In-situ reaction-type concrete air entraining agent

A reaction, carbon atom technology, applied in the field of concrete air-entraining agent, can solve the problems of unreasonable bubble size, large loss of air content, insufficient air-entraining, etc., and achieve good air-entraining effect, low concrete strength, and good foam stabilization effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

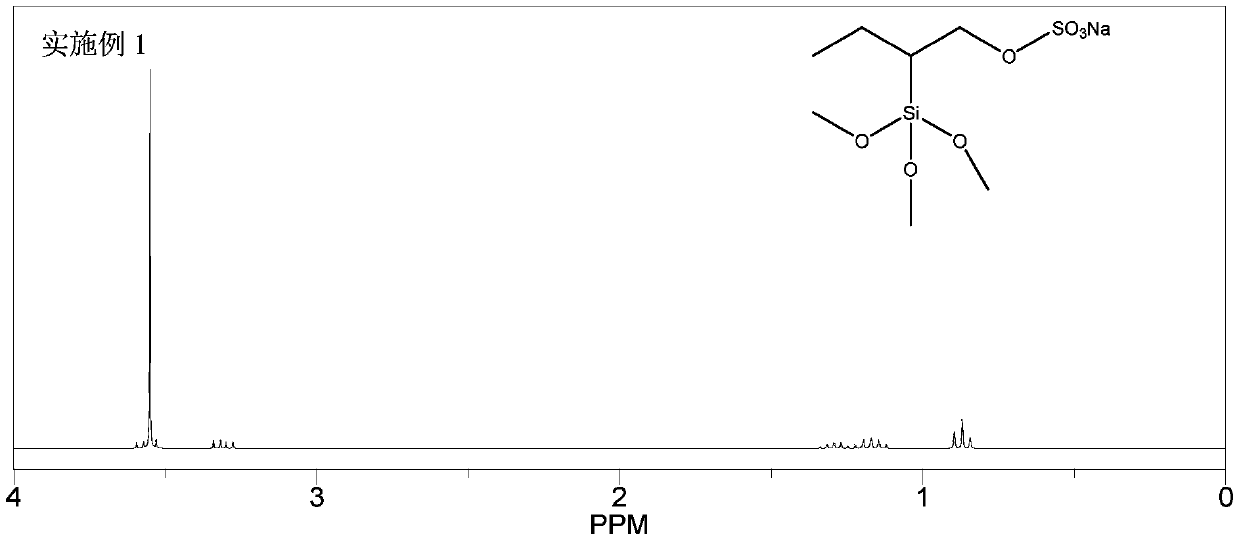

Embodiment 1

[0035] Step 1: Add 1.0 mol of 2-butenol into a reaction flask equipped with a thermometer, dropping funnel, condenser, stirrer and tail gas conduit. The temperature was raised to 30°C under stirring, and 1.1 mol of chlorosulfonic acid was added to the reaction flask within 1 h. During the dropwise addition of chlorosulfonic acid, the reaction temperature was controlled at 30-50°C. After the dropwise addition, the reaction was continued at 30°C for 30 minutes. The system was then immediately neutralized to pH=5 with NaOH.

[0036] Step 2: in the drying flask that is equipped with thermometer, condenser and stirrer, add the unsaturated alcohol sulfate that obtains in the step 1 of 1.0mol and the HSi(OCH 3 ) 3 . The temperature was raised under stirring, and when the temperature reached 50°C, 0.07ml of 0.01mol / L isopropanol solution of chloroplatinic acid (amount of 1 ppm) was added dropwise, and the temperature was controlled at 50-80°C during the dropwise addition. After t...

