One-furnace-two-section boiling baking process

A boiling roasting and roasting technology, which is applied in the field of boiling roasting technology, can solve problems such as environmental pollution, and achieve the effects of improving comprehensive recovery rate, improving leaching rate and saving energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

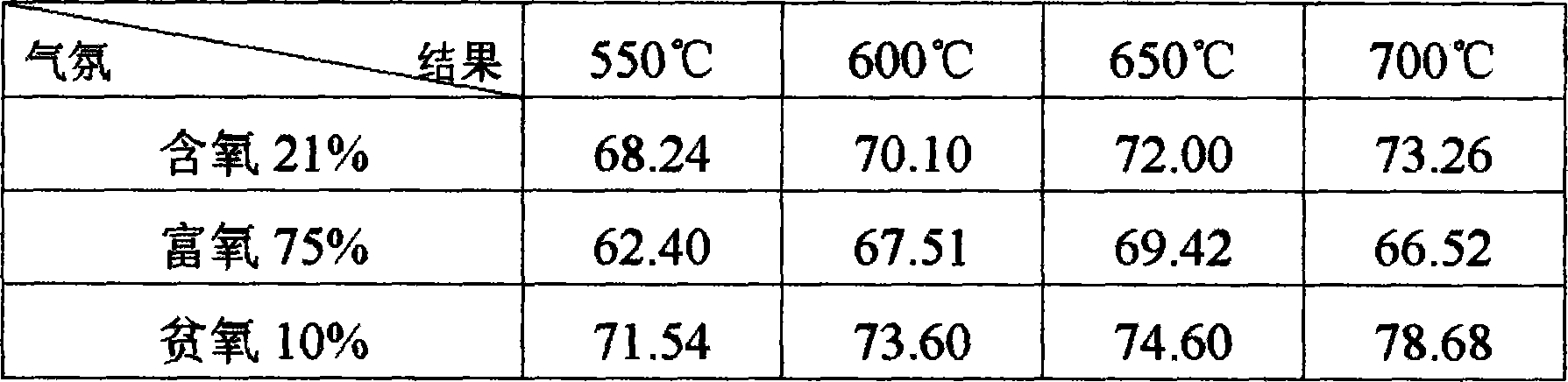

[0035] Grind the above-mentioned refractory gold ore until the content of -0.074mm accounts for 90%, and conduct different atmosphere and different roasting temperature tests in a single-stage roasting furnace, and the roasting time is 45 minutes;

[0036] The firing atmospheres are: air (21% oxygen);

[0037] Oxygen-enriched (75% oxygen);

[0038] Depleted of oxygen (10% oxygen);

[0039] Different temperature: 550°C; 600°C; 650°C; 700°C;

[0040] The results of the carbon leaching gold recovery roasting test are shown in Table 7:

[0041] Table 7 Test results of single-stage calcination at different temperatures and different atmospheres

[0042] Test results: Poor oxygen is better than air, and air is better than rich oxygen; high temperature is better than low temperature. From the test results of single-stage roasting at different temperatures and different atmospheres, the experimental research results are generally low, and the gold recovery index is not ideal.

