Patents

Literature

34 results about "Secondary loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Meaning Behind Secondary Loss. Secondary losses are the other losses that come with losing a loved one. This could be a physical object, a tradition that involved the deceased, or something else. Often, these secondary losses appear over time rather than all at once.

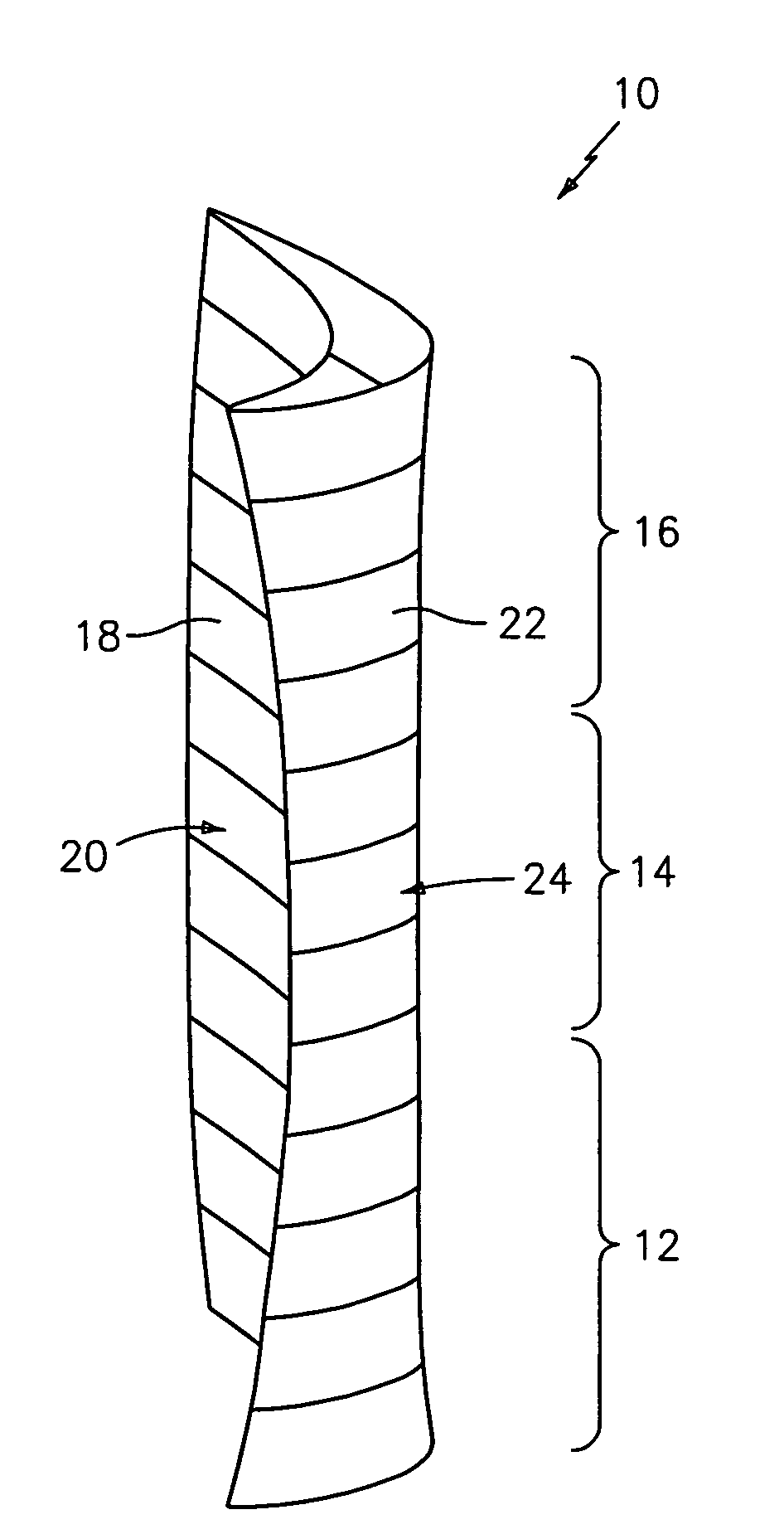

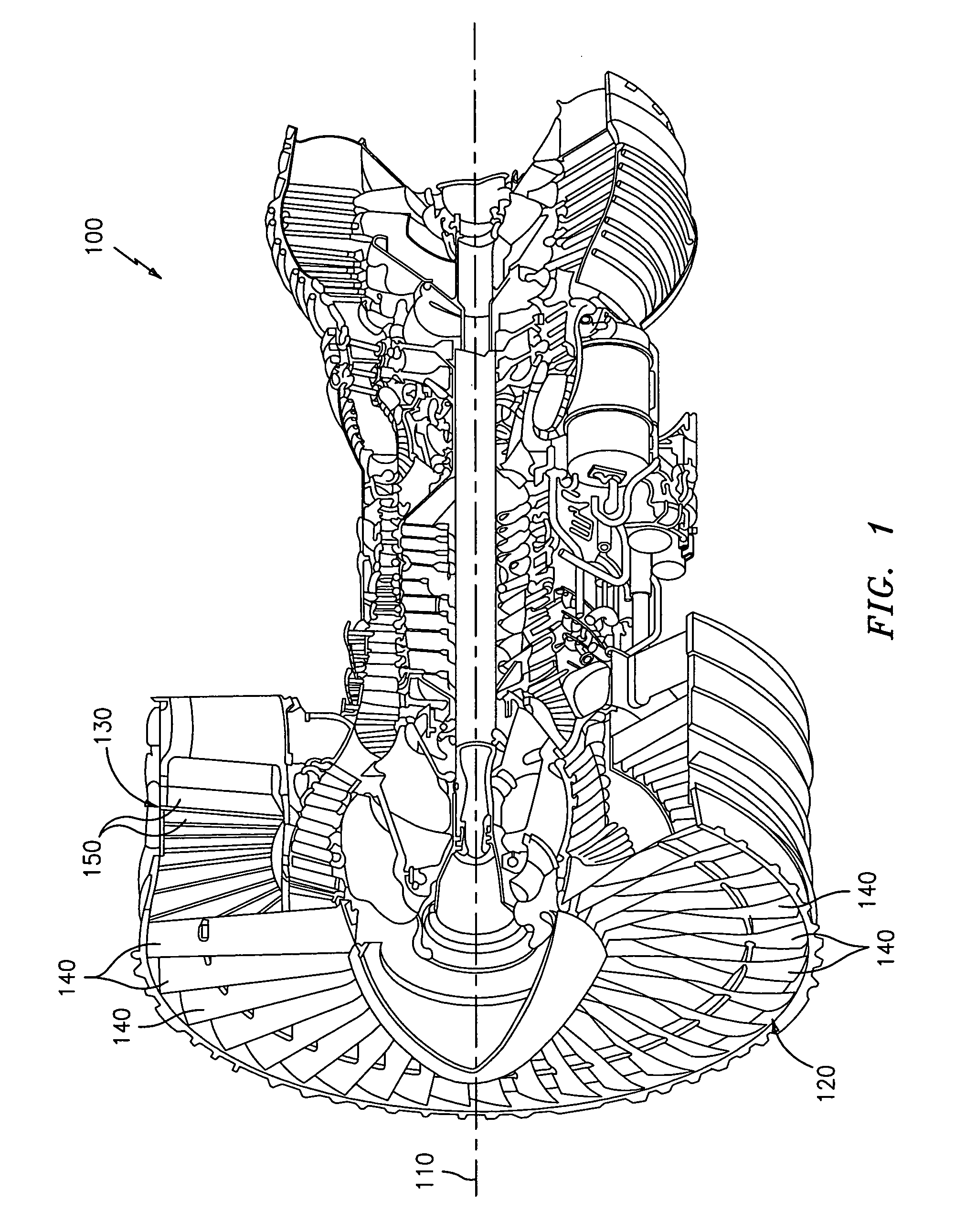

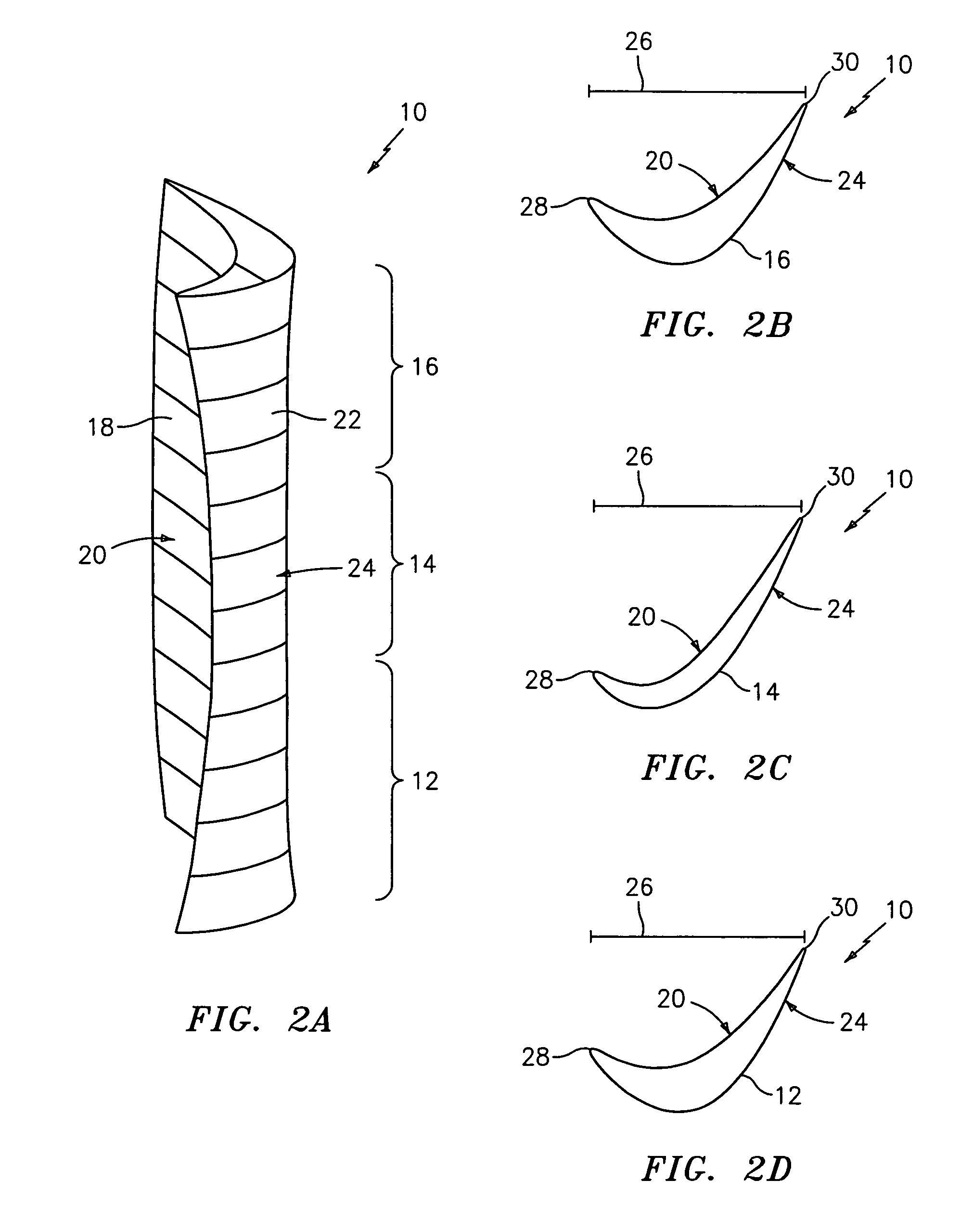

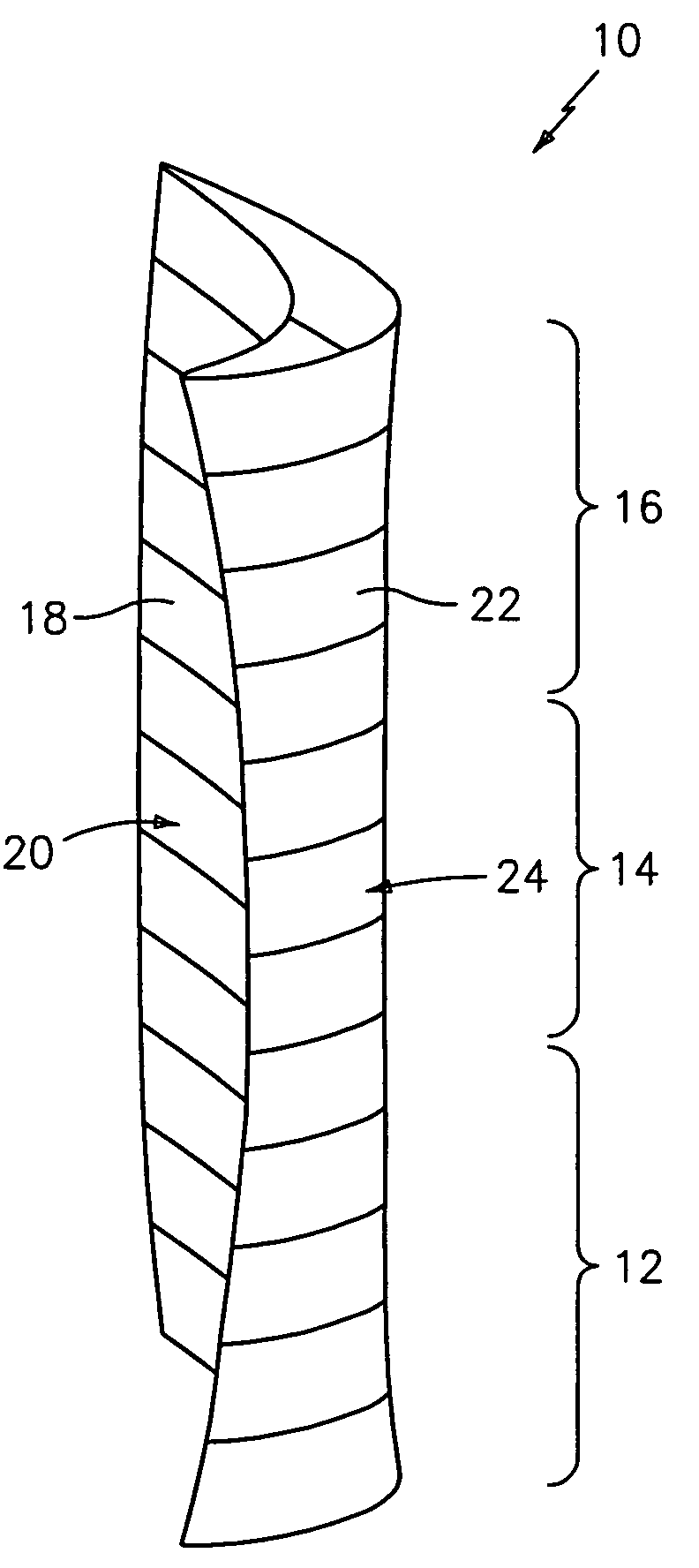

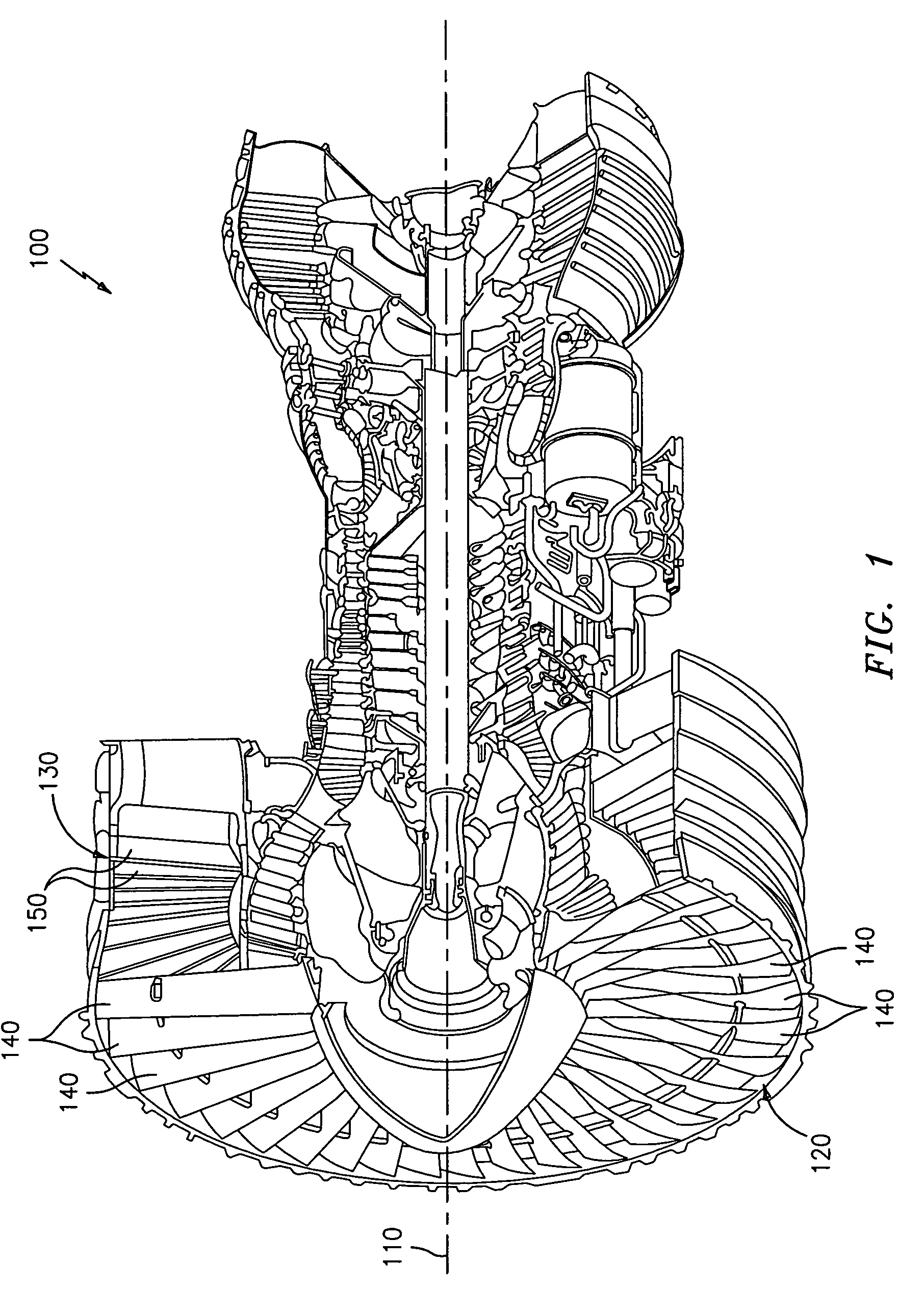

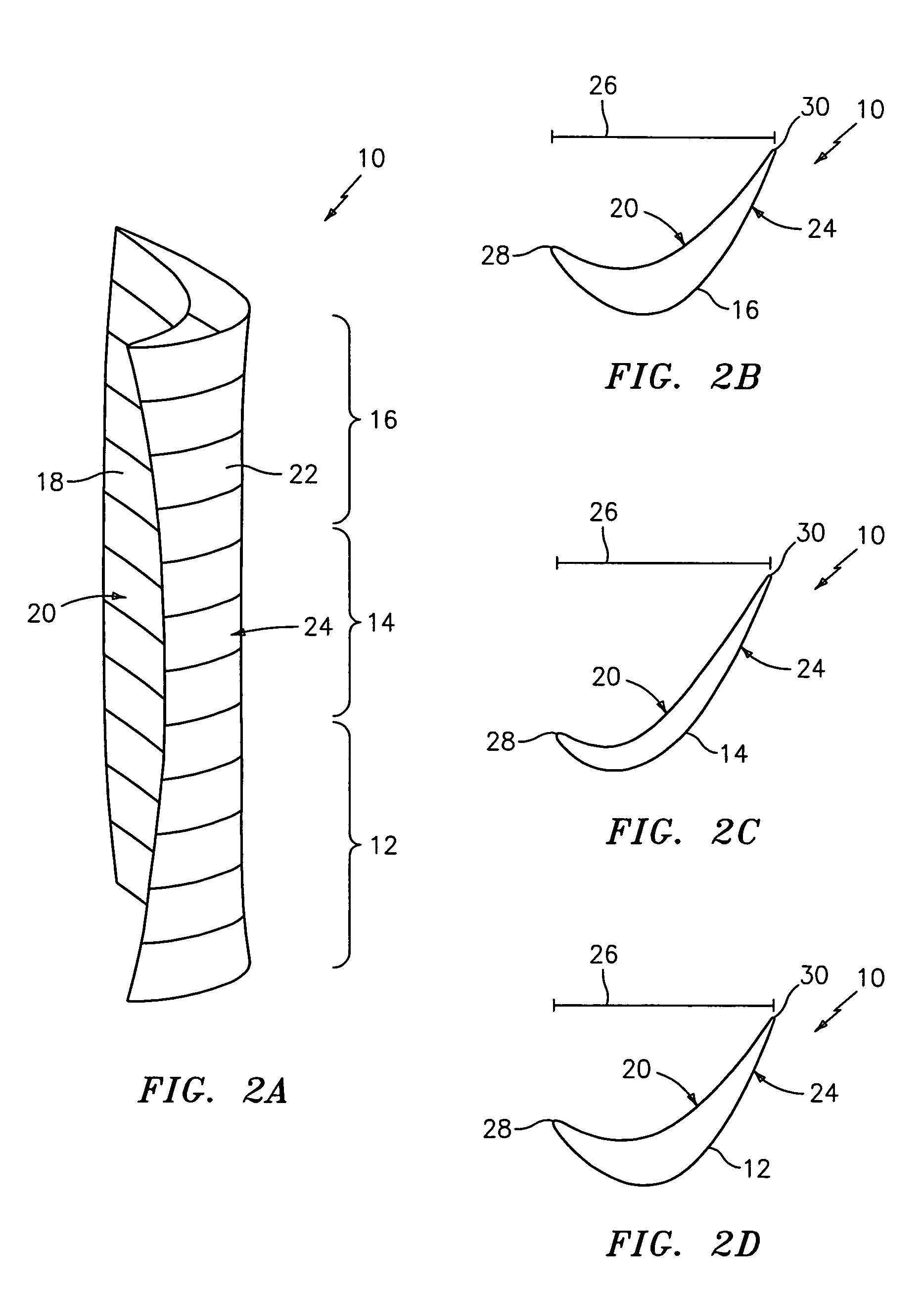

Airfoil embodying mixed loading conventions

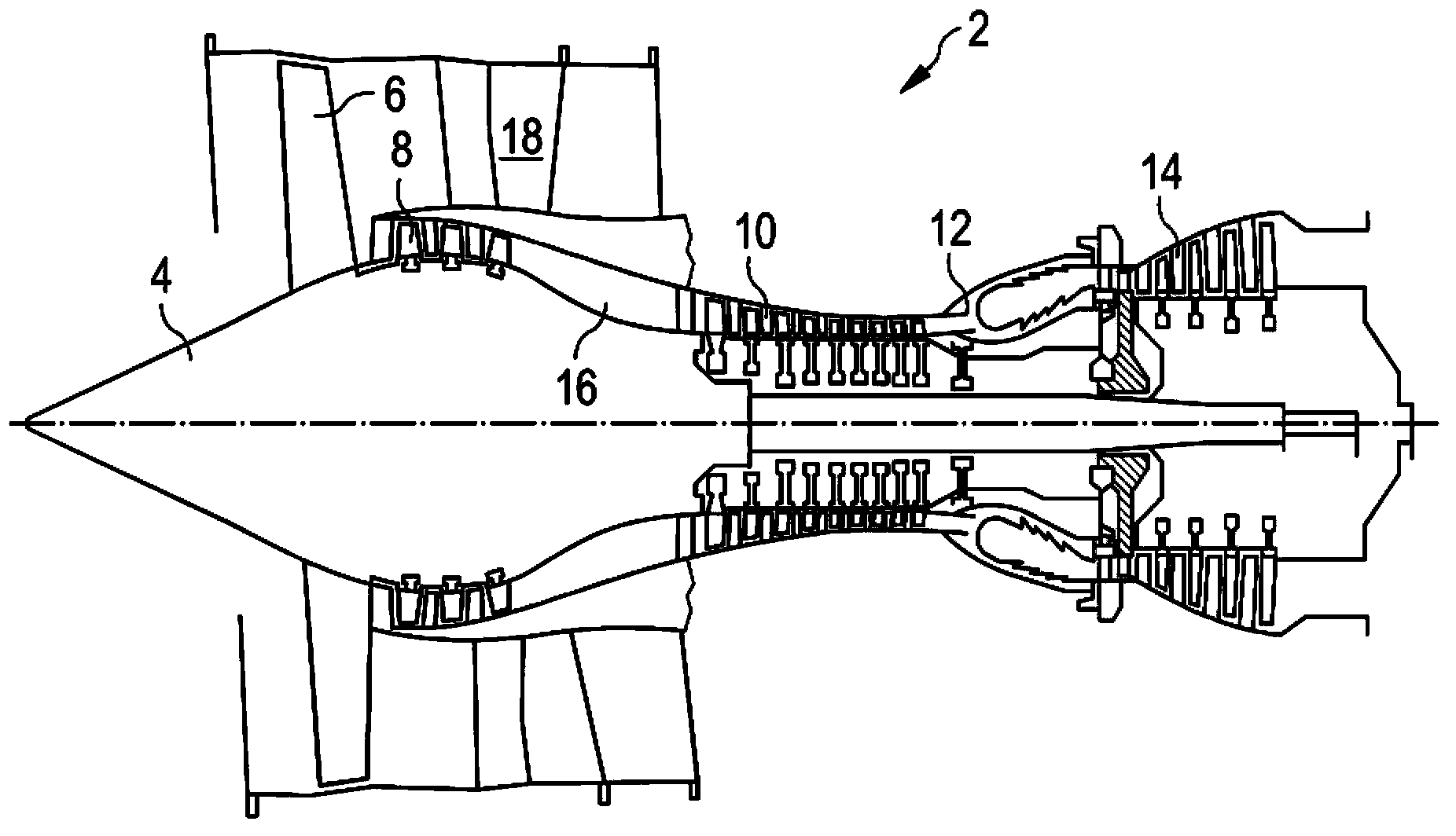

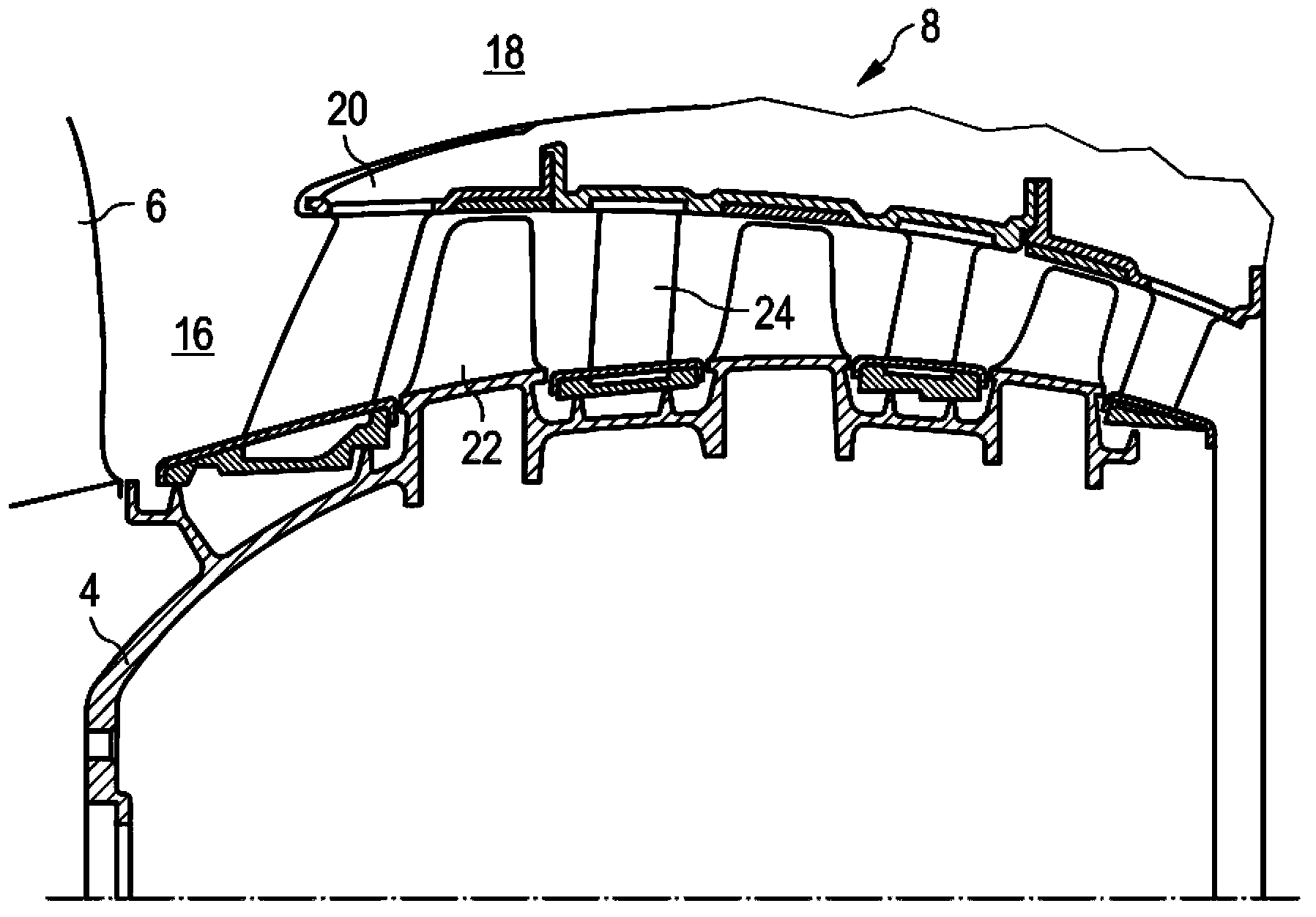

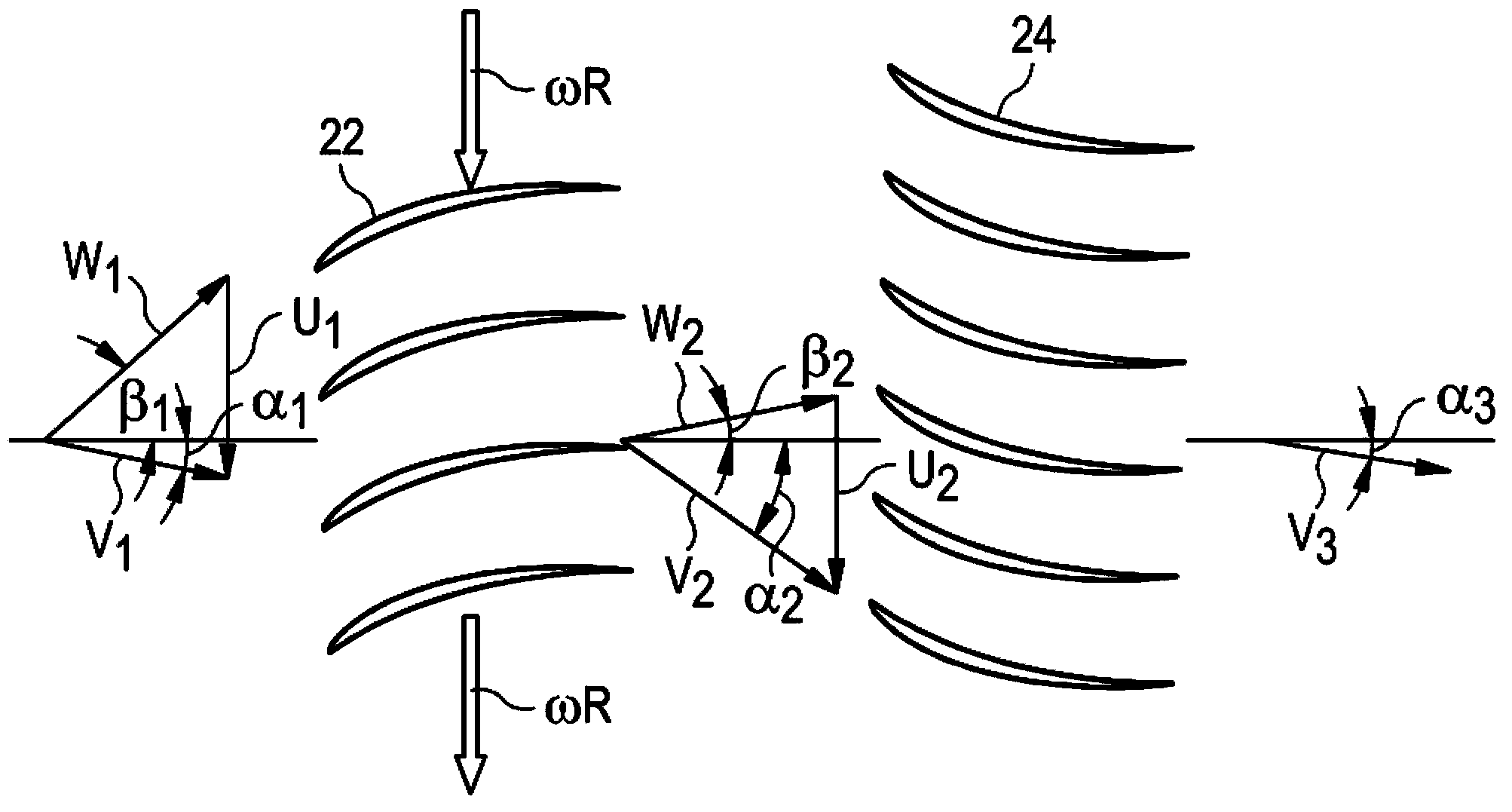

A high-lift airfoil embodying a combination of loading conventions in a single design specifically to reduce and control total pressure losses that occur in the flow channels between airfoils employed in turbomachinery applications is disclosed herein. The mixed-loading high-lift airfoil designs embody and exhibit the best total profile and secondary loss characteristics possessed by both aft-loaded airfoil and front-loaded airfoil conventions through controlling the development and interaction of boundary layers forming along the surfaces of the airfoils and the endwalls in such applications. The mixed-loading high-lift airfoil may be utilized in both rotating and non-rotating turbomachinery applications.

Owner:RAYTHEON TECH CORP

Extinguishing agent

InactiveCN102058951AReduce pollutionRestricted free movementFire extinguisherSesquioxideAluminium hydroxide

The invention discloses an extinguishing agent. The extinguishing agent is formed by mixing and stirring strong hydrophobic solid particles and aqueous solution at high speed, wherein the strong hydrophobic solid particles are one type or more of magnesium hydroxide particles, silicon dioxide particles, calcium carbonate particles, talcum particles, aluminium oxide particles, aluminium hydroxide particles, zinc borate particles, zinc oxide particles, iron sesquioxide particles, titanium dioxide particles, montmorillonite particles, hydrotalcite particles, coal ash particles, diatomite particles, mica particle, attapulgite particles and zeolite particles after hydrophobic modification. The extinguishing agent disclosed by the invention is nontoxic, environmental pollution is less, and secondary loss caused by strong flowability of water can be avoided while playing the advantages of the water as the extinguishing agent and reducing the using amount.

