Secondary concrete fluidizing agent

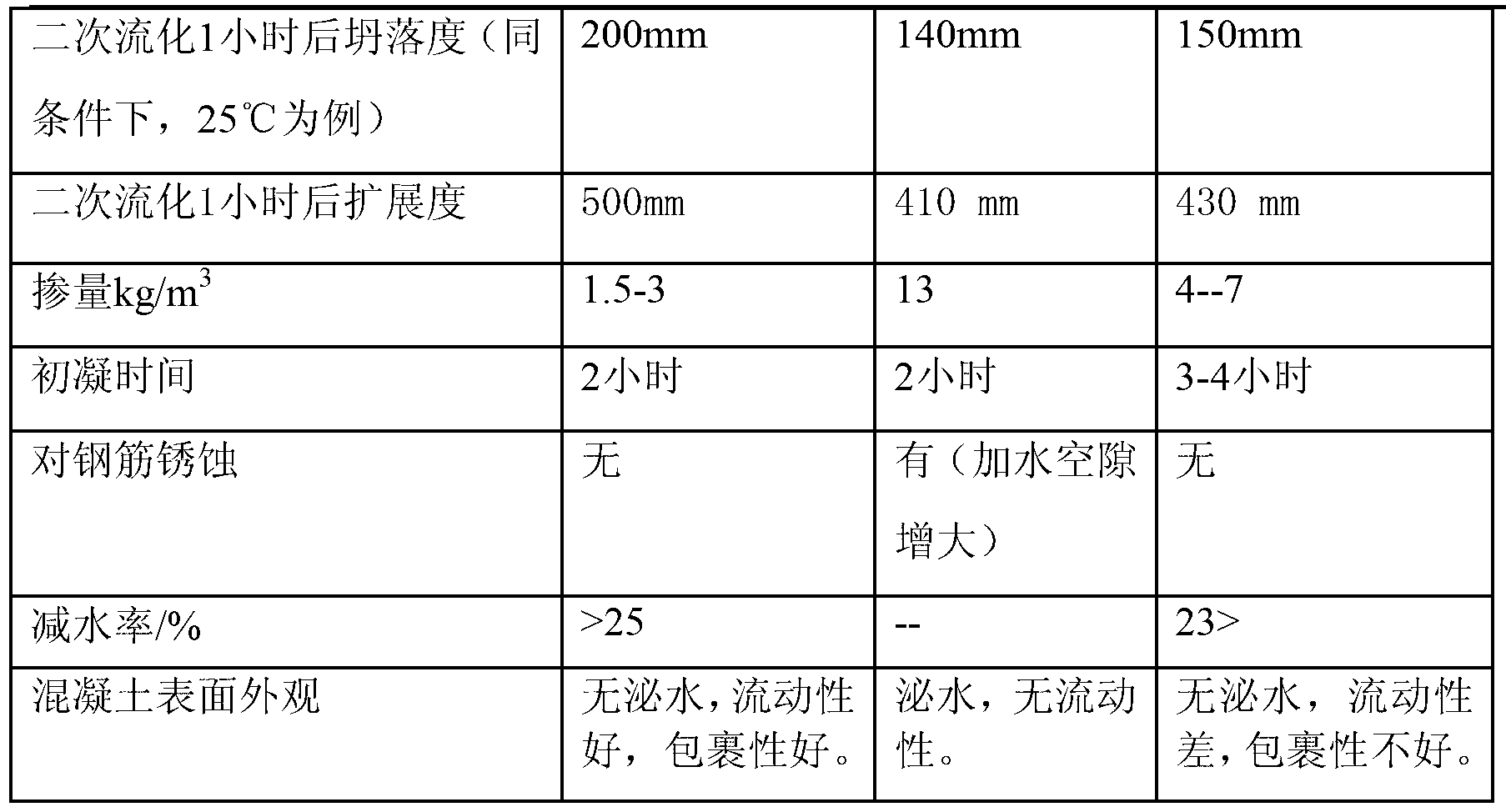

A technology for concrete and fluidizing agent, applied in the field of building materials, can solve the problems of insignificant fluidization effect of pumping agent, loss of strength and durability, fluctuation of concrete performance, etc., to achieve good material adaptability, small strength loss, The effect of small secondary loss of slump

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The preparation of embodiment 1 concrete secondary fluidization agent

[0033] Take 6.74kg of ether polycarboxylate water-reducer, which comes from Sichuan Jilong Chemical LonS-Mw water-reducing polycarboxylate mother liquor, with a solid content of 40%, mix with 12.978kg of water, and add lauryl sulfuric acid in turn 0.002kg of sodium and 0.28kg of sodium hexametaphosphate were mixed to obtain a secondary fluidizer for concrete.

Embodiment 2

[0034] The preparation of embodiment 2 concrete secondary fluidization agent

[0035] Take 6.74kg of ether polycarboxylate water-reducer, which comes from Sichuan Jilong Chemical LonS-Mw water-reducing polycarboxylate mother liquor, with a solid content of 40%, mix with 12.978kg of water, and add lauryl sulfuric acid in turn 0.002kg of sodium-based mixture and 0.28kg of sodium hexametaphosphate were mixed to obtain a secondary fluidizer for concrete.

[0036] Among them, the weight ratio of the components in the sodium lauryl sulfate-based mixture is sodium lauryl sulfate: stearic acid: sulfonated melamine = 78:10:12.

Embodiment 3

[0037] The preparation of embodiment 3 concrete secondary fluidization agent

[0038] Take 6kg of polycarboxylic acid-based water reducer, mix with 12.6kg of water, add 0.0018kg of sodium lauryl sulfate mixture, and 0.24kg of sodium hexametaphosphate in sequence, and mix well to obtain a concrete secondary fluidizer.

[0039] Among them, the weight ratio of the components in the sodium lauryl sulfate-based mixture is sodium lauryl sulfate: stearic acid: sulfonated melamine = 78:10:12.

PUM

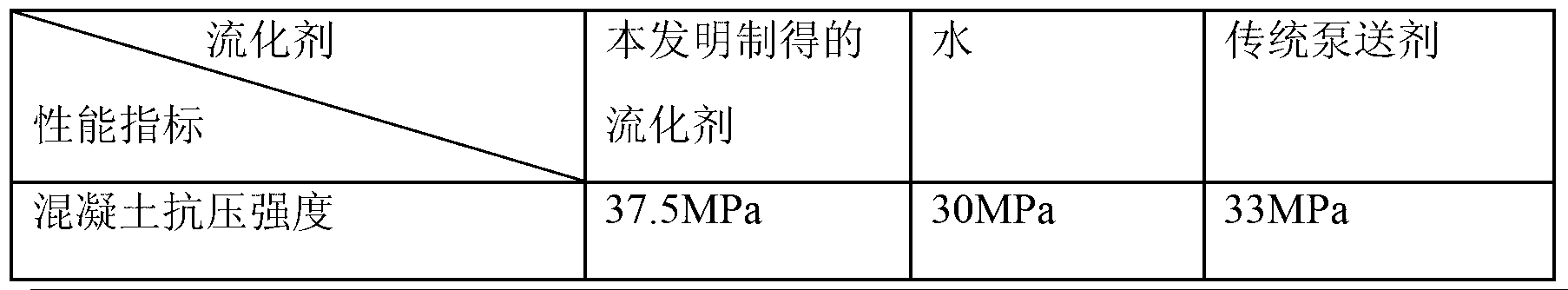

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com