Patents

Literature

46 results about "White arsenic" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

White arsenic. n a white powdered poisonous trioxide of arsenic; used in manufacturing glass and as a pesticide (rat poison) and weed killer.

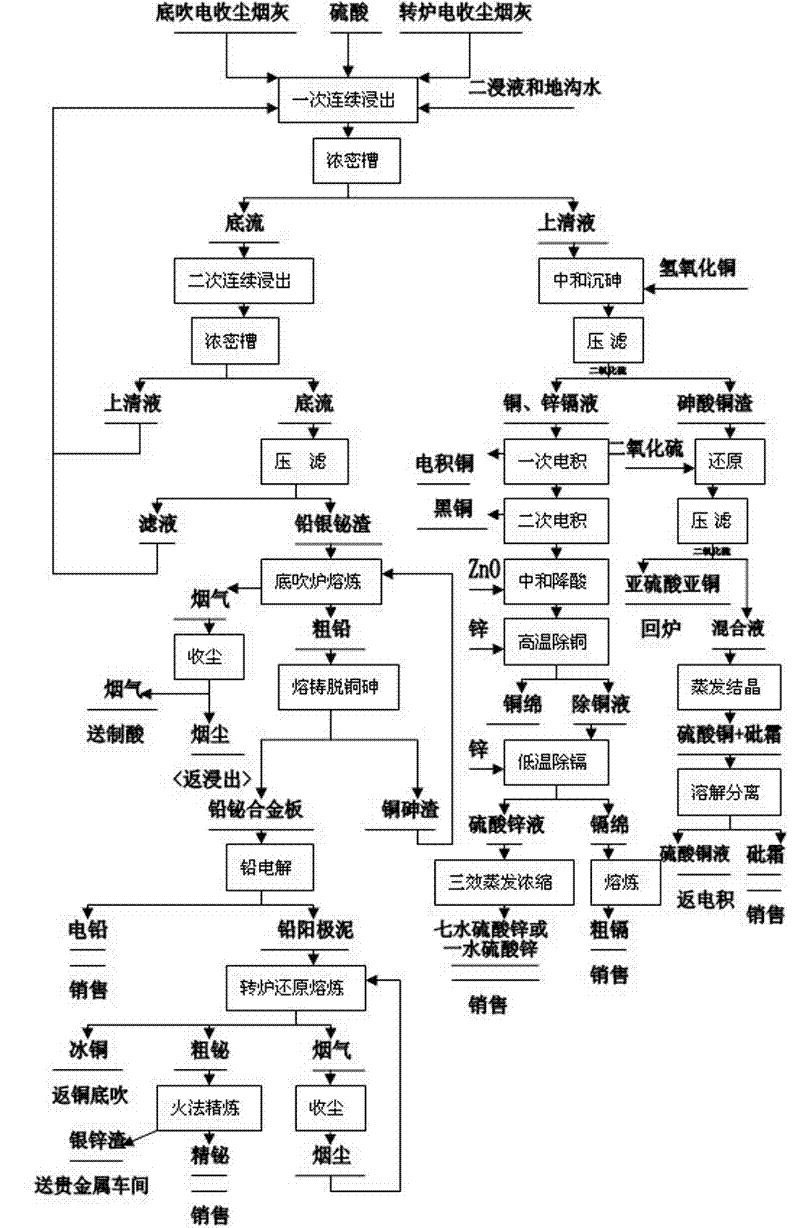

Comprehensive recycling technique of valuable elements in smelting soot

InactiveCN102517449AAdaptableHigh recovery rateProcess efficiency improvementElectrolysisSecondary loss

The invention provides a comprehensive recycling technique of valuable elements in smelting soot, which comprises the steps of: adding sulfuric acid in the smelting soot to pulpify the same, leaching for twice, and filter pressing the smelting soot to form lead-silver-bismuth slag; smelting, casting, electrolyzing, refining and reducing and smelting the lead-silver-bismuth slag in a converter to obtain rough lead, copper matte, pure bismuth and silver-zinc slag; adding cupric hydroxide in the supernatant to deposit arsenic, depositing the copper in the copper arsenate slag with deposited arsenic to form copper-arsenic solution, concentrating, crystallizing, dissolving and separating the solution to obtain white arsenic and cupric sulfate solution; performing twice electrodeposition treatments on the copper-zinc-cadmium solution with deposited arsenic to respectively obtain electrolytic copper and black copper, sequentially adding zinc oxide and zinc powder to perform deacidification, high-temperature copper removal and low-temperature cadmium removal treatments to obtain sponge cadmium, smelting the sponge cadmium to obtain rough cadmium, concentrating and crystallizing the zinc sulfate solution to obtain heptahydrate zinc sulfate. The comprehensive recycling technique provided by the invention has the advantages of improving the recovery of multiple metals, having extensive treatment raw materials, low production cost and high economic benefit, and avoiding the secondary pollution of decentralized processing and secondary loss of valuable metals.

Owner:SHANDONG FANGYUAN NON FERROUS METAL TECH SERVICE

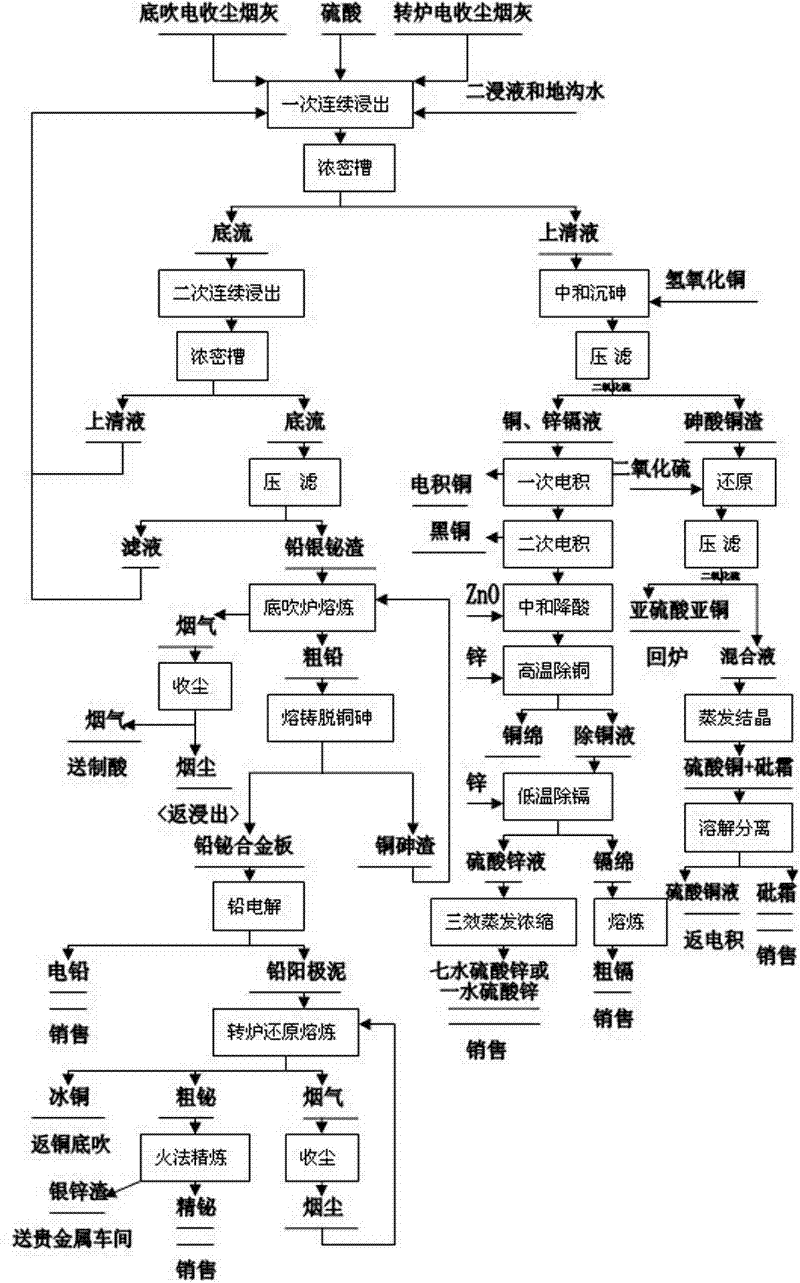

Method for removing arsenic in arsenic-containing smoke dust and recovering valuable metals

ActiveCN108998657AExtended service lifeLow running costAntimony compoundsProcess efficiency improvementWhite arsenicFiltration

The invention discloses a method for removing arsenic in arsenic-containing smoke dust and recovering valuable metals, and belongs to the field of metallurgical environmental protection. The method for removing arsenic in arsenic-containing smoke dust and recovering the valuable metals has the effect of separating and purifying the arsenic-containing smoke dust to obtain refined white arsenic. According to the key points of the technical scheme, the method for removing arsenic in arsenic-containing smoke dust and recovering the valuable metals comprises the steps that raw materials are mixed;roasting and arsenic removing are carried out; filtration is carried out by a high temperature membrane, specifically, the arsenic-containing smoke gas obtained by roasting is filtered by the high-temperature membrane, the filtering temperature interval is controlled to be 250-600 DEG C to obtain low-arsenic smoke dust and filtered arsenic-containing smoke gas, and the low-arsenic smoke dust is returned to the raw material mixing step; initial cooling is carried out; and secondary cooling is carried out to obtain the refined white arsenic. According to the method for removing arsenic in arsenic-containing smoke dust and recovering the valuable metals, through filtration by the high-temperature membrane, the effects of prolonging the service life of a filtering membrane, reducing the operation cost of filtering equipment, reducing the total installed power and reducing the dust emission concentration after filtration can be achieved.