Owner:XIAN UNIV OF SCI & TECH

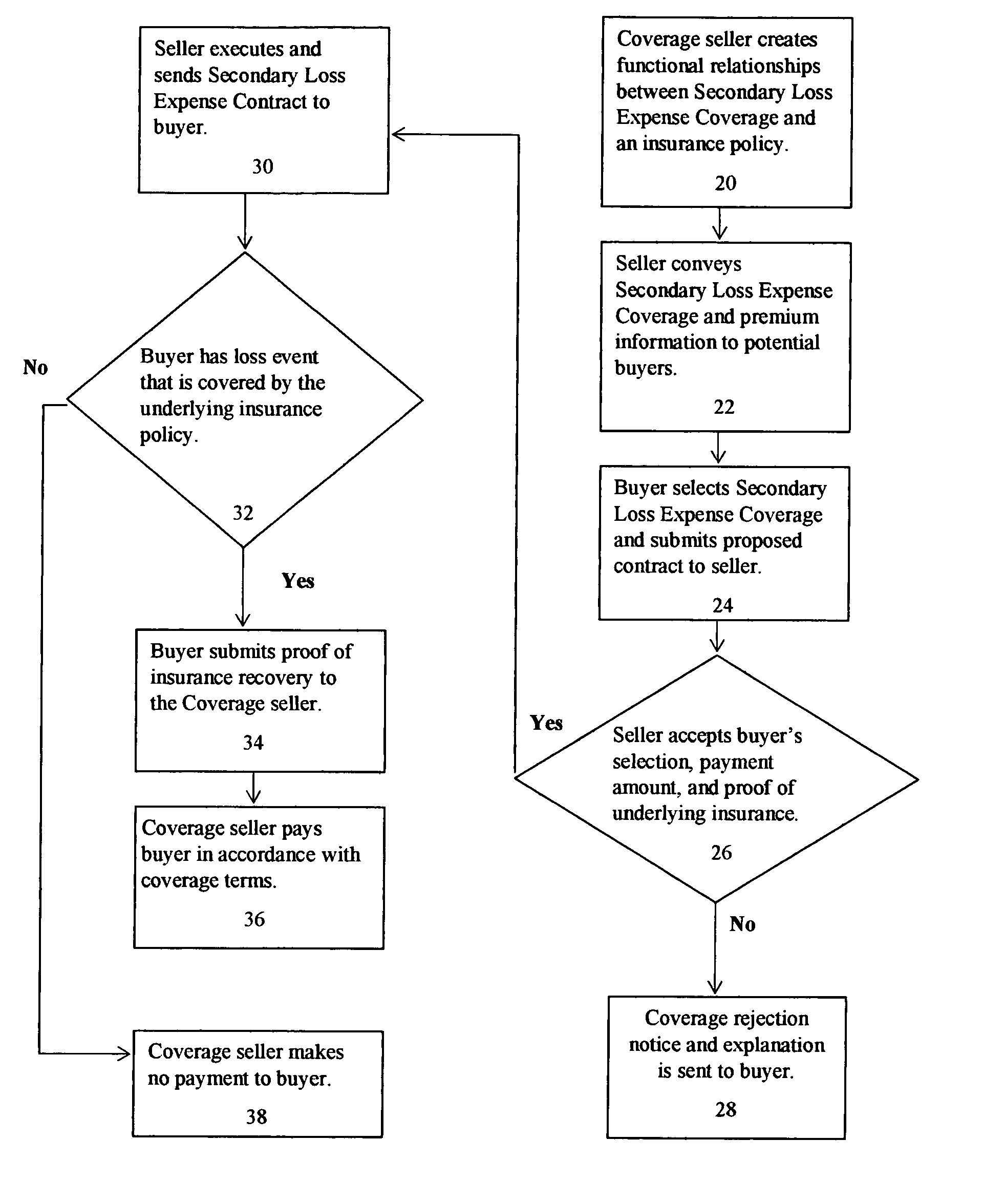

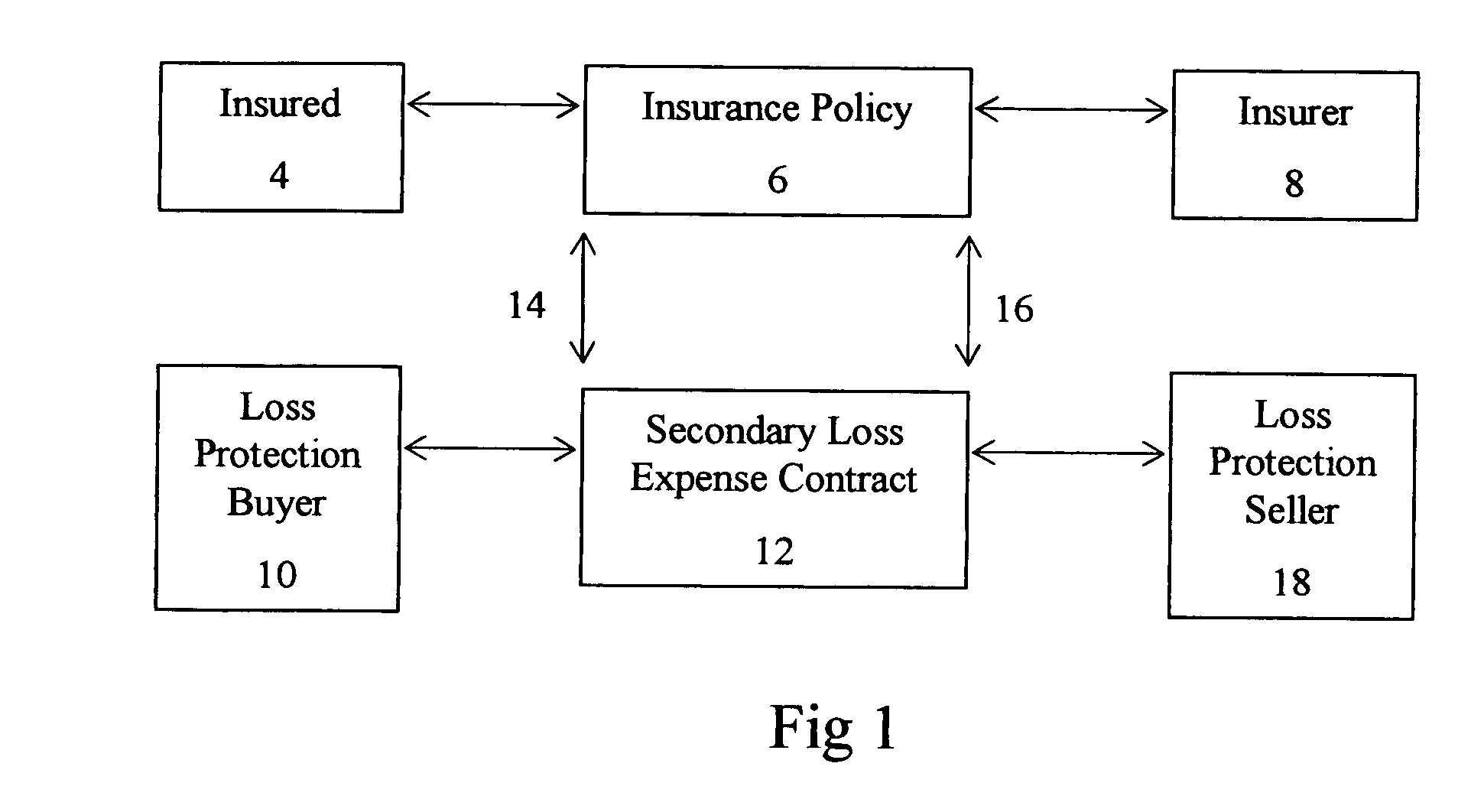

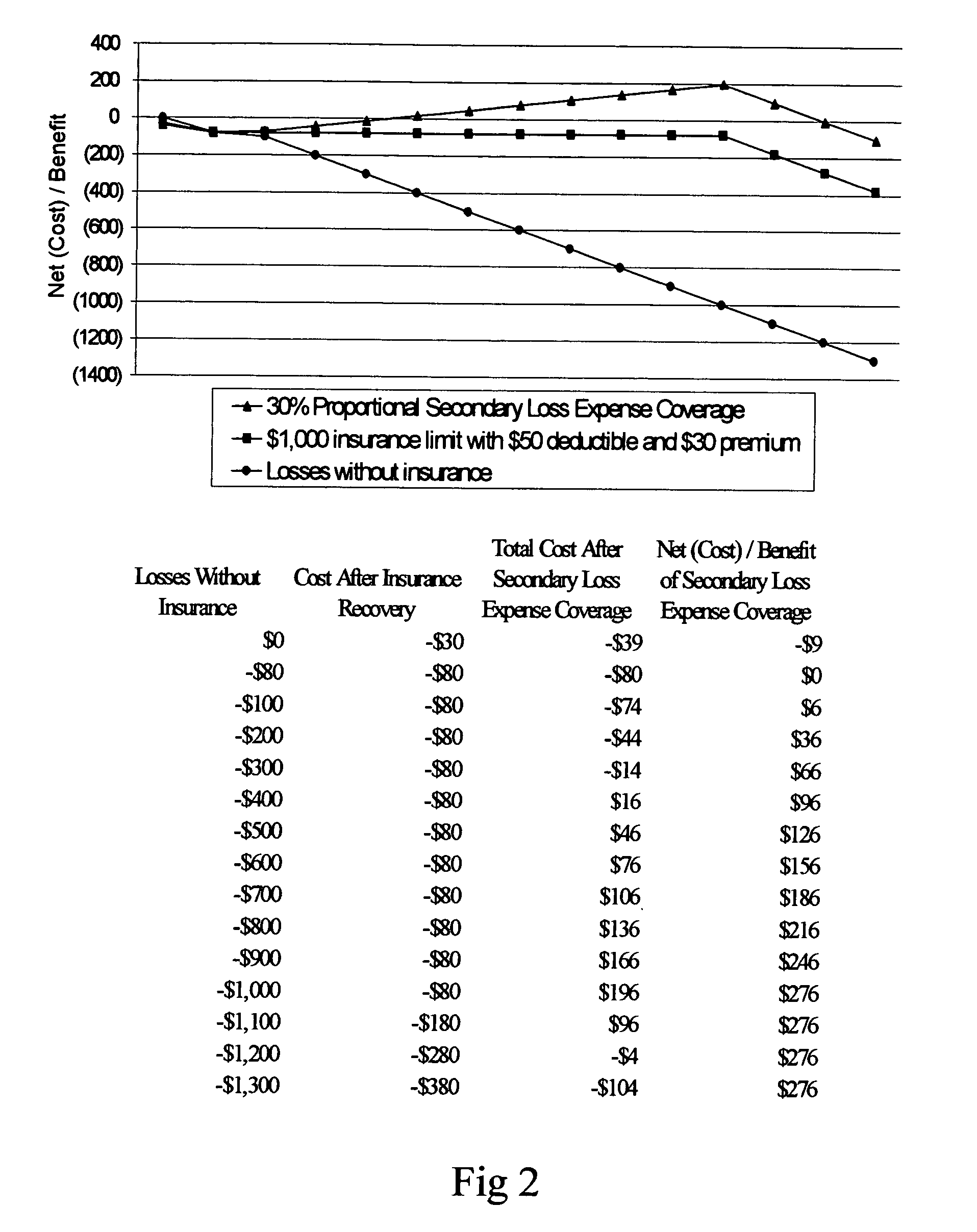

Secondary loss expense coverage

Owner:THOMAS BRUCE BRADFORD +1

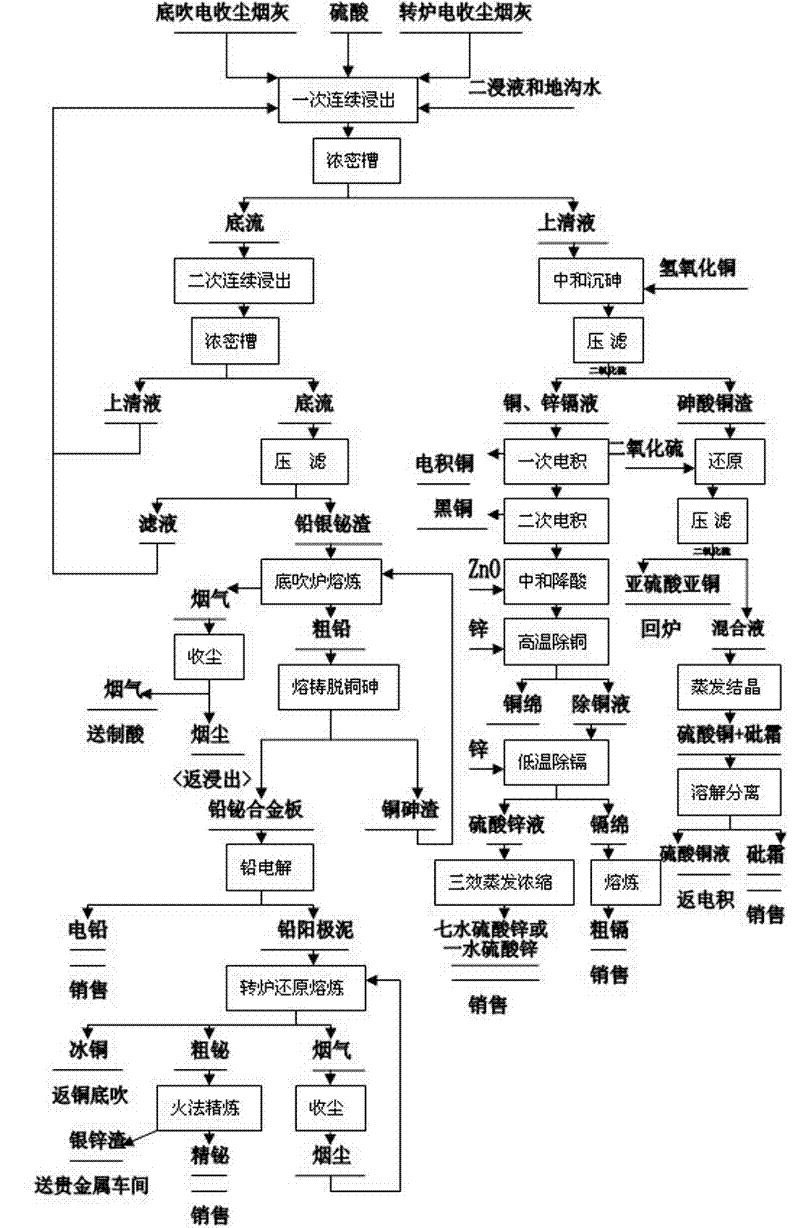

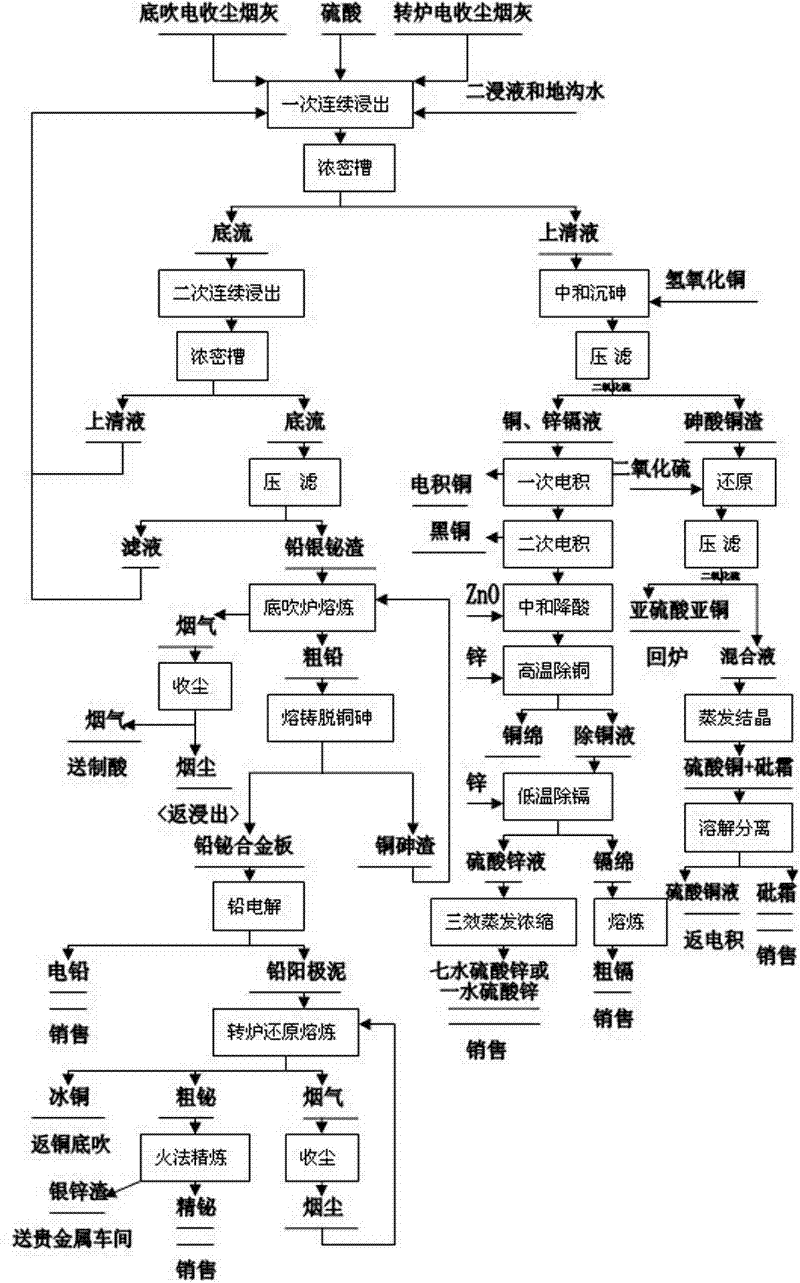

Comprehensive recycling technique of valuable elements in smelting soot

InactiveCN102517449AAdaptableHigh recovery rateProcess efficiency improvementElectrolysisSecondary loss

The invention provides a comprehensive recycling technique of valuable elements in smelting soot, which comprises the steps of: adding sulfuric acid in the smelting soot to pulpify the same, leaching for twice, and filter pressing the smelting soot to form lead-silver-bismuth slag; smelting, casting, electrolyzing, refining and reducing and smelting the lead-silver-bismuth slag in a converter to obtain rough lead, copper matte, pure bismuth and silver-zinc slag; adding cupric hydroxide in the supernatant to deposit arsenic, depositing the copper in the copper arsenate slag with deposited arsenic to form copper-arsenic solution, concentrating, crystallizing, dissolving and separating the solution to obtain white arsenic and cupric sulfate solution; performing twice electrodeposition treatments on the copper-zinc-cadmium solution with deposited arsenic to respectively obtain electrolytic copper and black copper, sequentially adding zinc oxide and zinc powder to perform deacidification, high-temperature copper removal and low-temperature cadmium removal treatments to obtain sponge cadmium, smelting the sponge cadmium to obtain rough cadmium, concentrating and crystallizing the zinc sulfate solution to obtain heptahydrate zinc sulfate. The comprehensive recycling technique provided by the invention has the advantages of improving the recovery of multiple metals, having extensive treatment raw materials, low production cost and high economic benefit, and avoiding the secondary pollution of decentralized processing and secondary loss of valuable metals.

