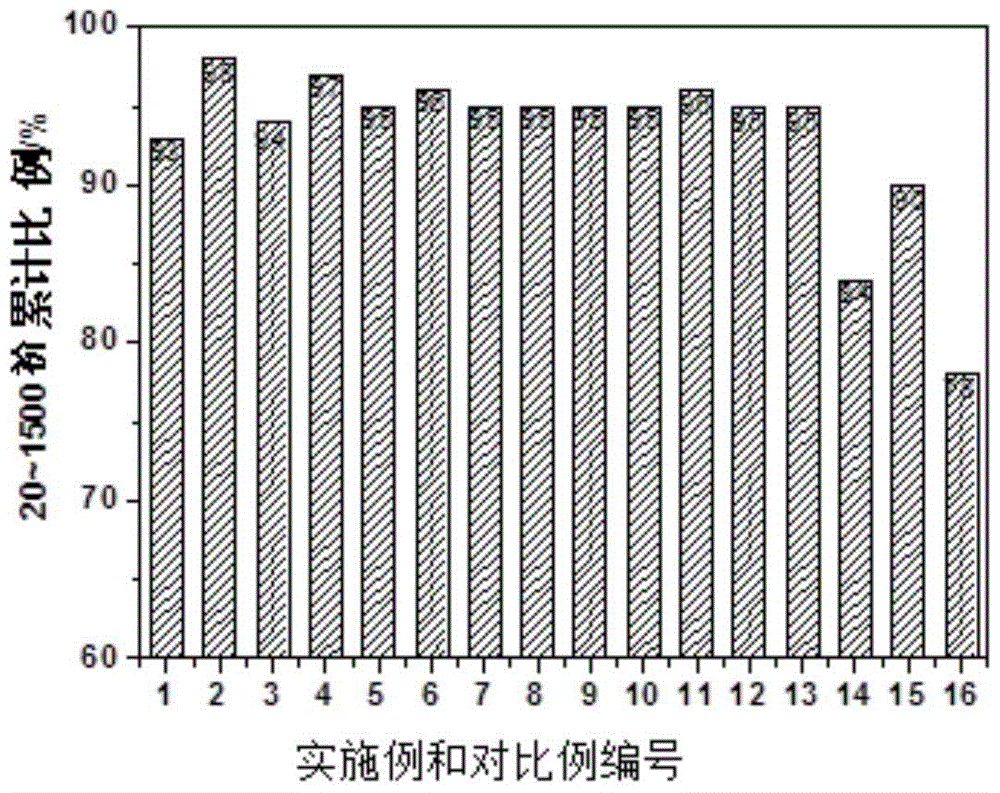

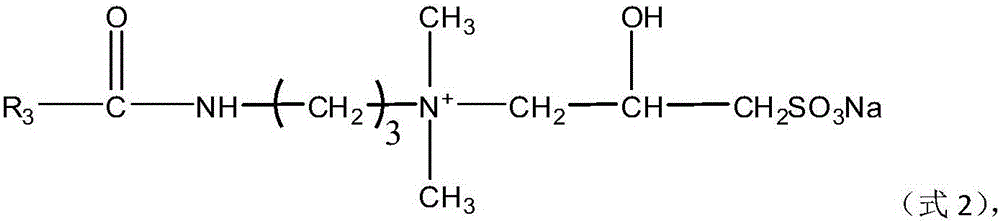

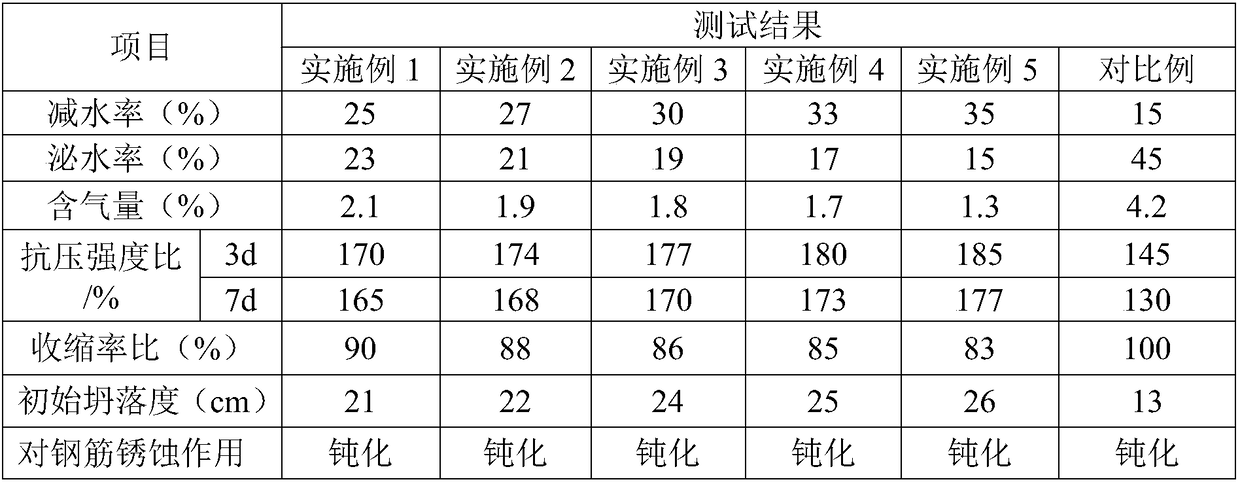

A composite concrete air-entraining agent, its preparation method and its application

ActiveCN104496525BGood effect of entraining airGood foam stabilityTransportation and packagingMixingSulfonateBetaine

The invention provides a composite concrete air-entraining agent, its preparation method and its application, characterized in that: the composite concrete air-entraining agent consists of sulfonate type gemini surfactant, betaine type amphoteric surfactant, alkane Alcohol amide type non-ionic surfactant and water; the solid content of the composite concrete air-entraining agent is 20±1%. The composite concrete air-entraining agent of the present invention has an excellent air-entraining effect in concrete, introduces a sufficient amount of 20-150 μm stable micro-bubbles, improves the workability of concrete (mortar), reduces bleeding rate and settlement, and While increasing the air content, it does not reduce the later strength of concrete.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

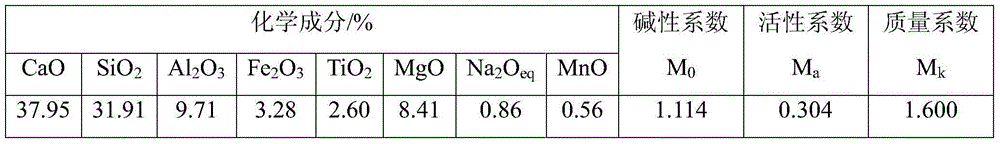

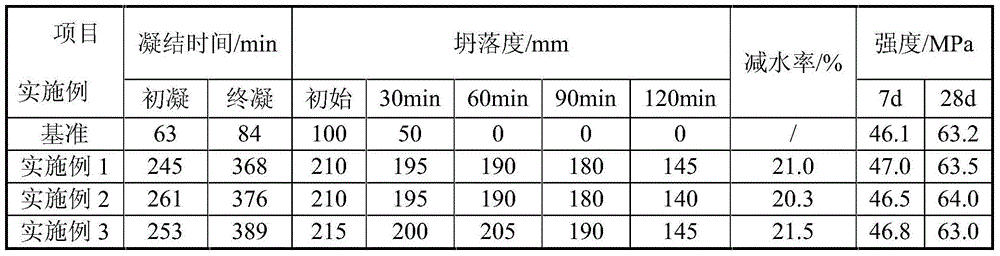

Alkali slag concrete water reducing agent

The invention discloses an alkali slag concrete water reducing agent which comprises following components, by mass: 11-23 parts of nitrates, 15-25 parts of a [beta]-naphthalenesulfonate-formaldehyde condensate, 3-5 parts of a lignosulfonate and 1-2 parts of a dodecyl benzene sulfonate. An alkali slag concrete is a WG-slag concrete and herein the WG represents for water glass; the [beta]-naphthalenesulfonate-formaldehyde condensate is [beta]-sodium naphthalenesulfonate-formaldehyde condensate; the lignosulfonate is calcium lignosulfonate; the dodecyl benzene sulfonate is sodium dodecyl benzene sulfonate; and the nitrates is a mixture composed of 1-3 parts of barium nitrate and 10-20 parts of lead nitrate. The water reducing agent can account for more than 20% of the WG-slag concrete, is good in adaptation with the WG-slag concrete, can effectively reduce an initial viscosity of newly-mixed WG-slag concrete, can improve a flowability and a workability of the concrete, can reduce a usage amount of the WG-slag concrete and can enhance the strength of the concrete.