Owner:无锡市华易环境科技有限公司

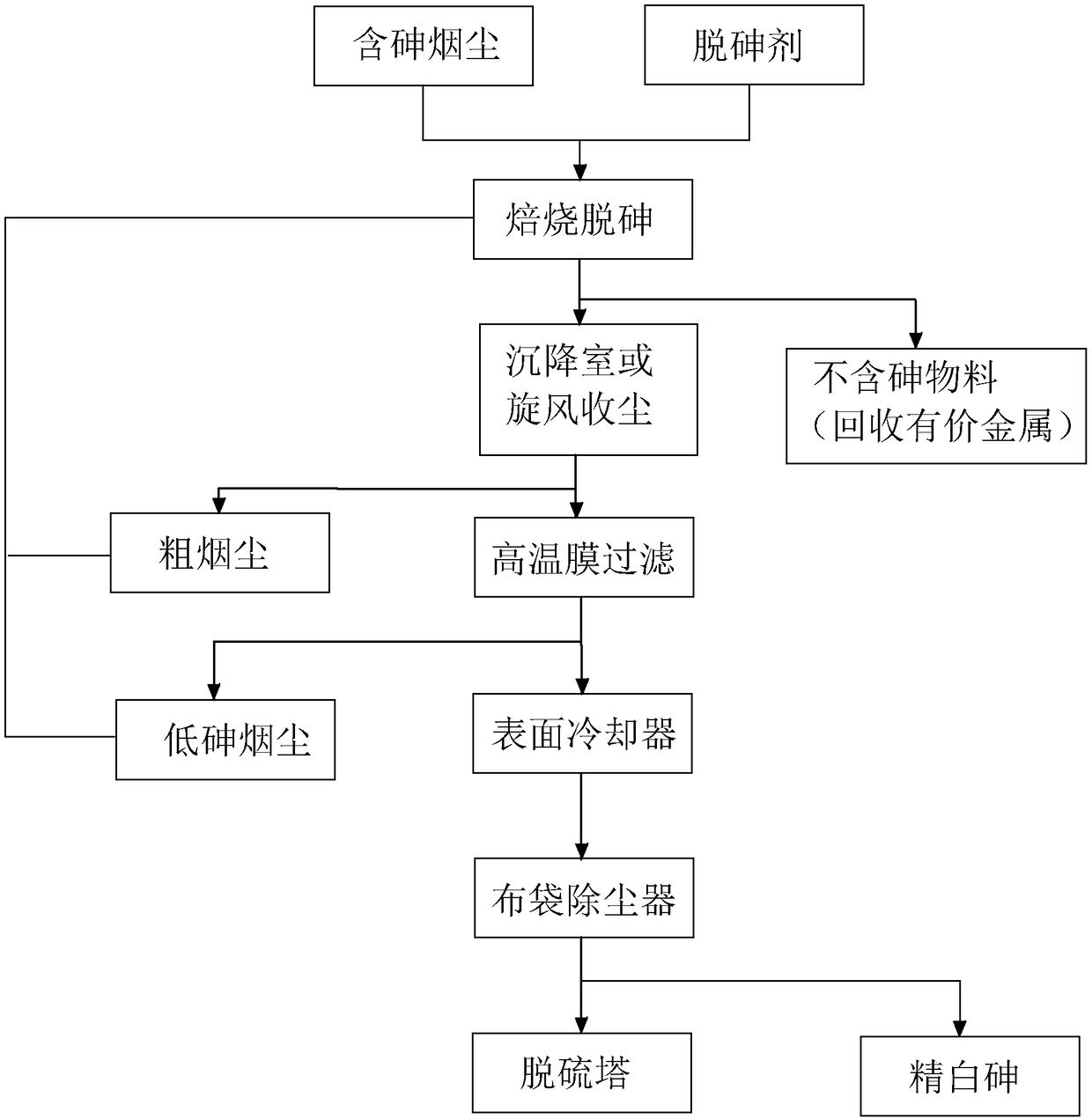

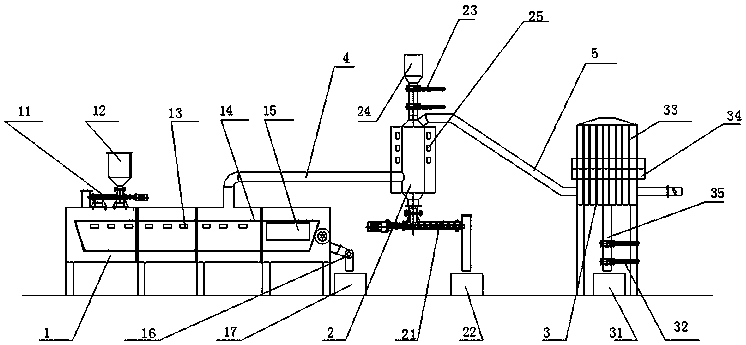

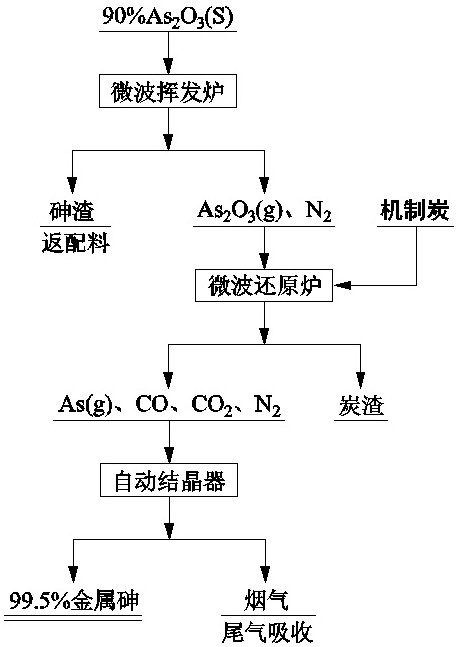

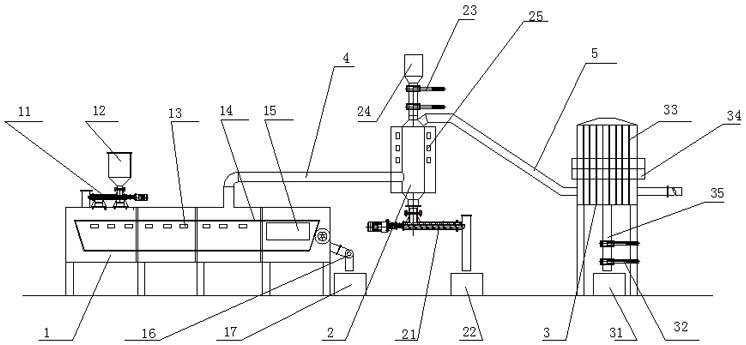

Technology and device for preparing metal arsenic from crude white arsenic

ActiveCN110747355AImprove thermal efficiencyReduce manufacturing costMicrowave heatingProcess efficiency improvementWhite arsenicEnvironmental engineering

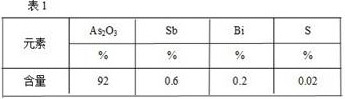

The invention provides a technology and device for preparing metal arsenic from crude white arsenic. The technology comprises the following technological steps: volatilizing crude arsenic trioxide ashcontaining As2O3 more than or equal to 90% at 600-700 DEG C to obtain arsenic trioxide steam, reducing the arsenic trioxide steam into arsenic steam by a reduction furnace accommodating machined carbon heated to 700-800 DEG C, and condensing the arsenic steam into metal arsenic containing As more than or equal to 99.5% by a crystallizer at 350-420 DEG C. The microwave metallurgy technology is applied to the technology of preparing metal arsenic from coarse white arsenic. The technology has the advantages of being low in production cost, high in thermal efficiency, environmentally friendly andenergy-saving, and product quality is good. The equipment has significant characteristics of high automation degree and high production efficiency.

