Method for collecting arsenic from smelting flue gas by dry process

A technology for smelting flue gas and dry arsenic recovery, which is applied in chemical instruments and methods, arsenic compounds, arsenic oxide/arsenic hydroxide/oxyacid arsenic, etc. , Increase the difficulty and frequency of internal cleaning and cleaning of the ring cooler, so as to ensure the effect of ensuring no corrosion and stable and good operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

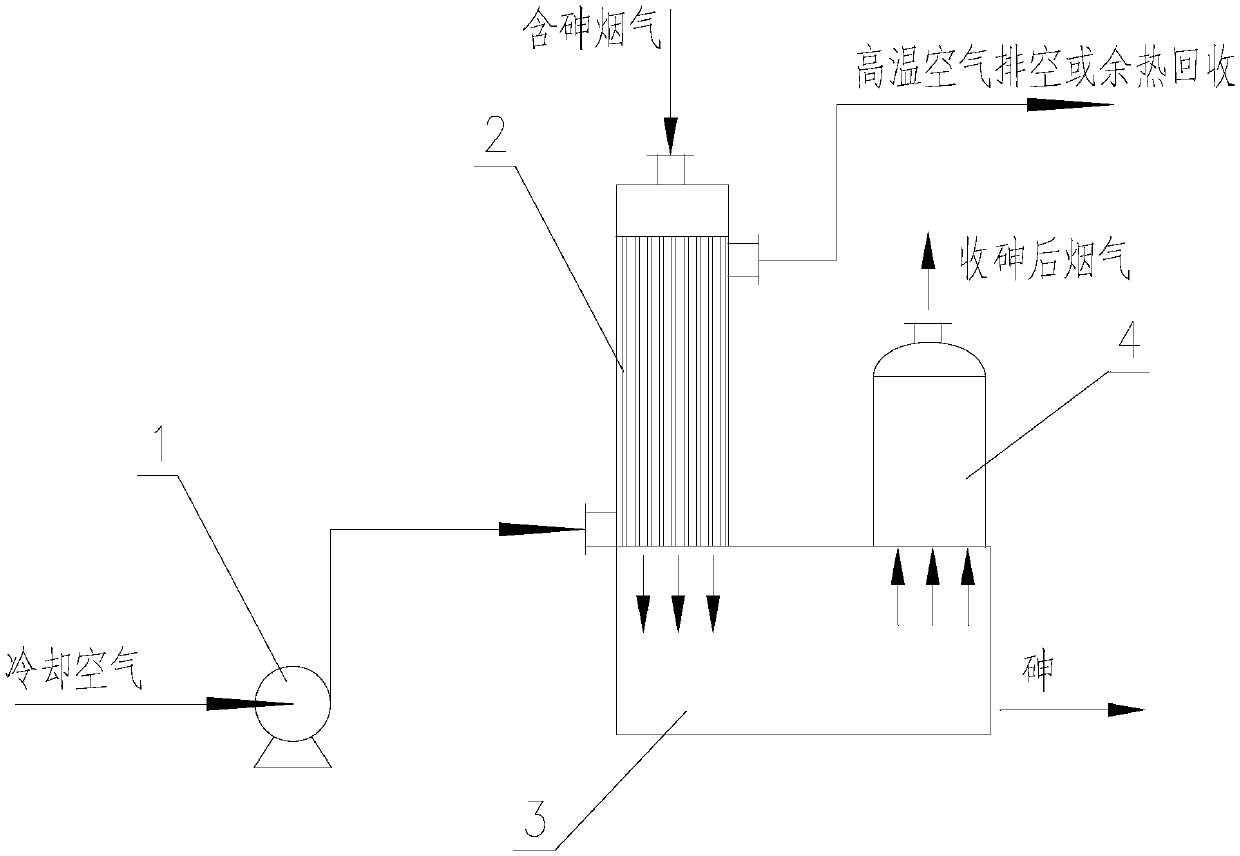

Image

Examples

Embodiment 1

[0027] The invention provides a method for collecting arsenic by dry method of smelting flue gas, comprising the following steps:

[0028] (1) Quenching: the arsenic content is 2g / Nm 3 The high-temperature copper smelting flue gas quickly passes through the quencher, and the arsenic-containing high-temperature smelting flue gas is quickly washed and cooled to about 130°C in the quencher. The gas velocity in the quencher is 20m / s, and the residence time does not exceed 0.3s. Indirect cooling, then discharge from the bottom of the quencher into the settler;

[0029] (2) Settlement to collect arsenic: the flue gas quenched in step (1) enters the settler, the temperature of the flue gas is stable at about 120°C, and the white arsenic and smoke dust in the flue gas naturally settle to the bottom of the settler in the settler , the settled flue gas is discharged from the upper flue gas outlet, and the settled arsenic is collected from the outlet at the bottom of the settler;

[00...

Embodiment 2

[0032] The invention provides a method for collecting arsenic by dry method of smelting flue gas, comprising the following steps:

[0033] (1) Quenching: the arsenic content is 1.8g / Nm 3 The high-temperature copper smelting flue gas quickly passes through the quencher, and the arsenic-containing high-temperature smelting flue gas is quickly washed and cooled to about 130°C in the quencher. The gas velocity in the quencher is 30m / s, and the residence time does not exceed 0.3s. Indirect cooling, then discharge from the bottom of the quencher into the settler;

[0034] (2) Settlement to collect arsenic: the flue gas quenched in step (1) enters the settler, the temperature of the flue gas is stable at about 120°C, and the white arsenic and smoke dust in the flue gas naturally settle to the bottom of the settler in the settler , the settled flue gas is discharged from the upper flue gas outlet, and the settled arsenic is collected from the outlet at the bottom of the settler;

[...

Embodiment 3

[0037] The invention provides a method for collecting arsenic by dry method of smelting flue gas, comprising the following steps:

[0038] (1) Quenching: the arsenic content is 2.5g / Nm 3 The high-temperature copper smelting flue gas quickly passes through the quencher, and the arsenic-containing high-temperature smelting flue gas is quickly washed and cooled to about 125°C in the quencher. The gas velocity in the quencher is 30m / s, and the residence time does not exceed 0.3s. Indirect cooling, then discharge from the bottom of the quencher into the settler;

[0039] (2) Sedimentation to collect arsenic: the flue gas that has been quenched in step (1) enters the settler, and the temperature of the flue gas is stable at about 110°C, and the white arsenic and smoke dust in the flue gas naturally settle to the bottom of the settler in the settler , the settled flue gas is discharged from the upper flue gas outlet, and the settled arsenic is collected from the outlet at the bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com