Positive electrode current collector laminate for lithium secondary battery

A technology of positive electrode collector and collector layer, which is applied in the direction of electrode carrier/collector, battery electrode, lithium battery, etc., and can solve problems such as cycle characteristics and battery capacity reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

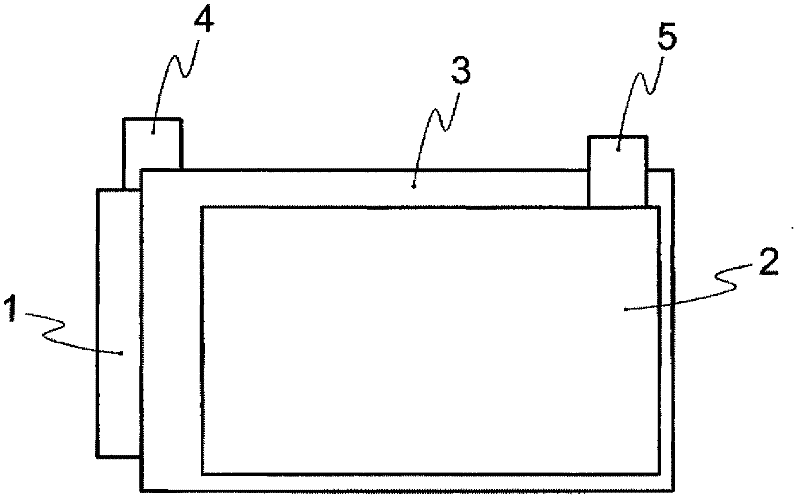

Image

Examples

preparation example Construction

[0055] What is necessary is just to mix each component by the usual mixing method used for the coating composition using resin about preparation of a coating composition.

[0056] The method for forming the coating film may be a conventionally known method. Apply to the substrate by, for example, roller coating, brush coating, dip coating, spray coating, gravure printing, coil coating, curtain coating, etc., and allow to dry naturally at ambient temperature or heat dried to form a coating film.

[0057] When the composition for forming a protective layer is in the form of a composition for molding, the fluororesin (b1), conductive filler (b2), and other components (b3) and solvent (b4) if necessary, are slurry by the usual method can be converted.

[0058] The conductive protective layer (B) obtained in this way can control the volume resistivity in the range of 0.001Ω·cm~50Ω·cm, and can provide a volume resistivity of 0.001Ω·cm~10Ω·cm, and further 1Ω·cm following a highly ...

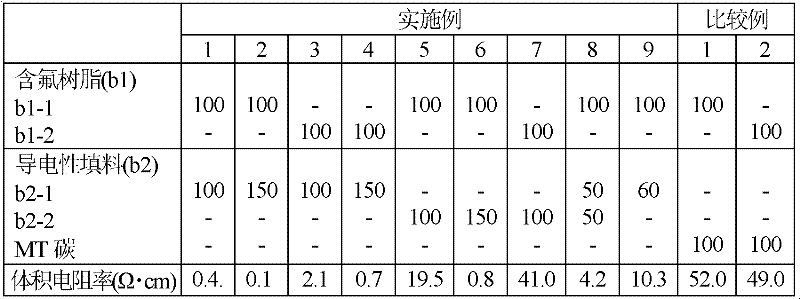

Embodiment 1

[0093] A composition having the following composition was prepared using a planetary rolling mill, and coated on an aluminum foil (thickness: 15 μm) with a bar coater to obtain a laminate in which a conductive protective layer (thickness: 5.8 μm) was formed on the aluminum foil.

[0094] (b1) 100 parts by mass of fluorine-containing resin

[0095] (b2) Conductive filler 100 parts by mass

[0096] (b4) 800 parts by mass of organic solvent

[0097] The ingredients are as follows.

[0098] (b1-1) Fluorine-containing resin:

[0099] Composition: PVdF

[0100] Weight average molecular weight (Mw): 110,000

[0101] (b2-1) Conductive filler:

[0102] A kind: Conductive graphite (artificial graphite HAG made by Nippon Black Lead Co., Ltd.)

[0103] Average particle size: 5μm

[0104] Volume resistivity: 0.05Ω·cm

[0105] (b4-1) Organic solvent: NMP (N-methylpyrrolidone)

[0106] In addition, the volume resistivity of the obtained laminate was examined. The results are listed...

Embodiment 2

[0108] In Example 1, except that the blending amount of the conductive filler was changed to 150 parts by mass, a paint was prepared in the same manner as in Example 1, and a laminate in which a conductive protective layer (thickness: 6 μm) was formed on an aluminum foil was obtained. body.

[0109] In addition, the volume resistivity of the obtained laminate was examined. The results are listed in Table 1.

[0110] The level of conductivity (0.09 Ω·cm) obtained in this example is in the range of what is called a high-conductivity material, and it is possible to achieve both good processability. It should be noted that when a voltage is applied to this laminate, heat generation is observed, so this can be used as a heater or an electrode.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com