Concrete composite air entraining agent and method of preparing the same

An air-entraining agent and concrete technology, applied in the field of concrete admixtures, can solve the problems of reducing concrete strength and other properties, general air-entraining effect, inability to comprehensively improve concrete performance, etc. The effect of the entrainment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

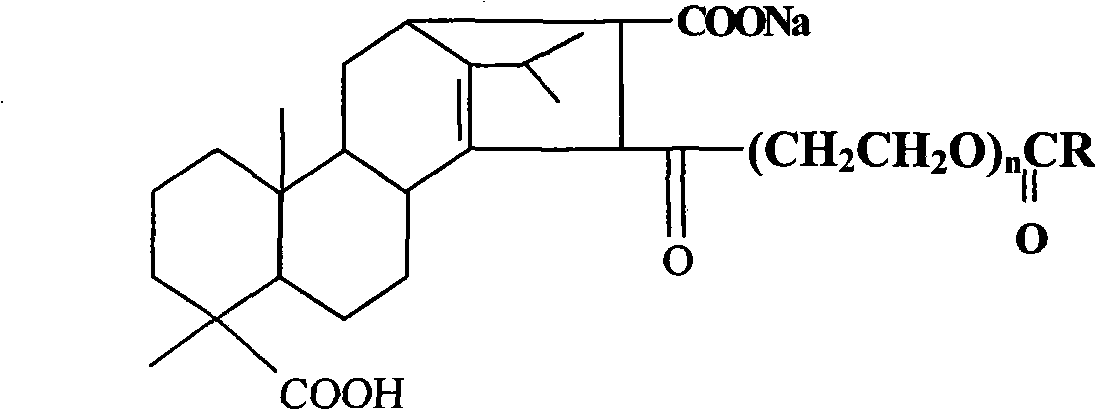

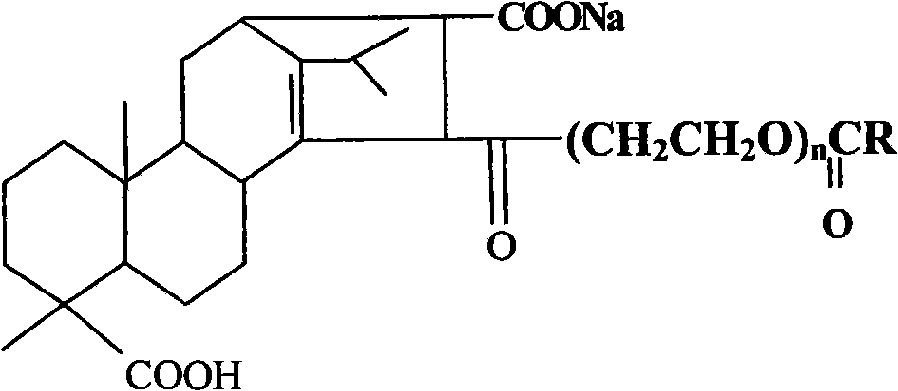

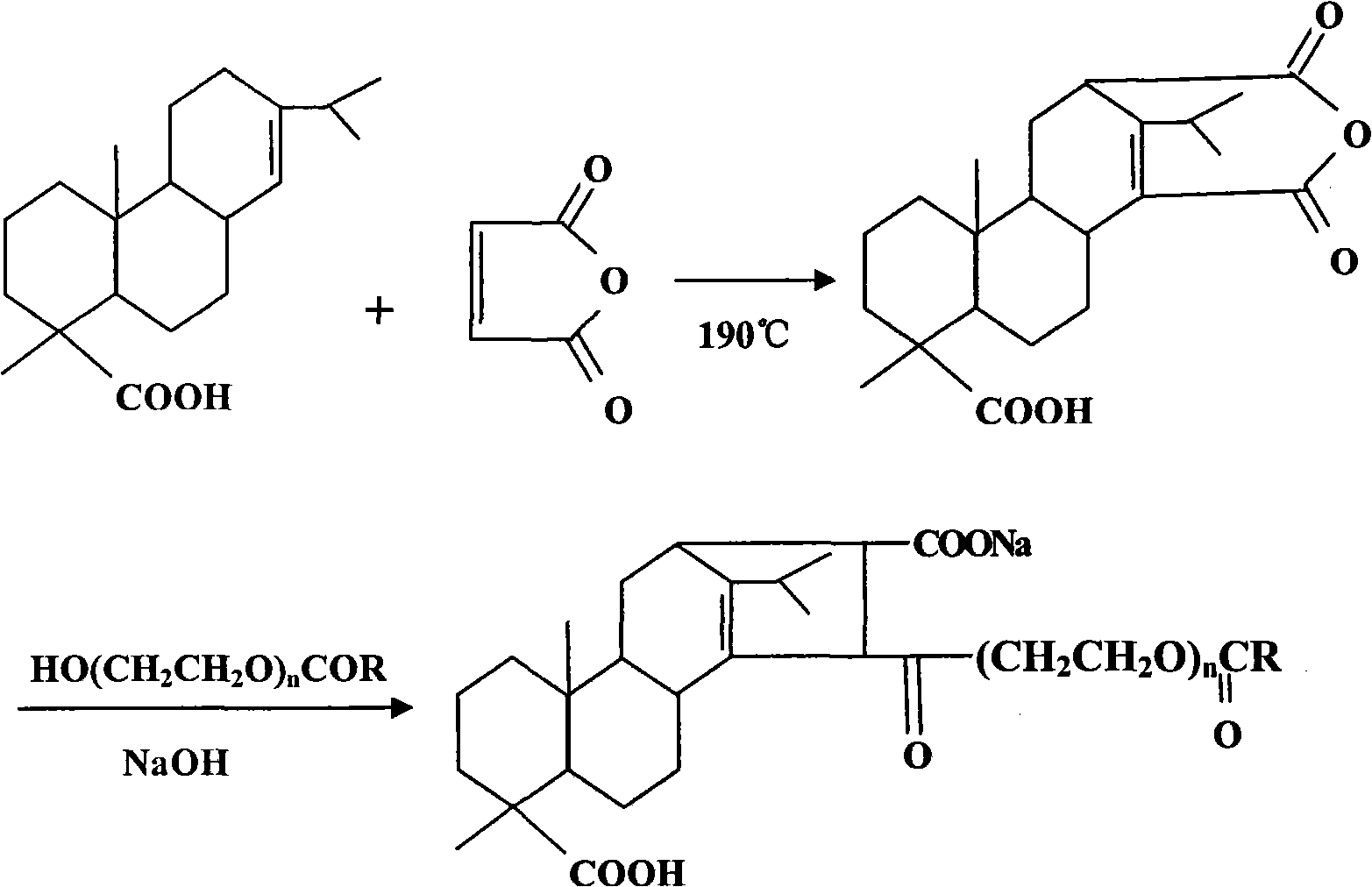

Image

Examples

Embodiment 1

[0029] A concrete composite air-entraining agent of the present invention, the composite air-entraining agent is prepared by mixing the following components in mass fractions:

[0030] Malay pine soap 30%

[0031] Sodium dodecylbenzenesulfonate 20%

[0032] Coconut Oil Diethanolamide 10% and

[0033] Water 40%.

[0034] The preparation method of the above-mentioned composite air-entraining agent for concrete is: add 3.0kg of male pine soap to 4.0kg of tap water and stir evenly, then add 2.0kg of dodecylbenzenesulfonic acid at a temperature of 70°C to 80°C The coconut oil diethanolamide of sodium and 1.0kg is fully mixed and stirred to obtain the concrete composite air-entraining agent of the present embodiment.

[0035] The male rosin soap used in this example is prepared by the following steps: get 4.0 kg of rosin and pulverize it into a reaction kettle, heat it to 130°C to 165°C under a nitrogen atmosphere to melt the rosin, and under constant stirring, Then add 0.8kg of...

Embodiment 2

[0037] A concrete composite air-entraining agent of the present invention, the composite air-entraining agent is prepared by mixing the following components in mass fractions:

[0038] Marathon Soap 25%

[0039] Sodium dodecylbenzenesulfonate 15%