Owner:SHANDONG FANGYUAN NON FERROUS METAL TECH SERVICE

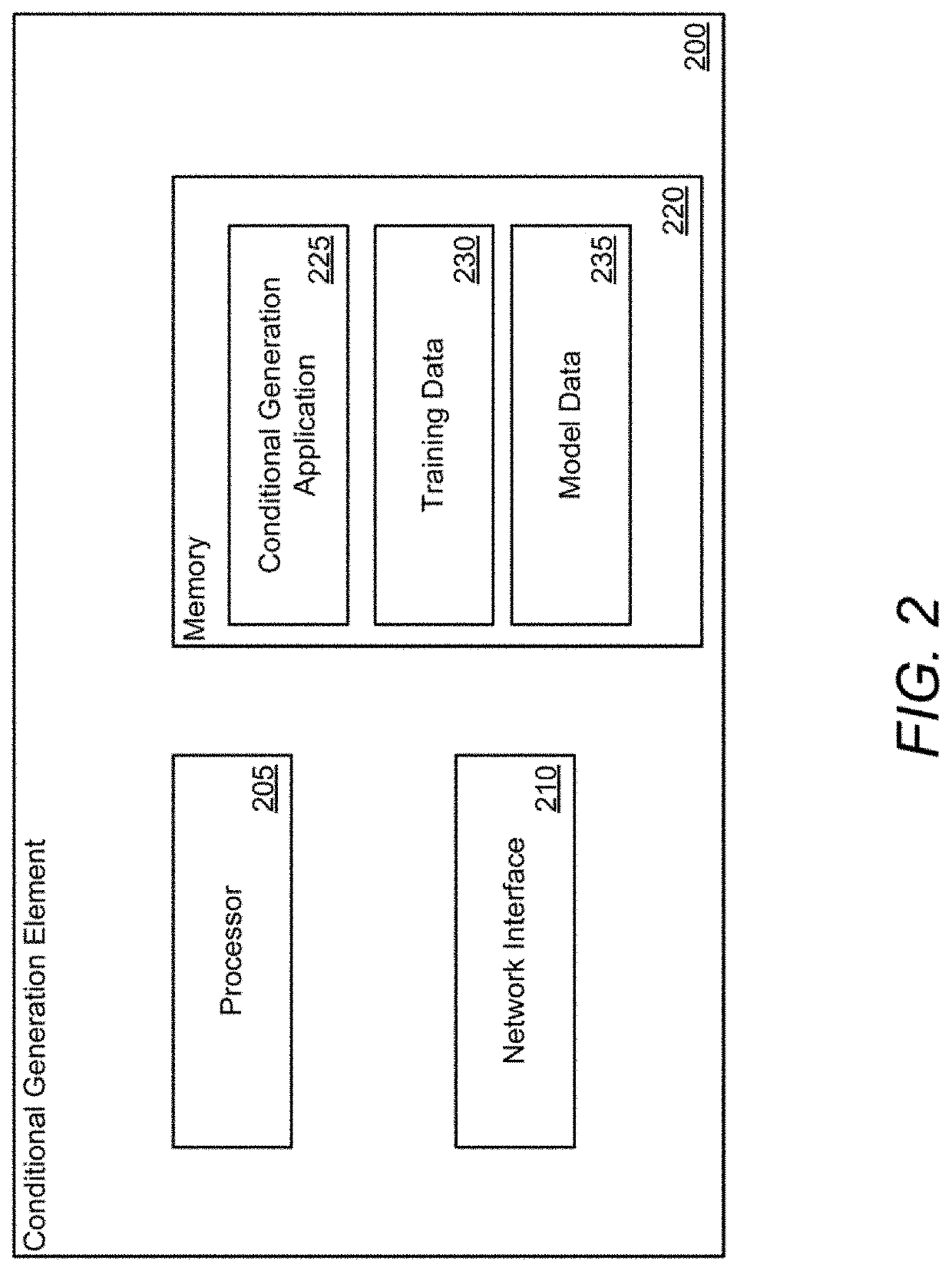

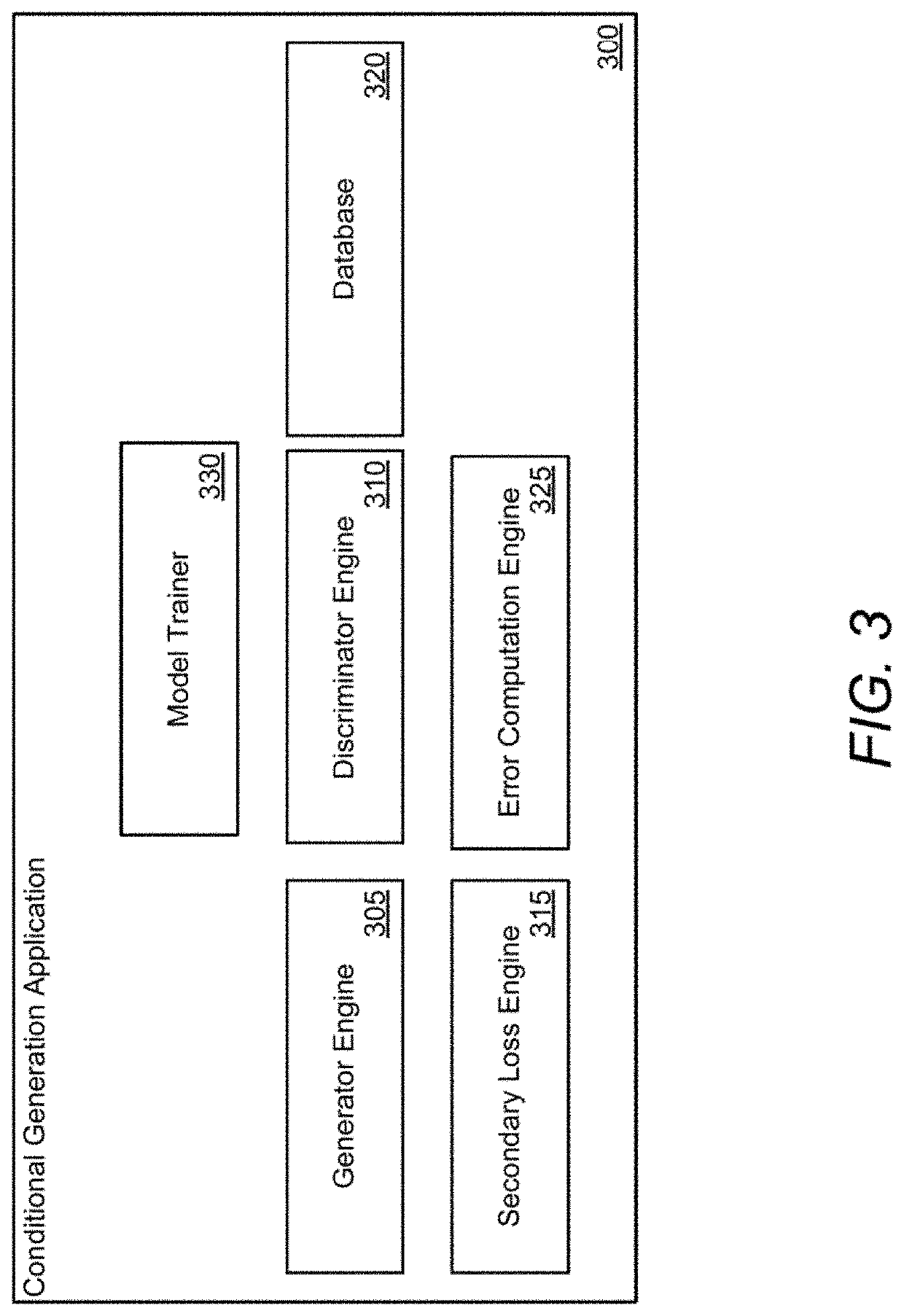

Systems and Methods for Conditional Generative Models

Systems and methods for training a conditional generator model are described. Methods receive a sample, and determine a discriminator loss for the received sample. The discriminator loss is based on an ability to determine whether the sample is generated by the conditional generator model or is a ground truth sample. The method determines a secondary loss for the generated sample and updates the conditional generator model based on an aggregate of the discriminator loss and the secondary loss.

Owner:FOTONATION LTD

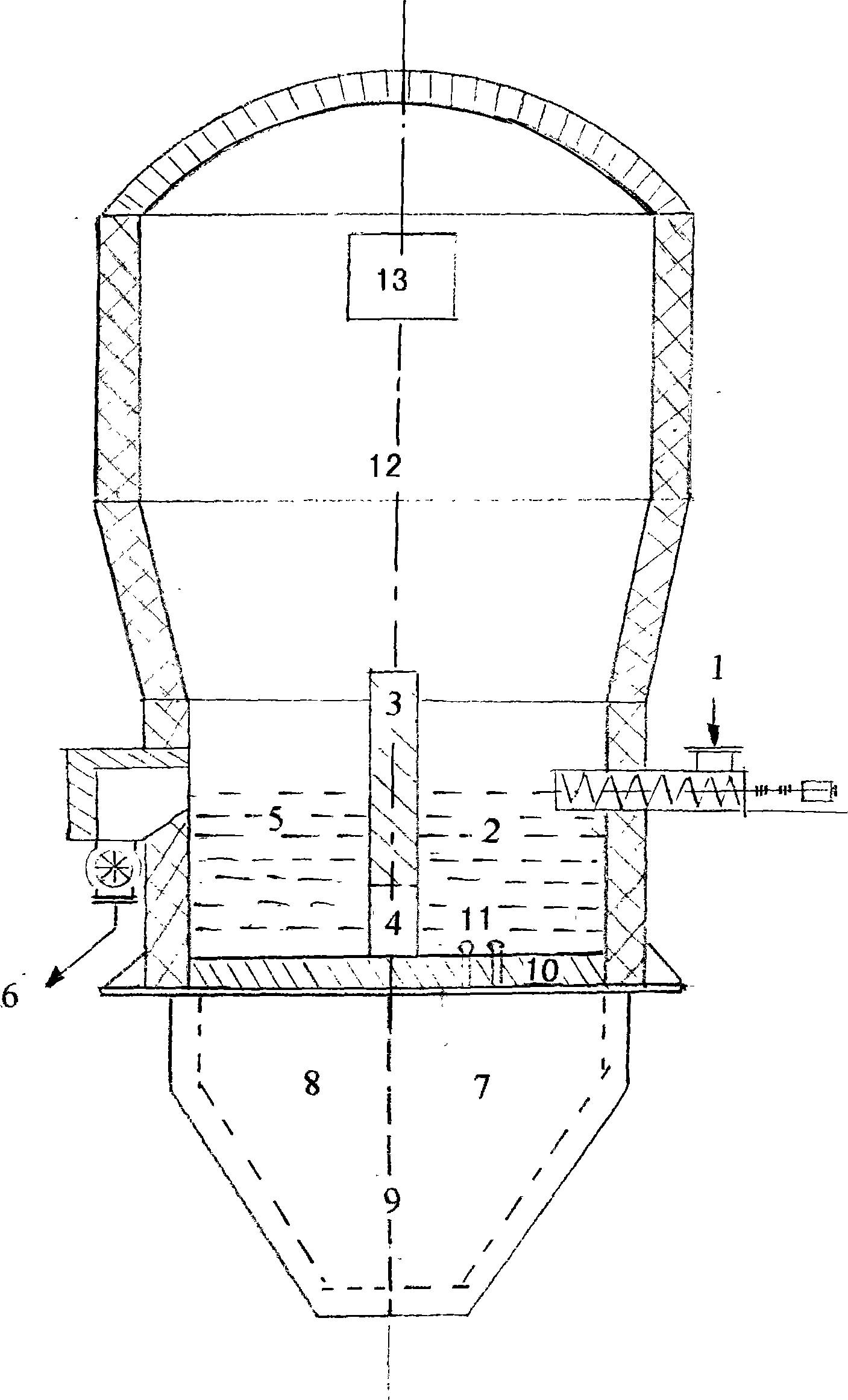

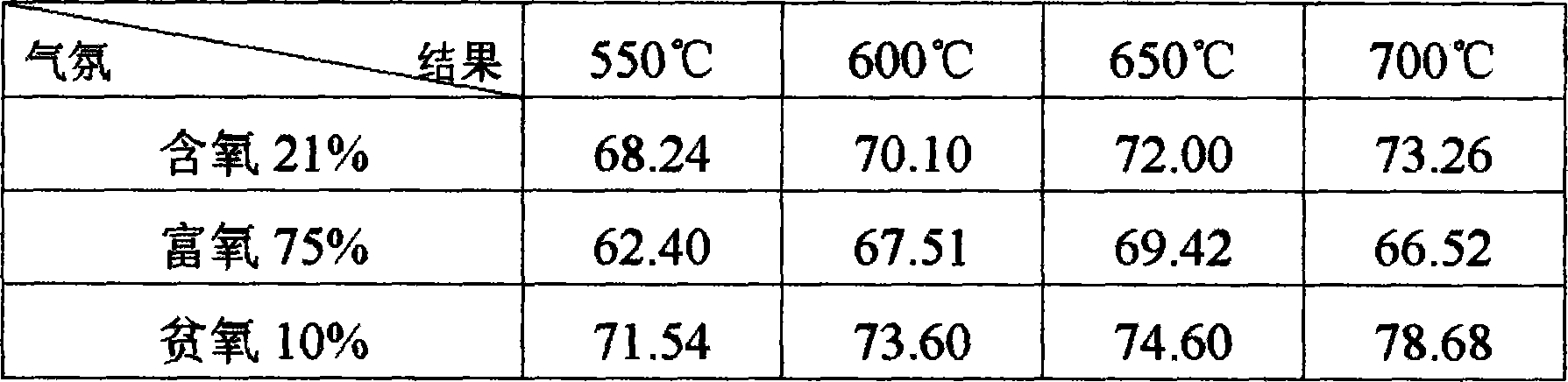

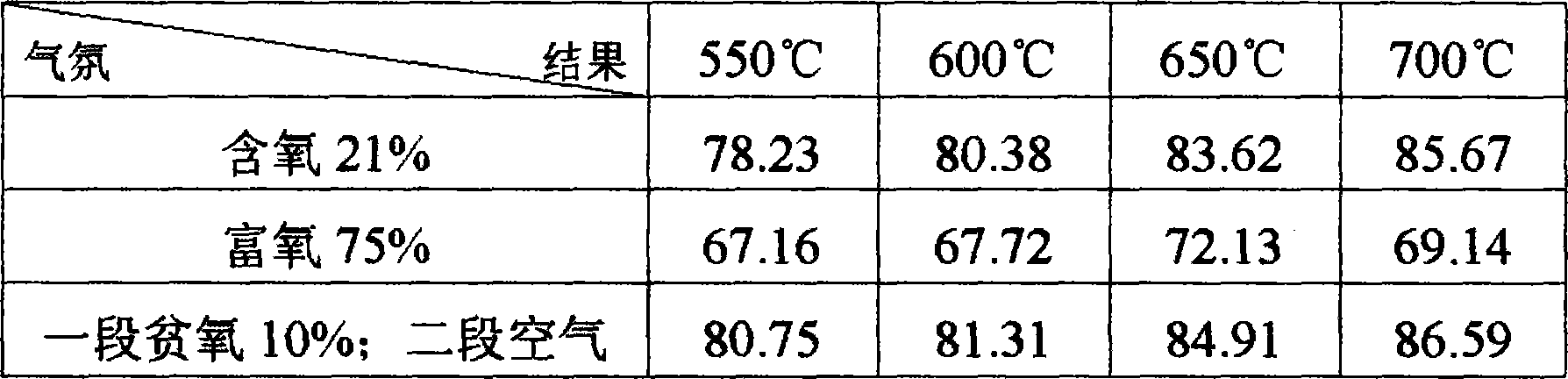

One-furnace-two-section boiling baking process

InactiveCN101082078AEfficient decompositionFully curedProcess efficiency improvementCarbideSecondary loss

The present invention is two-section fluidizing and roasting process for intractable gold bearing ore. The two-section fluidizing and roasting process includes the following steps: preparing material, roasting of the material one sealed spiral feeder provides to the roasting furnace in the first section, and roasting of the material passing through the passage in the bottom of the partition wall in the second section. During roasting in the second section, the air supply amount is controlled properly so that the sulfide and carbide in the ore may be oxidized completely. The present invention has the advantages of capacity of avoiding the secondary loss of dissolved gold, raised gold leaching rate, raised comprehensive recovery rate, environment friendship, etc.