Owner:重庆富普新材料有限公司

A kind of preparation method of polycarboxylate superplasticizer containing phosphonic acid group

The invention provides a preparation method of a polycarboxylic acid water reducing agent containing a phosphate group. The preparation method comprises the following steps: firstly, preparing a terminal alkenyl unsaturated phosphonic acid monomer; secondly, mixing acrylic acid, the unsaturated phosphonic acid monomer, a chain transferring agent and de-ionized water to prepare a mixed monomer solution; by taking an alkenyl polyoxyethylene ether macro-monomer solution as a base material, dropwise adding an initiator water solution and the mixed monomer solution respectively under a room-temperature polymerization condition; uniformly stirring, dropwise adding and reacting; and finally neutralizing with a sodium hydroxide solution to obtain the polycarboxylic acid water reducing agent. According to the water reducing agent, the terminal alkenyl unsaturated phosphonic acid monomer is introduced into a structure and primary adsorption is facilitated; the initial dispersity is improved, and hydration and agglomeration of cement are delayed; the slump retaining property is effectively improved and the sensitivity to concrete is reduced; and the stress resistance and adaptability on different aggregate are enhanced.

Owner:山西科腾环保新材料股份有限公司

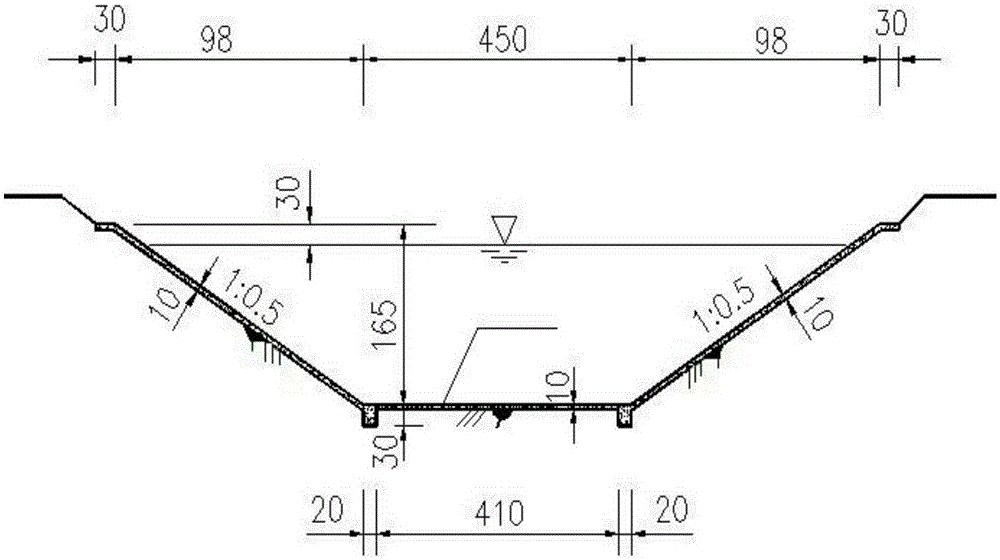

Channel side slope cast in situ concrete composite additive and preparation method thereof

The invention discloses a channel side slope cast in situ concrete composite additive, and a preparation method thereof. The channel side slope cast in situ concrete composite additive comprises, by weight, 25 to 50 parts of a water reducing agent, 1 to 5 parts of an air entraining agent, 5 to 15 parts of a thickening agent, 4 to 20 parts of an early strength agent, and 20 to 60 parts of water. The channel side slope cast in situ concrete composite additive obvious water reducing effect, air entraining effect, thickening effect, and early strength effect, is capable of increasing strength, compactibility, impermeability, and crack resistance of channel side slope concrete greatly, improving construction quality, and prolonging project service life. According to application processes of the channel side slope cast in situ concrete composite additive in channel side slope cast in situ concrete, the admixing amount of the channel side slope cast in situ concrete composite additive only accounts for 0.5 to 1.5% of the total mass of cement in the concrete; cost is relatively low; economic benefit is excellent; and the channel side slope cast in situ concrete composite additive is suitable for large-scale popularization.

Owner:广西壮族自治区水利科学研究院

Concrete air entraining agent

The invention belongs to the technical field of concrete admixture, and in particular relates to a concrete air entraining agent which is prepared from the following raw materials in parts by weight: 40-60 parts of rosin powder, 10-18 parts of sodium hydroxide, 6-16 parts of sulfuric acid, 8-18 parts of glycol, 5-13 parts of bisphenol A, 7-15 parts of pentaerythritol and 90-130 parts of water. When being used in concrete, the concrete air entraining agent is stable in bubble, appropriate in size, uniform in distribution, capable of increasing strength of concrete, and capable of improving peaceability of concrete.

Owner:GUILIN HUAYUE ENVIRONMENTAL PROTECTION TECH CO LTD

Concrete air-entraining and water-proof agent

The invention discloses a concrete air-entraining and water-proof agent and belongs to the field of building materials. The concrete air-entraining and water-proof agent comprises the following components in parts by weight: 40-60 parts of rosin, 6-20 parts of sodium alginate, 5-12 parts of sodium hydroxide, 3-10 parts of sodium dodecyl benzene sulfonate, 15-40 parts of stearic acid and 0.5-3 parts of sulfuric acid. Tiny bubbles can be uniformly introduced to the concrete air-entraining and water-proof agent, the workability and the water-proofness are improved, the concrete durability is enhanced; and the concrete air-entraining and water-proof agent has excellent air-entraining performance and bubble stability performance and is suitable for concrete structures with anti-freezing and water proof demands.

Owner:栾晓健

Environment-friendly concrete water reducer and preparation method thereof

InactiveCN109279804ASimple manufacturing methodRaw materials are easy to getSuccinic acidWater reducer

The invention provides an environment-friendly concrete water reducer. The concrete water reducer comprises the following components in parts by weight: 30-40 parts of a triethanolamine oleic soap-based polyacrylic acid copolymer, 10-15 parts of modified activated clay, 5-10 parts of 4-aminophenyl fucoside, 4-6 parts of polyether amine, 10-15 parts of isopropanol and 30-40 parts of water, whereinthe triethanolamine oleic soap-based polyacrylic acid copolymer is prepared by copolymerization of triethanolamine oleic soap, (2R,3S,4S)-rel-2-carboxyl-4-(1-methylvinyl)-3-pyrrolidine acetic acid, sulfo succinic acid-1-(2-propenyl)-4-tridecylester sodium salt and N-acryloyltris(hydroxymethyl)aminomethane. The invention further discloses a preparation method of the environment-friendly concrete water reducer. The environment-friendly concrete water reducer disclosed by the invention has the advantages that comprehensive performance is excellent, the water reducing effect is more obvious, the mixing amount is smaller, plasticizing performance is more excellent, cost is lower, influence on the environment is smaller, and use is safer and more environmentally friendly.