[0040] Coconut Oil Diethanolamide 9%

[0041] Water 51%.

[0042] The preparation method of the above-mentioned composite air-entraining agent for concrete is: 5.0kg of male pine soap is added to 10.2kg of tap water and stirred evenly, and then added 3.0kg of sodium dodecylbenzenesulfonate and 1.8 kg at a temperature of 150°C. kg of coconut oil diethanolamide, fully mixed and stirred to obtain the concrete composite air-entraining agent of the present embodiment.

[0043] The male rosin soap used in this example is prepared through the following steps: get 5.0 kg of rosin and pulverize it and add it to a reaction kettle, heat it to 130°C to 165°C under a nitrogen atmosphere to melt the rosin, and under constant stirring, Then ad...

Embodiment 3

[0045]A concrete composite air-entraining agent of the present invention, the composite air-entraining agent is prepared by mixing the following components in mass fractions:

[0046] Malay pine soap 20%

[0047] Sodium dodecylbenzenesulfonate 10%

[0048] Coconut Oil Diethanolamide 8%

[0049] Water 62%.

[0050] Add 5 kg of male pine soap to 15.5 kg of tap water and stir evenly, then add 2.5 kg of sodium dodecylbenzenesulfonate and 2 kg of coconut oil diethanolamide at a temperature of 100 ° C, and fully mix and stir to obtain Concrete composite air-entraining agent.

[0051] The male rosin soap used in this example is prepared through the following steps: get 6.0 kg of rosin and pulverize it and add it to a reaction kettle, heat it to 130° C. to 165° C. to melt the rosin under a nitrogen atmosphere, and, under constant stirring, Then the maleic anhydride of 1.2kg is added in the reactor to carry out reaction, and reaction temperature is controlled at 180 ℃~195 ℃, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com