Owner:SHANDONG HUMON SMELTING

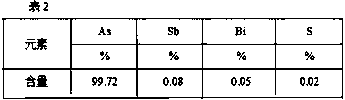

Method for efficiently separating copper and arsenic in copper smelting smoke dust

PendingCN108754167AEfficient separationSimple processProcess efficiency improvementSlagHydrometallurgy

The invention discloses a method for efficiently separating copper and arsenic in copper smelting smoke dust, and belongs to the technical field of wet metallurgy. The method comprises the steps of pulpifying the copper smelting smoke dust by adopting appropriate amount of water, a dilute sulphuric acid solution and a two-stage leaching solution, and leaching at the atmospheric pressure, wherein metallic oxide such as arsenic, copper, iron, zinc and cadmium in the smoke dust and salts are leached to enter a solution, and sulphides such as copper and arsenic hard to leach are remained in slags;and pressure leaching the leaching residues, so that the leaching rate of the arsenic and the copper is further improved, and the copper and the arsenic in the smoke dust are efficiently removed andrecycled. The invention provides the method for conveniently, quickly and efficiently removing the arsenic and the copper in the copper smelting smoke dust, so that the grade of slag containing lead and bismuth is improved; and the leaching solution is used for producing white arsenic or metal arsenic and recycling valuable metals such as the copper.

Owner:BEIJING MINING & METALLURGICAL TECH GRP CO LTD

Emulsion type automotive polishing agent and preparation method thereof

InactiveCN104559802AEasy to cleanReduce drynessSurface-active detergent compositionsSurface-active non-soap compounds and soap mixture detergentsMicrocrystalline waxCerium

The invention discloses an emulsion type automotive polishing agent. The emulsion type automotive polishing agent is prepared from the following components in percentage by weight: 10-20% of bee wax, 6-8% of oxidized microcrystalline wax, 1-4% of emulsified silicone oil, 1-2% of euphorbia kansui, 2-4% of dialkyl sodium benzenesulfonate, 4-8% of sodium citrate, 3-6% of kelps, 1-2% of a freshener, 5-8% of linalool, 1-2% of cerium dioxide, 4-6% of antimony oxide, 1-2% of white arsenic, 2-6% of malonic acid, 3-8% of sodium azide, 4-6% of sodium dihydrogen pyrophosphate and the balance of deionized water. The emulsion type automotive polishing agent has the advantages that a certain protective film is formed on the surface of the product when the product has a good cleaning effect, a process of drying after the cleaning process, and then polishing the car body are omitted, a protective film is formed by directly repairing the car body in the cleaning process and then attaching, the labor cost is reduced and the resources are saved.

Owner:TIANJIN YICHENG LONGDA ENVIRONMENTAL PROTECTION TECH DEV

Crashing-resistant glass cup and preparing method thereof

The invention discloses a crashing-resistant glass cup and a preparing method thereof. The preparing method includes the steps that white arsenic, silicon carbide, decolorizing agent, grinding agent, corrosion inhibitor, adhesive, silica, sodium carbonate and talcum powder are stirred and mixed to prepare a powder material; the powder material is heated to prepare into glass molten lava; the glass molten lava is mechanically formed; annealing is carried out, and the crashing-resistant glass cup is prepared; relative to 200 by weight parts of the talcum powder, the crashing-resistant glass cup is prepared from 10-25 by weight parts of the white arsenic, 10-30 by weight parts of the silicon carbide, 10-30 by weight parts of the decolorizing agent, 10-15 by weight parts of the grinding agent, 25-40 by weight parts of the corrosion inhibitor, 10-20 by weight parts of the adhesive, 10-30 by weight parts of the silicon dioxide and 10-25 by weight parts of the sodium carbonate. The crashing-resistant glass cup prepared with the method has the excellent mechanical performance.

Owner:安徽金生金世电子科技有限公司

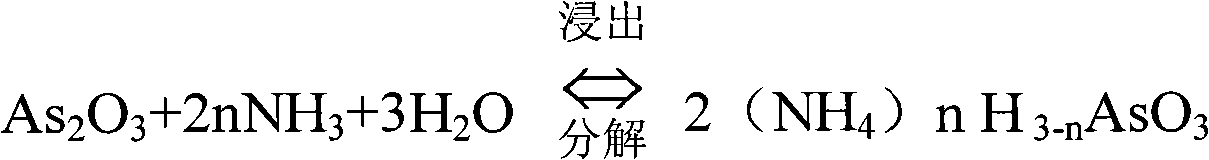

Process for purifying coarse arsenic

The invention provides a process for purifying coarse arsenic. The process is characterized in that: putting high-arsenic dust in a sealed reaction kettle, adding 2.0 to 8.0mol / L ammonia water in a liquid-solid ratio of 1.0-5.0:1 into the reaction kettle to perform a reaction for 2 to 6 hours at the temperature of between 30 and 65 DEG C; heating the mixed solution so as to evaporate excessive ammonia, making the distilled ammonia absorbed by an absorption tower, and after ammonia-absorbing solution is supplied with ammonia, returning the ammonia-absorbing solution for coarse arsenic extraction; after the ammonia is evaporated, filtering the mixed solution, washing residue by hot water in an amount which is 1 to 2 times the amount of the residue, returning filter residue for raw material dearsenization treatment, and performing impurity removing treatment of filtrate; heating feed liquid for evaporation and crystallization, and removing the adsorption water by drying; and heating the dried crystals in a decomposition furnace to between 200 and 600 DEG C for decomposition, collecting solids of white arsenic, and making decomposed gas enter the ammonia absorption tower for absorption so as to recover the ammonia. In the process of the invention, a wet method and a dry method are combined to pure the white arsenic, so that the production cost is greatly lowered, less raw materials are consumed, the total yield of arsenic is high, the circulation is realized in the whole process, and waste gas, water and solid are emitted.

Owner:NANCHANG UNIV

White arsenic local slow release chemical therapeutic medicine for treating malignant brain tumor

InactiveCN1615905AInorganic active ingredientsPharmaceutical delivery mechanismHydrolysisWilms' tumor

The present invention discloses a slowly releasing system of white arsenic and biodegradable polymer as local chemotherapeutic medicine. It is implanted into the operation area after excising malignant tumor for post-operational treatment to prolonging the survival period of the malignant tumor patient. Through a compounding process, antitumor white arsenic is fused into biodegradable polymer in the amount of 3-6 times white arsenic weight. The biodegradable polymer may be PLA, PGA, PLGA and / or PFAD-SA. By means of corrosion and hydrolysis of the polymer, the medicine is released slowly, continuously and stably to act. The present invention is used in the local slowly releasing chemotherapy of malignant tumor in other system.