Owner:魏菊宁

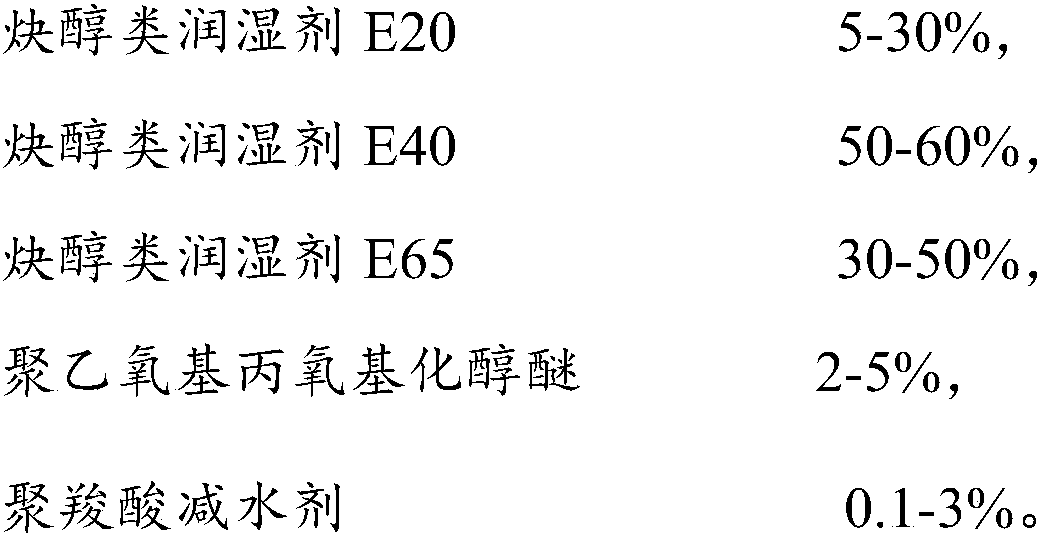

A kind of foam control agent and the air-entraining water-reducing compound agent thereof, concrete

The invention provides a foam control agent and an air-entraining water reducing compounding agent and concrete prepared thereof. The foam control agent is mainly formed by compounding the following components by weight: 5-40% of an alkynol wetting agent E20, 40-70% of an alkynol wetting agent E40, 20-50% of an alkynol wetting agent E65, and the balance other accessories. The foam control agent has double technical effects of air entraining and foam control, can control the foam density and the foam size of a system, makes foams more uniform, eliminates big harmful foams, and makes the cement strength, stability and other properties improved.

Owner:岳阳凯门水性助剂有限公司

Method for preparing mortar thickener

The invention discloses a method for preparing a mortar thickener and belongs to the field of construction. Corn starch is taken as a raw material to improve the substitution effect of carboxymethyl starch, which can prevent mortar from being separated and bleeding and can prevent water from evaporating too quickly in the early stage of curing or being absorbed too quickly by a base material, so that cement can be well hydrated; sugarcane black liquid is taken as a raw material for amination, positive ion groups are introduced in the molecular structure of lignin, so that the air-entraining performance is achieved, and the anti-cracking, anti-seepage and retarding effects are improved; propylene-based polyoxyethylene ether and maleic anhydride and the like are adopted as raw materials, anair-entraining delayed coagulation thickener additive is synthesized, and the mortar thickener has excellent performances such as good water reducing effect, good delayed coagulation effect and low air entrainment and the like. The peaceability of a mixture can be effectively improved, the water-reducing rate is high, the plasticity is strong, the slump loss is small, the amount of cement used canbe greatly reduced, and the cost performance of mortar is effectively improved.

Owner:广西御华混凝土有限责任公司

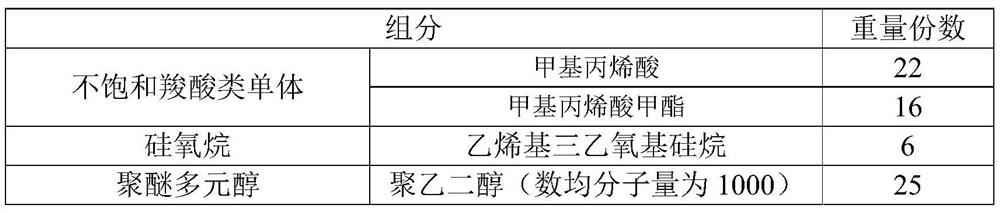

Polycarboxylic acid water reducing agent as well as preparation method and application thereof

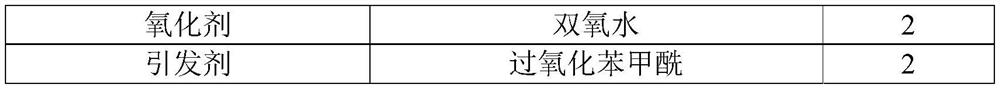

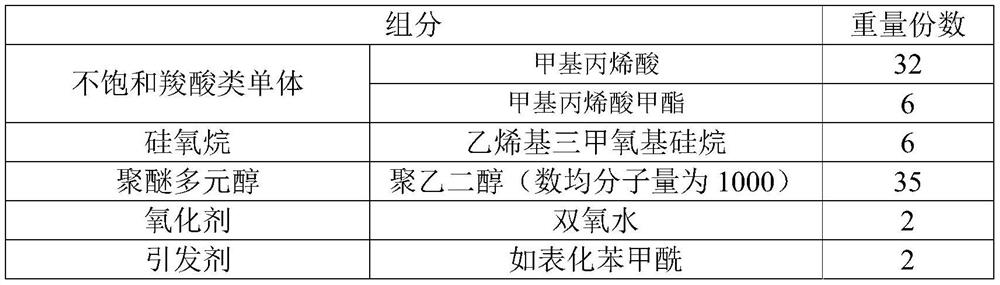

The invention provides a polycarboxylic acid water reducing agent as well as a preparation method and application thereof. The polycarboxylic acid water reducing agent is prepared from the following raw materials in parts by weight: 30 to 60 parts of unsaturated carboxylic acid monomers, 4 to 10 parts of siloxane, 20 to 60 parts of polyether polyol, 2 to 8 parts of an oxidant and 0.5 to 3 parts ofan initiator. Hydrophilic and hydrophobic groups are introduced into a polymer, the defects that concrete is high in air content and low in strength are overcome, meanwhile, the sulfate adsorption resistance of water reducing agent molecules is improved, and the water reducing agent has a more excellent performance.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

Bare concrete and preparation method thereof

The invention discloses bare concrete. The bare concrete is characterized by being prepared from, by weight, 5-10 parts of surface modified nano-boron fiber, 5-10 parts of kaolin, 10-15 parts of illite powder, 20-30 parts of gravel, 5-10 parts of vermiculite sand, 20-30 parts of silver sand, 40-50 parts of Portland cement, 1-5 parts of a compound additive and 20-30 parts of water. The compound additive comprises, by weight, 20-25 parts of a phosphate borate copolymer, 2-5 parts of zinc citrate, 1-3 parts of pyrophyllite powder, 1-3 parts of wollastonite powder, 2-4 parts of porous magnesium silicate, 0.5-1 part of a defoaming agent, 0.8-1.5 parts of polyaminopropyl biguanide, 0.5-2 parts of hydroxypropyl cyclodextrin, 1-3 parts of an activator and 80-100 parts of water. The invention further discloses a preparation method of the bare concrete. The bare concrete is high in compressive strength, good in corrosion resistance, impermeability and crack resistance and excellent in comprehensive performance, and production and application are safe and environmentally friendly.

