Environment-friendly concrete water reducer and preparation method thereof

An environmentally friendly concrete and water reducing agent technology, applied in the field of concrete additives, can solve the problems of low qualified rate of finished products, low anti-bleeding ability, difficult to master the method, etc., and achieves improved comprehensive performance, low anti-bleeding ability and equipment dependence. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

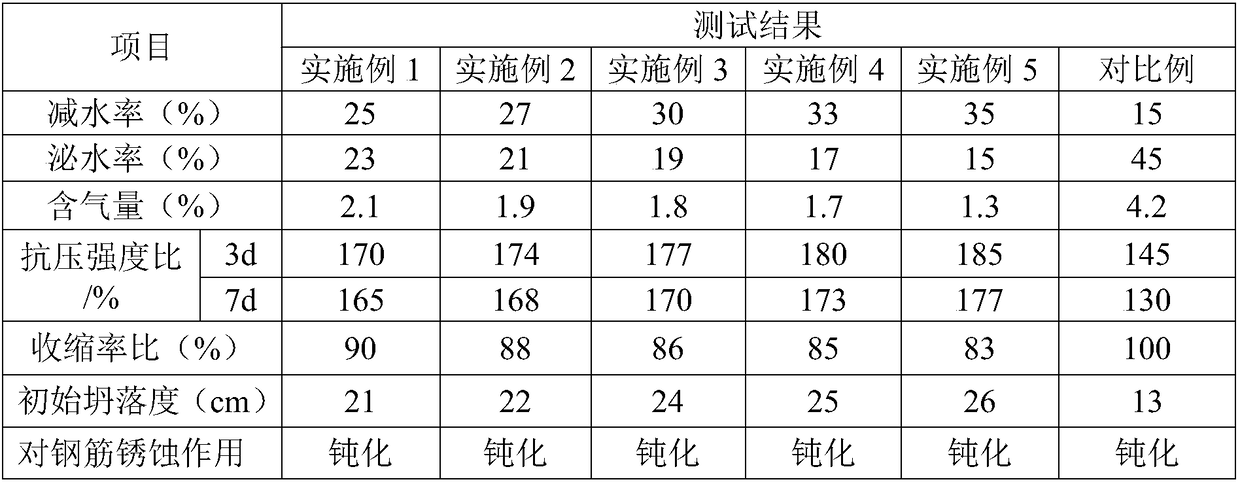

Examples

Embodiment 1

[0028] An environmentally friendly concrete water reducer, comprising the following components by weight: 30 parts of triethanolamine oleic acid soap-based polyacrylic acid copolymer, 10 parts of modified active clay, 5 parts of 4-aminophenyl fucoside, polyether 4 parts of amine, 10 parts of isopropanol, 30 parts of water.

[0029] The triethanolamine oleic acid soap-based polyacrylic acid copolymer is composed of triethanolamine oleic acid soap, (2R, 3S, 4S)-rel-2-carboxy-4-(1-methylvinyl)-3-pyrrolidine Acetic acid, sulfosuccinic acid-1-(2-propenyl)-4-tridecyl sodium salt, and N-trimethylolmethacrylamide are prepared by copolymerization.

[0030] The preparation method of the triethanolamine oleic acid soap-based polyacrylic acid copolymer comprises the steps of: mixing 10 g of triethanolamine oleic acid soap, (2R, 3S, 4S)-rel-2-carboxy-4-(1-methyl Vinyl)-3-pyrrolidine acetic acid 10g, sulfosuccinic acid-1-(2-propenyl)-4-tridecyl sodium salt 5g, N-trimethylolmethacrylamide 1...

Embodiment 2

[0036] An environmentally friendly concrete water reducer, comprising the following components by weight: 33 parts of triethanolamine oleic acid soap-based polyacrylic acid copolymer, 12 parts of modified active clay, 7 parts of 4-aminophenyl fucoside, polyether 5 parts of amine, 12 parts of isopropanol, 33 parts of water.

[0037] The triethanolamine oleic acid soap-based polyacrylic acid copolymer is composed of triethanolamine oleic acid soap, (2R, 3S, 4S)-rel-2-carboxy-4-(1-methylvinyl)-3-pyrrolidine Acetic acid, sulfosuccinic acid-1-(2-propenyl)-4-tridecyl sodium salt, and N-trimethylolmethacrylamide are prepared by copolymerization.

[0038] The preparation method of the triethanolamine oleic acid soap-based polyacrylic acid copolymer comprises the steps of: mixing 10 g of triethanolamine oleic acid soap, (2R, 3S, 4S)-rel-2-carboxy-4-(1-methyl Vinyl)-3-pyrrolidine acetic acid 10g, sulfosuccinic acid-1-(2-propenyl)-4-tridecyl sodium salt 5g, N-trimethylolmethacrylamide 1...

Embodiment 3

[0044] An environmentally friendly concrete water reducer, comprising the following components by weight: 36 parts of triethanolamine oleic acid soap-based polyacrylic acid copolymer, 13 parts of modified active clay, 8 parts of 4-aminophenyl fucoside, polyether 5 parts of amine, 13 parts of isopropanol, 36 parts of water.

[0045] The triethanolamine oleic acid soap-based polyacrylic acid copolymer is composed of triethanolamine oleic acid soap, (2R, 3S, 4S)-rel-2-carboxy-4-(1-methylvinyl)-3-pyrrolidine Acetic acid, sulfosuccinic acid-1-(2-propenyl)-4-tridecyl sodium salt, and N-trimethylolmethacrylamide are prepared by copolymerization.

[0046] The preparation method of the triethanolamine oleic acid soap-based polyacrylic acid copolymer comprises the steps of: mixing 10 g of triethanolamine oleic acid soap, (2R, 3S, 4S)-rel-2-carboxy-4-(1-methyl Vinyl)-3-pyrrolidine acetic acid 10g, sulfosuccinic acid-1-(2-propenyl)-4-tridecyl sodium salt 5g, N-trimethylolmethacrylamide 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com