Owner:CHINA NAT GOLD GROUP CORP TECH CENT

Airfoil embodying mixed loading conventions

A high-lift airfoil embodying a combination of loading conventions in a single design specifically to reduce and control total pressure losses that occur in the flow channels between airfoils employed in turbomachinery applications is disclosed herein. The mixed-loading high-lift airfoil designs embody and exhibit the best total profile and secondary loss characteristics possessed by both aft-loaded airfoil and front-loaded airfoil conventions through controlling the development and interaction of boundary layers forming along the surfaces of the airfoils and the endwalls in such applications. The mixed-loading high-lift airfoil may be utilized in both rotating and non-rotating turbomachinery applications.

Owner:RTX CORP

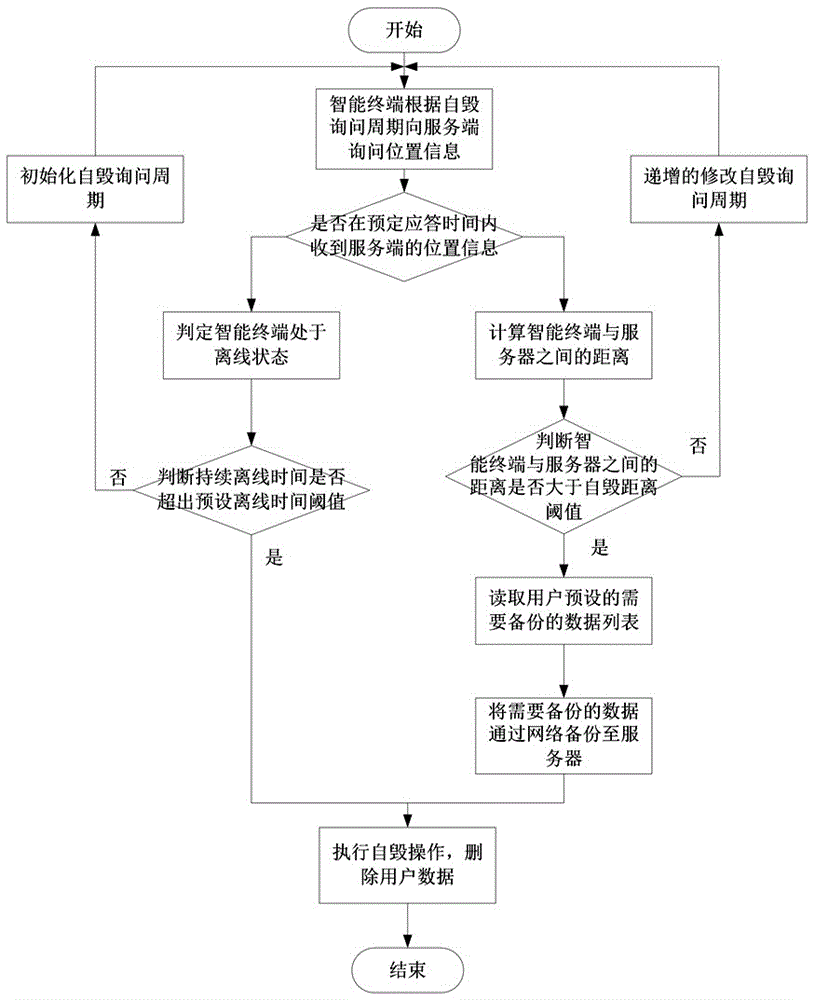

Self-destruction method of intelligent terminal

The invention discloses a self-destruction method of an intelligent terminal. According to the method, the intelligent terminal calculates a distance from the intelligent terminal itself to a server end according to a progressive increase variable self-destruct inquiry period and judges whether the intelligent terminal needs to perform self-destruction; and when the intelligent terminal needs to perform self-destruction, the intelligent terminal reads a data list which is preset by a user and requires backup, and packs user data according to the data list, and sends the packed data to the server end through a network, so that the server end can back up the data, and then, the intelligent terminal executes self-destruction operation. With the method of the invention adopted, the security of the user data can be protected; the risk of the leakage of the privacy data of a user can be eliminated; important data of the user will not be lost because of the self-destruction of the intelligent terminal; secondary loss brought to the user due to data loss can be alleviated; and the progressive increase variable self-destruct inquiry period is adopted, and therefore, the energy consumption of the intelligent terminal can be decreased, and the standby time of the device can be prolonged.

Owner:CENT SOUTH UNIV

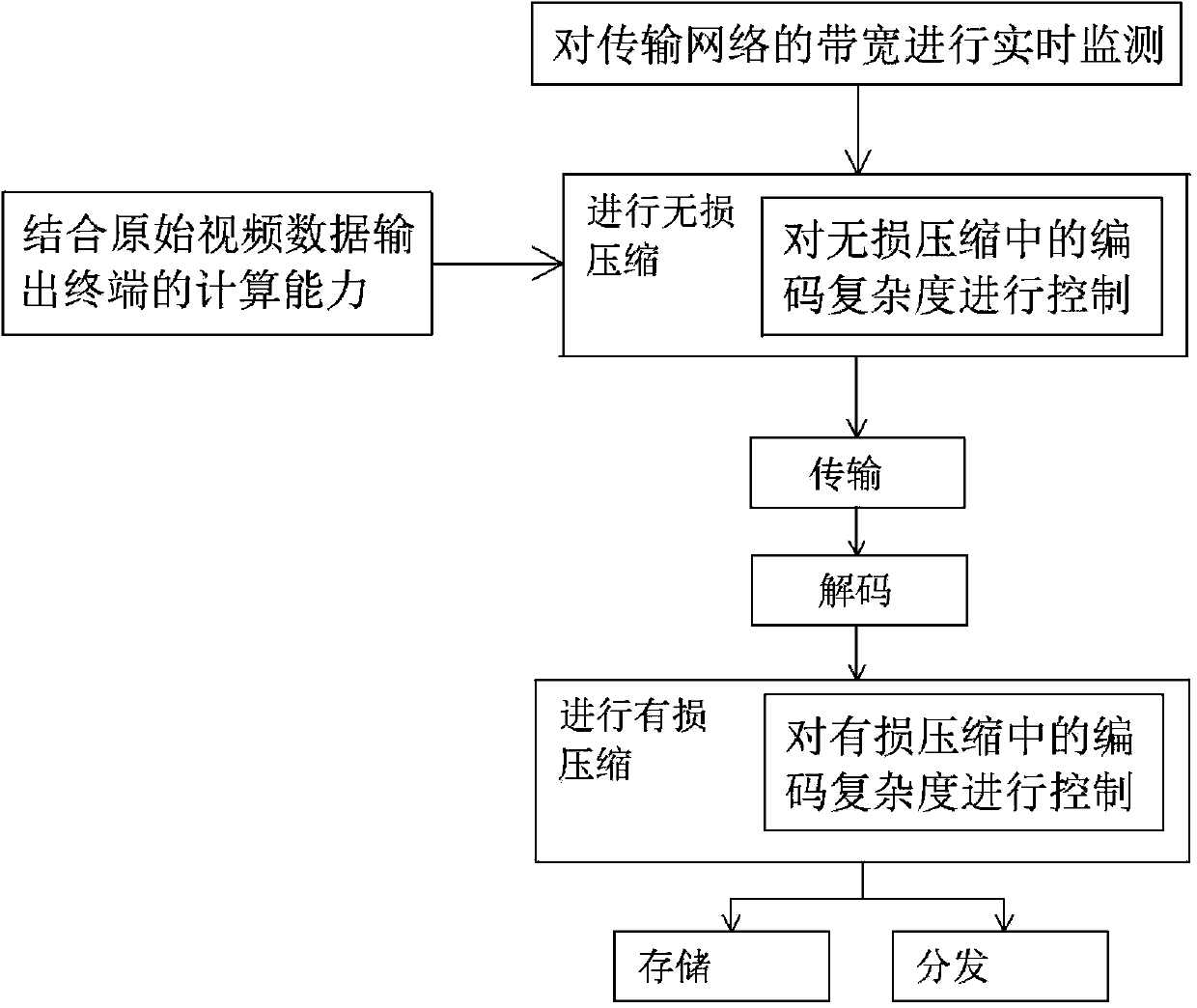

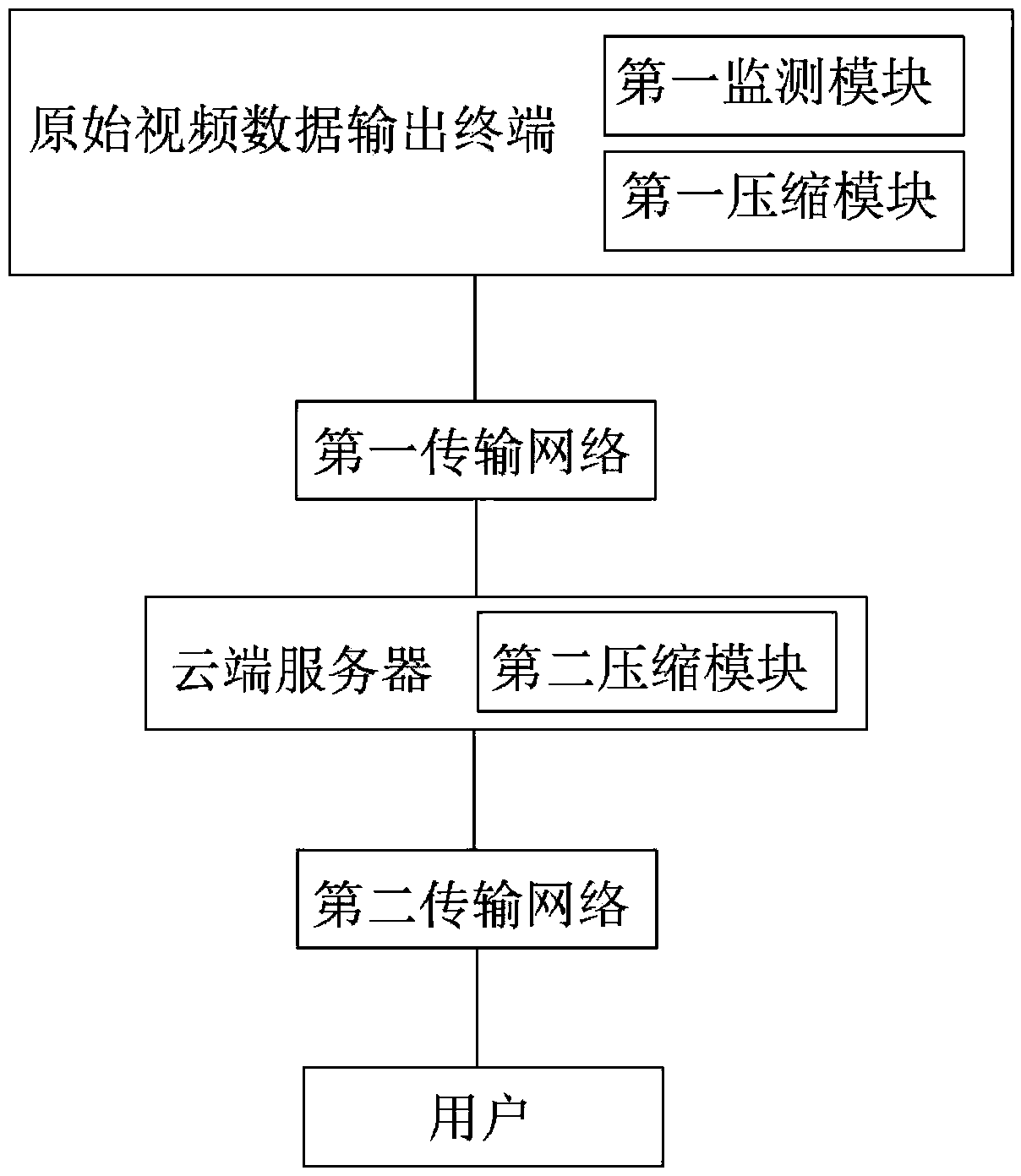

Coding transmission method for medium cloud video data

InactiveCN103428529ASolve slow transmissionSolve efficiency problemsTelevision systemsSelective content distributionComputer hardwareSecondary loss

The invention discloses a coding transmission method for medium cloud video data. The coding transmission method for the medium cloud video data comprises the following steps that real-time monitoring is conducted on the bandwidth of a transmission network on an original video data output terminal, lossless compression is conducted on the original video data according to a monitoring result combined with the computing power of the original video data output terminal, the coding complexity of lossless compression is controlled, lossless compression video data are obtained, and the lossless compression video data are uploaded to a cloud server through the network; the cloud server decodes the lossless compression video data, so that an original video signal is restored, secondary loss compression is conducted, and the coding complexity of the loss compression is controlled; finally, the cloud server stores loss compression video data or distributes the loss compression video data to request users. The coding transmission method for the medium cloud video data equivalently utilizes the computing power of a user side, limited transmission network bandwidth resources and the cloud server to the maximum extent so that the problems that transmission from the user side to a cloud side is slow and the calculation amount is large can be solved.

Owner:武汉眸博科技有限公司

S-shaped profile blade of axial turbomachine compressor, corresponding compressor and turbomachine

InactiveCN103452904AImprove efficiencyReduced eddy current lossEngine manufacturePump componentsLeading edgeEngineering

The invention relates to a subsonic rotor and / or stator blade profile of an axial turbomachine compressor, such as a turbojet. The blade has a leading edge with an S-shaped lateral profile in its mid-plane. Specifically, the profile includes, from its inner end to the outer end, a first convex portion including the foremost part of the blade, and a second concave portion including the rearmost area of the blade. This profile enables the fluid flow between 20% and 80% of the blade's length to be redistributed. This so-called 'sweep' profile increases the performance of the stage with such blades because it reduces blade tip vortex losses as well as secondary losses.

Owner:SAFRAN AERO BOOSTERS SA

Method for manufacturing reclaimed soil with iron tailings

InactiveCN106718269AAlleviate oppressionFull of nutritionGrowth substratesCulture mediaLand resourcesSludge

The invention discloses a method for manufacturing reclaimed soil with iron tailings; the method comprises: collecting iron tailings, quaternary-system secondary losses and organic material respectively, and getting ready for use; mixing well the iron tailings, the quaternary-system secondary losses and the organic materials according to a mass ratio of (45-55):(40-50):5 to obtain reclaimed soil; the organic material is decomposed waste of livestock and poultry industry or composed sludge discharged by urban domestic sewage plants. According to the method for manufacturing reclaimed soil with iron tailings, the iron tails, sludge and livestock and poultry industry waste are used as materials to manufacture reclaimed soil, a mine can be greened, and the wastes such as iron tailings and sludge are utilized comprehensively, the usage of land resources is reduced, and the environment is protected.

Owner:SHENYANG AGRI UNIV +1

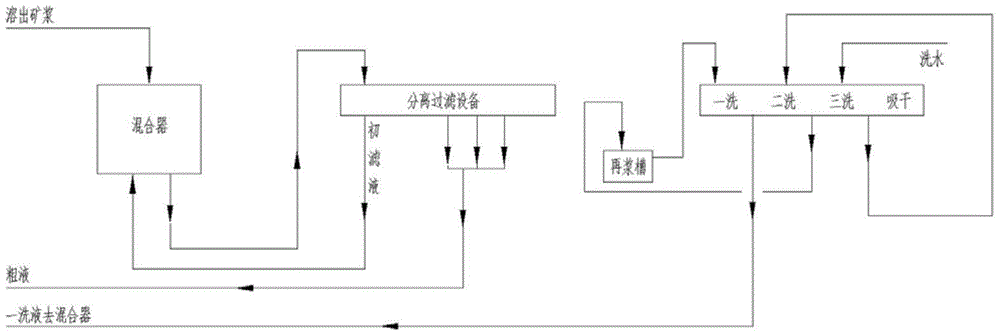

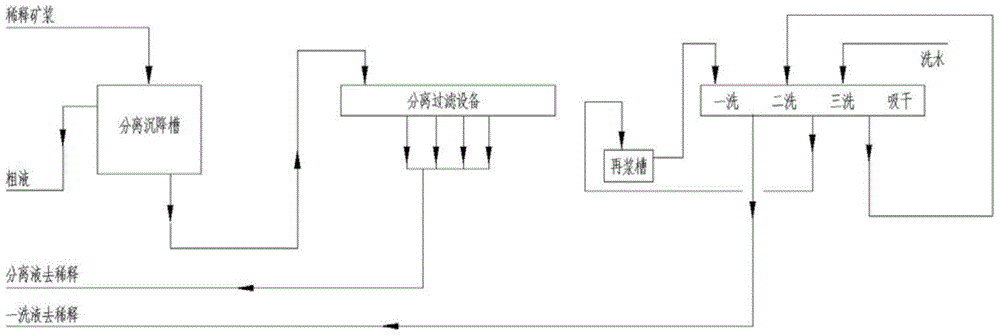

Process for rapidly separating sodium aluminate solution and washing red mud in aluminum oxide production

InactiveCN104876251AReduce secondary lossesReduce the rate of dissolution lossAlkali-metal aluminates/aluminium-oxide/aluminium-hydroxide preparationRed mudWastewater

The invention relates to a process for rapidly separating sodium aluminate solution and washing red mud in an aluminum oxide production. According to the process, stable operation of rapid separation of a large-scale industrialized sodium aluminate solution and red mud washing is realized through the steps of mixing dilution, rapid separation, repulping, rapid washing, circulating water balance and the like; a flocculating agent does not need to be added or the addition amount can be reduced; the consumption of the flocculating agent and the investment in a settling tank are avoided or reduced; secondary loss of the aluminum oxide caused by overlong separation and settlement time is avoided; the dissolution rate and the total recovery rate of the aluminum oxide are improved, so that bauxite resources are saved and the production cost is reduced; meanwhile, due to the circulating water balance, a lot of washing water is available for a filtering medium (filter cloth), so as to ensure the filtering property when large filtering and washing equipment continuously runs; through reduction of wastewater in the red mud, and rapid separation and washing, the washing water is greatly reduced; the target of high recovery rate is finished; and the production cost of the aluminum oxide is reduced.

Owner:刘永刚 +2

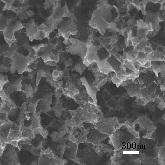

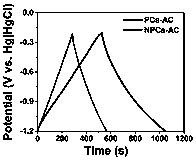

Method for preparing high-efficacy super capacitor material by heavy metal related biomass

InactiveCN109950057AImprove solubilityGood capacitance characteristicsCarbon compoundsHybrid capacitor electrodesPorous carbonSupercapacitor

The invention discloses a method for preparing a high-efficacy super capacitor material by a heavy metal related biomass, and aims at searching for a proper resource for heavy metal related plant bodies at present. Plant bodies rich in heavy metal in a general mine are sampled (in a five-point sampling method), the collected plant bodies (including the roots, stems and leaves) are preprocessed bycleaning, drying crushing and drying, and a preparation method for obtaining the high-efficiency porous carbon material by dissolving, activating, and pyrolyzing the dried plant leaf powder is provided. The heavy metal transferred by plants can be fixed, and the material can serve as an electrode material of a super capacitor to store energy. The difficulty in secondary loss of the transferred heavy metal is overcome, the new capacitor material is provided for energy storage, solid waste biomass resources are utilized, and the problem in heavy metal related plant resources is solved effectively.

Owner:SUN YAT SEN UNIV

Heavy metal aggregating fixative for soil remediation and preparation method thereof

ActiveCN107384419AGood effectAvoid distractionAgriculture tools and machinesOrganic fertilisersPhosphateSecondary loss

The invention provides a heavy metal aggregating fixative for soil remediation and a preparation method thereof. The heavy metal aggregating fixative for the soil remediation is obtained by grinding and refining raw materials rich in plant protein, and expanding after drying, and preparing with phosphate and calcium dioxide and granulating according to a certain proportion. The heavy metal aggregating fixative for the soil remediation has the obvious characteristics that after phosphate and calcium hydroxide collect heavy metal ions, large-particle protein materials are used and protein functional groups are preferentially combined with the heavy metal ions after the large-particle protein materials are expanded, the heavy metal ions and a protein spatial structure react to form a large aggregate, eventually, a tubercular substance is formed, so that heavy metal is fixed in the protein materials in the form of large particles to permanently fix the heavy metal ions in soil, and the process is irreversible, namely the heavy metal ions which are fixed by the way are no longer likely to have secondary loss basically.