Owner:佛山市政通混凝土有限公司

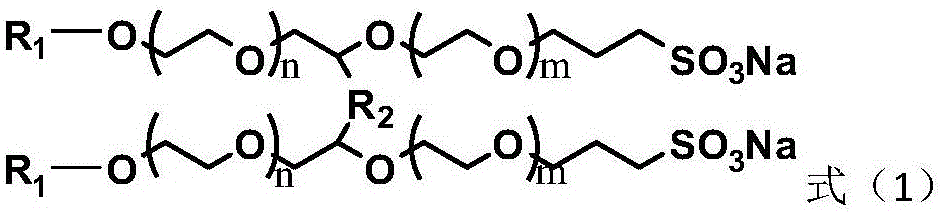

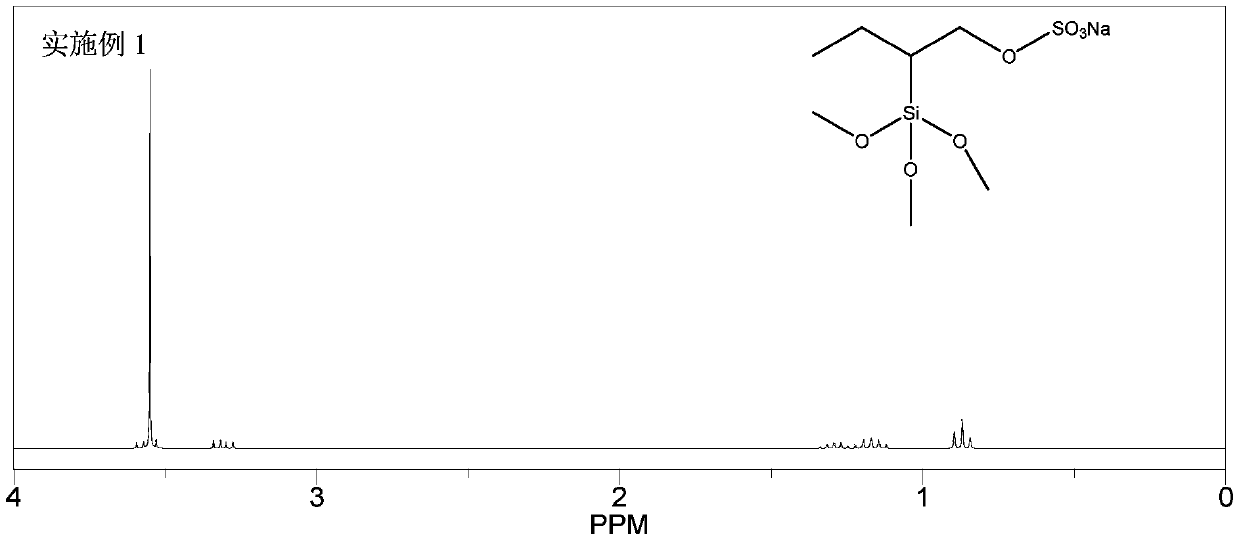

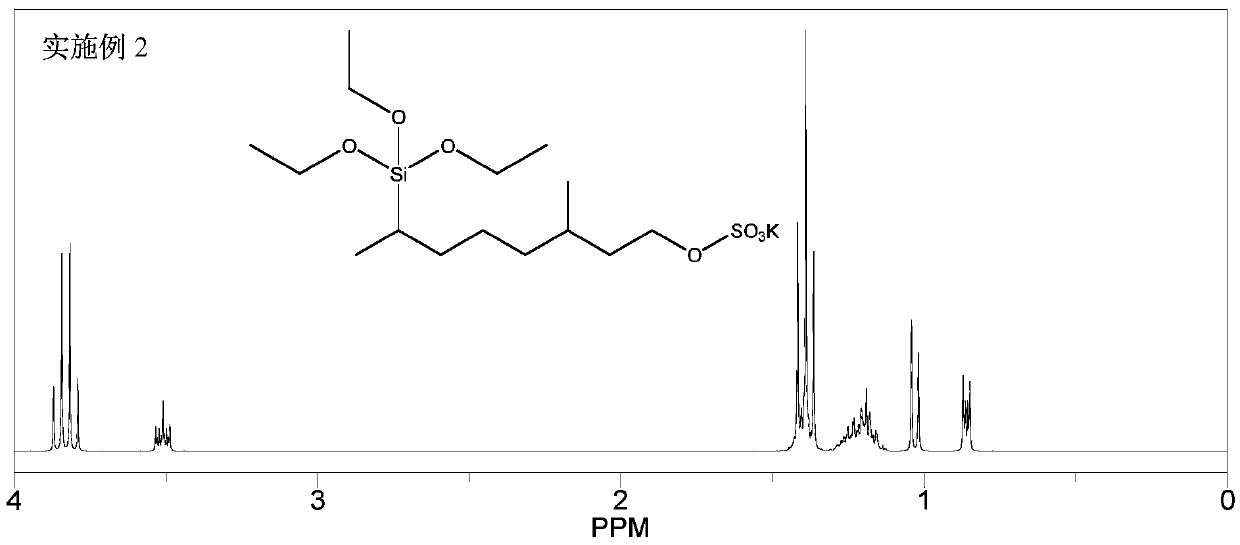

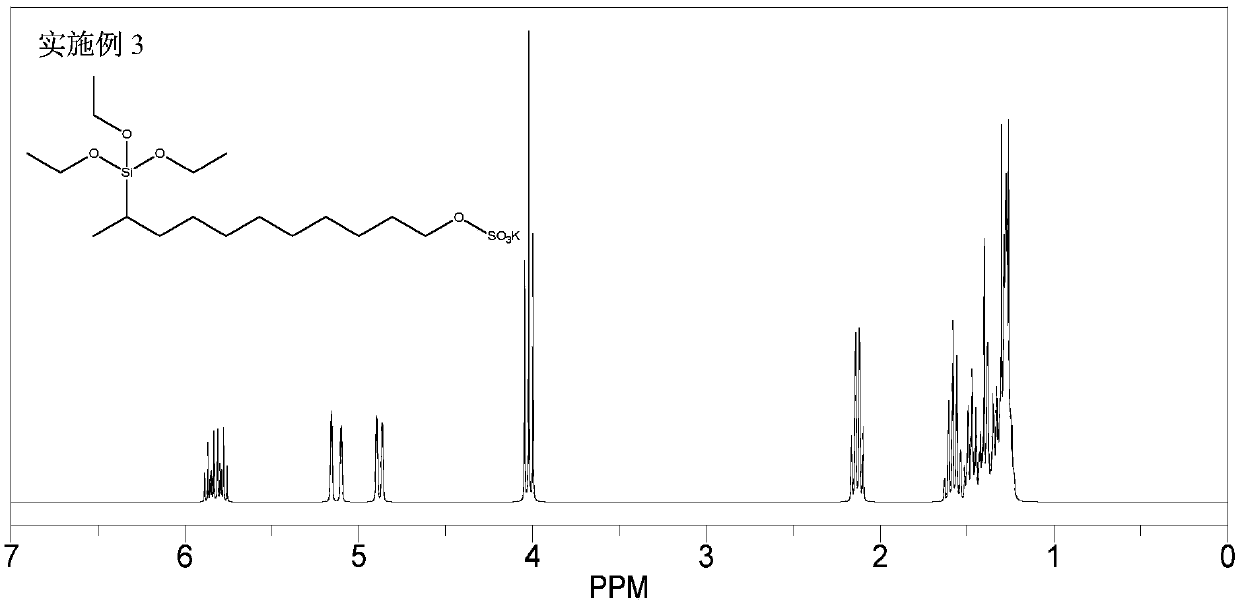

In-situ reaction-type concrete air entraining agent

The invention discloses a concrete air entraining agent molecule with a sulfate ion as a hydrophilic group and reactable alkoxysilane-modified aliphatic hydrocarbon as a hydrophobic part. The concrete air entraining agent molecule is prepared according to a molecular designing principle and has a structure shown in the formula (I). The invention also provides a preparation method of the above compound and a use of the compound as a concrete air entraining agent. The compound has surface activity and in-situ reactivity. The concrete air entraining agent has good air entraining effects at a low mixing ratio, reasonable entrained bubble size distribution, good foam stabilizing effects, high gas content and small influence on concrete strength.