Owner:赵世光

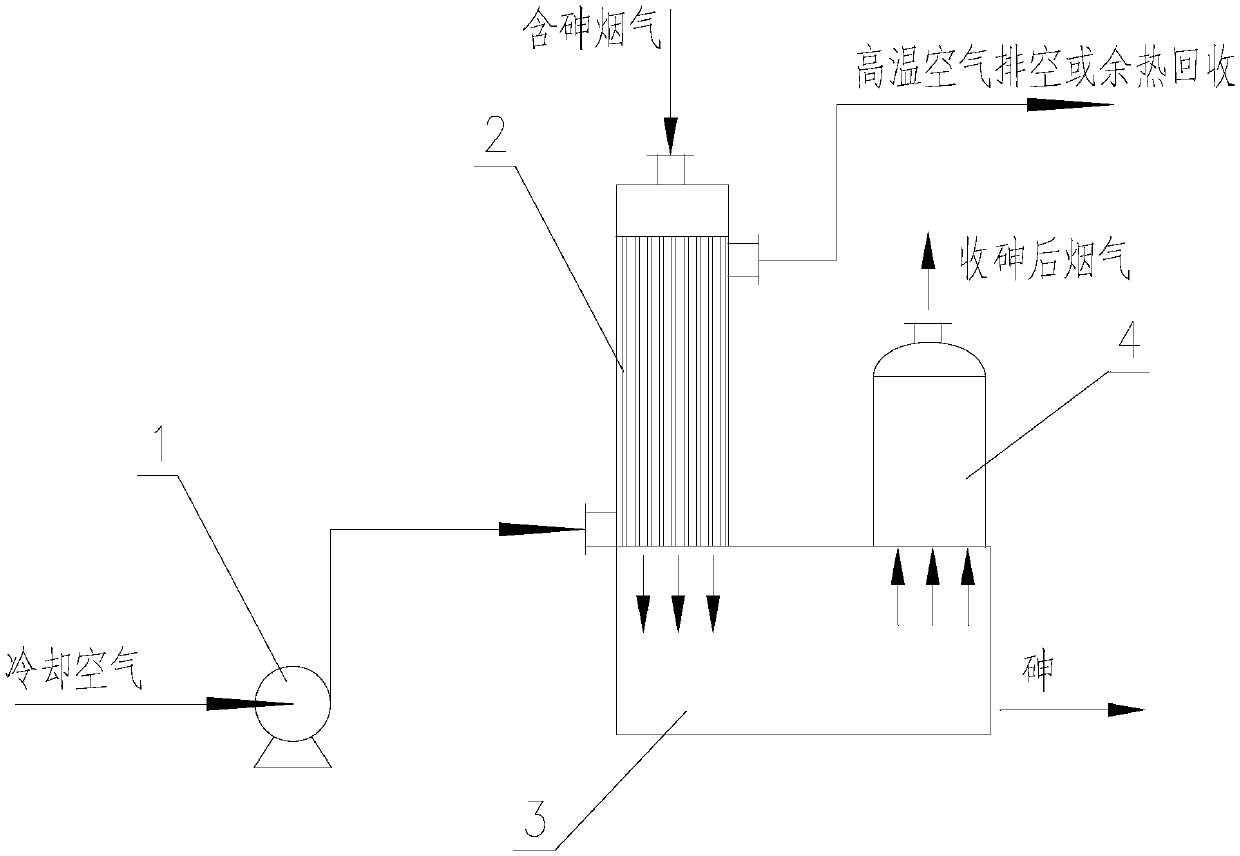

Method for collecting arsenic from smelting flue gas by dry process

InactiveCN109553131ADoes not increase water vapor contentNot corrodedArsenic oxides/hydroxides/oxyacidsWhite arsenicBaghouse

The invention discloses a method for collecting arsenic from smelting flue gas by a dry process, and belongs to the field of comprehensive recycling of metallurgical waste gas. The method comprises the steps of: 1) quenching: arsenic-containing high-temperature smelting flue gas rapidly passes through a quencher for indirect cooling; 2) settling collection of arsenic: after the quenched flue gas enters a settler, white arsenic and smoke dust in the flue gas in the settler naturally settle to the bottom of the settler, and the flue gas subjected to settling is discharged from an upper flue gasoutlet, and arsenic is collected from an outlet at the bottom of the settler; and 3) electrostatic collection of arsenic: the flue gas discharged from the top of the settler enters an electrostatic demister, a small amount of residual white arsenic and smoke dust in the flue gas is collected, and the collected white arsenic and smoke dust fall into the settler. The method of the invention does notintroduce water into the flue gas, and does not reduce the dew point of the flue gas; the settler can collect dust with dew; no corrosion to equipment and pipelines are ensured; glass arsenic and thelike are prevented from blocking a bag type deduster and causing paralysis of a system; the method is applicable to smelting flue gas under different working conditions through a frequency-conversionfan; and the method can reduce sewage generated by the process.

Owner:CINF ENG CO LTD

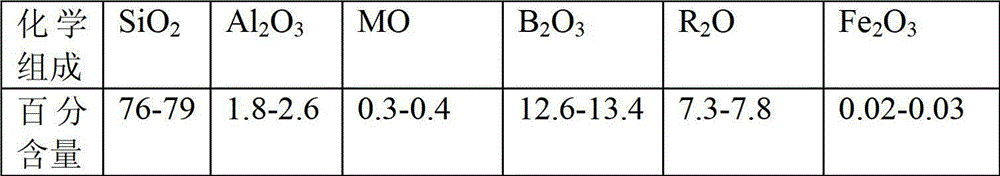

Formula and preparation method for first-level waterproof glass molding injection bottle glass

The invention relates to a formula and a preparation method for first-level waterproof glass molding injection bottle glass, and belongs to the field of pharmaceutical glass infusion bottles. The first-level waterproof glass molding injection bottle glass comprises the following raw materials: by mass, 76-79% of SiO2, 1.8-2.6% of Al2O3, 0.3-0.4% of MO, 12.6-13.4% of B2O3, 7.3-7.8% of R2O and 0.02-0.03% of Fe2O3. The melting quality is ensured, and the gas ratio is relatively low. Cold heading melting is adopted, so that the volatilization of the raw materials is reduced, and the pollution of the air is reduced. Cerium oxide is used for replacing white arsenic as a fining agent, so that the remaining of toxic components in the glass is avoided, and safety of use is promoted.

Owner:SHANDONG PHARMA GLASS

Beer bottle glass and preparation method thereof

InactiveCN104086082AHigh strengthThe method steps are simpleGlass shaping apparatusCalciteShock resistance

The invention discloses a beer bottle glass and a preparation method thereof. The method comprises the following steps: 1) mixing and melting quartz sand, sodium carbonate, calcite, wood charcoal, white arsenic, mirabilite, copper sulfate, aluminum oxide and potassium dichromate at 1400-1550 DEG C to prepare a melt; 2) casting the melt at 1200-1250 DEG C to obtain a primary finished product; and 3) annealing the primary finished product at 540-560 DEG C to obtain the beer bottle glass. The beer bottle glass disclosed by the invention has the advantages of thin wall, excellent internal pressure resistance and excellent shock resistance.

Owner:XIN LI DE GLASS PROD

Method for preparing arsenic-containing borosilicate glass through arsenic solid waste treatment

ActiveCN112919801AEffective disposal of solid wasteReduce the impactGlass furnace apparatusEngineeringWaste treatment

The invention relates to a method for preparing arsenic-containing borosilicate glass through arsenic solid waste treatment. The method comprises the following steps: preparing arsenic-containing solid waste into mixed valence arsenate through a purification process, uniformly mixing the mixed valence arsenate and silicon dioxide as main glass raw materials, heating and melting uniformly, and cooling and curing to obtain transparent or milk white arsenic-containing borosilicate glass. The glass comprises the following raw materials in percentage by mass: 60-80% of silicon dioxide and 2-20% of mixed valence arsenate. When the precipitation amount of the prepared arsenic-containing borosilicate glass is detected according to the GB19778-2005 standard, the arsenic precipitation amount is less than or equal to 0.02 mg / dm < 2 >; and the arsenic precipitation amount is detected to be less than or equal to 0.24 mg / L according to a GB / T5086.1 standard method. According to the method, solid waste of nonferrous metal can be effectively treated, recycling is achieved, influence on the environment is reduced, the method is more environmentally friendly and low in cost, and compared with other arsenic-containing borosilicate glass, the prepared arsenic-containing borosilicate glass has the advantages of being transparent, high in heat resistance, excellent in chemical stability and extremely low in arsenic precipitation amount.

