Patents

Literature

35results about How to "Strong slump retention" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

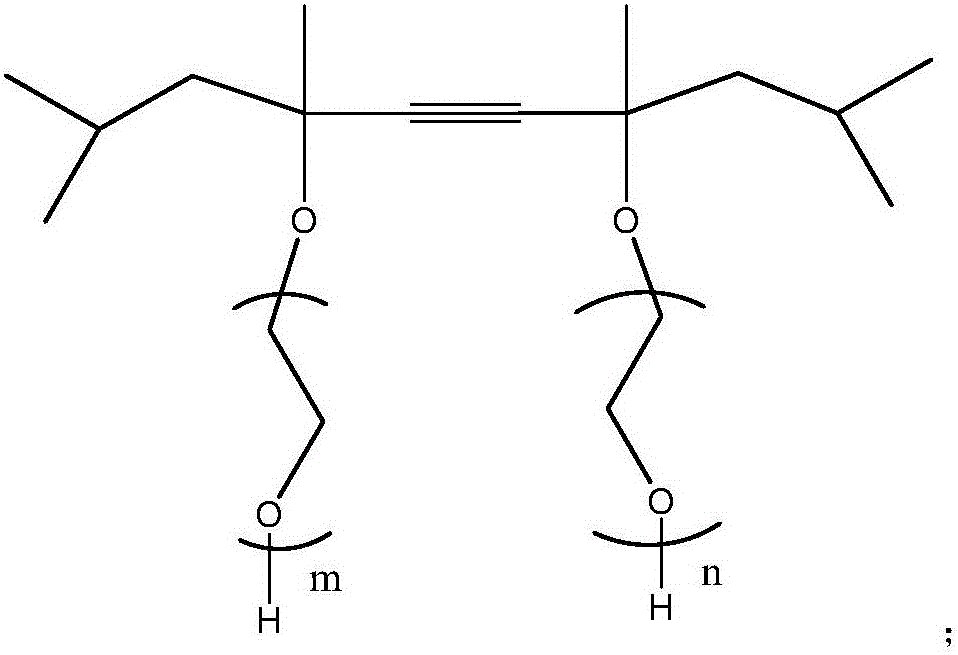

Water-plastic retaining polycarboxylic acid water reducer and method for preparing same