Owner:JIANGSU SOBUTE NEW MATERIALS +3

Dry-mixed mortar thickening agent and preparation method thereof

The invention relates to a building material. The invention aims to provide a dry-mixed mortar thickening agent and a preparation method thereof. The dry-mixed mortar thickening agent provided by theinvention has the characteristics of the low cost, the good water reducing effect, the good retarding effect and low air entraining. The preparation method provided by the invention has the characteristics of the simple process and convenience in preparation. According to the technical scheme, the dry-mixed mortar thickening agent is characterized by comprising the following components in parts bymass: 40-60 parts of a thickening agent base material A, 35-55 parts of a thickening agent base material B, 0-5 parts of hydroxymethyl cellulose, and 2-5 parts of sodium hydroxide and 5-10 parts of zeolite powder, wherein the thickening agent base material A comprises maltodextrin, polyethylene glycol and molasses in a mass ratio of (1-2):(2-4):(6-10), and the thickening agent base material B comprises carbonyl pyroaldehyde and sodium lignin sulfonate in a mass ratio of (25-30):(1-5).

Owner:杭州斯曼特建材科技有限公司

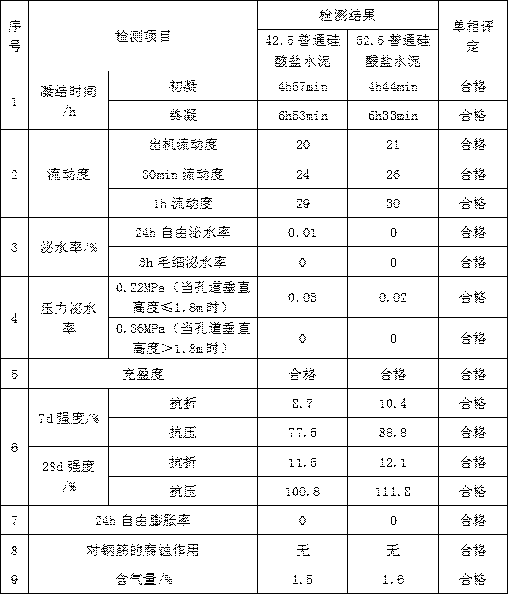

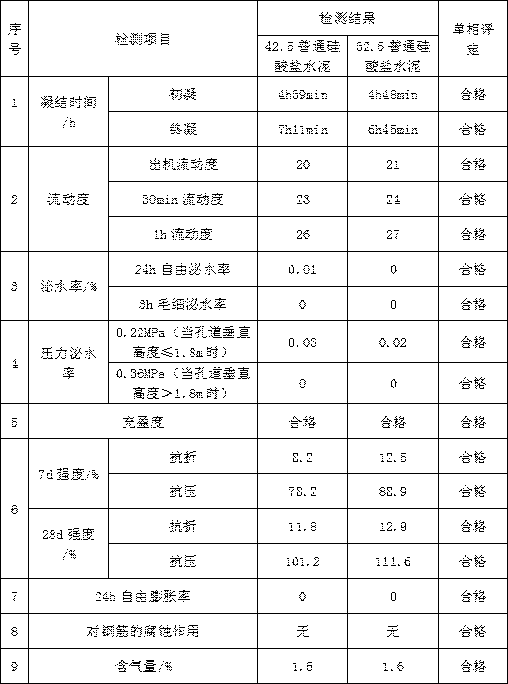

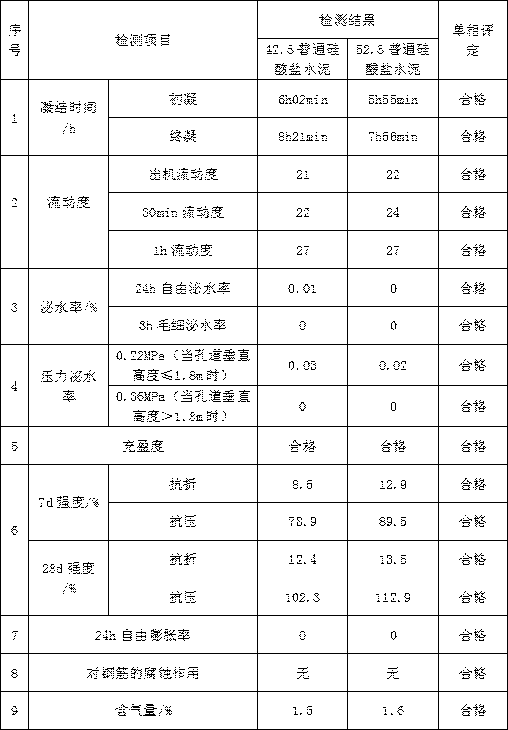

Grouting agent and preparation method thereof

The invention provides a grouting agent and a preparation method thereof, and relates to a concrete additive and a preparation method thereof. The grouting agent prepared according to the method is applicable to the fields of grouting of equipment foundation, and anchoring grouting of ground anchor systems. The grouting agent comprises 7-12 parts of silica fume, 2-4 parts of fly ash, 3-5 parts ofpolycarboxylic acid, 1-1.5 parts of magnesium oxide, 0-0.05 part of sodium thiosulfate, 0.3 part of sodium sulfate, 0.1-0.2 part of beta-naphthalene sulfonated formaldehyde condensates, 0.01 part of organic silicon, 0.1 part of rosin saponated substance, 0.2-0.3 part of sodium carbonate, and 550-650 parts of cement. According to the grouting gent prepared according to the method, the dose of the added components can be adjusted and controlled based on different types of the used cement and different use temperatures, so that the grouting agent prepared according to the method can work normallyin various environments and is not influenced by different types of cement.

