Process for rapidly separating sodium aluminate solution and washing red mud in aluminum oxide production

A technology of sodium aluminate and red mud, which is applied to the production of alumina, fly ash, and hydrometallurgical bauxite from nepheline, and can solve the problem of rapid separation of red mud, sufficient washing and alkali consumption of washing water that cannot be completed by a single separation equipment , large consumption of flocculant, large difference in dissolution rate of alumina net dissolution rate, etc., to achieve the effect of shortening separation and settling time, saving new water consumption, and saving bauxite resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

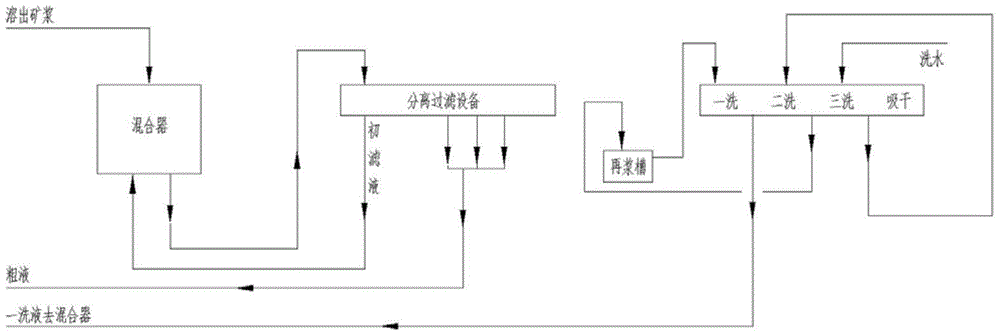

[0035] see figure 1 , a sodium aluminate solution rapid separation and red mud washing process, comprising the following steps:

[0036] Step 1: Dilution of the dissolved pulp, the sodium aluminate clinker dissolved pulp is pumped to the mixer and mixed with a washing liquid for dilution, one of which is the first washing filtrate of red mud for washing and filtering equipment behind the process, after dilution The alkali concentration of the dissolved ore pulp is 150-180g / L, and the temperature is 100-110°C; preferably, the mixer is preferably a pipeline forced mixer manufactured by the Venturi principle.

[0037] The second step: separate and filter the diluted pulp, transport the mixed diluted pulp to the separation and filtration equipment for rapid separation, and separate the sodium aluminate solution from the red mud. An unqualified coarse filtration system is added to the separation and filtration equipment (the amount is very small, just the amount at the moment when...

Embodiment 2

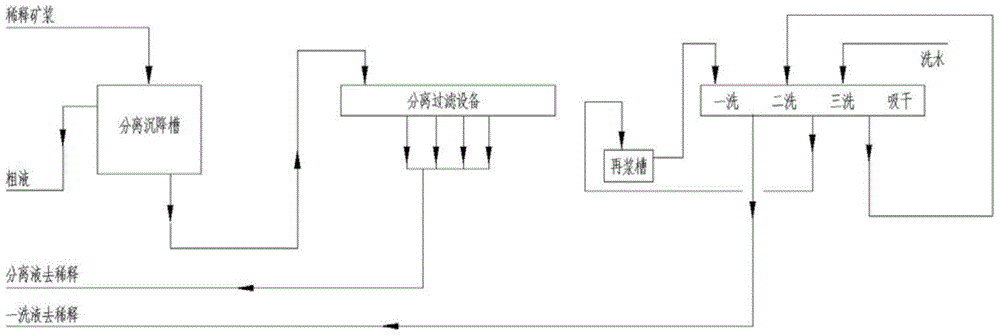

[0043] see figure 2 , a sodium aluminate solution rapid separation and red mud washing process, comprising the following steps:

[0044] Step 1: The dissolved ore pulp is diluted and transported to the separation and settling tank, and 40-50g flocculant is added per ton of red mud for sedimentation and separation. The flocculant is preferably a synthetic flocculant, and the separation and sedimentation time is 0.25-1.5 hours; overflow The liquid is the crude liquid, which is sent to the semen control and filtration system in the crude liquid tank, and the floating matter in the crude liquid is controlled at 1-10g / L; the bottom flow of the settling tank enters the separation and filtration equipment, and the rapid separation operation time is 2-10 minutes, and the separation liquid is refluxed It is used for the dilution of the stripping pulp, and the red mud filter cake enters the subsequent process flow, and the liquid content of the filter cake is controlled at 35-45%.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com