Method for resource utilization of copper smelting smoke

A copper smelting and recycling technology, applied in the field of metallurgy, can solve problems such as high process cost, arsenic pollution, and low arsenic recovery rate, and achieve the effect of simple process flow, good effect, and high resource utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

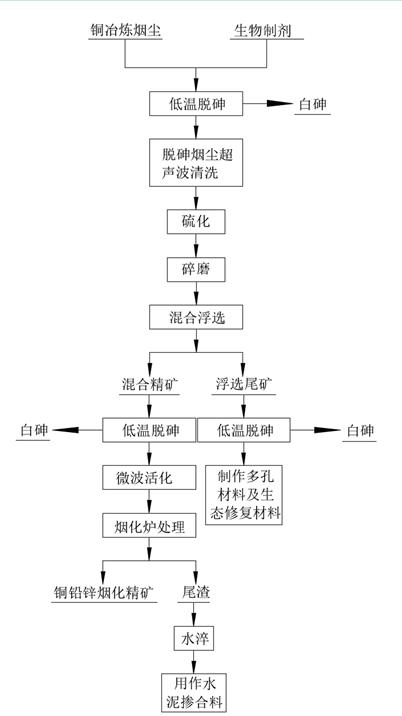

[0024] Embodiment 1: the method for resource utilization of copper smelting dust, such as figure 1 As shown, the specific steps are as follows:

[0025] (1) Fully mix the copper smelting dust and biological agent to obtain the mixed material. The biological agent is a mixture of sulfur-loaded biochar, microsilica fume, arsenic-enriched plant straw biochar, sulfuric acid and water. It is divided into 20% sulfur-loaded biochar, 20% micro-silica fume, 30% arsenic-enriched plant straw biochar, 10% sulfuric acid, and 20% water, and the quality of biological preparations accounts for 1% of the mass of copper smelting smoke. Carry out low-temperature dearsenization at 350°C to obtain white arsenic and dearsenic dust;

[0026] (2) Ultrasonic cleaning the arsenic removal dust obtained in step (1), and then performing vulcanization pretreatment to obtain the pretreated arsenic removal dust material;

[0027] (3) Grinding the pretreated arsenic-removing dust material in step (2) to -0....

Embodiment 2

[0035] Embodiment 2: the method for resource utilization of copper smelting dust, such as figure 1 As shown, the specific steps are as follows:

[0036] (1) Fully mix the copper smelting dust and biological agent to obtain the mixed material. The biological agent is a mixture of sulfur-loaded biochar, microsilica fume, arsenic-enriched plant straw biochar, sulfuric acid and water. Divided into 40% of sulfur-loaded biochar, 10% of silica fume, 20% of arsenic-enriched plant straw biochar, 15% of sulfuric acid, and 15% of water, and the quality of biological preparations accounted for 2% of the mass of copper smelting dust. Low-temperature dearsenization at 450°C to obtain white arsenic and arsenic removal dust;

[0037] (2) Ultrasonic cleaning the arsenic removal dust obtained in step (1), and then performing vulcanization pretreatment to obtain the pretreated arsenic removal dust material;

[0038] (3) Grinding the pretreated arsenic-removing dust material in step (2) to -0.0...

Embodiment 3

[0046] Embodiment 3: the method for resource utilization of copper smelting dust, such as figure 1 As shown, the specific steps are as follows:

[0047] (1) Fully mix the copper smelting dust and biological agent to obtain the mixed material. The biological agent is a mixture of sulfur-loaded biochar, microsilica fume, arsenic-enriched plant straw biochar, sulfuric acid and water. It is divided into 50% sulfur-loaded biochar, 20% micro-silica fume, 10% arsenic-enriched plant straw biochar, 10% sulfuric acid, and 10% water, and the quality of biological preparations accounts for 3% of the mass of copper smelting smoke. Low-temperature dearsenization at 550°C to obtain white arsenic and dearsenic dust;

[0048] (2) Ultrasonic cleaning the arsenic removal dust obtained in step (1), and then performing vulcanization pretreatment to obtain the pretreated arsenic removal dust material;

[0049] (3) Grinding the pretreated arsenic-removing dust material in step (2) to -0.074mm by m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com