Owner:浙江中地净土科技有限公司

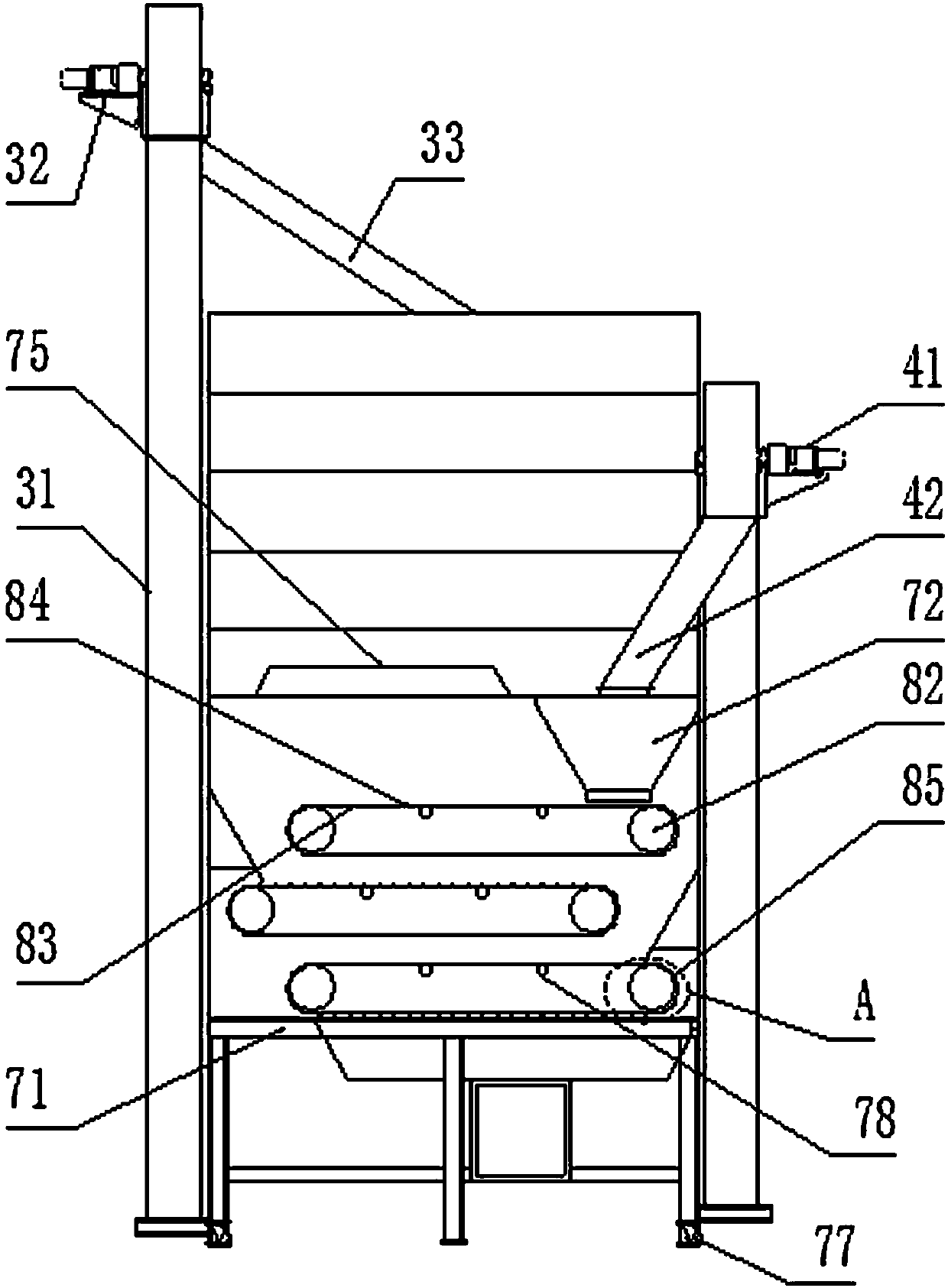

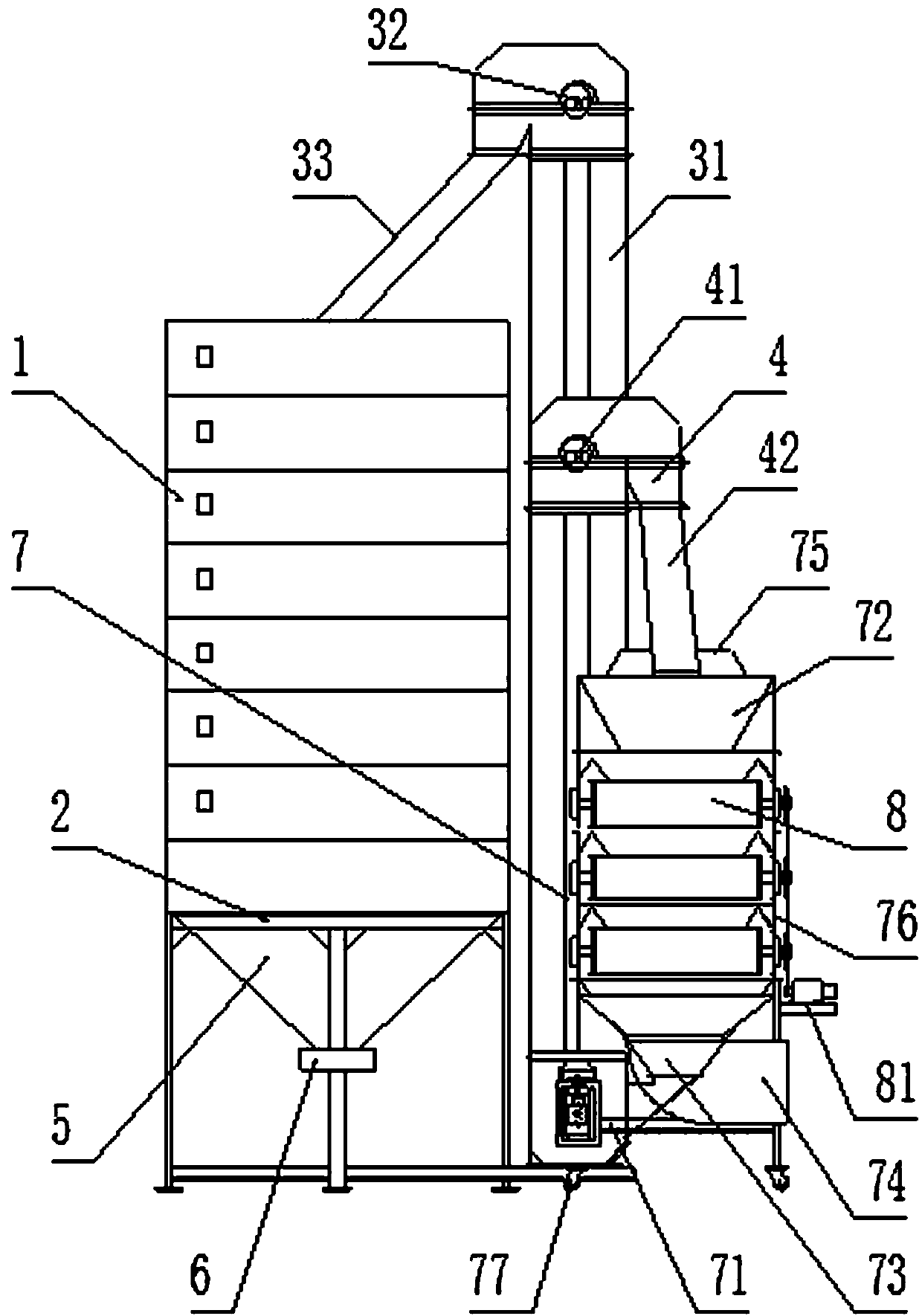

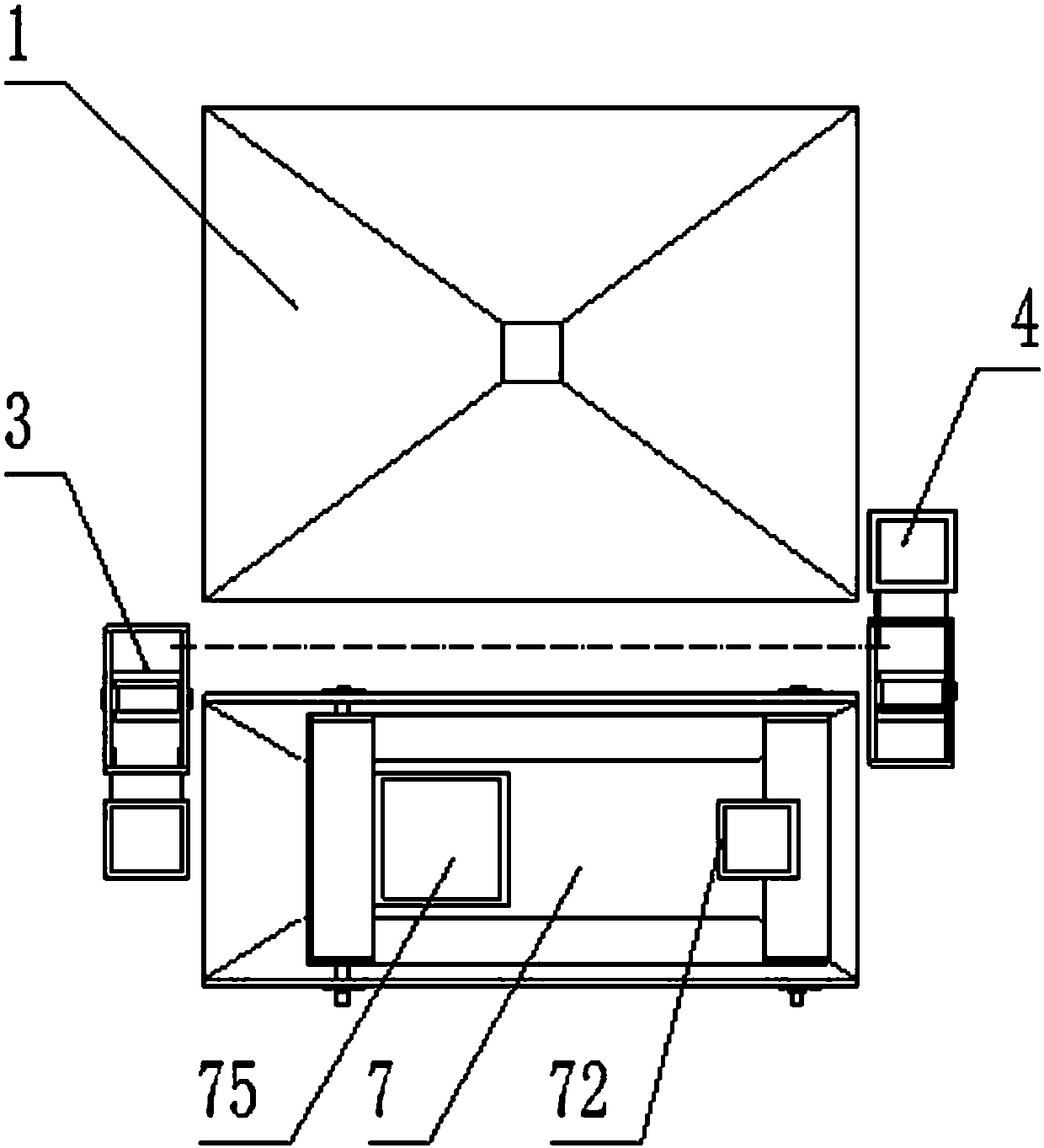

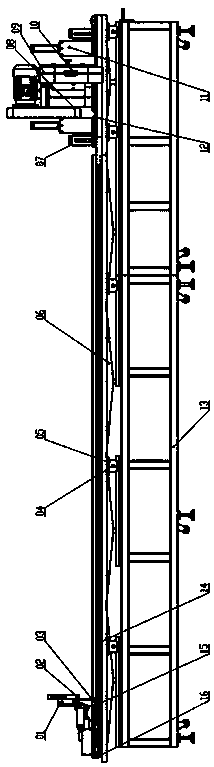

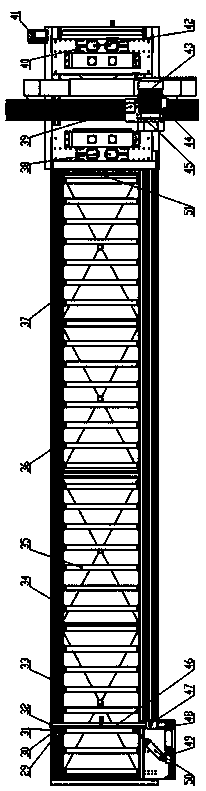

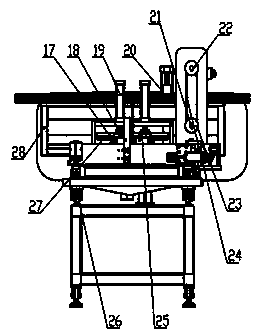

Separating speed adjustable type circulating grain drying machine

PendingCN107621157AQuality is not affectedLower the altitudeDrying gas arrangementsSeed preservation by dryingAgricultural engineeringSprocket

The invention discloses a separating speed adjustable type circulating grain drying machine which comprises a grain storing cabin, a feeding hoister, a feeding hopper hoister and a drying system, wherein the feeding hoister and the feeding hopper hoister are mounted on two sides of a grain storing cabin base; the drying system is mounted below the feeding hopper hoister and comprises a fixed rack,a feeding elephant trunk, a discharging elephant trunk, a hot-blast air inlet connecting pipe, an air outlet pipe, a fixed coaming and a drying device; the fixed coaming is mounted around the dryingdevice; the drying device comprises a driving motor, a driving sprocket, a pulling chain, a porous screen plate and a heat-resisting rubber flexible plate; and grain in the grain storing cabin is controlled by a discharging gate to enter the feeding hopper hoister, enters into the drying device to be dried on the drying system via a feeding pipe, is conveyed to the discharging elephant trunk to bedischarged, and enters the grain storing cabin via a grain feeding pipe through the feeding hoister. According to the technical scheme, the separating speed adjustable type circulating grain drying machine is simple in structure and safe and reliable; a grain storing layer, a drying layer and a transportation device are designed in a separating manner, so that secondary loss of grain is avoided;and the separating speed adjustable type circulating grain drying machine is convenient in mounting and overhaul and uniform in heating, improves the drying quality and reduces energy consumption andfailure rate.

Owner:安徽野田农业装备有限公司

Extinguishing agent

InactiveCN102058951BReduce pollutionRestricted free movementFire extinguisherSesquioxideAluminium hydroxide

Owner:XIAN UNIV OF SCI & TECH

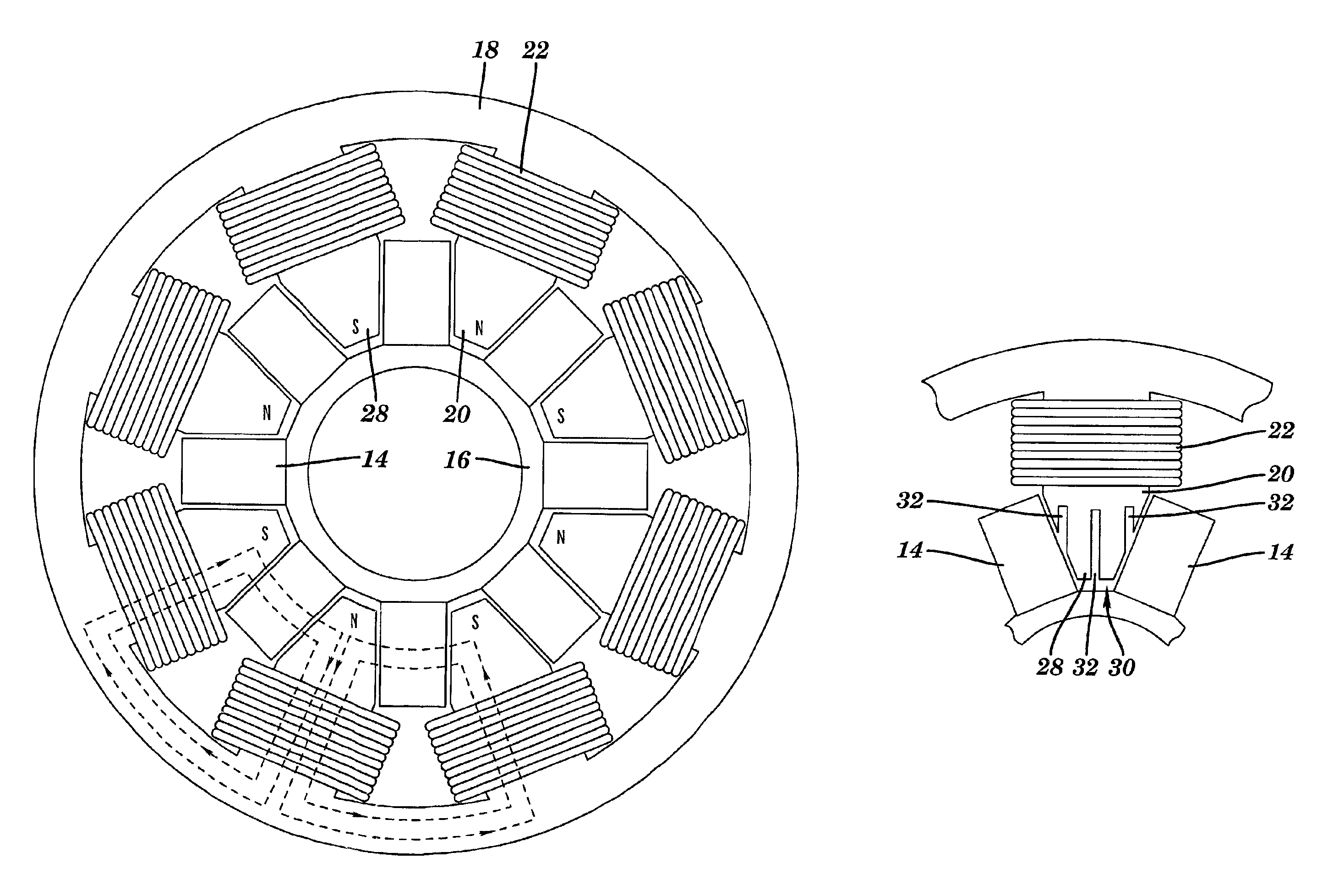

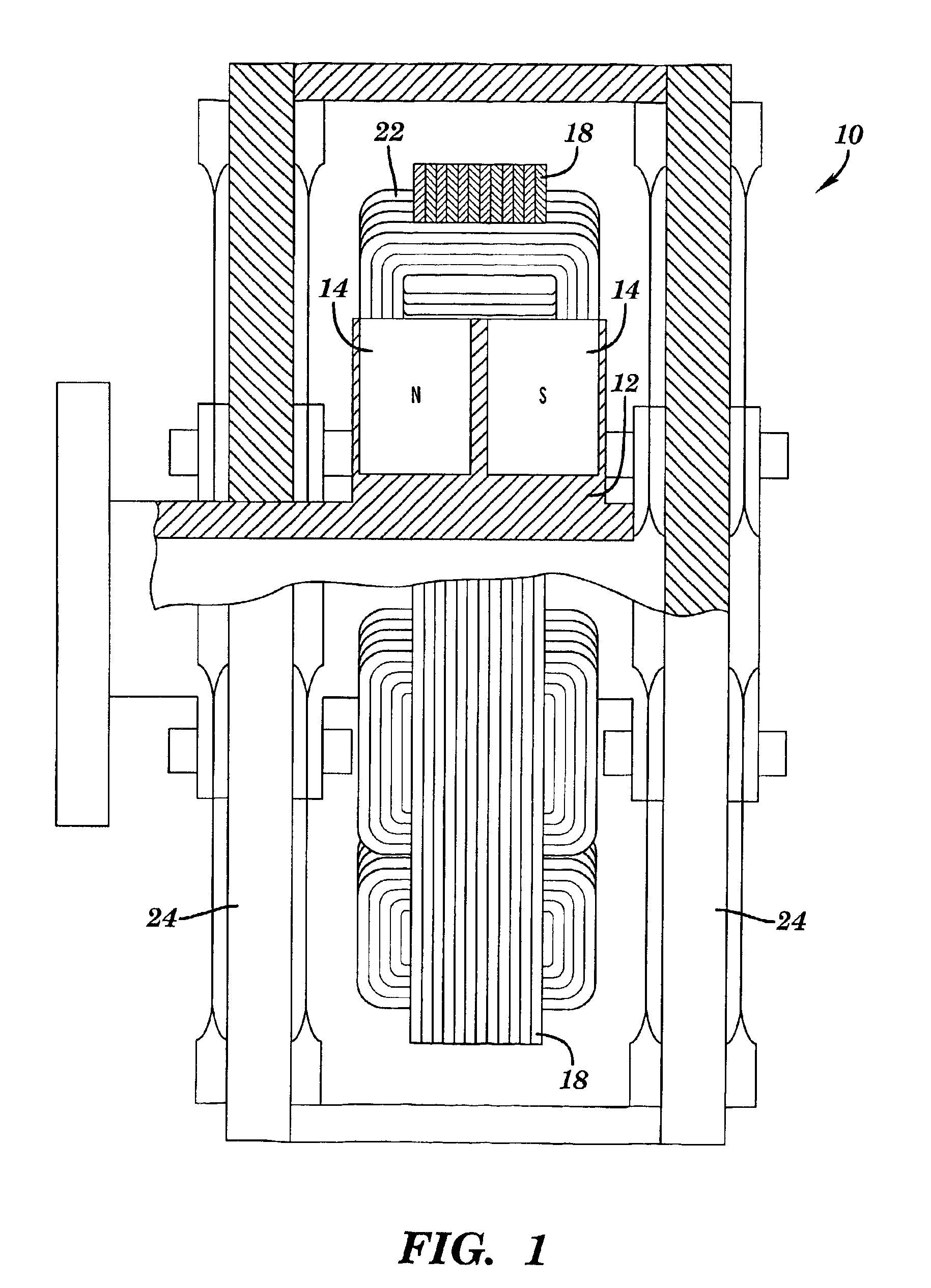

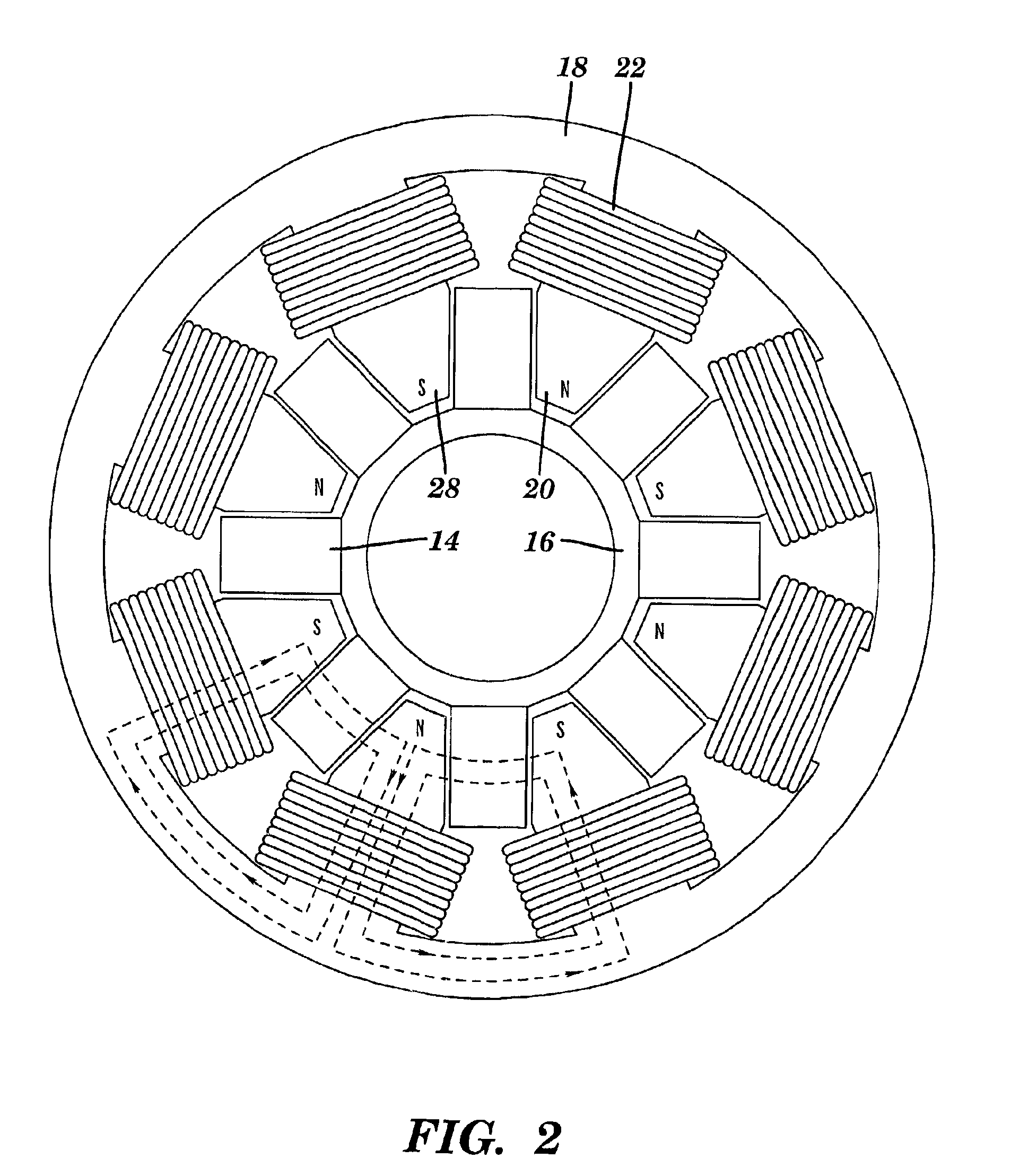

Low loss reciprocating electromagnetic device

InactiveUS6927506B2Reducing eddy-current lossesLow densityReciprocating/oscillating/vibrating magnetic circuit partsPropulsion systemsSecondary lossEngineering

The present invention relates generally to reciprocating electromagnetic devices, and more particularly to a construction of a reciprocating electromagnetic device for reducing secondary losses in magnetically-permeable elements, but without compromising manufacturability as required in prior art. The device provides for shaped pole faces to reduce local magnetic flux density and / or interruptions of electrically-conductive paths in the planes of the laminated layers of the stationary element of the device.