Owner:深圳市新能通环境科技有限公司

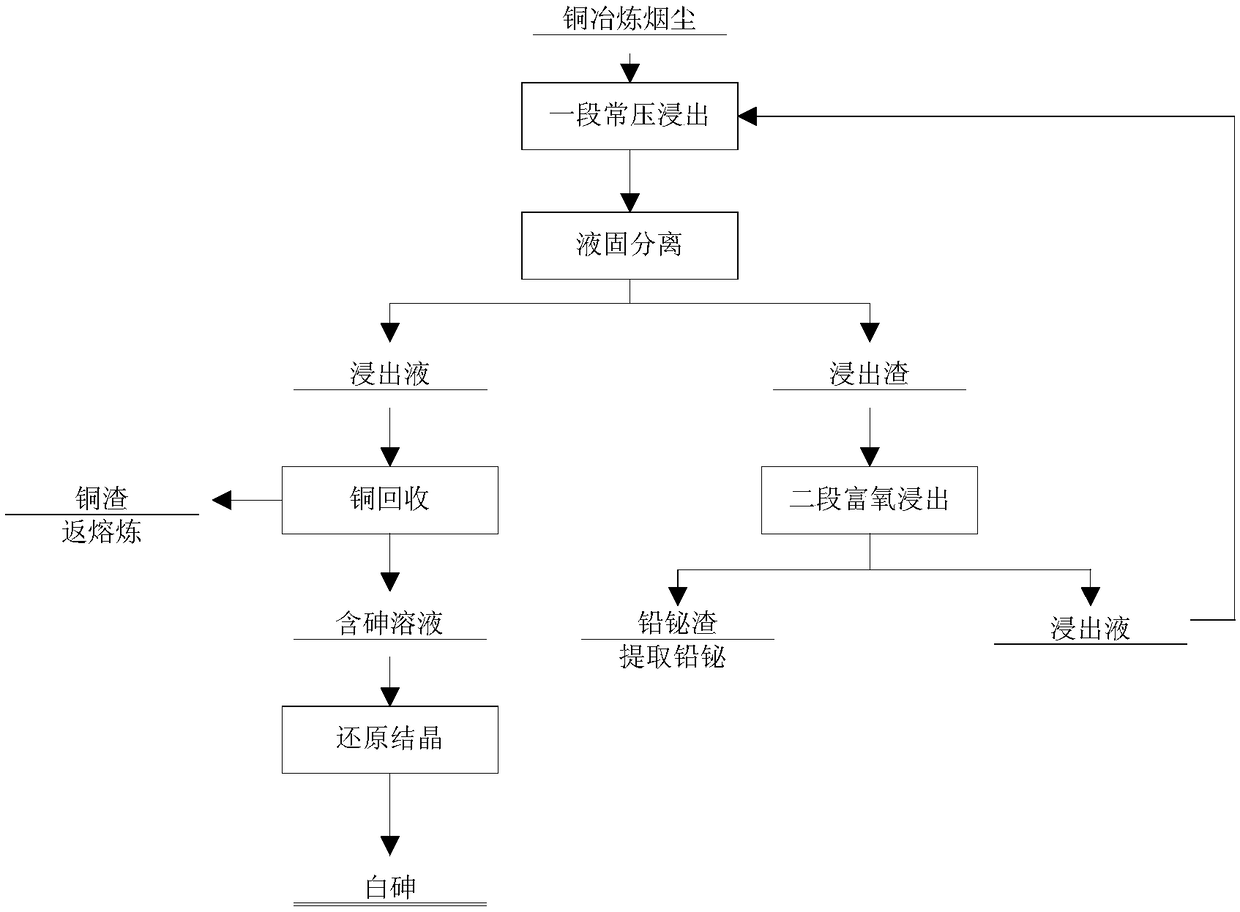

Method for resource utilization of copper smelting smoke

ActiveCN112251609AEfficient resource utilizationAchieve reductionCement productionProcess efficiency improvementWhite arsenicRestorative material

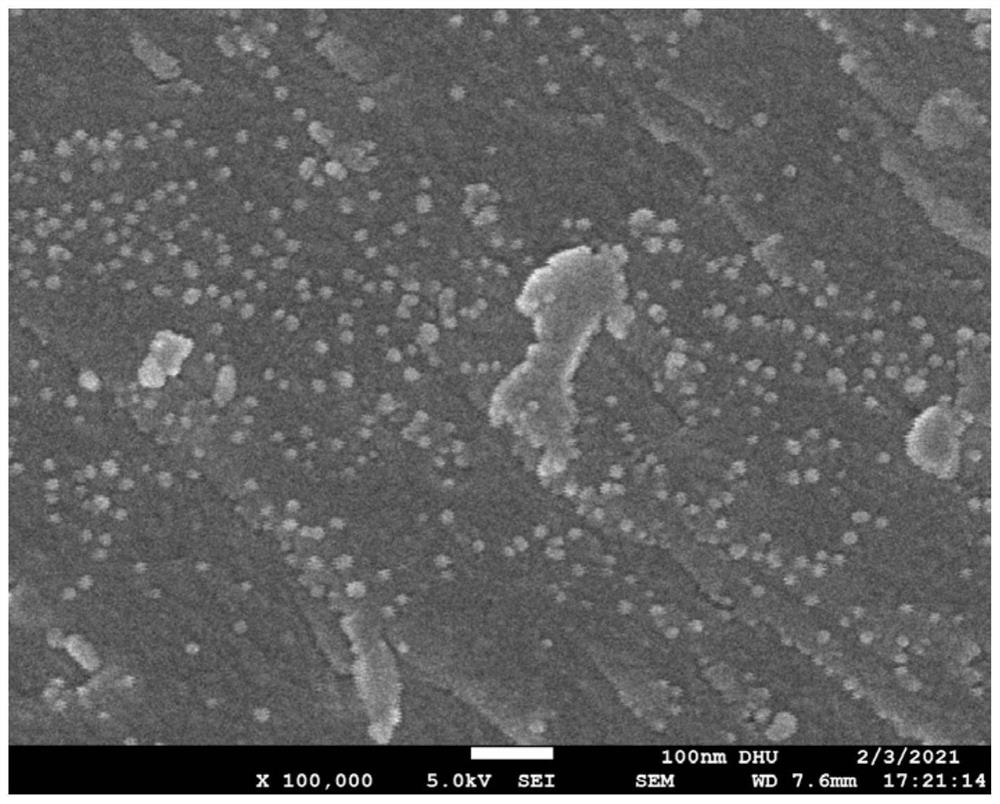

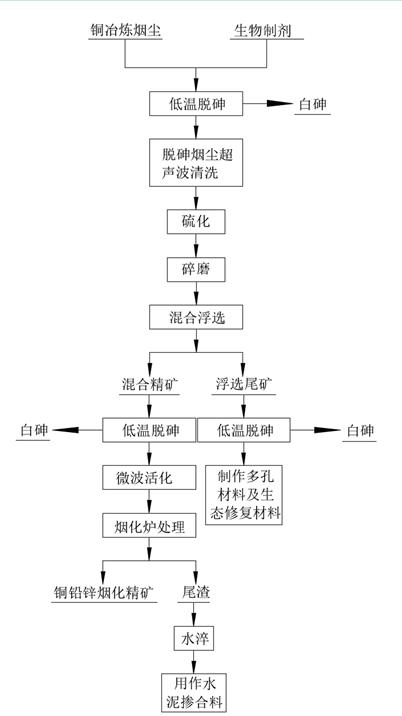

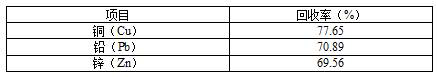

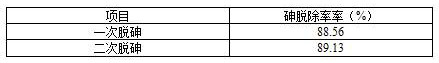

The invention discloses a method for resource utilization of copper smelting smoke. The method comprises the following steps of mixing the copper smelting smoke dust with a biological agent, performing low-temperature arsenic removal to obtain white arsenic and arsenic-removed smoke dust, performing ultrasonic cleaning on the arsenic-removed smoke dust, then conducting vulcanizing to obtain a pretreated arsenic-removed smoke dust material, grinding the material, and performing bulk flotation to obtain flotation bulk concentrate and flotation tailings; adding the biological agent into the flotation bulk concentrate and the flotation tailings respectively, performing low-temperature arsenic removal to obtain white arsenic, arsenic-removed bulk concentrate and arsenic-removed tailings, performing microwave activation on the arsenic-removed bulk concentrate, enabling the arsenic-removed bulk concentrate to enter a fuming furnace for treatment, and promoting valuable metals such as copper,lead and zinc in the bulk concentrate to volatilize to form smoke dust; and then conducting collection through a bag collector to obtain copper-lead-zinc fuming concentrate, discharging fuming furnacetailings from the tail of a furnace body, and obtaining mineral powder after water quenching treatment, wherein the mineral powder can be used as a cement admixture, and the arsenic-removed tailingscan be used for manufacturing porous materials and ecological restoration materials.

Owner:云南省生态环境科学研究院

Toxicopathy treating composite medicine

The Chinese medicine composition for curing toxipathy resulted from taking hypertoxin medicines of guangdan, medicinal materials of eighteen clashes, raw aconite main tuber, raw wild aconite tuber, nux vomica, white arsenic and tengwang, etc. is made from 13 Chinese medicinal materials of Chinese angelica root, dried / fresh rehmannia, ledebouriella root, schizonepeta, plantago seed, fennel fruit and others. Said invented medicine can also be used for curing headache and common cold, etc.