Owner:云南森博混凝土外加剂有限公司

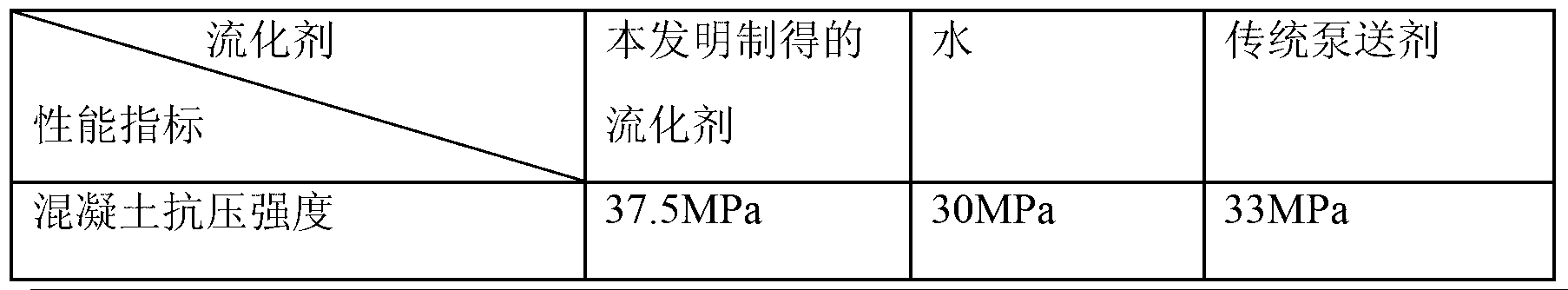

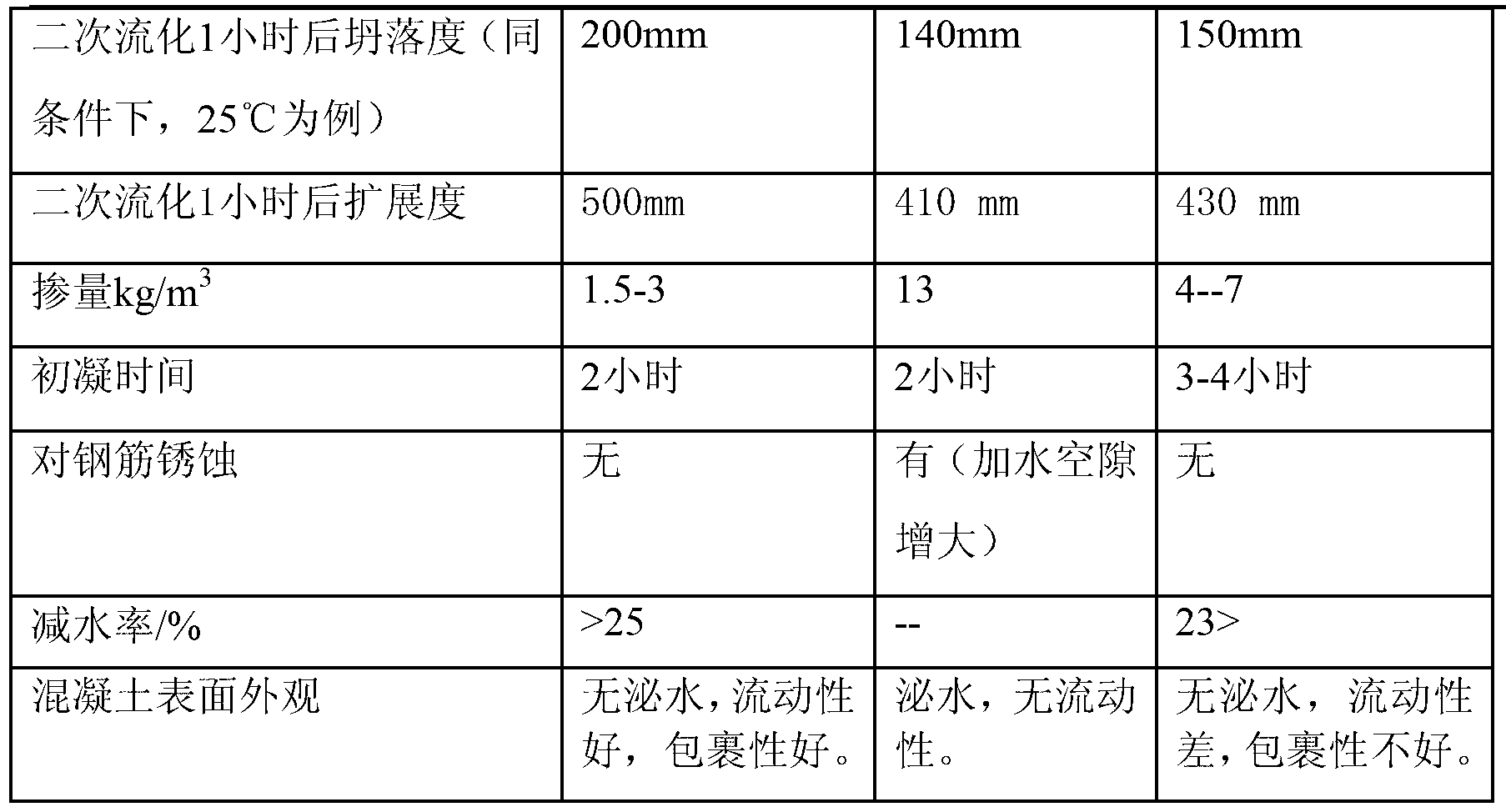

Secondary concrete fluidizing agent

InactiveCN103214210ALittle loss of strengthSmall slump secondary lossSecondary lossUltimate tensile strength

The invention relates to a secondary concrete fluidizing agent which mainly solves the technical problem of providing a secondary concrete fluidizing agent. The secondary concrete fluidizing agent comprises the following ingredients in parts by weight: 300-350 parts of a polycarboxylate-type water reducing agent, 0.08-0.10 part of an air-entraining agent, 12-16 parts of a retarder and 630-660 parts of water. A method for preparing the secondary concrete fluidizing agent mainly comprises the following steps: evenly mixing the polycarboxylate-type water reducing agent with water, sequentially adding the air-entraining agent and the retarder, and evenly stirring to obtain the secondary concrete fluidizing agent. The secondary concrete fluidizing agent is fluid, has the functions of ensuring that the secondarily fluidized concrete is small in strength loss, normal in setting time, small in secondary slump loss and the like, and also solves the quality fluctuation problem of the secondarily fluidized concrete.

Owner:CHINA 19TH METALLURGICAL CORP CHENGDU CONSTR +1

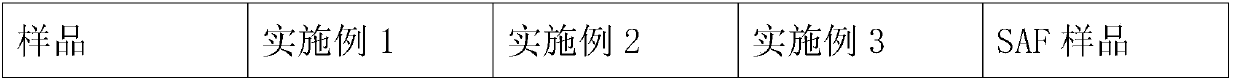

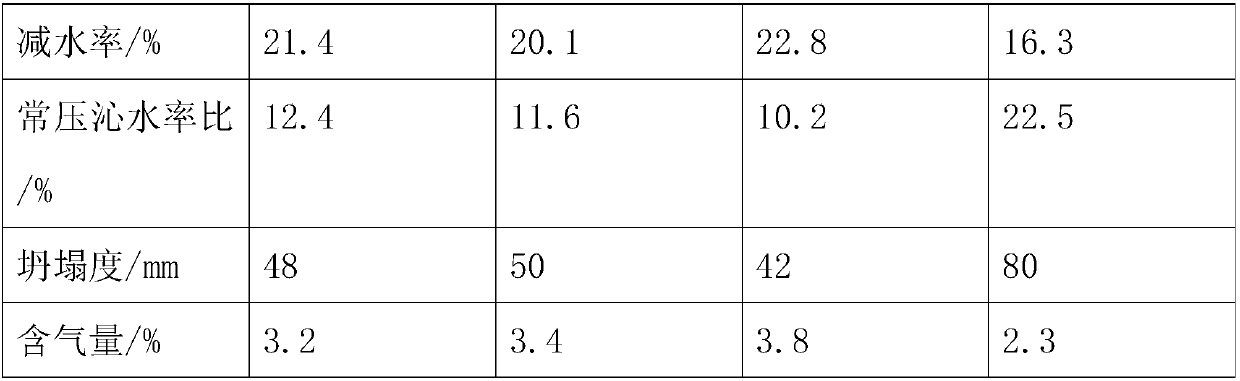

High-performance polycarboxylate water reducing agent and preparation method thereof

The invention discloses a high-performance polycarboxylate water reducing agent and a preparation method thereof. The high-performance polycarboxylate water reducing agent is prepared from the following raw materials in parts by weight: 375 to 600 parts of water, 300 to 400 parts of monomers, 2 to 4 parts of catalysts and 80 to 120 parts of materials A. According to the method, the raw materials are sequentially prepared into the high-performance polycarboxylate water reducing agent through the steps of dissolution mixing, flowing addition mixing, heat insulation and the like. The high-performance polycarboxylate water reducing agent prepared by the invention has the advantages that the water reducing rate is high; the slump loss resistant effect is enhanced, and the gas content is high, so that the air-entraining performance is good; the problem of easy water secretion is solved; the process is simple; the performance is stable.

Owner:HUAIBEI XURI BUILDING MATERIALS

Preparation method of air entraining agent applied to preparation of modified cassava starch-polycarboxylic acid composite water reducing agent

The invention discloses a preparation method of an air entraining agent applied to preparation of a modified cassava starch-polycarboxylic acid composite water reducing agent, and belongs to the fieldof building materials. The preparation method of the air entraining agent comprises the following steps: putting rosin powder, p-toluenesulfonic acid and sodium hydroxide into a reaction kettle, adding water accounting for 50% of the total mass of the mixture A, mixing and stirring for 30 minutes, heating to 80 DEG C, keeping the temperature for 50 minutes, heating to 80 DEG C, and keeping the temperature for 45 minutes; heating the mixed solution A to 85 DEG C, slowly adding pentaerythritol and tall oil, keeping the temperature for 35 minutes, heating to 70-85 DEG C, slowly adding mahogany petroleum sulfonate, and keeping the temperature for 1 hour to obtain the air entraining agent. The air entraining agent has a good air entraining effect, the average pore diameter of air entraining bubbles is small, the durability of concrete is remarkably improved, meanwhile, the workability of the concrete is obviously improved, the slump loss of the concrete is reduced, and the strength of theconcrete is not reduced.