Owner:CHART INC

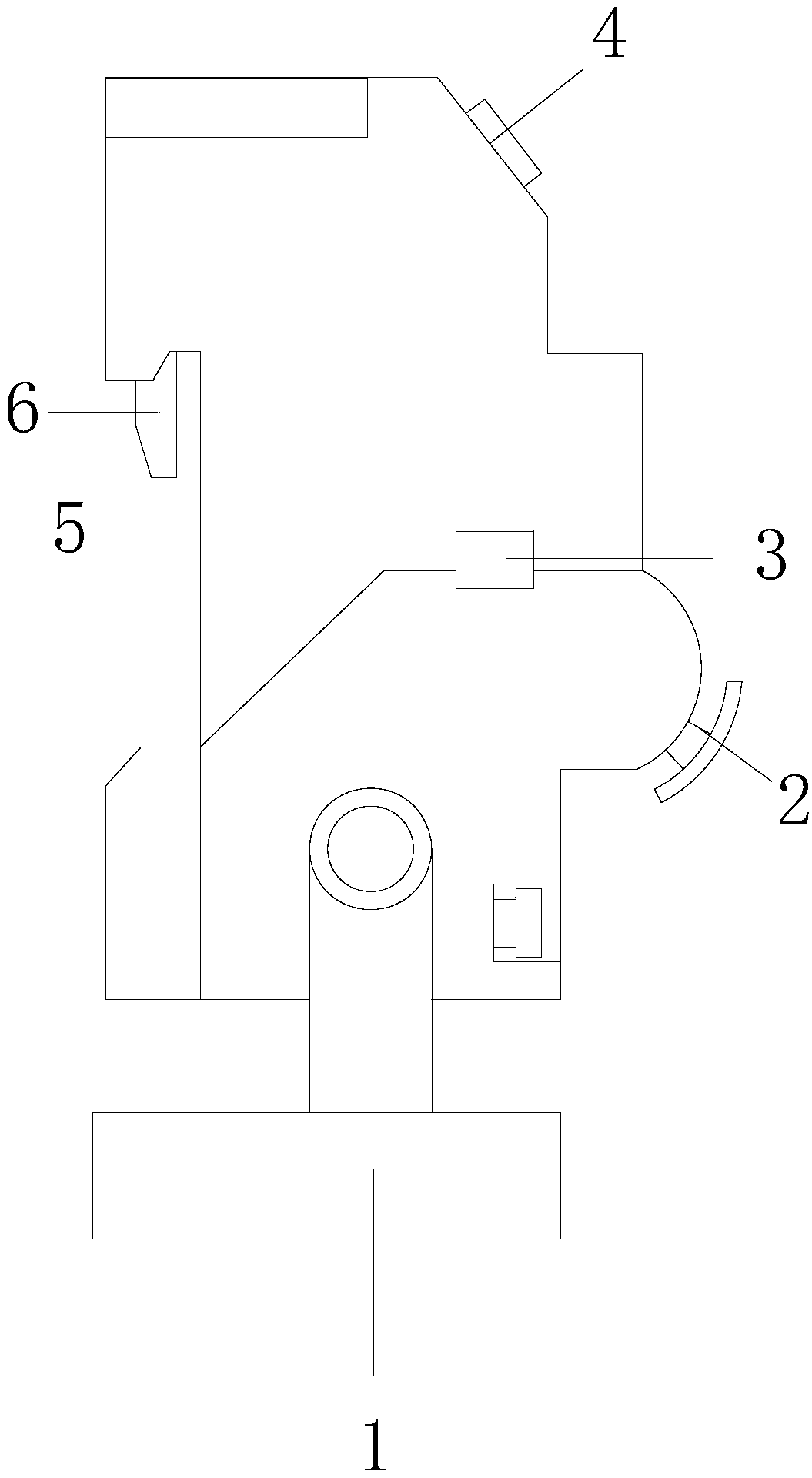

Miniature circuit breaker with double-hook linkage protection

InactiveCN109545629AAvoid the risk of secondary accidentsReduce the number of untripped situationsProtective switch operating/release mechanismsPower flowSecondary loss

The invention discloses a miniature circuit breaker with double-hook linkage protection. The structure of the device comprises two-end protectors, a control handle, a connecting buckle, a fastening bolt, a control casing, and a fixing back end. The two-end protectors are fixed at the two sides of the control casing in an embedded mode and fixed to the axis of the control handle. The connecting buckle is arranged at the top of the groove of the control casing through welding, and the fixed back end is embedded in a clamping seat at the left side of the control casing. In conclusion, after improvement, the two-end protectors are used for immediately cutting off connection between n internal main line and a control end after a disconnecting reaction occurs, the situation that tripping cannotbe achieved due to large current and aging of internal contacts is reduced, the inner cavity linkage electric claw is separated for rapid response, and the situation of secondary loss is avoided.

Owner:泉州市在梦里信息科技有限公司

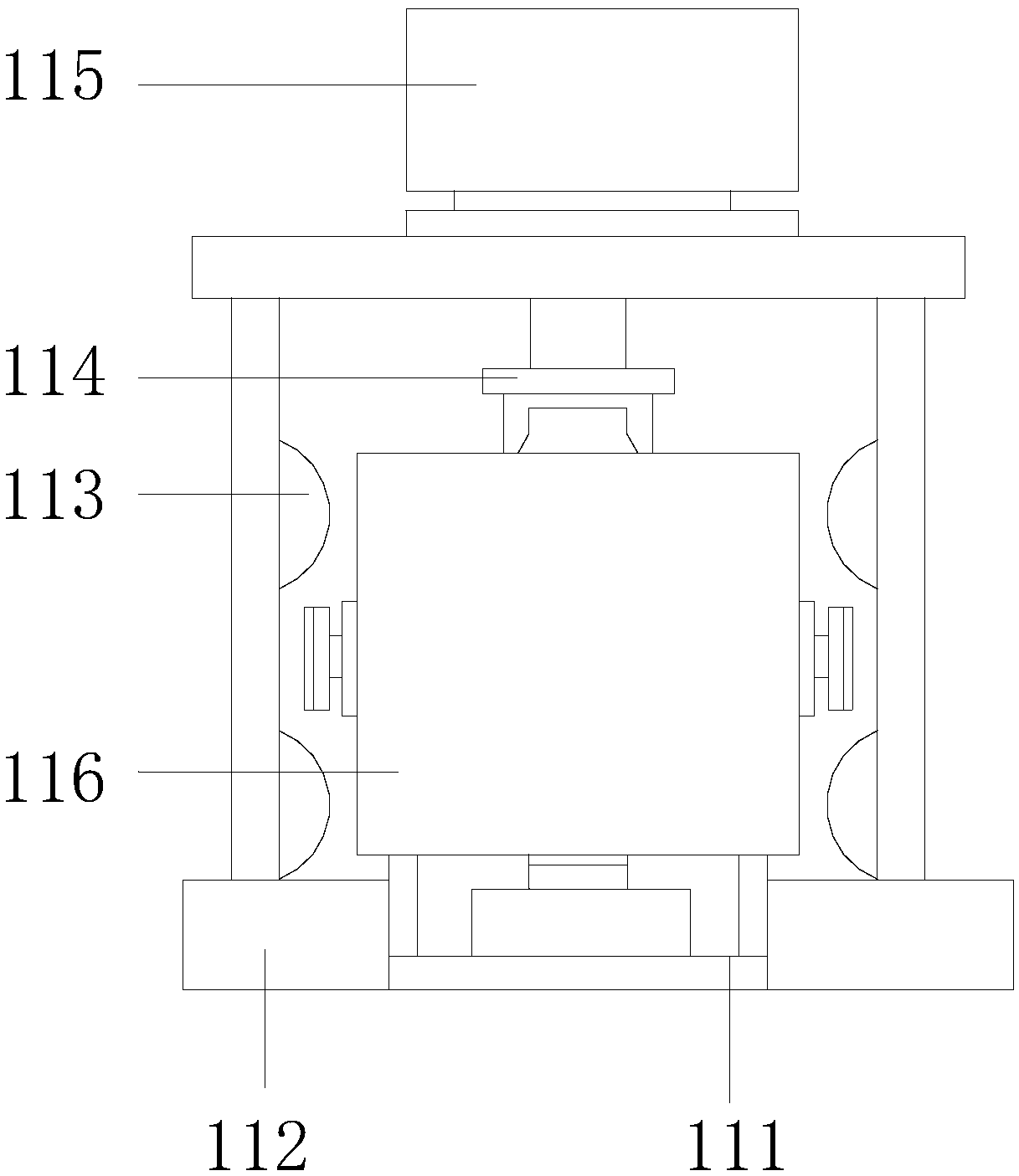

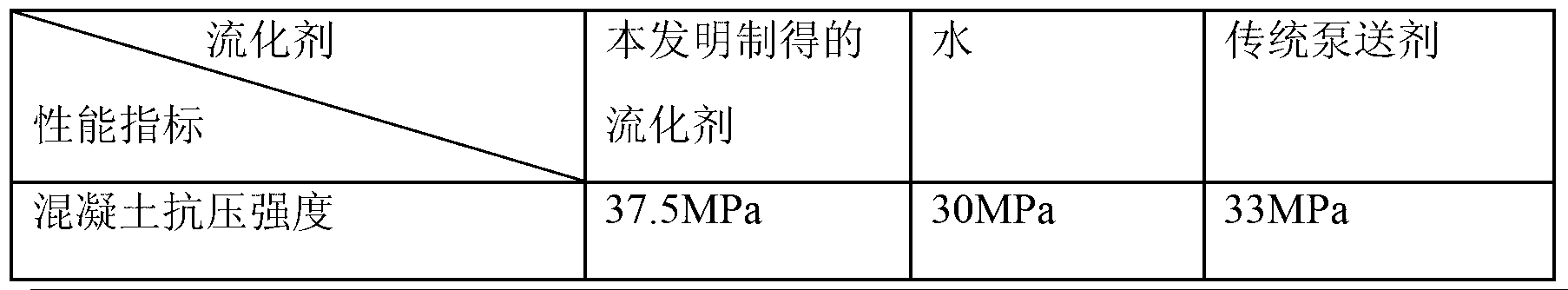

Secondary concrete fluidizing agent

InactiveCN103214210ALittle loss of strengthSmall slump secondary lossSecondary lossUltimate tensile strength

The invention relates to a secondary concrete fluidizing agent which mainly solves the technical problem of providing a secondary concrete fluidizing agent. The secondary concrete fluidizing agent comprises the following ingredients in parts by weight: 300-350 parts of a polycarboxylate-type water reducing agent, 0.08-0.10 part of an air-entraining agent, 12-16 parts of a retarder and 630-660 parts of water. A method for preparing the secondary concrete fluidizing agent mainly comprises the following steps: evenly mixing the polycarboxylate-type water reducing agent with water, sequentially adding the air-entraining agent and the retarder, and evenly stirring to obtain the secondary concrete fluidizing agent. The secondary concrete fluidizing agent is fluid, has the functions of ensuring that the secondarily fluidized concrete is small in strength loss, normal in setting time, small in secondary slump loss and the like, and also solves the quality fluctuation problem of the secondarily fluidized concrete.

Owner:CHINA 19TH METALLURGICAL CORP CHENGDU CONSTR +1

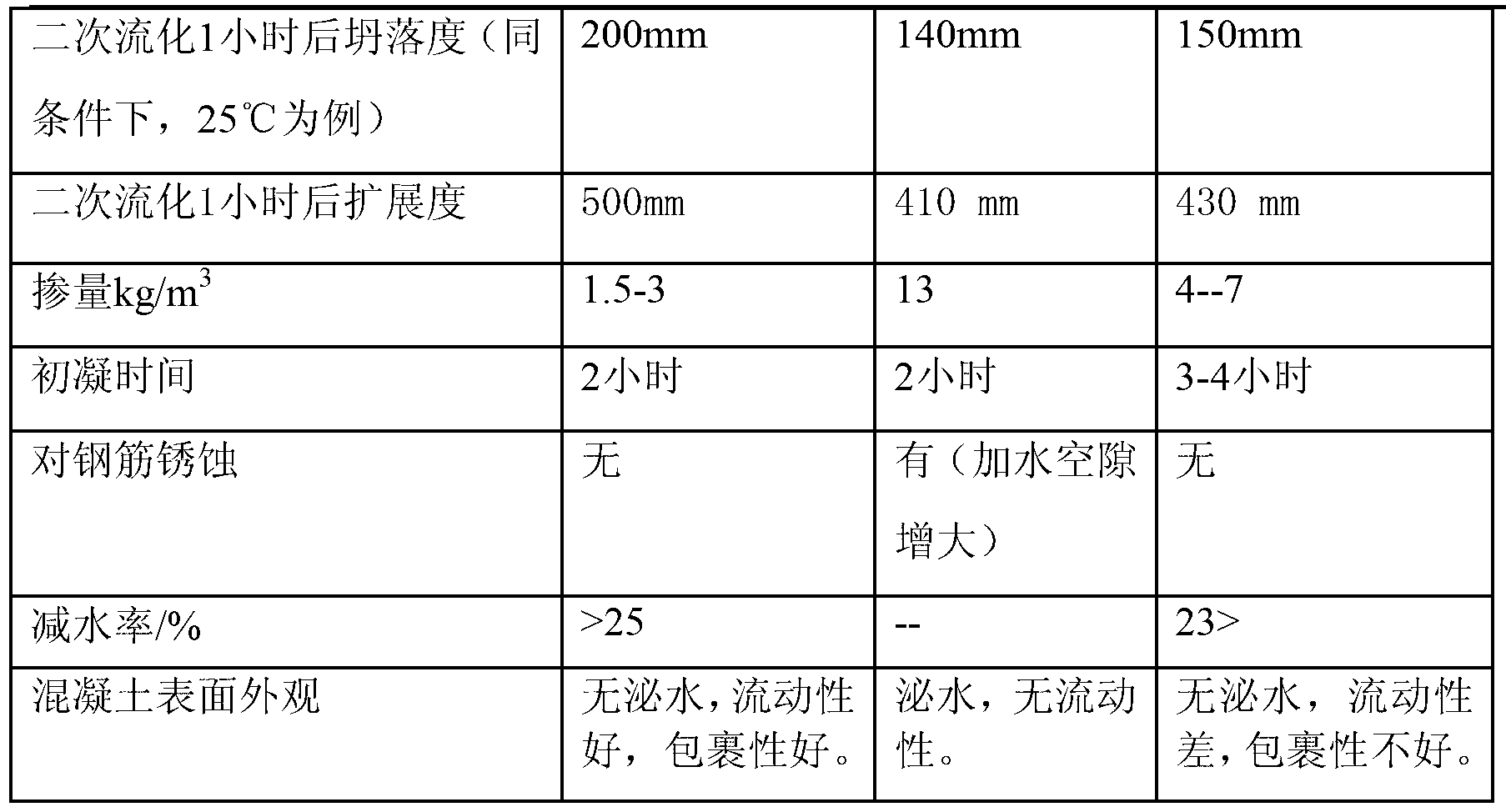

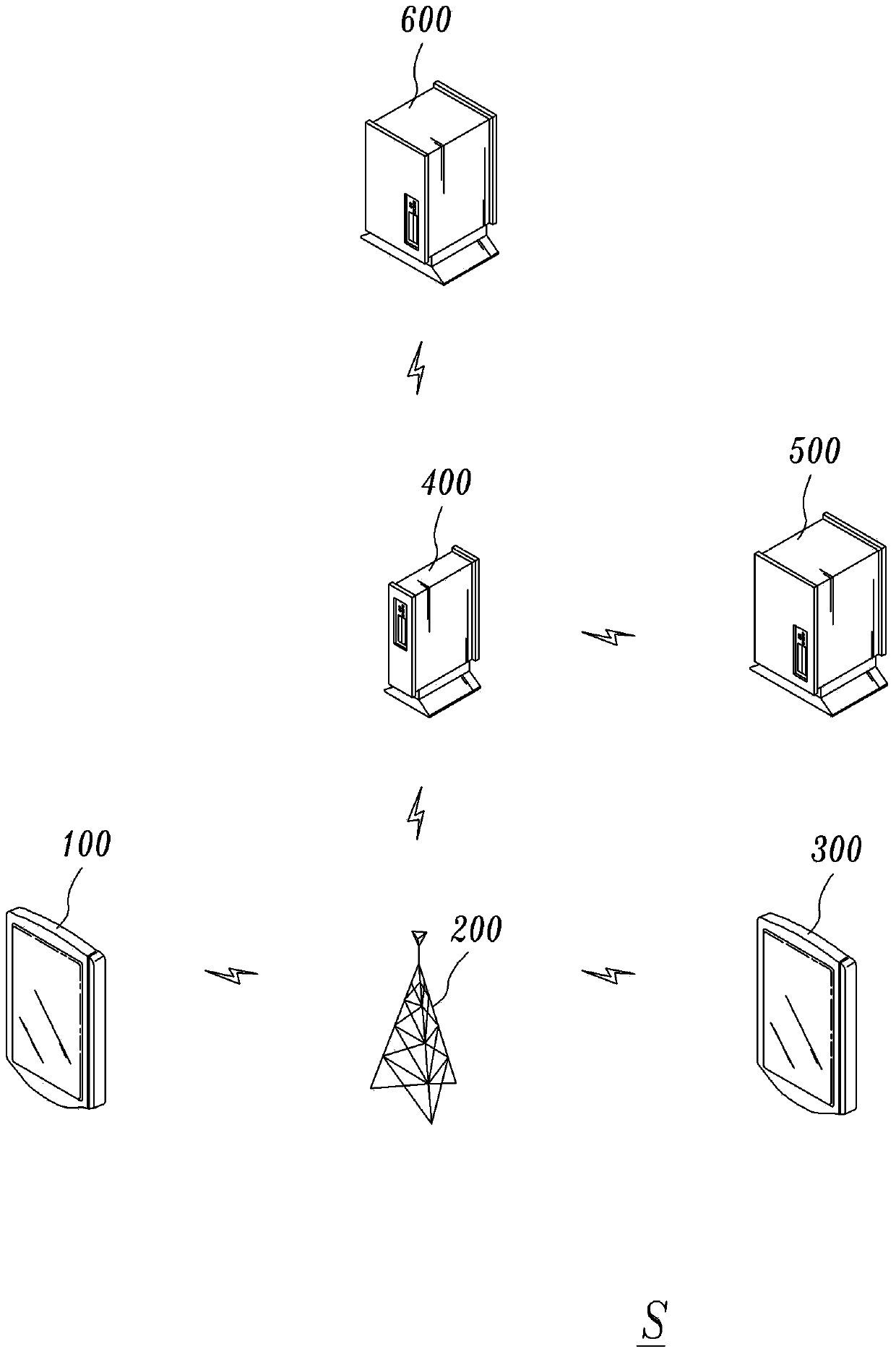

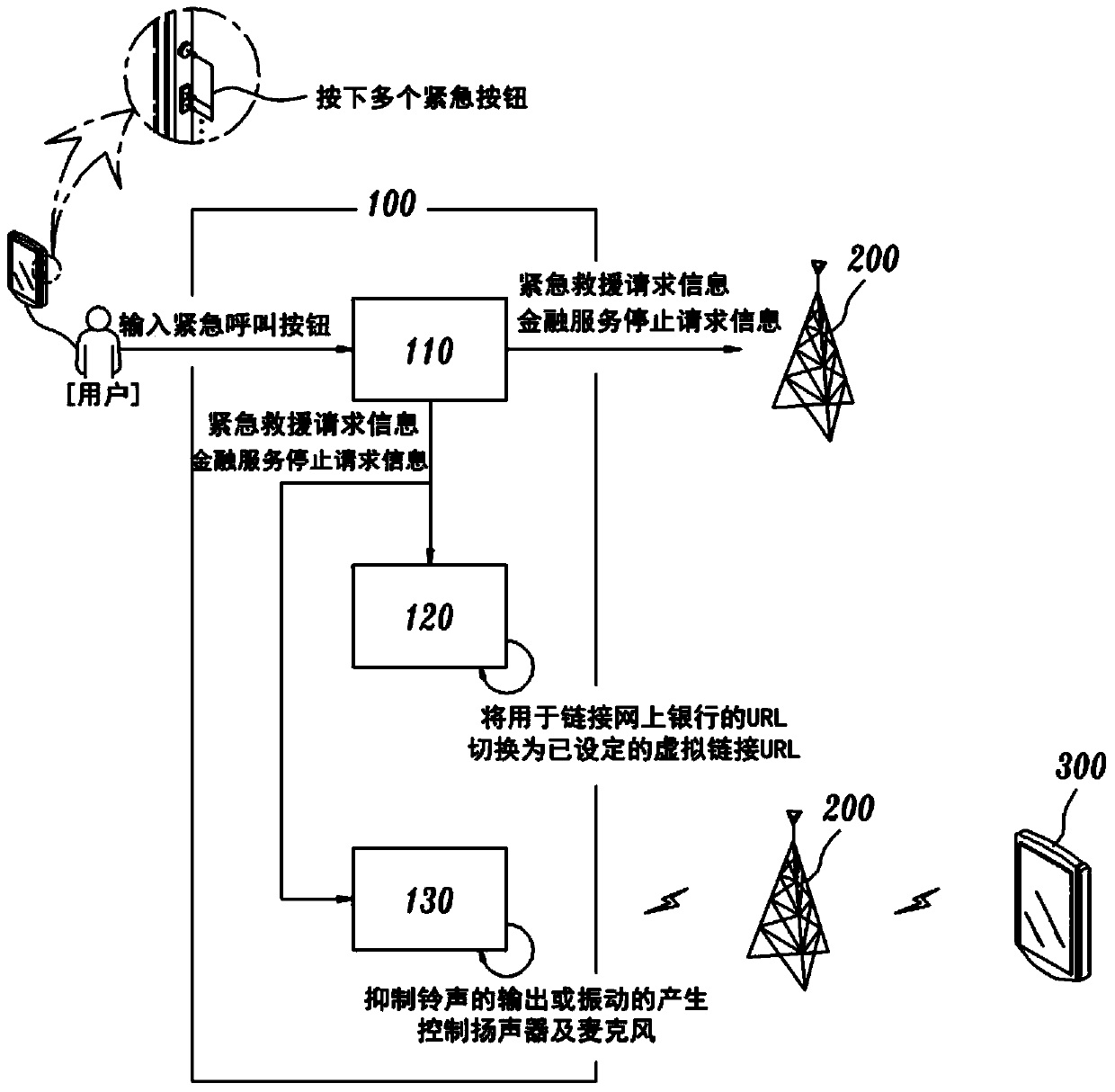

System and method for preventing abuse of emergency calls placed using smartphone

InactiveCN104221408ASecondary loss preventionPrevention of secondary lossesAgricultural buildingsWireless commuication servicesBank accountSecondary loss

The present invention relates to a system and method for preventing the abuse of emergency calls placed using a smartphone. When emergency information is transmitted to a preset guardian terminal by pressing a plurality of emergency buttons, a guardian terminal verifies whether or not there is an emergency and transmits an emergency situation experienced by a smartphone user to a server of an organization, and an officer from the organization having the server is sent to the coordinates of the location of the smartphone user which were received from the mobile communication service provider, thus enabling an organization such as a police department or a fire department to react to an emergency in the shortest possible amount of time when the smartphone user experiences said emergency. An Internet bank account of the smartphone user is converted to a preset virtual Internet bank account so as to be provided with a virtual Internet banking procedure. A bank account connected to a debit card or check card corresponding to a smartphone identification number is converted to a preset virtual bank account so as to enable an offline banking service, thus preventing additional damage to the smartphone user as a result of a cash withdrawal using the smartphone. The credit card information of the smartphone user is registered as information on a lost card, thus preventing additional damage to the smartphone user resulting from a payment by a credit card or from a card loan being taken out.

