Anti-freeze and anti-cracking concrete

A concrete and anti-cracking technology, applied in the field of concrete, can solve the problem that the frost resistance and anti-cracking properties of concrete cannot meet the requirements, and achieve the effect of improving resource utilization rate, stable performance and slowing down the development of cracks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A kind of frost-resistant and anti-cracking concrete proposed by the present invention, its raw material comprises by weight: Portland cement 220 parts, limestone powder 20 parts, steel slag powder 35 parts, sand 650 parts, fine stone 850 parts, modified rubber powder 25 parts 8 parts of potassium silicate, 10 parts of expanded perlite, 20 parts of natural zeolite superfine powder, 4 parts of polypropylene fiber, 3 parts of glass fiber, 5 parts of water reducer, and 100 parts of water.

Embodiment 2

[0019] A kind of frost-resistant and anti-cracking concrete proposed by the present invention, its raw material comprises by weight: 320 parts of Portland cement, 10 parts of limestone powder, 50 parts of steel slag powder, 800 parts of sand, 700 parts of fine stones, 45 parts of modified rubber powder 15 parts of potassium silicate, 15 parts of expanded perlite, 15 parts of natural zeolite superfine powder, 6 parts of polypropylene fiber, 5 parts of glass fiber, 6 parts of water reducer, and 140 parts of water.

[0020] Among them, the fineness modulus of sand is 1.8, and the mud content is not more than 1.2wt%;

[0021] The modified rubber powder is prepared according to the following process: soak the waste rubber powder in aqueous sodium hydroxide solution, take it out and wash it, then soak it in absolute ethanol, then add vinyl triethoxysilane, acetic anhydride and initiator , stirred, filtered, added acetone for precipitation and separation, then washed, dried, and pulv...

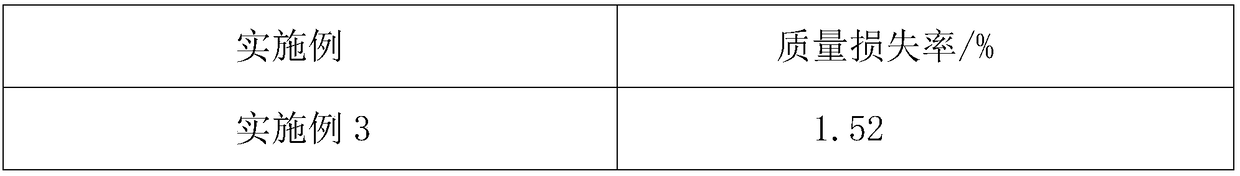

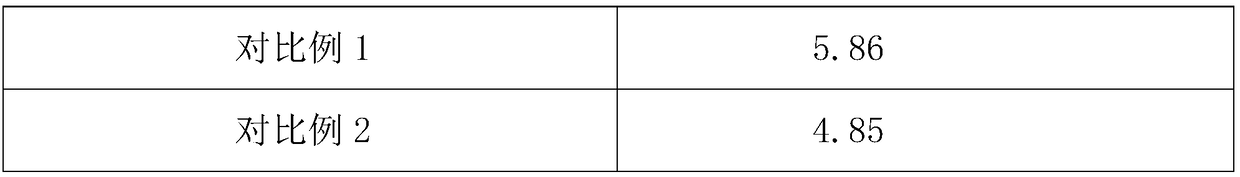

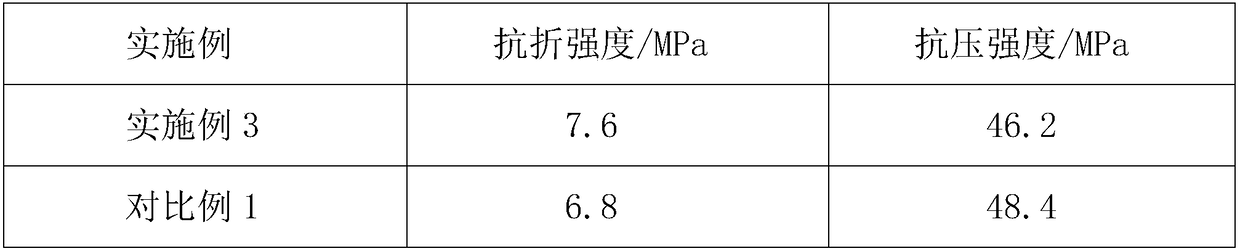

Embodiment 3

[0024] A kind of antifreeze anticracking concrete proposed by the present invention, its raw material comprises by weight: Portland cement 270 parts, limestone powder 15 parts, steel slag powder 44 parts, sand 720 parts, fine stone 780 parts, modified rubber powder 35 parts 12 parts of potassium silicate, 12 parts of expanded perlite, 18 parts of natural zeolite superfine powder, 5 parts of polypropylene fiber, 4.2 parts of glass fiber, 5.5 parts of water reducer, and 120 parts of water.

[0025] Wherein, the fineness modulus of sand is 2.1, and the mud content is 1wt%;

[0026] The modified rubber powder is prepared according to the following process: the waste rubber powder is soaked in an aqueous sodium hydroxide solution with a concentration of 16.5wt% for 19 hours, taken out, washed with water to neutrality, and then soaked in absolute ethanol for 1.2 hours. Then add vinyltriethoxysilane, acetic anhydride and initiator, stir at 72°C for 2.5h, filter, add acetone for preci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com