Owner:NANNING TONGCAI TECH CO LTD

Air-entraining composite concrete waterproof agent and preparation method thereof

The invention discloses an air-entraining composite concrete waterproof agent and a preparation method thereof. The air-entraining composite concrete waterproof agent comprises the following components: tetraethyl orthosilicate, sodium stearate, phenyl salicytate, polyvinyl alcohol, alum, silk white powder, sodium fluosilicate, sodium dodecyl sulfate, propylene glycol, silicon dioxide, bentonite, rosin, sodium alginate, sodium hydroxide and sulfuric acid. Micro-bubbles can be uniformly introduced; and the waterproof agent has good air entraining property and bubble stability, obviously improves the anti-seepage and waterproof property, enhances the compactibility and compressive strength, improves the working performance of concrete, enhances the concrete durability, has the characteristics of safety and no toxicity or corrosion and is suitable for the concrete requiring certain air content in ports, wharfs, water conservancy projects, highway pavements, freeze-thaw resistance, corrosion resistance, anti-seepage projects and the like.

Owner:WENDENG LANDAO ARCHITECTURAL ENG CO LTD

Anti-freezing green vegetation concrete and preparation method thereof

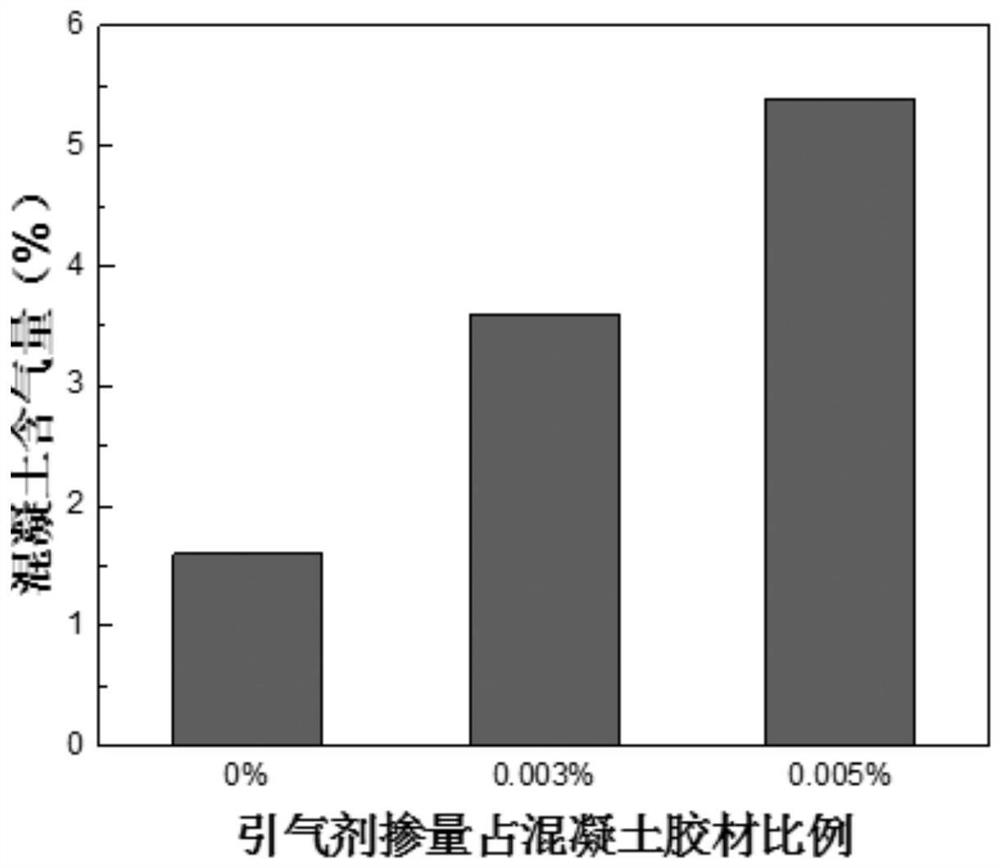

ActiveCN114230246AImprove frost resistanceImprove deformation resistanceCeramicwareMatrix fertilisersROSIN POWDERFiber

The invention relates to the field of concrete, and particularly discloses anti-freezing green vegetation concrete and a preparation method thereof.The anti-freezing green vegetation concrete is prepared from, by weight, 200-300 parts of cement, 60-80 parts of kieselguhr, 300-380 parts of aggregate, 60-100 parts of soil, 10-20 parts of composite fibers, 1-2.5 parts of air entraining agent, 4-10 parts of water reducing agent and 120-160 parts of water; the air entraining agent is prepared from the following components in parts by weight: 20 to 35 parts of rosin powder, 8 to 14 parts of nekal, 12 to 16 parts of melamine, 5 to 15 parts of sulfuric acid, 10 to 20 parts of sodium hydroxide and 12 to 18 parts of polyethylene glycol. The anti-freezing green vegetation concrete disclosed by the invention has relatively good anti-freezing performance.

Owner:杭州汉特建材有限公司

Preparation method of air entraining agent

The invention relates to the technical field of composite material preparation, and particularly discloses a preparation method of an air entraining agent, and the preparation method of the air entraining agent comprises the following steps: in a stirring state, adding an initiator and sodium hydroxide into a reaction kettle A, conducting heating to 65-75 DEG C, conducting vacuumizing and stirring for 30-90 minutes, putting ethylene oxide into a reaction kettle B, dropwise adding ethylene oxide into the reaction kettle A from the reaction kettle B, heating the reaction kettle A to 120-130 DEG C, and maintaining the system pressure of the reaction kettle A in a medium-pressure environment; slowly dropwise adding the residual ethylene oxide in the reaction kettle B into the reaction kettle A to obtain an intermediate A; adding the intermediate A, phosphoric acid and a cosolvent into a cleaned reaction kettle A, conducting heating to 120-130 DEG C, and conducting stirring for 15-18 hours; and conducting cooling, concentrating and cleaning to obtain the air entraining agent. The invention aims to solve the problems that in the prior art, an air entraining agent is poor in foam stabilizing effect, and more air entraining agents need to be added to improve the workability of concrete.