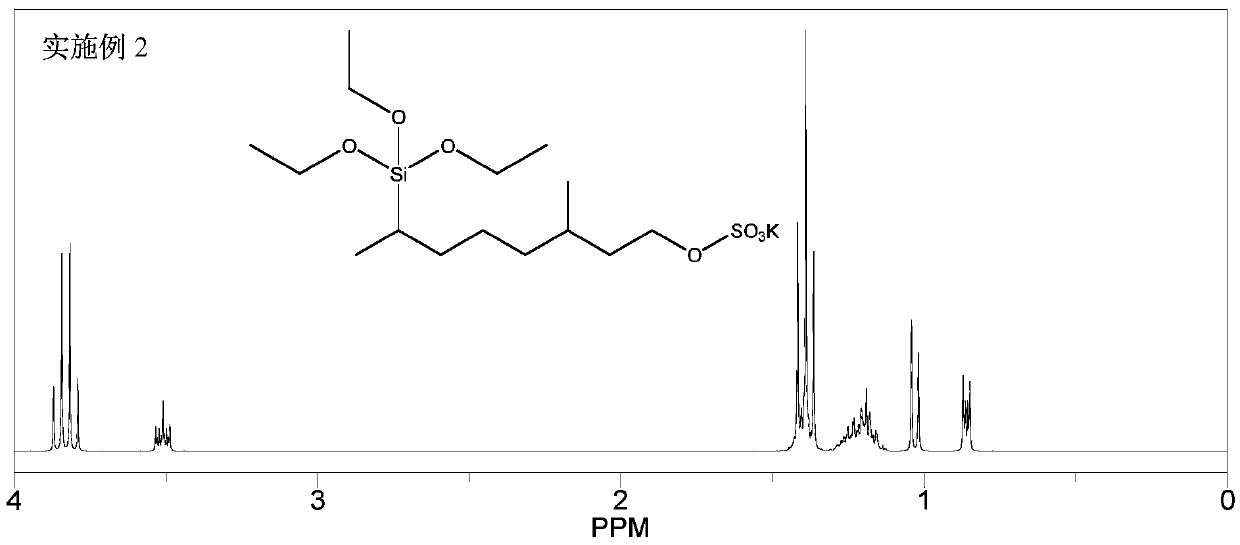

Embodiment 2

[0040] Step 1: Add 1.0 mol of 3-methyl-7-heptenol into a reaction flask equipped with a thermometer, dropping funnel, condenser, stirrer and tail gas conduit. The temperature was raised to 30°C with stirring, and 1.2 mol of chlorosulfonic acid was added to the reaction flask within 1 h. During the dropwise addition of chlorosulfonic acid, the reaction temperature was controlled at 30-60°C. After the dropwise addition was completed, the reaction was continued at 50° C. for 10 minutes. The system was then immediately neutralized to pH=6 with KOH.

[0041] Step 2: in the drying flask that is equipped with thermometer, condenser and stirrer, add the unsaturated alcohol sulfate that obtains in the step 1 of 1.0mol and the HSi(OCH 2 CH3 ) 3 . The temperature was raised under stirring, and when the temperature reached 50°C, 0.9ml of 0.01mol / L chloroplatinic acid solution in isopropanol (amount of 10ppm) was added dropwise, and the temperature was controlled at 50-100°C during the...

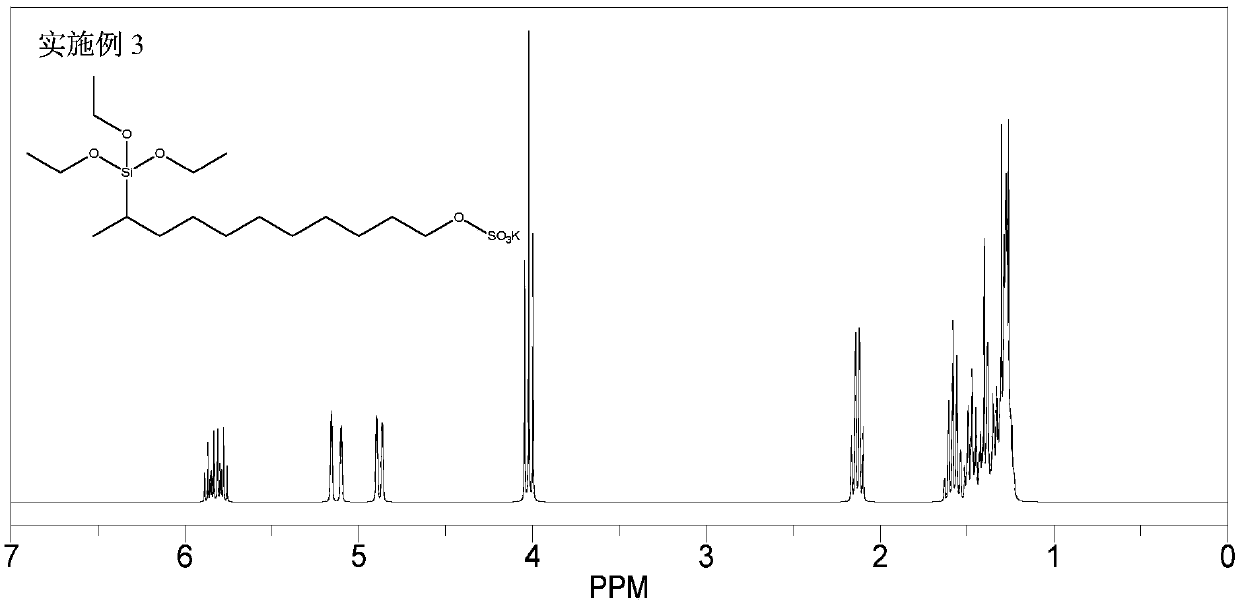

Embodiment 3

[0045] Step 1: Add 1.0 mol of undecenyl alcohol into a reaction flask equipped with a thermometer, dropping funnel, condenser, stirrer and tail gas conduit. The temperature was raised to 30°C under stirring, and 1.0 mol of chlorosulfonic acid was added to the reaction flask within 1 h. During the dropwise addition of chlorosulfonic acid, the reaction temperature was controlled at 40-60°C. After the dropwise addition, the reaction was continued at 60°C for 60 min. The system was then immediately neutralized to pH=7 with KOH.

[0046] Step 2: in the drying flask that is equipped with thermometer, condenser and stirrer, add the unsaturated alcohol sulfate that obtains in the step 1 of 1.0mol and the HSi(OCH 2 CH 3 ) 3 . The temperature was raised under stirring, and when the temperature reached 50°C, 11.8ml of 0.01mol / L isopropanol solution of chloroplatinic acid (amount of 100ppm) was added dropwise, and the temperature was controlled at 60-90°C during the dropwise addition...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com