Comprehensive recycling technique of valuable elements in smelting soot

A technology of valuable elements and soot, which is applied in the field of comprehensive recovery process of smelting soot, to achieve the effect of simple process, high comprehensive recovery rate and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

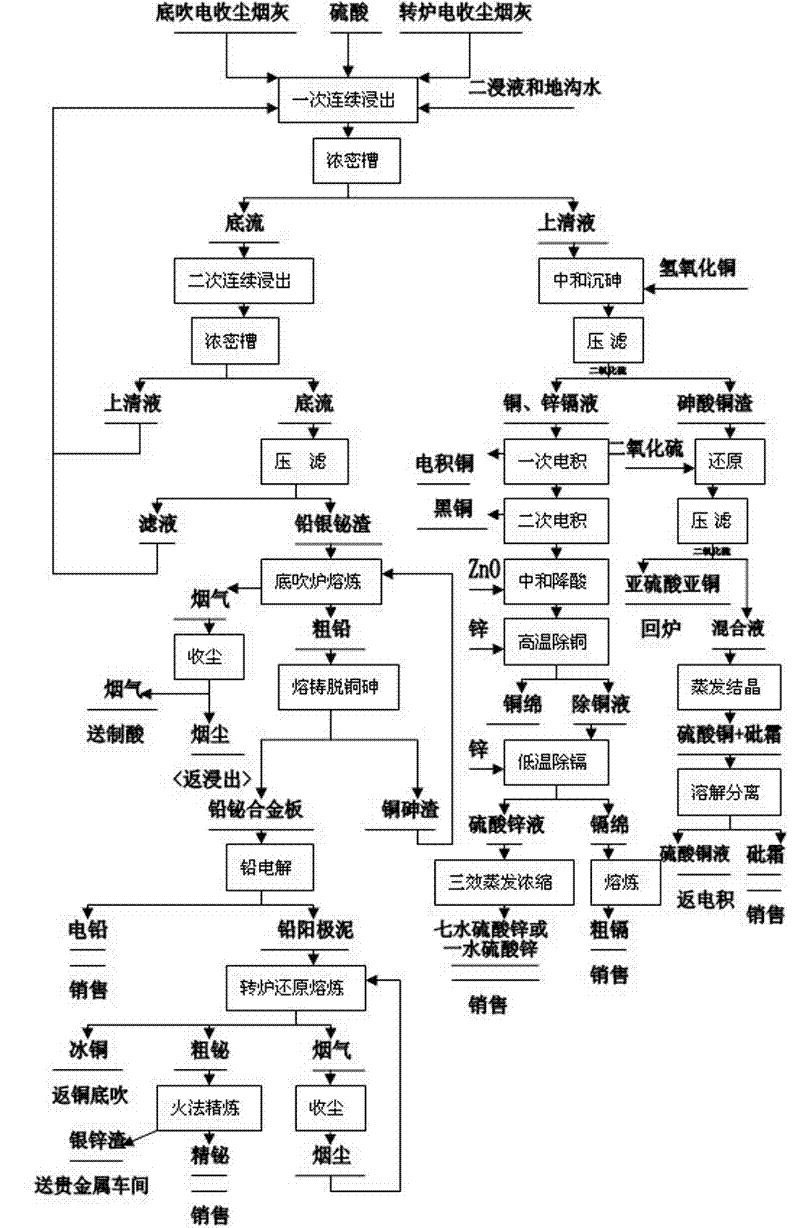

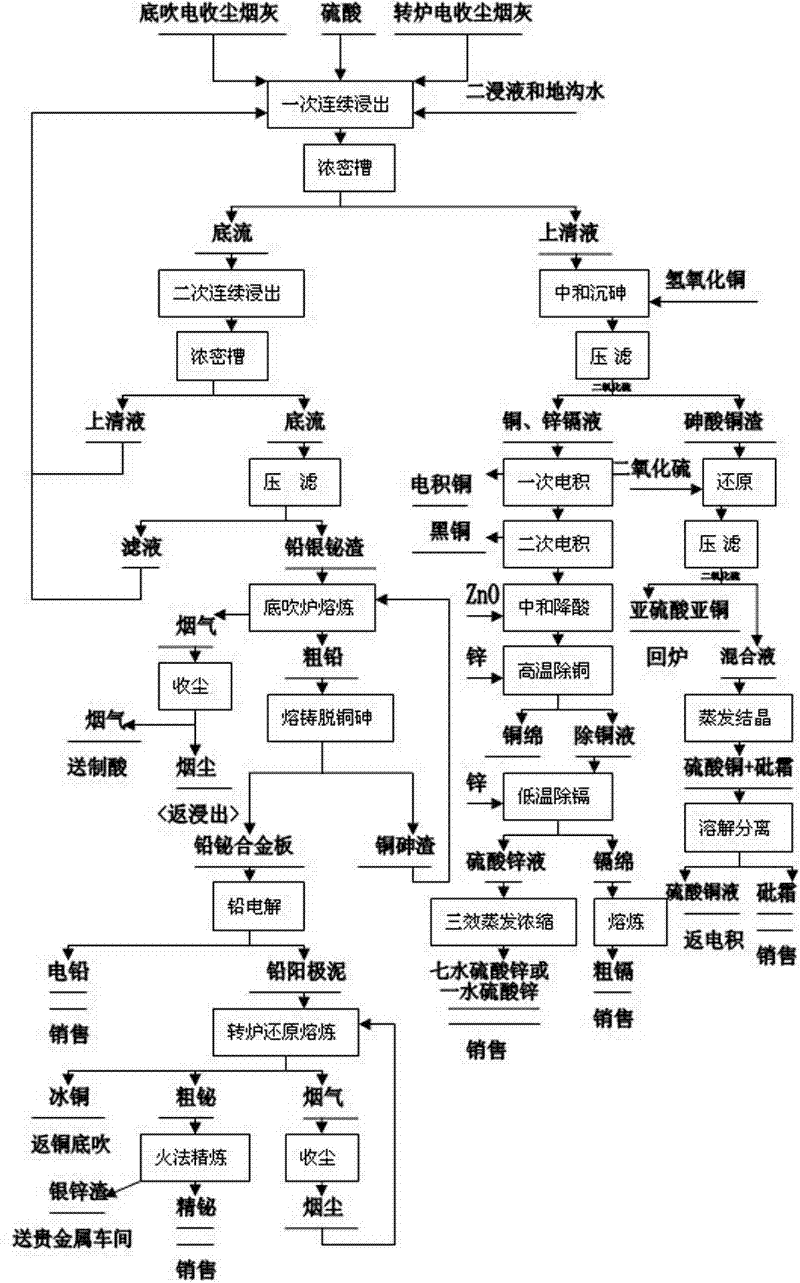

[0022] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0023] A comprehensive recovery process for valuable elements in smelting soot, using a recovery technology combining wet and fire methods, the specific steps are:

[0024] 1) After smelting soot is pulped with sulfuric acid, it is continuously leached once, and the leachate is divided into underflow I and supernatant I through a dense tank;

[0025] 2) The underflow I is continuously leached twice, and the leaching solution passes through the dense tank to form underflow II and supernatant II;

[0026] 3) The supernatant II is returned to a continuous leaching tank, and the underflow II is filtered to form lead, silver and bismuth slag;

[0027] 4) The lead-silver-bismuth slag is smelted to obtain crude lead, and the crude lead is melted and cast to remove copper and arsenic to form copper-arsenic slag and lead-bismuth alloy plate;

[0028] 5) The c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com