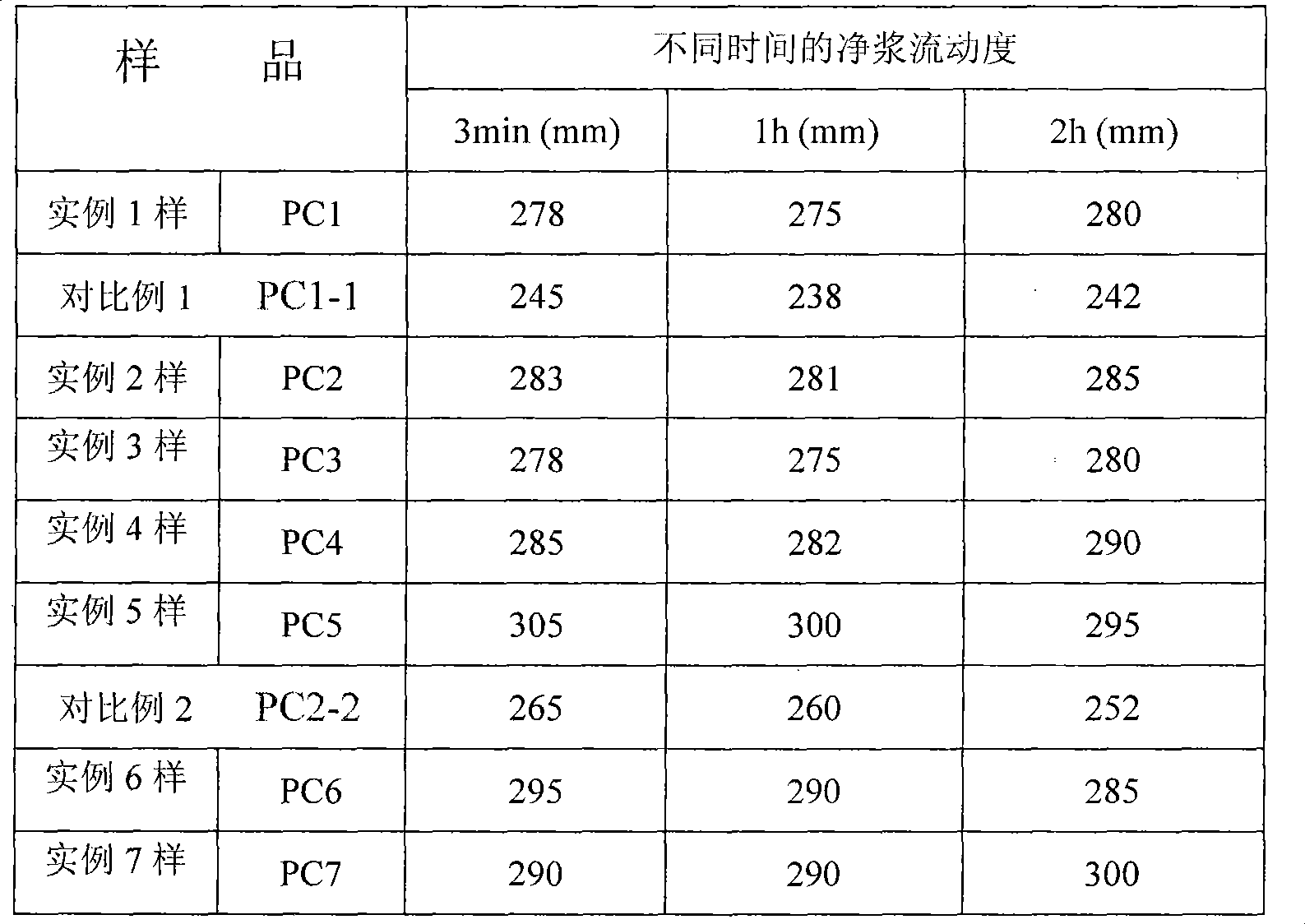

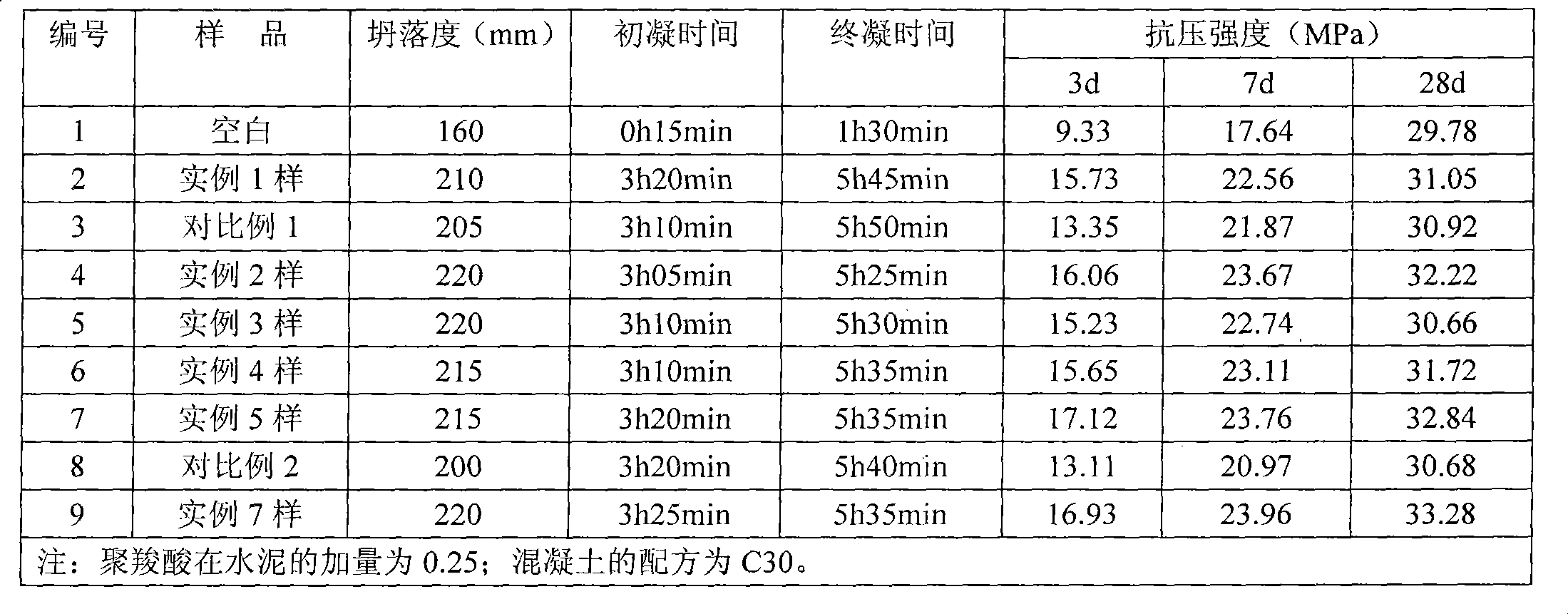

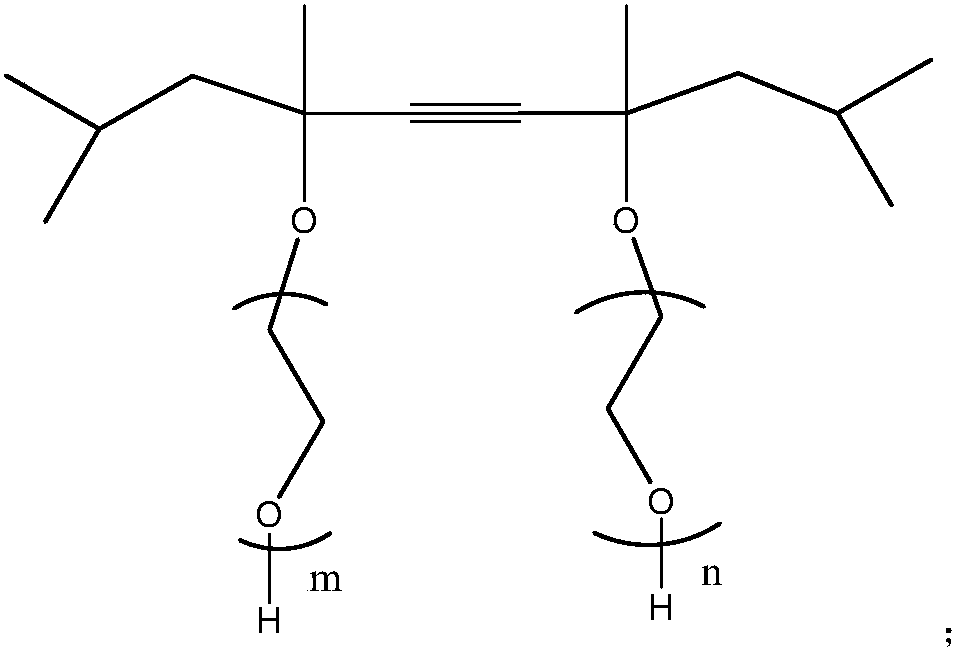

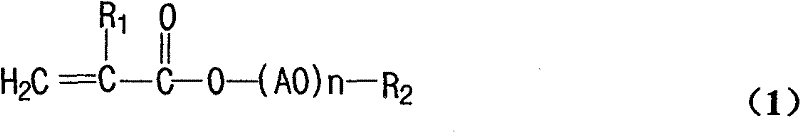

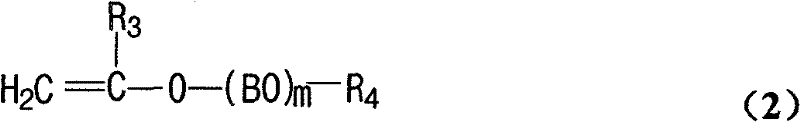

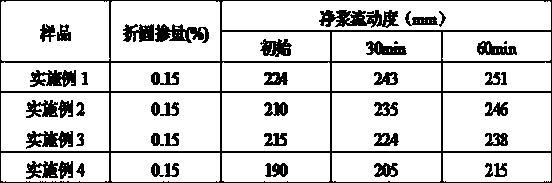

The invention provides water-plastic retaining polycarboxylic acid water reducer and a method for preparing same, belonging to the technical field of the cement dispersant. The water-plastic retaining polycarboxylic acid water reducer is characterized by being prepared in nature through copolymerizing a big water-plastic retaining monomer and a small water-plastic retaining monomer, wherein the big water-plastic retaining monomer is prepared by mixing a big ester monomer with a small ester monomer. Prepared from the big water-plastic retaining monomer, the water-plastic retaining polycarboxylic acid water reducer can well retain the water and the plastic of concrete which is prepared through stirring different cement and different aggregate, and the ubiquitous problems of the segregation due to water bleeding and the