Owner:熊火则

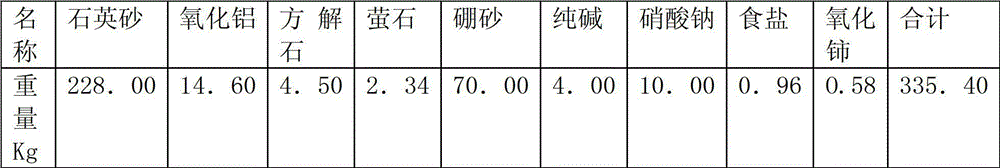

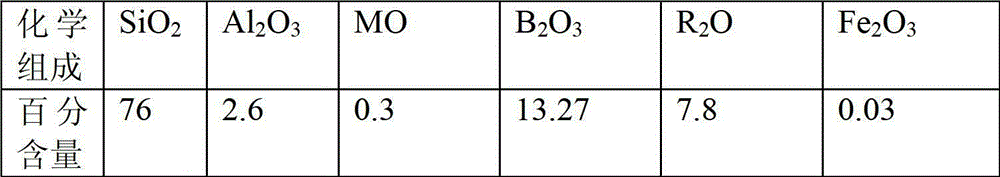

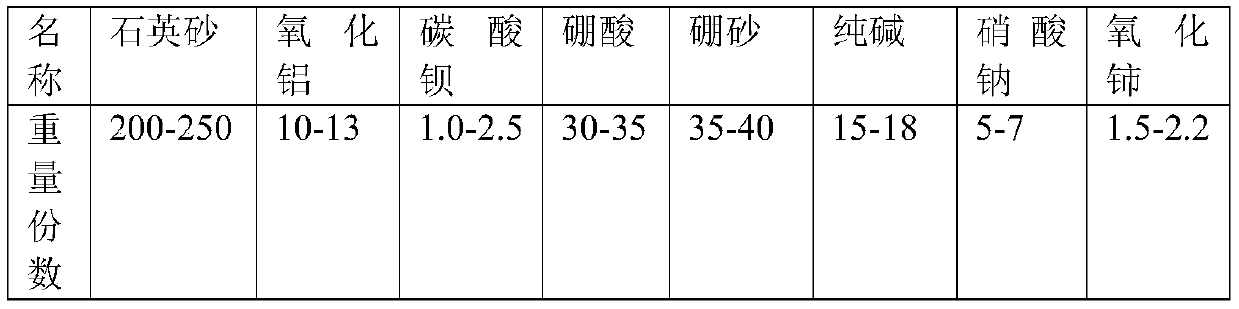

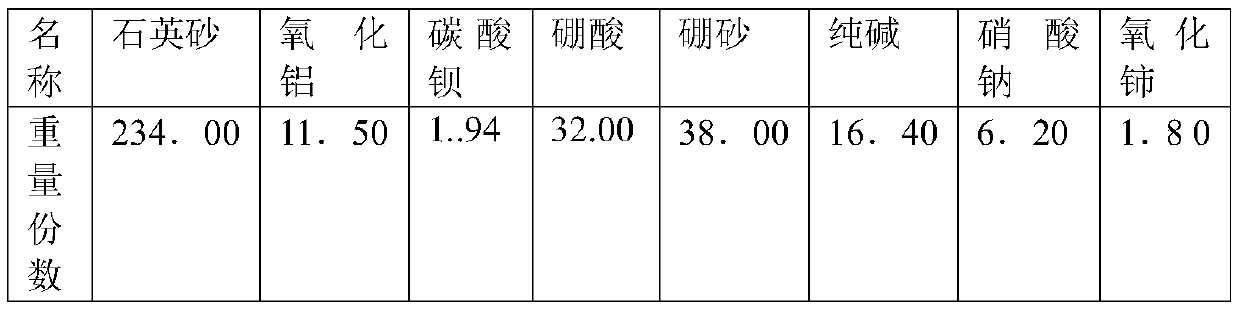

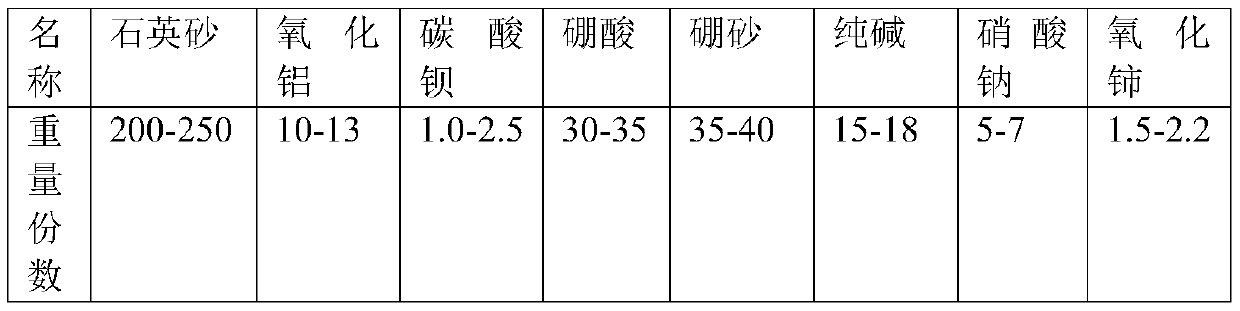

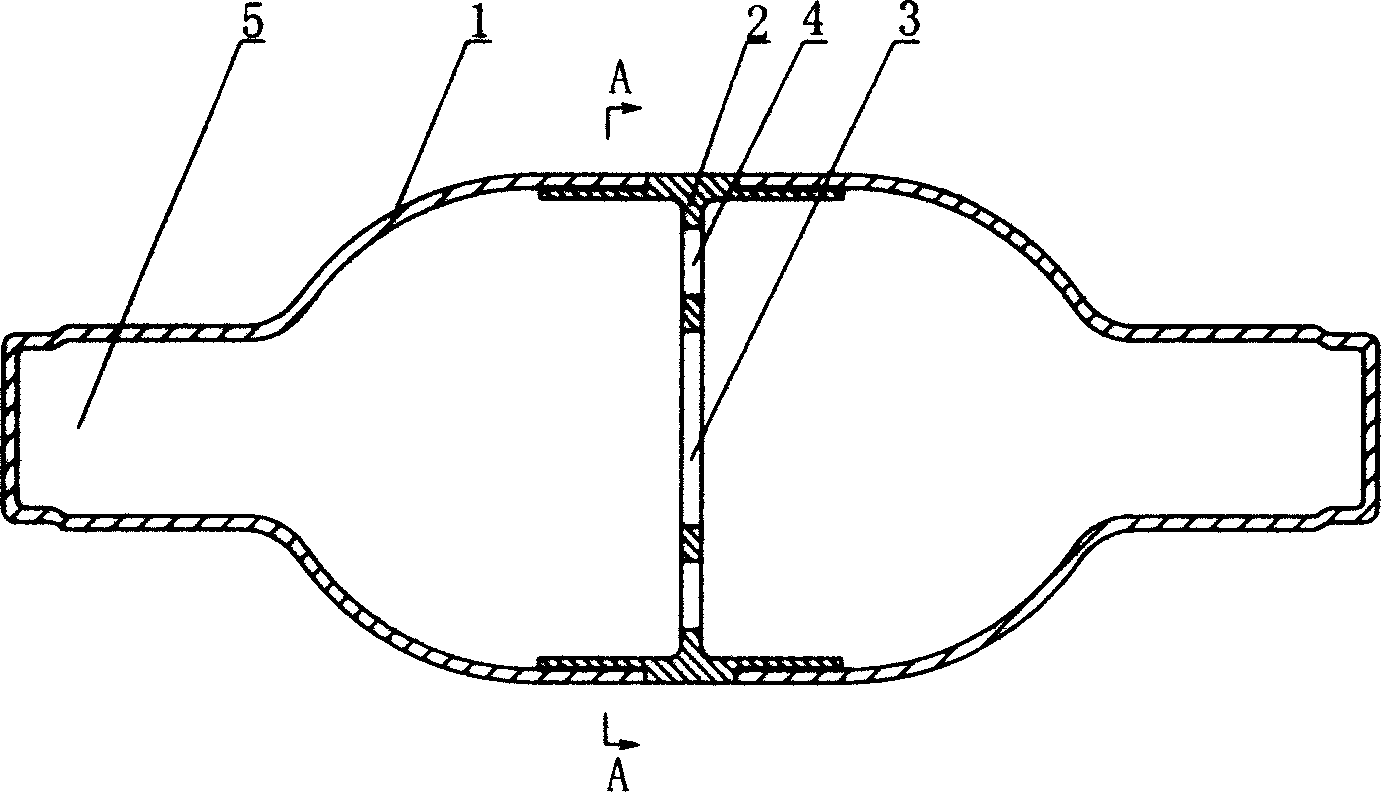

Medium borosilicate glass injection agent bottle for small-dose injection

The invention relates to a medium borosilicate glass injection agent bottle for small-dose injection, and belongs to the field of medicinal glass. The medium borosilicate glass injection agent bottleis prepared from the following raw materials in parts by mass: 200 to 250 parts of quartz sand, 10 to 13 parts of aluminum oxide, 1.0 to 2.5 parts of barium carbonate, 30 to 35 parts of boric acid, 35to 40 parts of borax, 15 to 18 parts of sodium carbonate, 5 to 7 parts of sodium nitrate and 1.5 to 2.2 parts of cerium oxide. According to the invention, by reasonably matching SiO2, Al2O3, B2O3, Na2O and other components in the formula, the performances of glass can meet the neutral requirements; the gas rate is low, and a cold top melting mode is adopted, so that the volatilization of the rawmaterials is reduced, and the pollution to the atmosphere is reduced; and cerium oxide is used as a clarifying agent to replace white arsenic, so that the residue of toxic components in the glass areavoided, and the use safety is improved.

