Online automatic cutting machine for composite material

A composite material and cutting machine technology, applied in metal processing and other directions, can solve the problems of unreachable dimensional accuracy and uneven end faces of profiles, and achieve the effects of high production efficiency, high degree of automation and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

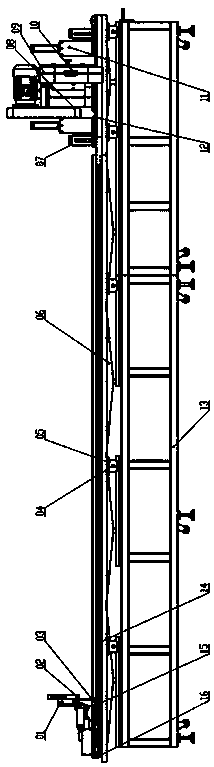

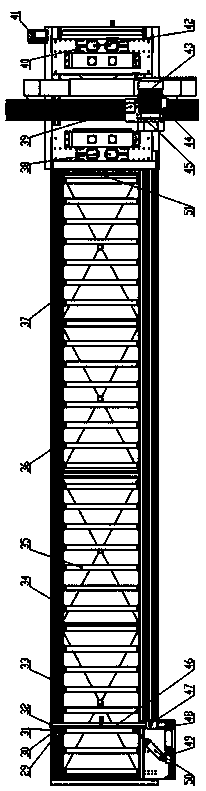

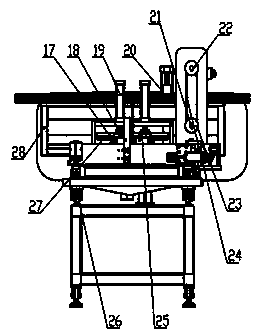

[0018] Taking an online automatic cutting machine for composite materials as an example, when the composite material is transported to the sensing element 02, the sensing element 02 senses the composite material, and the platform moves the cylinder 51 back to its position. When the baffle plate 46 of the mechanism is in place, the sliding bracket 36 of the sliding support platform moves forward, giving a signal to the pressing cylinder 19 to press down, and the cutting motor 45 of the cutting mechanism starts cutting with an alarm sound. After cutting, lock the cylinder 31 Return first, push material cylinder 50 and then return, the whole sizing mechanism is opened, and platform moving cylinder 51 pushes the whole sliding support platform to the initial cutting origin position. Manually remove the cut composite material, push and pull the cylinder 50 to push the baffle 46 out after an interval of half a minute, and lock the cylinder 31 to push down the lock 32 and get stuck in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com