Anti-freezing green vegetation concrete and preparation method thereof

A green vegetation and concrete technology, applied in the field of concrete, can solve the problems of affecting the service life of green vegetation concrete, poor cold and frost resistance, and damage to concrete structures, and achieve good air-entraining performance, improved frost resistance, and foam stabilization time long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

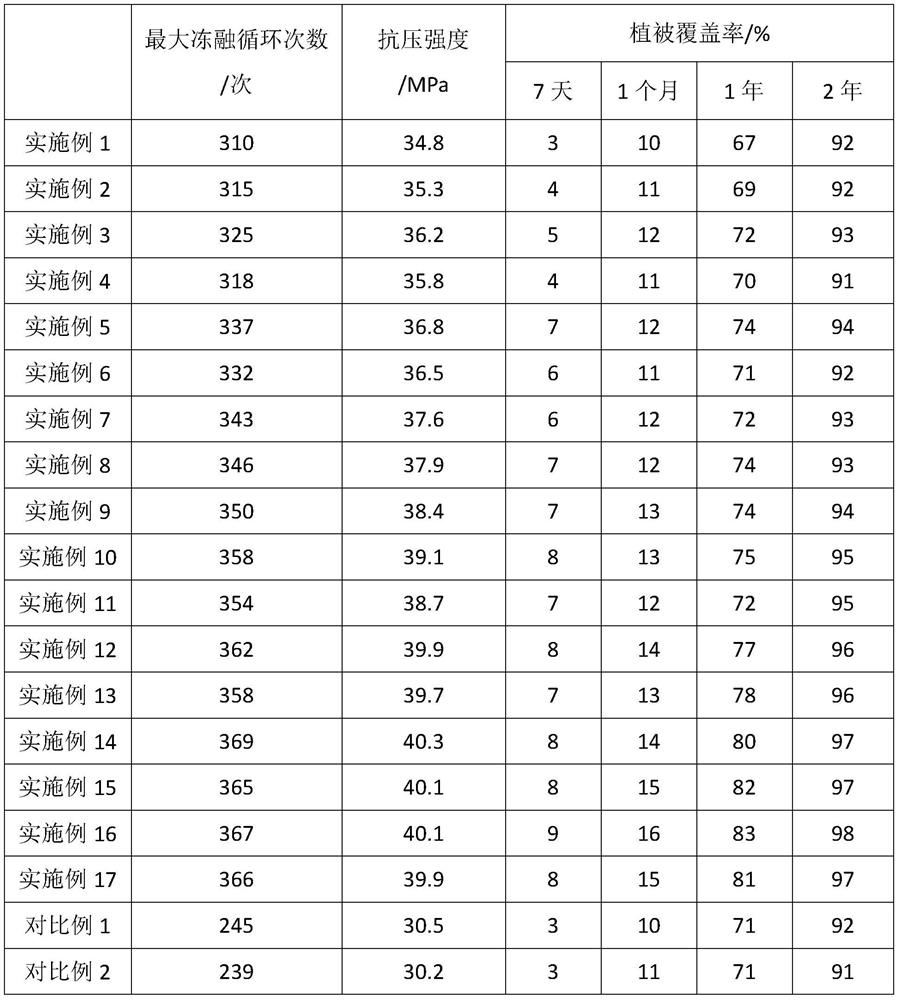

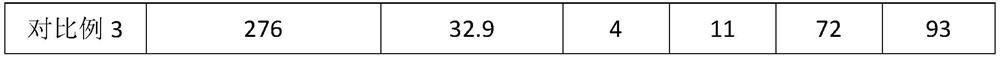

Examples

preparation example 1-3

[0045] One ventilator of Example 1-3, the amount of the raw materials and each raw material, as shown in Table 1, the preparation steps are as follows:

[0046] 1) Mix the rosin powder, dibutylnaphthamethoalk sodium hydrochloride, and sodium hydroxide, stir for 15 min, heating to 70 ° C, heat insulation for 30 min;

[0047] 2) Then warm to 80 ° C, add melamine and sulfuric acid, heat insulation for 25min;

[0048] 3) Then hete the temperature to 85 ° C, add polyethylene glycol, heat insulation for 40 min to give the air intake.

[0049] Table 1 Preparation Example 1-3 Each of the raw materials and the amount of raw materials (kg)

[0050] Preparation 1 Preparation 2 Preparation Example 3 Loose powder 20 26 35 Dibutylnaphthalene sodium sodium dibutyl 14 10 8 Melamine 12 14 16 sulfuric acid 15 10 5 Sodium hydroxide 10 15 20 Polyethylene glycol 18 15 12

preparation example 4-6

[0052] One composite fiber of Example 4-6, each of its raw materials and the amount of raw materials are shown in Table 2, and the preparation steps are as follows:

[0053] Each raw material was weighed according to Table 2, and then the raw materials were mixed well, and the composite fibers were obtained.

[0054] Table 2 Preparation Example 4-6 Composite Fiber Each raw material and the amount of raw materials (kg)

[0055] Preparation 4 Preparation Example 5 Preparation 6 Polypropylene fibers 15 20 25 Wood fiber 12 10 8 Hemp fiber 4 5 6

preparation example 7-9

[0057] One soil of Preparation Example 7-9, the amount of raw materials and the amount of raw materials are shown in Table 3, and the preparation steps are as follows:

[0058] Each raw material is weighed in Table 3, and then the raw materials are mixed well, that is, the soil is obtained.

[0059] Table 3 Preparation Example 7-9 of the soil raw materials and all raw materials (kg)

[0060] Preparation 7 Preparation 8 Preparation Sand 80 90 100 Grass species 0.5 0.3 0.1 fertilizer 4.5 3 1.5

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com