Owner:SHANDONG PHARMA GLASS

Traditional Chinese medicine composition for treating psoriasis and preparation method thereof

InactiveCN108186683AAnti-itch and insecticidalRealgar is highly toxicHeavy metal active ingredientsUnknown materialsConvulsionCinnabar

The invention belongs to the field of processing of traditional Chinese medicines and particularly provides a traditional Chinese medicine composition for treating psoriasis. The traditional Chinese medicine composition is prepared by adopting sulfur, realgar, cinnabar, sanandana, white arsenic, beewax and sesame oil as raw materials, crushing the raw materials, adding in sequence, heating, mixinguniformly, condensing into solid and preparing into a finished product. The traditional Chinese medicine composition for treating psoriasis provided by the invention has the beneficial effects of eliminating necrotic tissues and promoting granulation, clearing heat and removing toxicity, clearing heart fire and relieving convulsion, diminishing inflammation and relieving pain, stopping itching and promoting blood circulation, and is fast in effect, convenient in use and difficult in relapse. The sulfur has strong effects of stopping itching and killing sarcoptic mites and is a principal drugfor treating the psoriasis; the realgar is strong in toxicity and better in toxicity-removing and furuncle-treating effect; the cinnabar has the effects of clearing heart fire and relieving convulsion, calming the nerves, improving the eyesight and removing toxicity; the hydrargyrum oxydatum crudum has the effects of drawing out toxins and pus, generating new blood, corroding furuncle and eliminating necrotic tissues; the white arsenic has the effects of killing the sarcoptic mites, removing phlegm and preventing malaria; the beewax has the effects of removing toxicity, promoting granulation and relieving pain; the sesame oil has the effects of enriching blood and promoting body-fluid production, improving blood circulation, promoting metabolism, diminishing inflammation and stopping itching.

Owner:王晓华

Withered pipe strip for treating haemorrhoids and preparation method of withered pipe strip

InactiveCN105477192AGood treatment effectQuick resultsAmphibian material medical ingredientsHeavy metal active ingredientsCinnabarSide effect

The invention discloses a withered pipe strip for treating haemorrhoids and a preparation method of the withered pipe strip. The withered pipe strip is prepared from the following components in parts by weight: 3-8 parts of bear gall, 3-8 parts of goldthread root, 12-18 parts of lilac daphne flower buds, 2-4 parts of musk, 12-18 parts of cinnabar, 12-18 parts of frankincense, 50-70 parts of dried alum, 10-15 parts of calomel, 3-8 parts of venenum bufonis, 20-40 parts of the top of the skull of a black dog, 15-25 parts of pulp of fructus mume, 6-15 parts of realgar, and 6-15 parts of white arsenic. The preparation method comprises the following steps: firstly grinding bear gall, goldthread root, venenum bufonis, the top of the skull of a black dog and dried alum into fine medicinal powder, placing the fine medicinal powder into a Yangcheng pot, adding charcoals for calcination, taking out, and placing on the wet ground for removing fire toxins; grinding cinnabar, realgar, frankincense, lilac daphne flower buds, musk, calomel, pulp of fructus mume and white arsenic into fine medicinal powder; disinfecting the mixed fine medicinal powder, blending by using water, placing on the fire, stirring to form paste, and uniformly blending the medicinal powder; and twisting the pasty medicinal powder after being uniformly blended into needle-shaped strips, and drying the needle-shaped strips in the shade for later use. The withered pipe strip for treating haemorrhoids is good in treatment effect, rapid in taking effect, short in course of treatment, and free of side effects, and the cure rate achieves 100%.

Owner:刘昌林

A comprehensive recovery process for arsenic, copper and bismuth in copper-bismuth slag

ActiveCN112609085BEasy to separateEfficient recyclingProcess efficiency improvementLead smeltingHydrolysis

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

Respiratory medicine for treating cancer, production method there for and specific application tool

The present invention discloses a pure Chinese medicine preparation for curing carcinomatosis by adopting respiratory medication mode, its preparation method and special-purpose application device. Said medicine preparation is made up by using 6 Chinese medicinal materials of musk, croton seed, white arsenic, sulfur, castor bean and jujube through a certain preparation process.

Owner:张荷香

Process for comprehensively recovering arsenic, copper and bismuth from copper-bismuth slags

ActiveCN112609085AEasy to separateEfficient recyclingProcess efficiency improvementLead smeltingCopper sulfate

The invention relates to a process for comprehensively recovering arsenic, copper and bismuth from copper-bismuth slags. The process for comprehensively recovering the arsenic, the copper and the bismuth from the copper-bismuth slags comprises the following steps of carrying out oxygen pressure leaching on the copper-bismuth slags in a sulfuric acid system by taking the copper-bismuth slags generated by sulfuration fractional precipitation of copper-bismuth-containing acidic waste liquid generated by acid production from copper smelting flue gas as a research object, then adding the copper-bismuth slags into the leaching slurry, replacing arsenic sulfide in the copper-bismuth slags with copper sulfate in the slurry, reducing pentavalent arsenic into trivalent arsenic by the copper-bismuth slags, and filtering to obtain a trivalent arsenic solution and a slag phase; evaporating, concentrating, cooling and crystallizing the trivalent arsenic solution to obtain a white arsenic product; adding sodium chlorate and hydrochloric acid into the slag phase under a normal pressure condition to leach the copper and the bismuth, firstly adding a dilute alkali solution into leachate to carry out hydrolysis reaction so as to generate bismuth oxychloride, carrying out solid-liquid separation, and adding solid alkali into filtrate to neutralize the solution so as to recover copper; and returning leaching residues to a lead smelting system to recover the lead, and returning hydrolysate to the leaching procedure of copper and bismuth. The process for comprehensively recovering the arsenic, the copper and the bismuth from the copper-bismuth slags provided by the invention is short in technological process, economical, applicable, free of pollution and low in energy consumption, and efficient separation and comprehensive recovery of the arsenic, the copper and the bismuth are achieved.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

Beer bottle glass and preparation method thereof

InactiveCN104086082BHigh strengthThe method steps are simpleGlass shaping apparatusInternal pressureWhite arsenic

The invention discloses a beer bottle glass and a preparation method thereof. The method comprises the following steps: 1) mixing and melting quartz sand, sodium carbonate, calcite, wood charcoal, white arsenic, mirabilite, copper sulfate, aluminum oxide and potassium dichromate at 1400-1550 DEG C to prepare a melt; 2) casting the melt at 1200-1250 DEG C to obtain a primary finished product; and 3) annealing the primary finished product at 540-560 DEG C to obtain the beer bottle glass. The beer bottle glass disclosed by the invention has the advantages of thin wall, excellent internal pressure resistance and excellent shock resistance.

Owner:XIN LI DE GLASS PROD

Degradable packaging foam material and preparation method thereof

InactiveCN108715660AIncreased degradation rateImprove mechanical propertiesFlexible coversWrappersWhite arsenicTri calcium phosphate

The invention discloses a degradable packaging foam material and a preparation method thereof, belonging to the field of glass production field. The degradable packaging foam material contains the following components: quartz sand, glass cullet, industrial alkali, sodium nitrate, white arsenic, antimony trioxide, borax, vanadium trioxide, iron oxide, manganese trioxide, high-molecular-weight dimethicone, tricalcium phosphate micropowder and corn oligopeptide powder. The degradable packaging foam material is prepared by the steps of fusion, frothing, secondary frothing, formation and the like.By utilizing high-molecular-weight dimethicone, the tricalcium phosphate micropowder and the corn oligopeptide powder as a reinforcing system, the degrading rate of a glass product is increased, and the mechanical properties and effects of the glass product are improved.

Owner:长沙浩然医疗科技有限公司

A traditional Chinese medicinal prescription for removing toxic materials, dredging collaterals, and relieving pain, and an ointment thereof

InactiveCN109200107ATo achieve the purpose of self-healingTo achieve the purpose of dispelling poison and clearing the collaterals, clearing the side without painHeavy metal active ingredientsHydroxy compound active ingredientsMentholDisease

The invention relates to a traditional Chinese medicine prescription, in particular to a traditional Chinese medicinal prescription for removing toxic materials, dredging collaterals, and relieving pain, and an ointment thereof. The prescription comprises the following ingredients in parts by mass: 0.5-1.5 parts of muscone, 5-15 parts of toad venom powder, 1-3 parts of white arsenic, 4-6 parts ofcalomel, 0.5-1.5 parts of salmiacum, 15-25 parts of menthol, 6-8 parts of lodinketn, and 15-25 parts of pendulous monkshood root. The prescription and the ointment are used for treating rheumatism, osteopathy and internal diseases of neck, shoulder, waist and leg, and can be used for removing toxin, dredging collaterals and relieving side pain.

Owner:吴国春

Medicine for treating pediatric acute gumboil and preparation method thereof

InactiveCN106491796AEffective treatmentPowder deliveryHydroxy compound active ingredientsSide effectWhite arsenic

The invention discloses a medicine for treating pediatric acute gumboil and a preparation method thereof. The medicine is mainly prepared from white arsenic, borneol and golden cypress according to a certain weight ratio. The medicine has the functions of clearing heat, cooling blood, eliminating dampness, discharging fire, opening orifice, dispersing blood stasis and detoxifying, can take a quick response for the treatment of the pediatric acute gumboil, is good in treating effect and has no side effects.

