Method for preparing high-efficacy super capacitor material by heavy metal related biomass

A supercapacitor and supercapacitor technology, applied in the field of environmental management and resource utilization, to achieve the effects of good capacitance characteristics, excellent stability and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

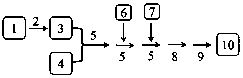

Method used

Image

Examples

Embodiment 1

[0028] The corn stalk leaves collected in the Dabaoshan mining area are subjected to pretreatment steps such as washing with water, drying, crushing, and drying, and then sealed and stored in containers for later use.

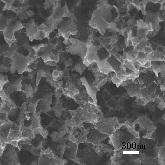

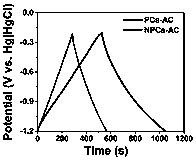

[0029] Take 1 g of the above-mentioned corn stalk leaf powder, dissolve it in 20 mL of ammonia water and stir for 12 h to obtain A solution; at the same time, take 1 g of P 123 Put it into 20 mL of absolute ethanol and stir for 12 h to dissolve completely to obtain solution B; mix solution A and solution B and stir for 6 h. Then 1 g of urea was added to the above mixture and stirred for 2 h. Add 0.4 g KOH to the above mixture and stir for 12 h. After the stirring was completed, the above mixture was dried in a water bath (80 °C) (about 2-3 h). Then the above mixture was put into a tube furnace (argon, the heating rate was 2 °C / min, 120 °C / 3 h, 450 °C / 3 h, 700 °C / 3 h). Finally the samples were washed with hydrochloric acid and water until the pH was neutral. ...

Embodiment 2

[0033] The Miscanthus leaves collected in the Dabaoshan mining area are washed with water, dried, crushed, dried and other pretreatment steps, and then sealed and stored in containers for later use.

[0034] Take 1 g of Miscanthus leaf powder mentioned above, dissolve it in 20 mL of ammonia water and stir for 12 h to obtain solution A; at the same time, take 2 g of P123 and put it into 20 mL of absolute ethanol and stir for 12 h to obtain solution B; The solution was mixed and stirred for 6 h. Then 2 g of urea was added to the above mixture and stirred for 2 h. Add 0.4 g KOH to the above mixture and stir for 12 h. After the stirring was completed, the above mixture was dried in a water bath (80 °C) (about 2-3 h). Then the above mixture was put into a tube furnace (argon, the heating rate was 2 °C / min, 120 °C / 3 h, 450 °C / 3 h, 700 °C / 3 h). Finally the samples were washed with hydrochloric acid and water until the pH was neutral. After drying at 80°C for 5 h, take it out, gri...

Embodiment 3

[0038] The masson pine leaves collected from the farmland next to the mining area are washed with water, dried, crushed, dried and other pretreatment steps, and then sealed and stored in containers for later use.

[0039] Take 1 g of the above-mentioned pine leaf powder and dissolve it in 20 mL of ammonia water and stir for 12 h to obtain solution A; meanwhile, take 2 g of P123 and put it into 20 mL of absolute ethanol and stir for 12 h to obtain solution B; Solution B was mixed and stirred for 6 h. Then 1 g of urea was added to the above mixture and stirred for 2 h. Add 0.4 g KOH to the above mixture and stir for 12 h. After the stirring was completed, the above mixture was dried in a water bath (80 °C) (about 2-3 h). Then the above mixture was put into a tube furnace (argon, the heating rate was 2 °C / min, 120 °C / 3 h, 450 °C / 3 h, 700 °C / 3 h). Finally the samples were washed with hydrochloric acid and water until the pH was neutral. After drying at 80°C for 5 h, take it ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com