High-performance polycarboxylate water reducing agent and preparation method thereof

A technology of polycarboxylic acid and water reducing agent, applied in the field of building materials, can solve the problems of poor slump retention performance and low water reduction rate, and achieve the effects of good air entrainment, high water reduction rate and enhanced slump retention effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

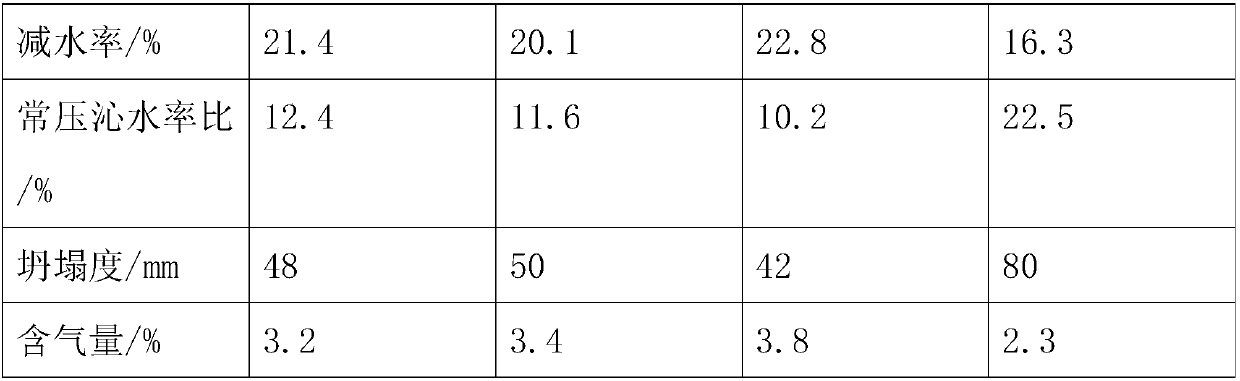

Examples

Embodiment 1

[0024] A high-performance polycarboxylate water reducer, made of the following raw materials in parts by weight: 375 parts of water, 300 parts of monomer, 2 parts of catalyst, and 80 parts of material A;

[0025] One or more of allyl alcohol polyoxyethylene ether APEG, isopentenyl alcohol ether TPEG, methallyl alcohol HPEG, propylene polyoxyethylene ether HPEG, methoxy polyethylene glycol MPEG is selected as the monomer ;

[0026] The catalyst is made from the following raw materials in parts by weight: 0.2 parts of initiator, 2 parts of hydrogen peroxide;

[0027] The material A is made of the following raw materials in parts by weight: 30 parts of water, 0.2 parts of vitamin C, 2 parts of stabilizer, and 30 parts of acrylic acid.

Embodiment 2

[0029] A high-performance polycarboxylate water reducer, made of the following raw materials in parts by weight: 600 parts of water, 400 parts of monomer, 4 parts of catalyst, and 120 parts of material A;

[0030] One or more of allyl alcohol polyoxyethylene ether APEG, isopentenyl alcohol ether TPEG, methallyl alcohol HPEG, propylene polyoxyethylene ether HPEG, methoxy polyethylene glycol MPEG is selected as the monomer ;

[0031] The catalyst is made from the following raw materials in parts by weight: 0.5 parts of initiator, 4 parts of hydrogen peroxide;

[0032] The material A is made of the following raw materials in parts by weight: 90 parts of water, 0.5 parts of vitamin C, 5 parts of stabilizer, and 40 parts of acrylic acid.

Embodiment 3

[0034] A high-performance polycarboxylate water reducer, made of the following raw materials in parts by weight: 375 parts of water, 375 parts of monomer, 3 parts of catalyst, and 100 parts of material A;

[0035] One or more of allyl alcohol polyoxyethylene ether APEG, isopentenyl alcohol ether TPEG, methallyl alcohol HPEG, propylene polyoxyethylene ether HPEG, methoxy polyethylene glycol MPEG is selected as the monomer ;

[0036] The catalyst is made from the following raw materials in parts by weight: 0.3 parts of initiator, 2 parts of hydrogen peroxide;

[0037] The material A is made of the following raw materials in parts by weight: 62 parts of water, 0.3 parts of vitamin C, 3.8 parts of stabilizer, and 34 parts of acrylic acid.

[0038] As an optional scheme, the initiator is sodium hypophosphite.

[0039] As an optional solution, the stabilizing agent is one or more of sodium bisulfite, hanging white powder, and sodium metabisulfite.

[0040] The preparation method ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com