Owner:侯颍

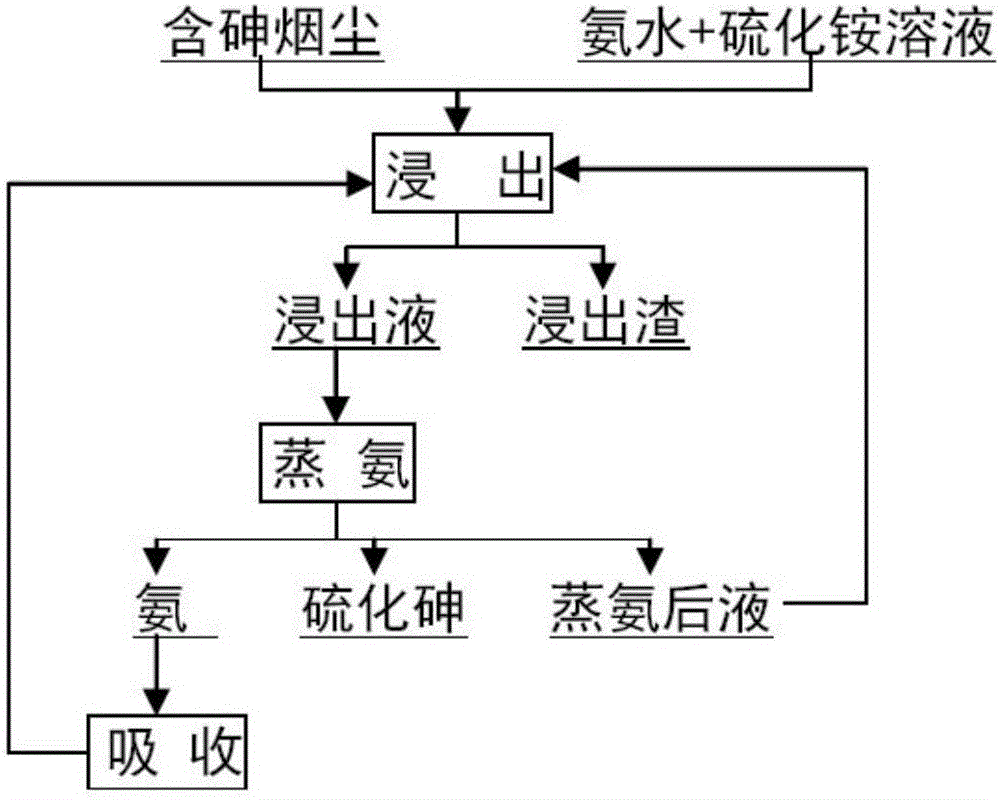

Method for removing arsenic from arsenic-contained smoke

ActiveCN105907982ALow toxicityAchieve selective removalProcess efficiency improvementAmmonium sulfideEvaporation

The invention provides a method for removing arsenic from arsenic-contained smoke, and belongs to the technical field of wet metallurgy. According to the method, arsenic is selectively leached out of the arsenic-contained smoke through ammonia and an ammonium sulfide solution, the arsenic is leached out to enter the solution, and valuable metal stays in residue; arsenic leaching liquid is subject to evaporation and deamination, and arsenic sulfide precipitation is obtained; ammonia generated through evaporation is absorbed and returns to leaching of the arsenic-contained smoke, and liquid obtained after ammonia evaporation returns to the leached-out arsenic-contained smoke; and according to the process, selective removing of arsenic is achieved, white arsenic obtained through volatizing of arsenic sulfide residue relative to the pyrogenic process is low in virulence, a reagent for leaching out is circularly used, and the method has the beneficial effects of being short in process flow and small in number of working procedures and can meet the clean production requirement.

Owner:UNIV OF SCI & TECH BEIJING

Solder sheet for black copper and silver production and preparation method thereof

ActiveCN109530965BWill not be damagedAchieve a beautifully integrated effectWelding/cutting media/materialsSoldering mediaWhite arsenicAlloy

The invention discloses a soldering sheet for manufacturing black copper with sliver running through and a preparation method thereof. The soldering sheet for manufacturing black copper r with sliverrunning through is prepared from, by mass: 100 parts of sliver powder, 15-25 parts of red copper, 10-15 parts of zinc powder, 2-5 parts of salt, and 0.2-0.8 part of white arsenic. The method comprisesthe steps that after mixing the components, heating the components to melt into an alloy and then making the alloy into a sheet, that is, the soldering sheet is completed; cutting the soldering sheetinto small pieces according to the size of the to-be-welded black copper with sliver running through, proportionally mixing the sodium borate and water, stirring and heating the mixture of the sodiumborate and water; painting the mixture on weld bonds or welded joints, dipping the smaller pieces into the mixture and heating by a welding gun, and then the weld bonds or welded joints can be welded. The soldering sheet for manufacturing black copper with sliver running through and the preparation method thereof enable the welded parts to stay firm without falling-off and the soldering flux smooth. The welding temperature is proper, the sliver grain pattern is not damaged and the silver in the gains neither is melted by heating nor flows out, so that the effect of the elegant combination ofthe black copper and the silver is achieved. The soldering sheet for manufacturing black copper with sliver running through and the preparation method thereof effectively improve the efficiency of manufacturing black copper with silver running through. The operation is convenient and the effect is lasting.

Owner:云南乌铜走银文化产业有限公司

Process and equipment for preparing metallic arsenic from crude white arsenic

ActiveCN110747355BImprove thermal efficiencyReduce manufacturing costMicrowave heatingProcess efficiency improvementWhite arsenicPhysical chemistry

The invention provides a process and equipment for preparing metal arsenic from crude white arsenic, comprising the following process steps: containing As 2 O 3 ≥90% of the crude arsenic trioxide soot is volatilized at 600℃~700℃ to obtain arsenic trioxide vapor. The arsenic trioxide vapor is reduced to arsenic vapor through a reduction furnace equipped with mechanical carbon heated to 700℃~800℃, and the arsenic vapor passes through 350℃~420℃ The crystallizer condenses to contain As ≥ 99.5% metallic arsenic. The process applies microwave metallurgy technology to the process of preparing metal arsenic from crude white arsenic, and has the advantages of low production cost, high thermal efficiency, environmental protection and energy saving, and good product quality. The equipment has a high degree of automation and high production efficiency.

Owner:SHANDONG HUMON SMELTING

Compound anti-T2DM and vascular lesion preparation for treating diabetes great blood vessel complication and preparation method and usage method thereof

InactiveCN106266155AQuick resultsGood curative effectAmphibian material medical ingredientsOrganic active ingredientsToad VenomSide effect

The invention provides a compound anti-T2DM and vascular lesion preparation for treating diabetes great blood vessel complication. The compound preparation is prepared from, by weight, 0.05-0.07 part of white arsenic, 15-18 parts of tender willows, 19-21 parts of bitter gourds, 11-18 parts of five-leaf gynostemma herb, 12-15 parts of spinach roots, 12-16 parts of mung bean shells, 12-13 parts of bergamot, 2-9 parts of acanthopanax obovatus hoo, 2-4 parts of kiwi fruit roots and 3-8 parts of toad venom and is prepared through decoction with water. The preparation has is quick in effect, good in curative effect, free of toxic and side effects, non-poisonous, harmless and strong in curing effect and makes the complication not relapse.

Owner:刘江月

Medicament for treating psoriasis, skin stubborn dermatitis

InactiveCN101428061AHeavy metal active ingredientsAnthropod material medical ingredientsWhite arsenicCure rate

The invention discloses a medication for curing psoriasis and skin intractable tinea, which is prepared by taking white arsenic, dried alum, Chinese cantsarides, calomel and Chinese cinnamon as the raw materials to be matched with white vinegar in a processed manner. The invention adopts the method of fighting poison with poison of the Chinese traditional medicine to cure the patients with psoriasis and skin intractable tinea, the cure rate is above 92 percent, and the invention is a new breakthrough for curing the difficult and complicated dermatoses.

Owner:邓运春

Traditional Chinese medicine for curing bone tuberculosis

InactiveCN101721454AReach killAntibacterial agentsInorganic active ingredientsWhite arsenicPathogenic bacteria

In toxic traditional Chinese medicines curing bone tuberculosis, white arsenic (white), catechu and water are put into a utensil according to a certain quantity, the hands of a patient are fumigated by heating the utensil, the steam of the medicines infiltrates into a human body through pores to circulate along with blood and qi so as to combat poison with poison, the pathogenic bacteria of the bone tuberculosis are killed, and the bone tuberculosis is cured.

Owner:李屏松

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com