Owner:GUIZHOU DR SHI TECH

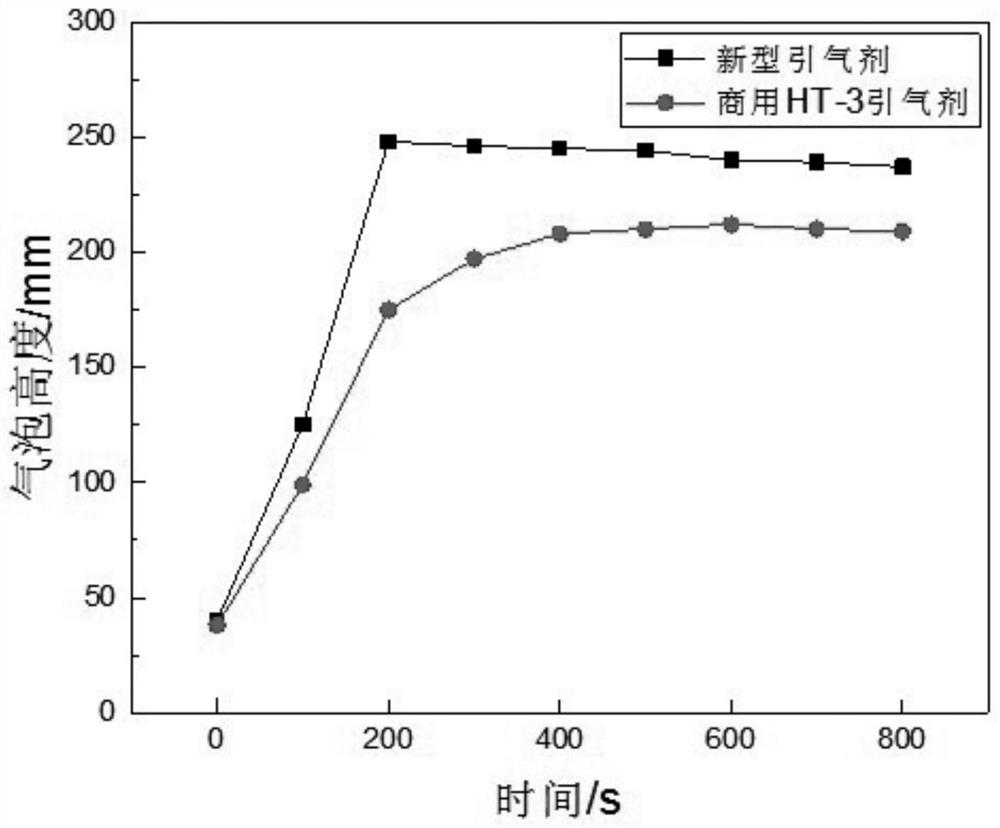

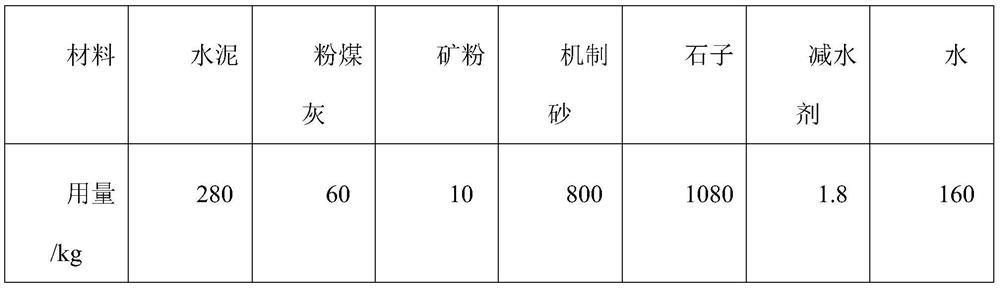

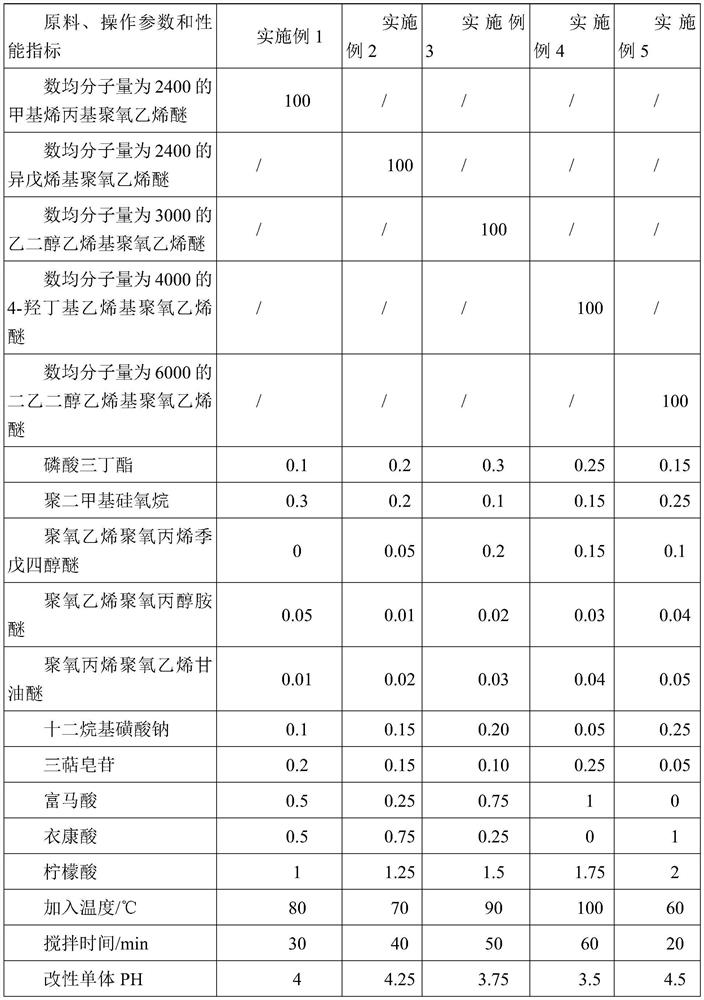

Modified polyether macromonomer as well as preparation method and use method thereof

The invention discloses a modified polyether macromonomer as well as a preparation method and a use method thereof, and belongs to the technical field of water reducers. The modified polyether macromonomer is prepared from the following components in parts by weight: 100 parts of polyether macromonomer, 0.1-0.3 part of tributyl phosphate, 0.1-0.3 part of polydimethylsiloxane, 0-0.2 part of polyoxyethylene polyoxypropylene pentaerythritol ether, 0.01-0.05 part of polyoxyethylene polyoxypropylene alcohol amine ether, 0.01-0.05 part of polyoxyethylene polyoxypropylene glycerol ether, 0.05-0.25 part of sodium dodecyl sulfate, 0.05-0.25 part of triterpenoid saponin, 0-1 part of fumaric acid, 0-1 part of itaconic acid and 1-2 parts of citric acid. The technical problems of high air content, reduced strength, poor durability and the like in concrete after the polycarboxylic acid water reducer is used are solved.

Owner:连云港石化有限公司

An air-entraining controllable polycarboxylate water reducer for pure machine-made sand concrete and its preparation method

The invention belongs to the field of concrete additives, and concretely relates to an air entrainment-controllable polycarboxylic water reducer used for purely machine-made sand concrete, and a preparation method thereof. The preparation method comprises the following steps: carrying out an esterification reaction on an alkylphenol polyoxyethylene monomer and an unsaturated carboxylic acid to generate an unsaturated carboxylic acid-alkylphenol polyoxyethylene esterification product monomer, carrying out an aqueous solution copolymerization reaction on the unsaturated carboxylic acid-alkylphenol polyoxyethylene esterification product monomer, an unsaturated polyether monomer and an unsaturated sulfonic acid monomer through an oxidation-reduction initiation system, and adding a proper amount of a molecular weight control agent to control the molecular weight in order to obtain the air entrainment-controllable polycarboxylic water reducer. The water reducer prepared in the invention has the advantages of high water reduction rate, good adaptability, small bubble diameters, stable sealing property and controllable air entrainment when applied to the purely machine-made sand concrete, and well solves the problems of difficult air entrainment, poor bubble stability and large concrete pumping loss of the purely machine-made sand concrete.

Owner:中建商品混凝土(福建)有限公司 +1

High-efficiency concrete water reducer and preparation method thereof

The invention discloses a high-efficiency concrete water-reducing agent, which is prepared from the following raw materials in parts by weight: 80-90 parts of polycarboxylate water-reducing agent, 0.16-0.18 parts of defoaming agent, 1-1.2 parts of viscosity regulator, modified 0.8-0.9 parts of lignin; the invention also discloses a preparation method of the high-efficiency concrete water-reducing agent. The present invention uses the self-made polycarboxylate water-reducing agent as the main substance, and the hydrophilic groups carboxyl (-COO-), amino (-NH) contained in the self-made polycarboxylate water-reducing agent 2 ), hydrophobic group ester group (‑COOR) and the synergistic effect of polyether side chains are beneficial to its wetting and adsorption on the surface of concrete and concrete particles and the relative lubrication between aggregate particles; through defoamer and modified wood Quantitative addition of the element can lead to proper amount of air entrainment in the concrete, improve the workability of the concrete and reduce the viscosity of the concrete, and has a certain slump retention performance for the concrete. Workable concrete water reducer.

Owner:陕西省建筑高新技术开发有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com