Owner:金汉锡

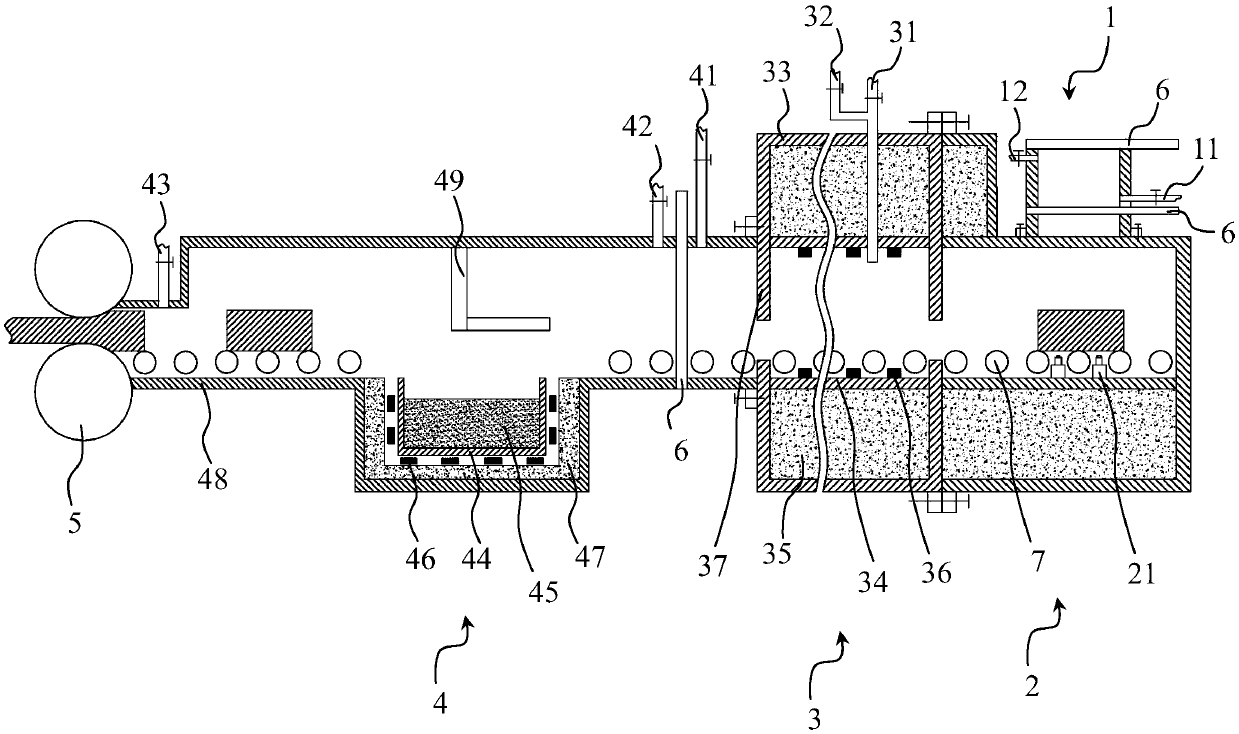

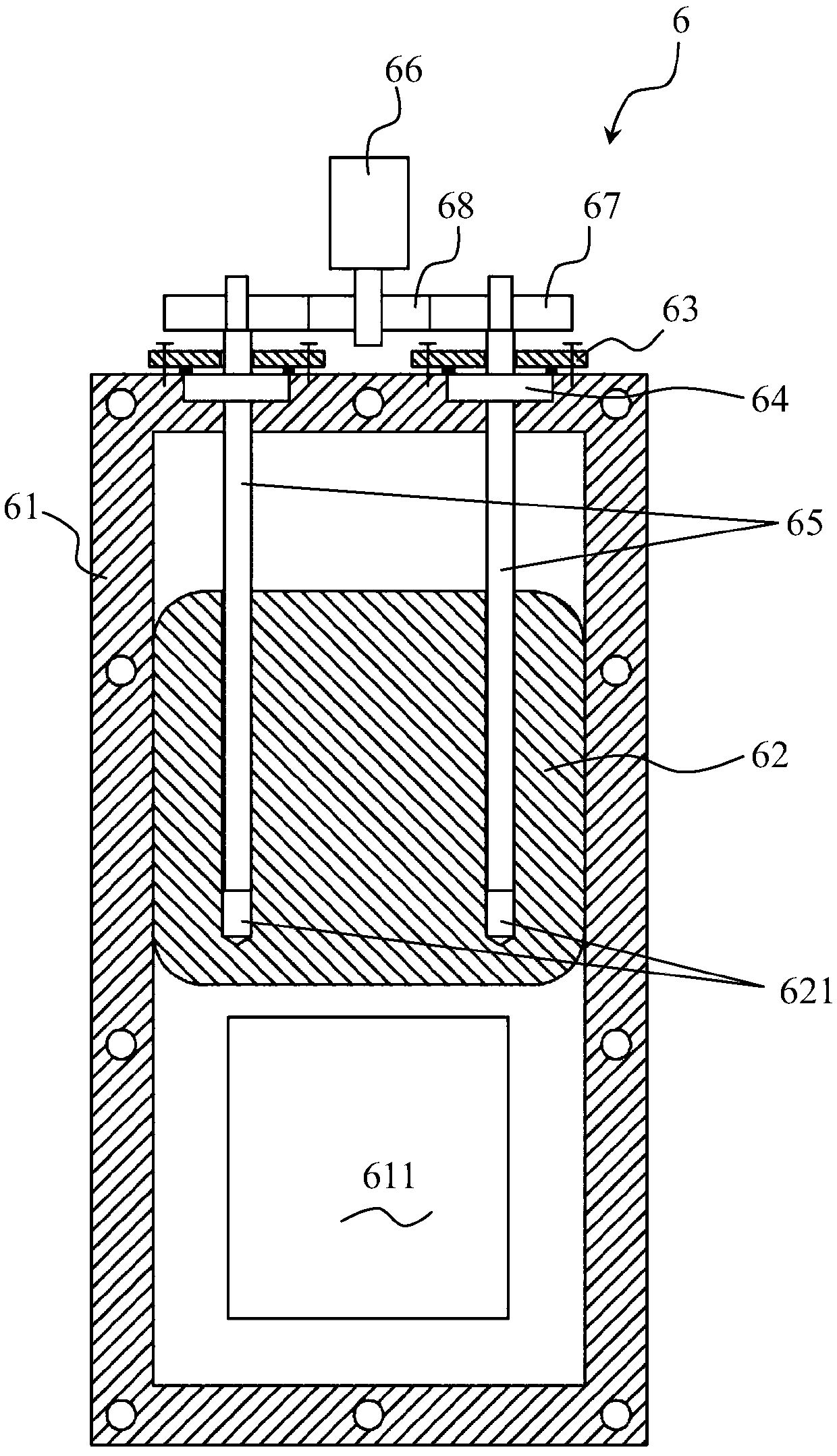

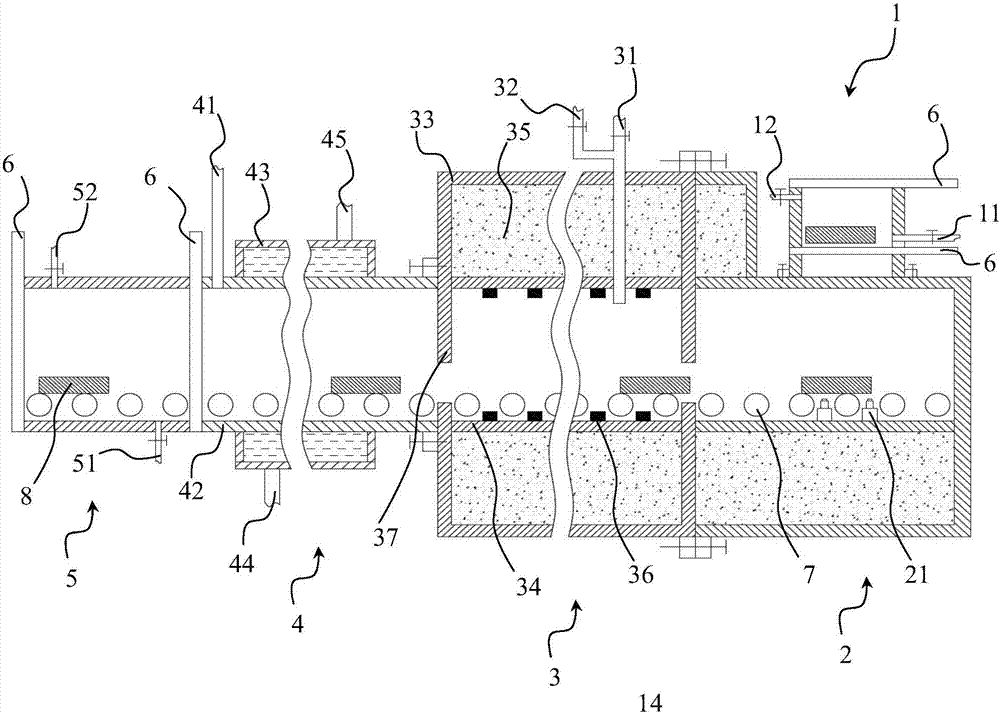

Reduction hot-dip aluminum plating device and method thereof

ActiveCN106929789BAvoid secondary lossIncrease profitHot-dipping/immersion processesInlet valveSecondary loss

The invention discloses a reducing and hot-dip aluminum-plating device and method. The device comprises an inlet section, a spare part section furnace body, a heating section furnace body, an aluminum-plating section furnace body and a rolling mill, wherein the inlet section is mounted above the spare part section furnace body in a sealing mode; the spare part section furnace body, the heating section furnace body and the aluminum-plating section furnace body are sequentially connected in sequence from right to left; both the top and the lower part of the inlet section are equipped with sealing valves; a lifting connecting part device is arranged on a position, which corresponds to the inlet section, of the inner cavity of the spare part section furnace body; the right end of the aluminum-plating section furnace body is equipped with a sealing valve and an aluminum-plating section inert gas inlet valve; the lower part of the aluminum-plating section furnace body is equipped with an aluminum melting furnace; a mechanical arm is arranged in a shell of the aluminum-plating section furnace body; and the rolling mill is arranged at the left end of the aluminum-plating section furnace body. The device can realize continuous production, can obtain a metal workpiece with a flat surface, improves bonding strength between aluminum and a metal workpiece, guarantees working efficiency, effectively protects the surrounding environment, avoids secondary loss of metal, and increases a metal utilization rate.

Owner:柯富荣

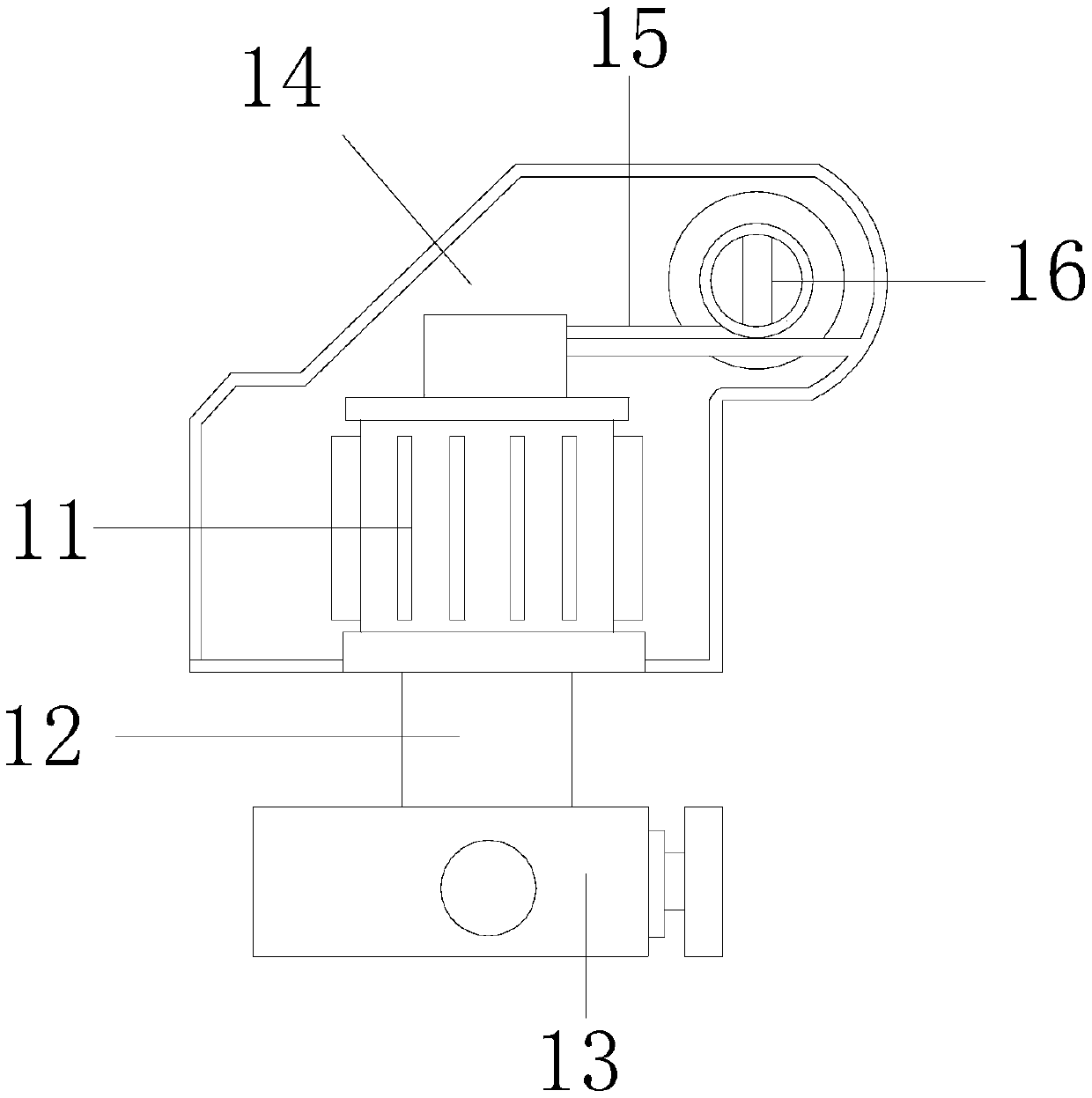

Speed reducer

InactiveCN106895121AAvoid Secondary LossReduce transmission noiseGearingPortable liftingGear wheelEngineering

The invention relates to the technical field of machinery, in particular to a speed reducer, comprising a first gear, a second gear and a power chain, and the first gear, the second gear and the power chain form an integrated transmission structure. The invention is equipped with a plurality of gears and transmission chains with different diameters, and the transmission is carried out through the transmission chain, the transmission noise is small, the speed is controlled by detecting the transmission ratio, the deceleration ratio is controlled with high precision, and high-strength low-carbon alloy steel and high-strength alloy steel are used. Made of molecular materials, it has strong concession and avoids secondary loss of the machine.

Owner:TIANJIN CARMEL TECH DEV CO LTD

Online automatic cutting machine for composite material

PendingCN108789554AReasonable structureSmooth transmissionMetal working apparatusHuman–machine interfaceSecondary loss

The invention relates to a cutting machine, in particular to an online automatic cutting machine for a composite material, and belongs to the technical field of cutting machines. The online automaticcutting machine for the composite material comprises four parts including an auxiliary cutting device, a sizing system, a cutting system and a human-computer interface, the cutting system is controlled and operated through the human-computer interface under the action of the auxiliary cutting device and the sizing system, and the cutting requirements are met. According to the design, on one hand,quick online automatic cutting is achieved, the cutting end face has no burr and is flat and smooth, and the product quality and precision are improved; and on the other hand, the end repairing problem in secondary machining is solved, and manpower resource and equipment input and secondary losses in the secondary end repairing process are reduced. The online automatic cutting machine for the composite material has the advantages that firstly, the structure is reasonable, transmission is steady, and the production efficiency is high; and secondly, operation is convenient and safe, and the needed cutting length of various composite materials can be easily modified.

Owner:盐城恒华智造科技有限公司

Metal workpiece surface reduction device and method

The invention discloses a metal workpiece surface reduction device and method. The device comprises an inlet section, a spare part section furnace body, a heating section furnace body, a cooling section furnace body and an outlet section. The inlet section is installed above the spare part section furnace body in a sealed mode. The spare part section furnace body, the heating section furnace body, the cooling section furnace body and the outlet section are sequentially connected in a sealed mode from right to left. Heating units of the heating section furnace body are evenly distributed in a furnace wall. A lifting connection piece device is arranged at the position, corresponding to the inlet section, of an inner cavity of the spare part section furnace body. Roll gangs locate in the same horizontal level are arranged in the spare part section furnace body, the heating section furnace body, the cooling section furnace body and the outlet section. According to the metal workpiece surface reduction device and method, continuous production can be achieved, working efficiency is ensured, the labor intensity of workers is reduced, nitrogen is adopted for reducing an oxidation layer on the surface of a metal workpiece, the metal workpiece with the flat surface can be obtained, the surrounding environment is effectively protected, secondary loss of metal is avoided, and the metal utilization rate is improved.

