Separating speed adjustable type circulating grain drying machine

A separate dryer technology, applied in the direction of dryers, drying, drying solid materials, etc., can solve the problems of increasing secondary losses, increasing failure rates, and inconvenient maintenance, so as to avoid secondary losses and reduce blockages materials, easy installation and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

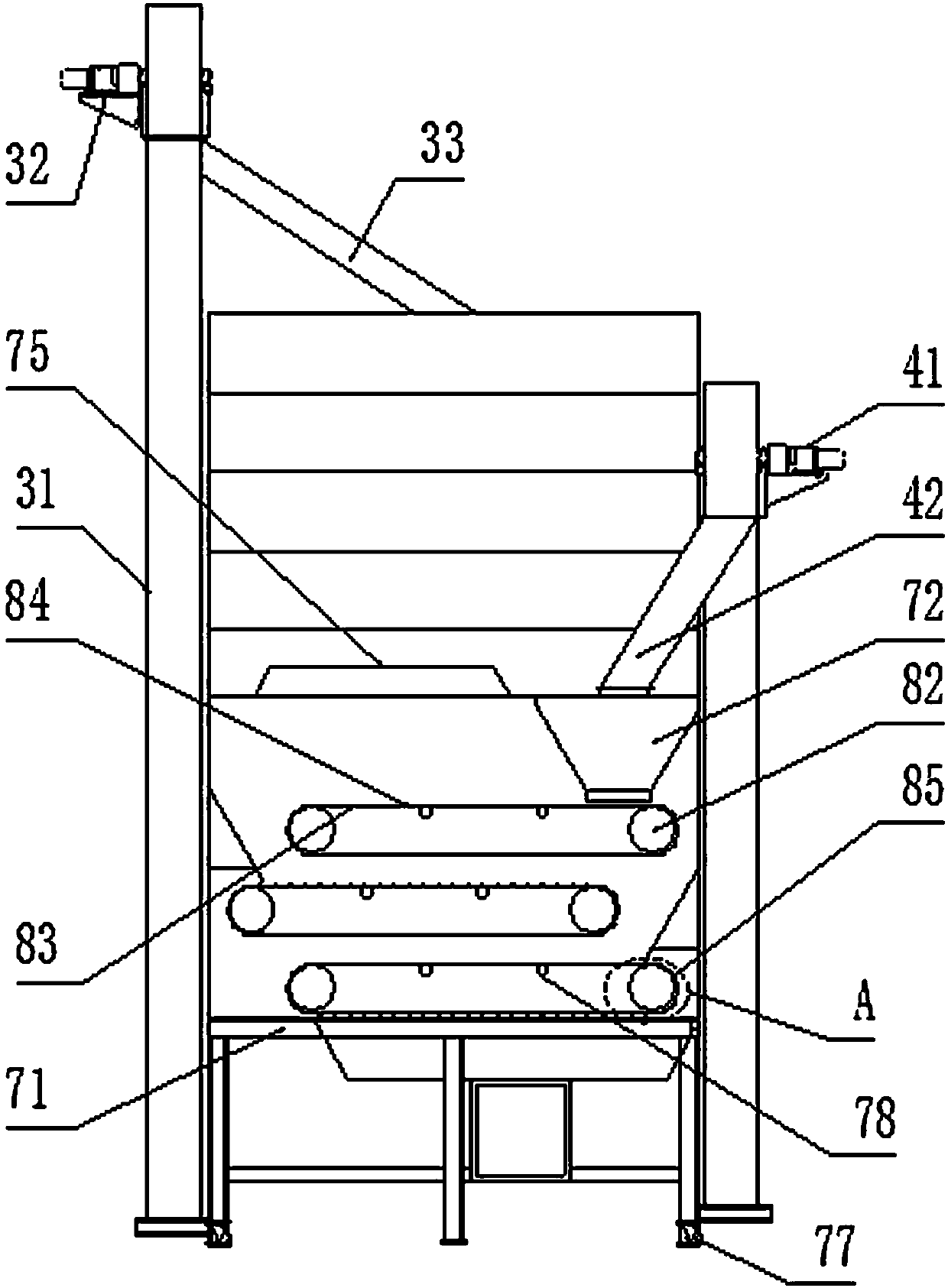

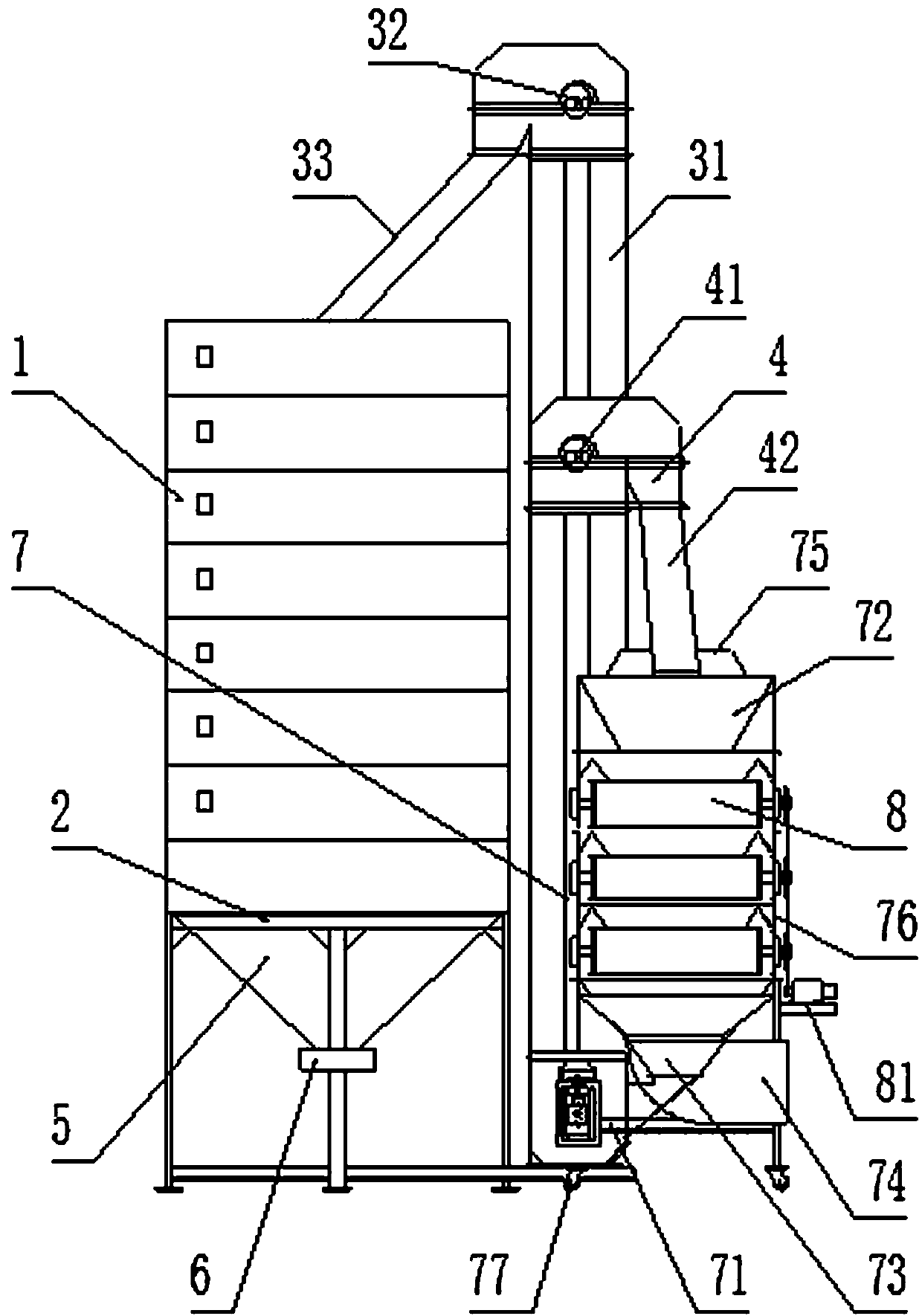