Embodiment 2

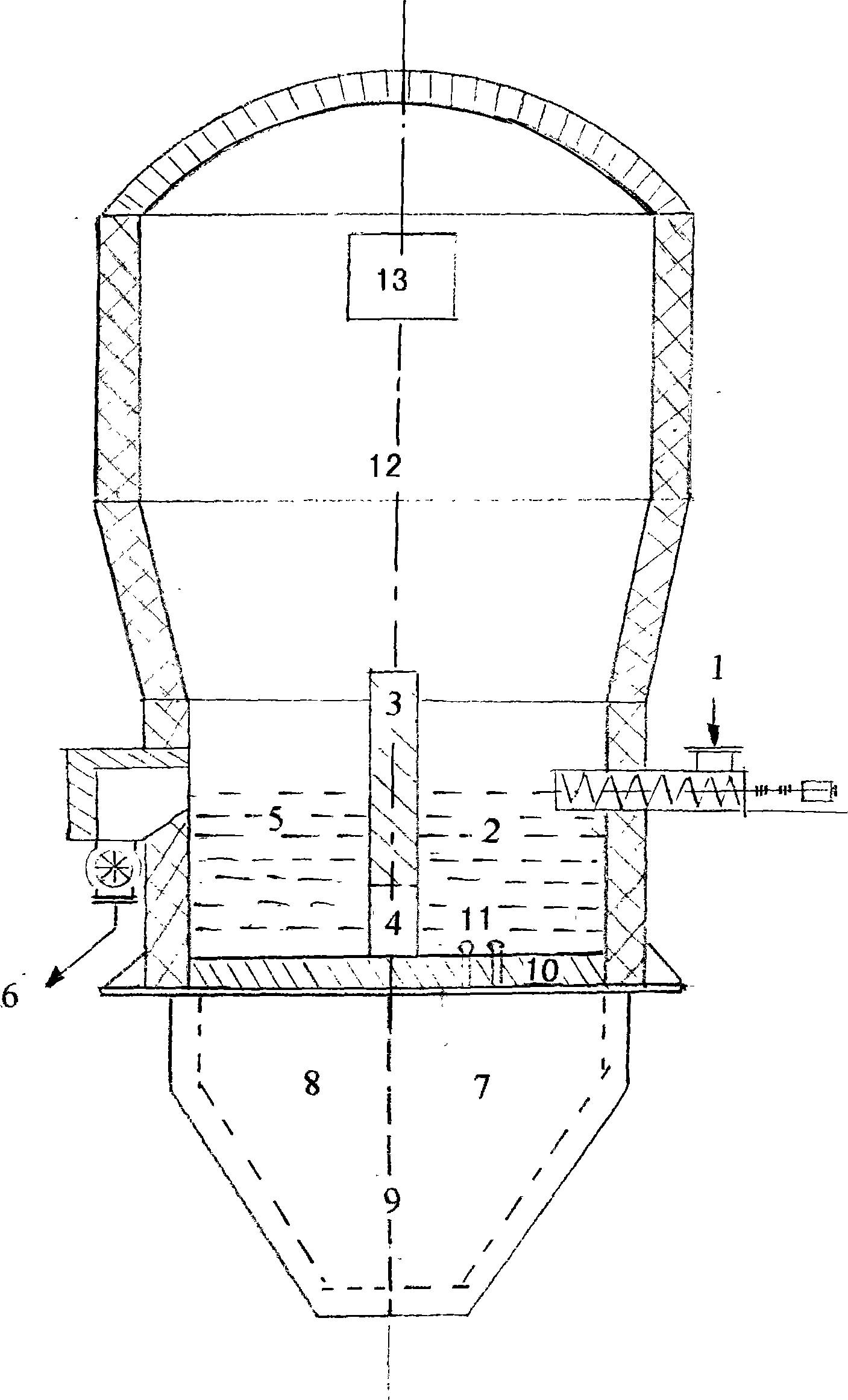

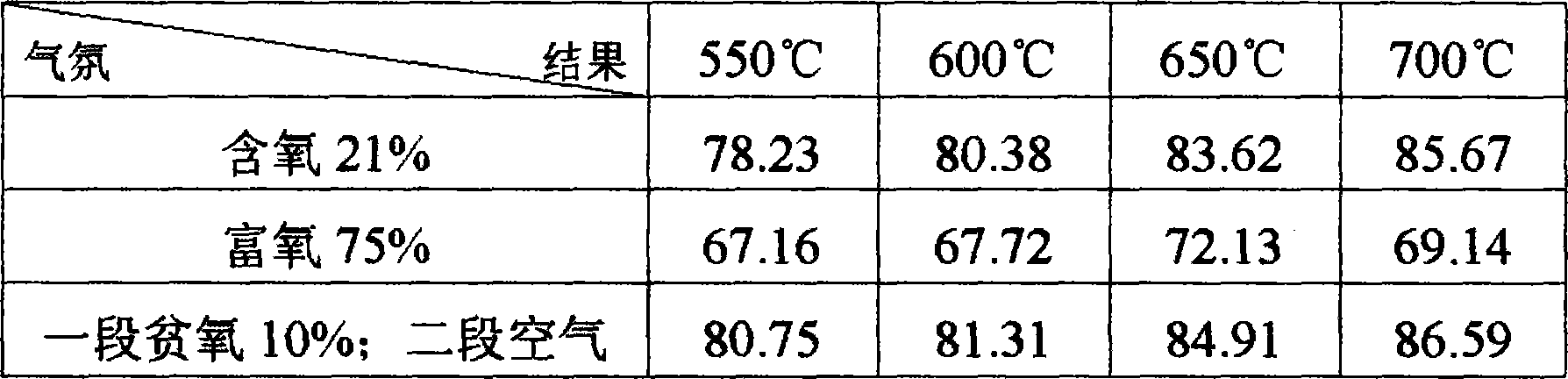

[0044] As shown in accompanying drawing 1, under different atmosphere conditions, different temperature two-stage roasting tests have been carried out to ore, two-stage roasting time is respectively 45min, 30min, 60min, roasting test procedure is:

[0045] Step 1 is roasting material preparation:

[0046] The refractory gold ore in Example 1 was passed through a dry grinding process, and the grinding particle size -0.074mm accounted for 90%; the water content of the ore after dry grinding was less than 2%; the proportion of coal added was 3%;

[0047] Step 2 is the first stage of roasting:

[0048] Through the sealed screw feeder 1, it is fed into the fluidized roasting front chamber 2 of the fluidized roasting furnace for the first stage of roasting; the materials fed into the fluidized roasting front chamber 2 of the fluidized roasting furnace are strictly controlled according to the ore properties. The main parameters such as the air supply volume, the oxygen content of th...

Embodiment 3

[0057] As shown in accompanying drawing 1 and on the basis of embodiment 2, comprehensive optimal working condition has been carried out to expand continuous verification test, and test procedure is identical with embodiment 2, and test parameter is as follows:

[0058] Roasting test ore processing capacity: 8t / d

[0059] Coal burning ratio: 2.8%

[0060] Material particle size: -0.074mm content accounts for 90%

[0061] Two-stage roasting test:

[0062] Roasting temperature: one-stage roasting 680℃~700℃;

[0063] Two-stage roasting at 680°C to 700°C;

[0064] Roasting atmosphere: air is used for the first and second stage roasting, and the oxygen content of the air is 21%

[0065] Roasting time: a period of 30min

[0066] 30 minutes for the second stage

[0067] Air supply volume: a section of 84m 3 / h

[0068] Section 2 84m 3 / h

[0069] The test steps are as follows:

[0070] Step 1 is roasting material preparation:

[0071] The refractory gold ore of Example 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com