Owner:柯富荣

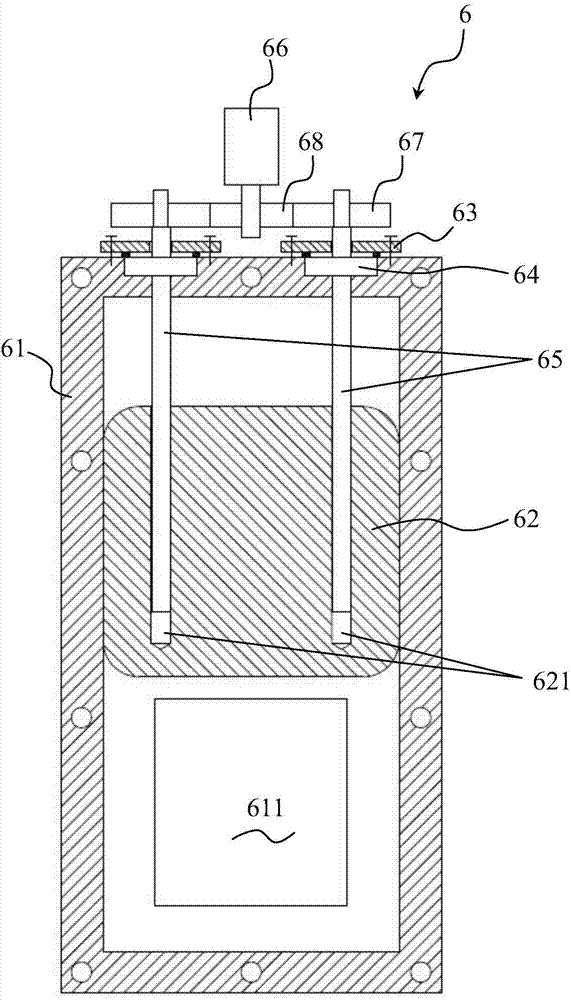

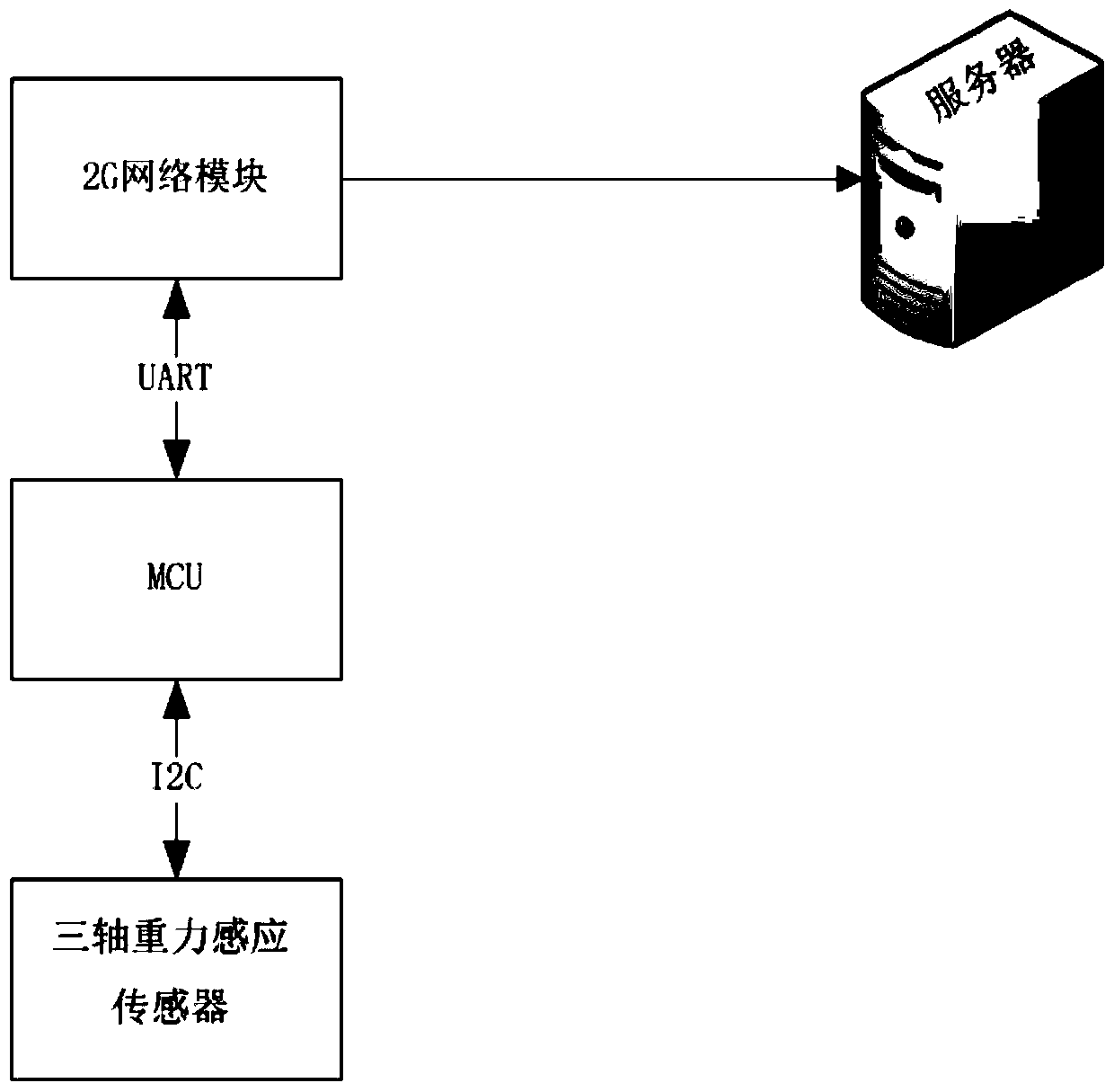

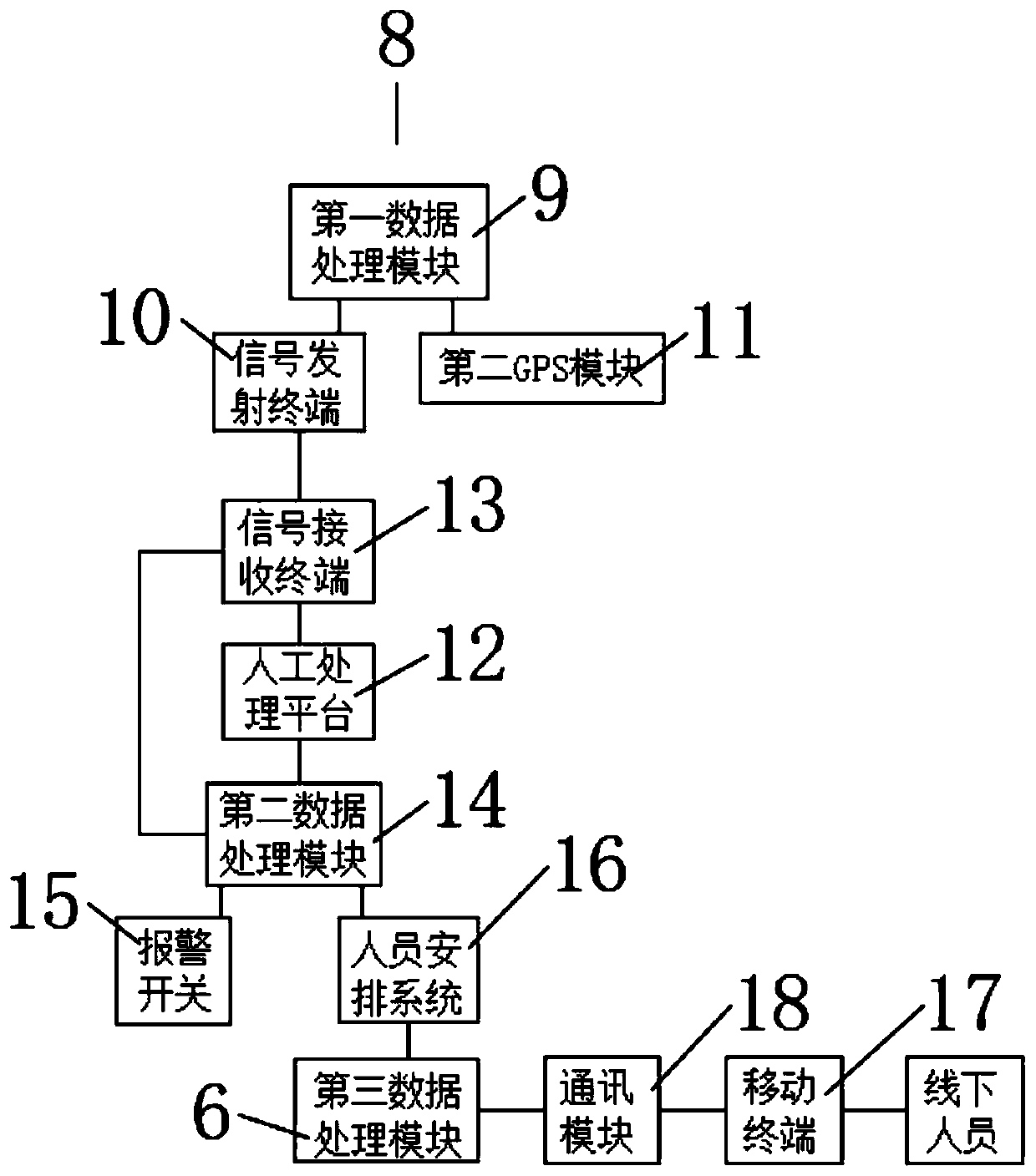

A vehicle condition intelligent monitoring system based on vehicle rollover monitoring

ActiveCN105353710BAvoid secondary lossRescue in timeProgramme controlComputer controlRolloverData acquisition

The invention discloses a vehicle condition intelligent monitoring system based on vehicle rollover monitoring. The system mainly includes a data acquisition module, a positioning module, a wireless communication module, a vehicle condition monitoring MCU and a vehicle condition intelligent monitoring platform, wherein the data acquisition module is provided with a three-axis gravity inductive sensor used for monitoring a vehicle rollover. The vehicle condition intelligent monitoring system based on vehicle rollover monitoring realizes timely rescue after a rollover accident of a vehicle happens, has the technical effects of saving manpower cost, reducing processing time and improving rescue request processing efficiency, prevents the life property of accident personnel from secondary loss, and has application and popularization prospects.

Owner:JIANGSU TIANAN SMART SCI & TECH

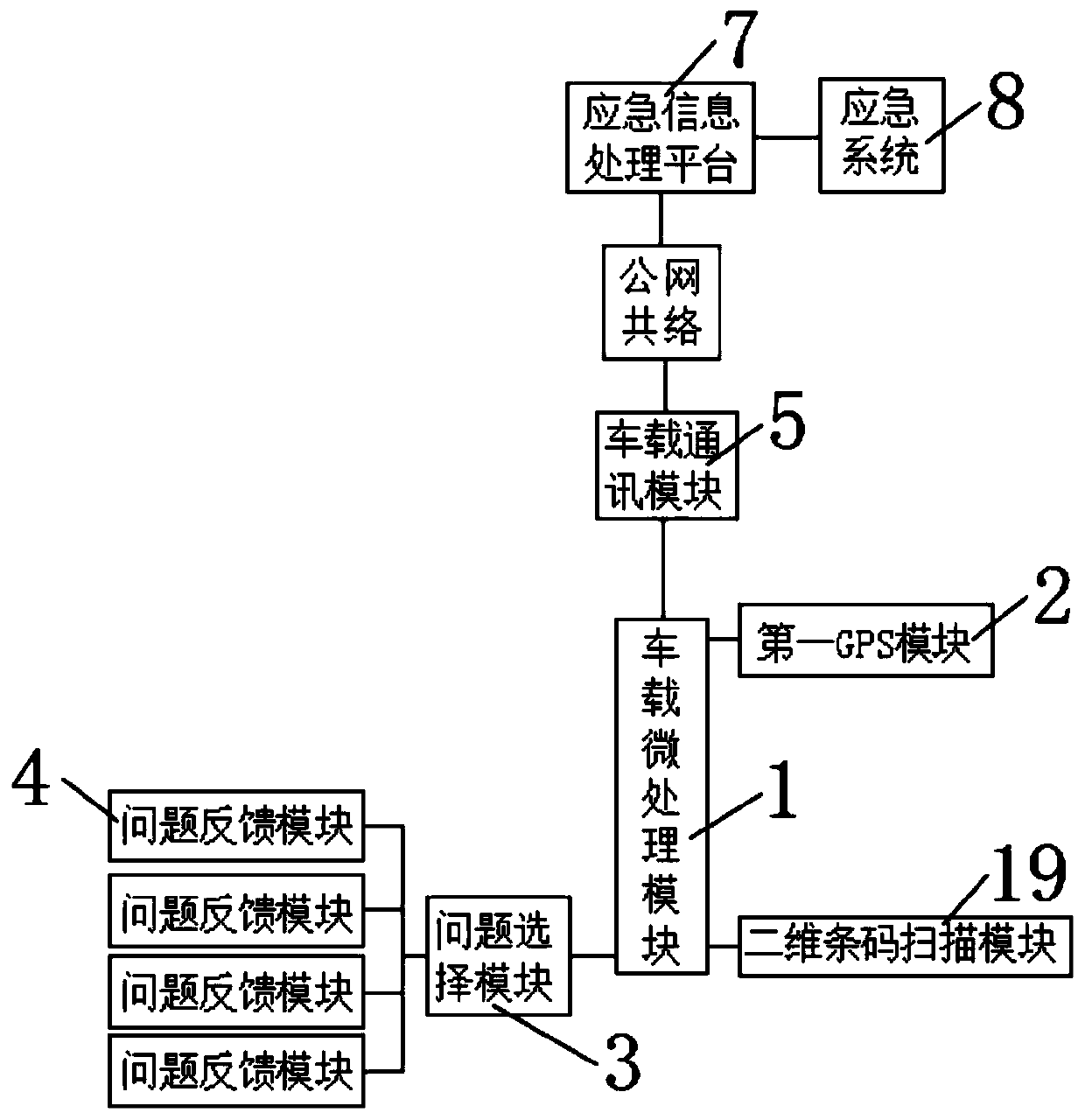

Vehicle emergency system based on Internet

InactiveCN109849812APerfect competitionEasily damagedParticular environment based servicesVehicle infrastructure communicationInformation processingComputer module

The invention discloses a vehicle emergency system based on the Internet. The system comprises a protective case, and a vehicle-mounted micro-processing module fixedly connected to the interior of theprotective case; the vehicle-mounted micro-processing module is electrically connected with a problem selection module, a two-dimensional bar code scanning module, a first GPS module and a vehicle-mounted communication module; the vehicle-mounted communication module is in signal connection with an emergency information processing platform; the emergency information processing platform is electrically connected with an emergency system. The invention discloses the vehicle emergency system so as to improve competition of tires in the market; the system is applicable to all vehicles; when vehicle tires are broken in the field travel of people, the system can be used for calling the nearest maintenance station, so the maintenance station can timely arrange maintenance personnel for maintenance, and secondary losses caused by the fact that people need to wait for a long time in situ or forcibly drive the vehicle when tires of the vehicle are damaged can be avoided; the mode of the systemcan be developed in the form of a company, people do not need to take one or more spare tires when going out, and money and effort are saved.

Owner:江苏车在囧途互联网科技有限公司

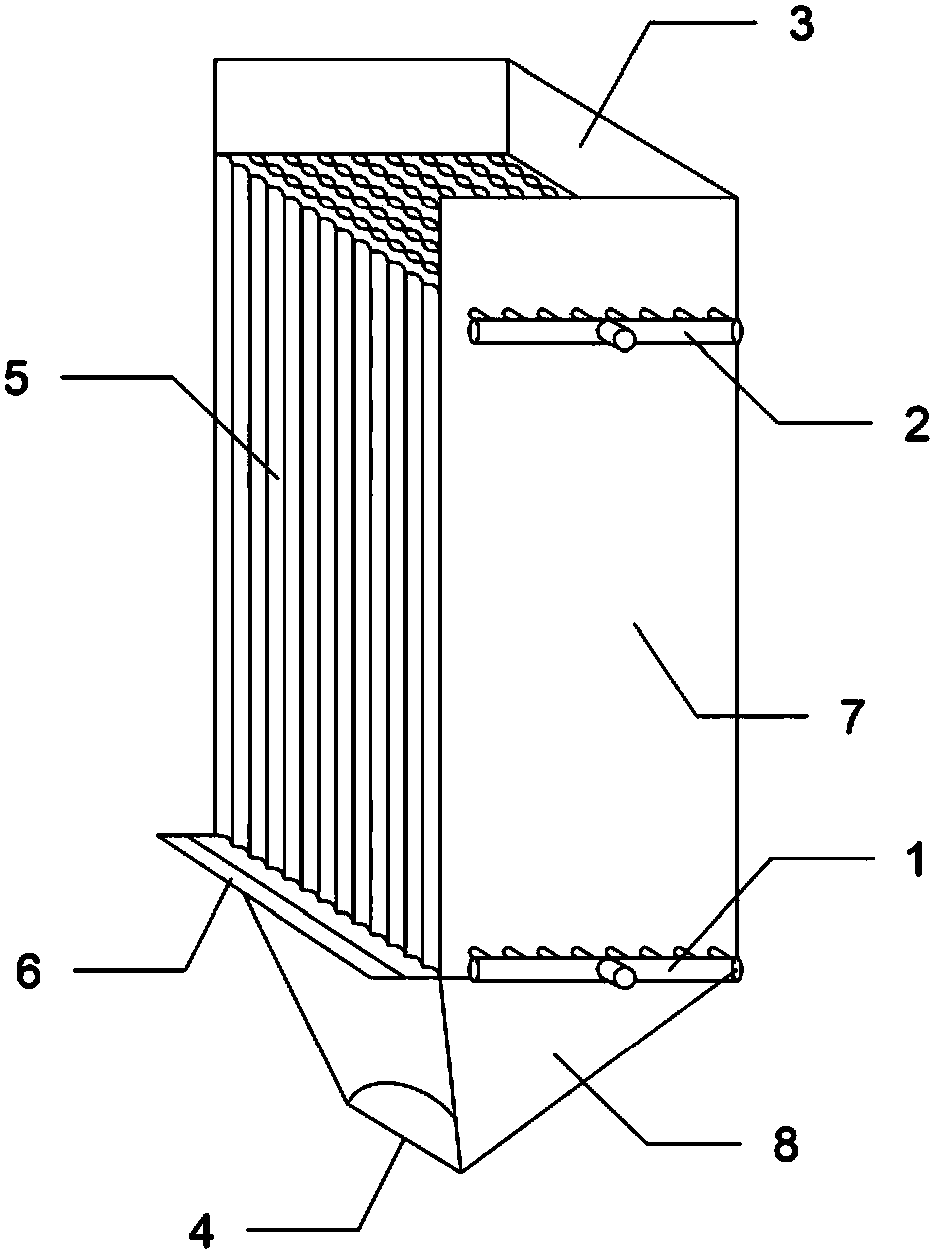

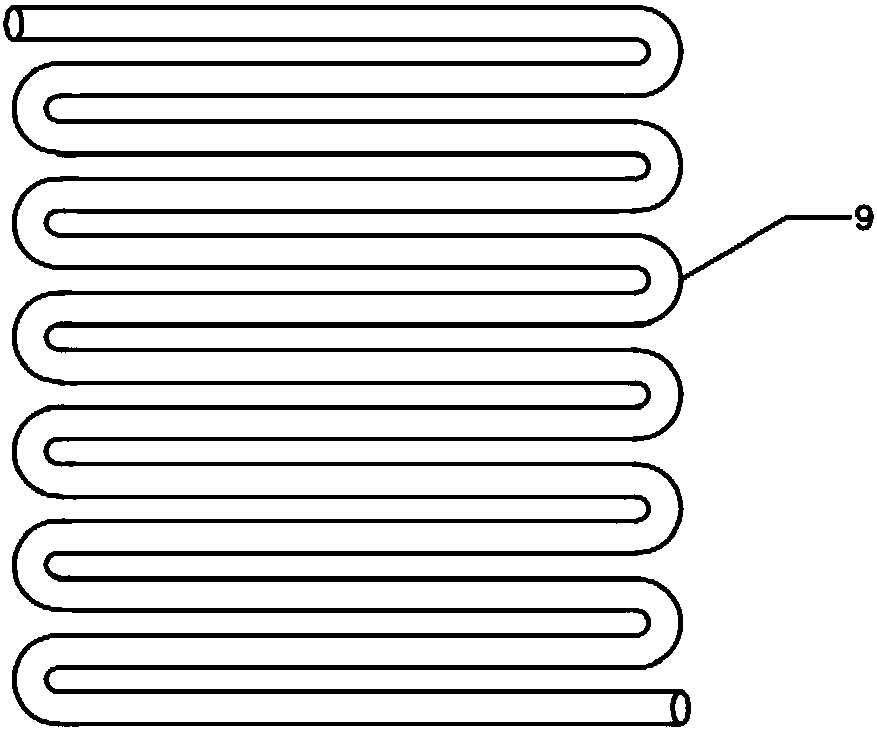

A blast furnace slag sensible heat recovery slag cooler

ActiveCN106834571BEfficient use ofImprove heat recovery efficiencyIncreasing energy efficiencyWaste heat treatmentSlagWater flow

The invention relates to a blast furnace slag sensible heat recovery slag cooler which is used for furnace slag waste heat recovery, and belongs to the field of heat exchange. The blast furnace slag sensible heat recovery slag cooler comprises a plate or tube type heat exchange core, a furnace slag inlet, a louver type furnace slag outlet baffle, a furnace slag outlet hopper, a furnace slag outlet, a cooling water inlet, a steam outlet, a shell and a heat preservation layer; the heat exchange core of the blast furnace slag sensible heat recovery slag cooler is formed by stacking a plurality of plate bundles or tube bundles according to a certain manner. High-temperature furnace slag particles are poured in from the upper portion of the slag cooler, evenly flow downwards, and sweep past a heat exchange plate tube, and heat is transferred to water in the plate tube through a plate wall or tube wall. Cold water flows in a channel in the plate or tube, cross flow or adverse flow is formed between the cold water and the flowing direction of the furnace slag, and entering water is heated to form steam to be discharged out from an upper header. The cooled slag particles are discharged from an outlet in the lower portion. The flowing speed of the slag particles can be adjusted according to the louver type furnace slag outlet baffle at the lower portion of the slag cooler. The water cooling type slag cooler is simple and compact in heat exchange structure, running operation is convenient, the waste heat using efficiency is higher, and secondary losses of heat are avoided.

Owner:TONGJI UNIV

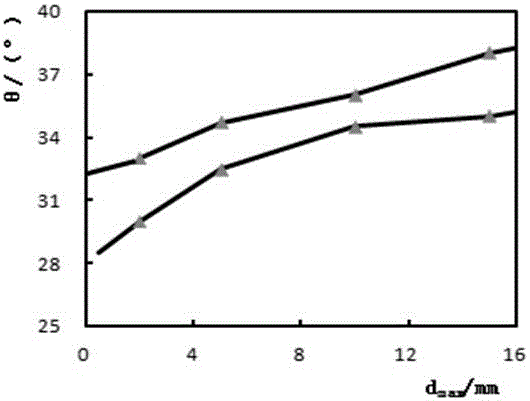

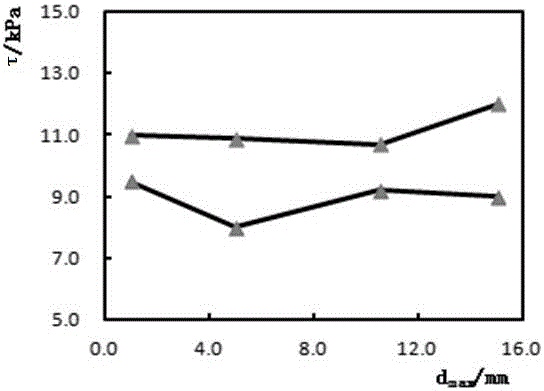

Determination method for trench angle of bottom structure

ActiveCN105927227AImprove liquidityAvoid insecurityUnderground miningSurface miningSecondary lossStoping

The invention discloses a determination method for the trench angle of a bottom structure, specifically to a method for determining a trench angle for a steeply dipping medium-thick or thick ore body (>= 55 DEG, > 4 m, and f=3 to 20) employing a bottom structure for ore removal. The method separately quantifies influence on the trench angle by uncertain factors consisting of firmness and stability of ore rocks, the caking properties, water content and lumpiness of ore, thickness of the ore body, technical parameters of rock drilling equipment and the like by using an orthogonal testing method, an engineering analogy method, an induction method, a numerical simulation method and the like, so relationships between the trench angle and the factors are clearly determined; and thus, an optimal trench angle can be eventually determined. The determination method provided by the invention can improve mobility of caved ore and ensure stability of continuous ore removal, thoroughly overcomes the technical problems of insecurity of suspended arching of ore, secondary loss rate of caved ore and the like and is of important practical significance to safety of a stope room and economic stoping.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

Method for increasing current efficiency of aluminum electrolysis cell

The invention discloses a method for increasing the current efficiency of an aluminum electrolysis cell and relates to the improvement on a method for producing electrolytic aluminum and an aluminum master alloy. The method is characterized in that: in the electrolytic process of the aluminum electrolysis cell, copper, a waste aluminum copper master alloy for producing refined aluminum or other waste aluminum copper alloys is added, so that the copper accounts for 2 to 25 percent of the mass of an alloy cathode, the cathode in the aluminum electrolysis cell is made of an aluminum copper liquid alloy which is formed by liquid aluminum and a small quantity of copper, the density of the aluminum copper liquid alloy is 2,400 to 2,800 kg / m<3>, and the liquidus temperature of the alloy is between 560 and 690 DEG C. In the method, a certain quantity of copper or aluminum copper alloy is added into the electrolysis cell termly; the method aims to reduce the secondary loss of the aluminum, improve the current efficiency of the electrolytic production, reduce or eliminate precipitates at the cell bottom of the electrolysis cell by reducing the activity of the aluminum and increasing the density of a metallic cathode; and the product in the electrolysis cell is the aluminum copper master alloy with corresponding content.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

A Method for Determining the Ditch Angle of Bottom Structure

ActiveCN105927227BImprove liquidityAvoid insecurityUnderground miningSurface miningSecondary lossStoping

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com