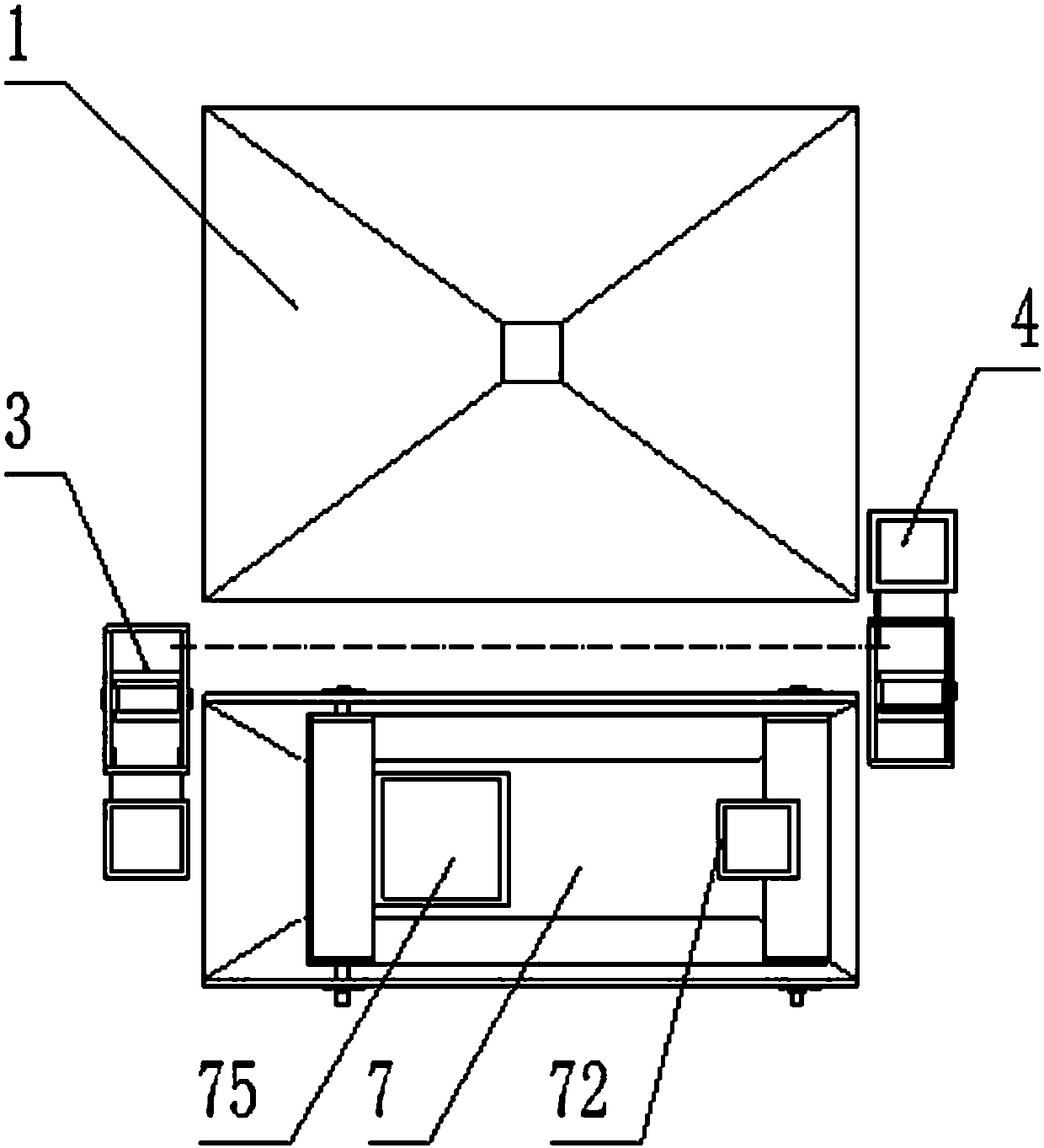

[0020] A separate adjustable speed circulating grain dryer of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The accompanying drawings constituting this application are used to provide a further understanding of the present invention, and the schematic embodiments of the present invention and their descriptions are used to explain the present invention, and do not constitute improper limitations to the present invention.

[0021] Depend on Figure 1 to Figure 4 It can be seen that a separate speed-adjustable circulation grain dryer in this embodiment includes a grain storage bin 1 installed on a base 2 of the grain storage bin, a feeding hoist 3 , a hopper hoist 4 and a drying system 7 .

[0022] The bottom of the grain storage bin 1 of the present embodiment is equipped with an inclined chute 5, and a discharge gate 6 is installed outside the outlet of the inclined chute 5.

[0023] The feeding h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com