quick slump loss are effectively solved. The water is used as solvent for the polymerization reaction, which is good for the industrial production and ensures the safe and environmental-friendly production process.

Owner:山东华伟银凯建材科技股份有限公司

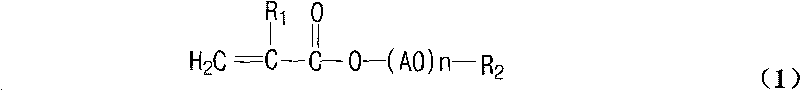

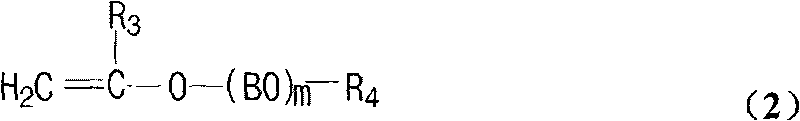

Polycarboxylate-type cement water-reducing agent and preparation method thereof

The invention discloses a polycarboxylate-type high-performance cement water-reducing agent, which is prepared by copolymerizing vinyl polyoxyethylene ether which is taken as a big monomer, a mixture of derivatives of binary anhydride and micro-molecular monohydric alcohol or dihydric alcohol as well as derivatives of maleic anhydride and amino acid taken as an unsaturated monomer, and an acrylic monomer which is comparatively high in activity. The water-reducing agent disclosed by the invention is low in cost, good in dispersion, excellent in slump loss resistant property, high in strength of the concrete, and high in cost performance.

Owner:TAIYUAN UNIV OF TECH +1

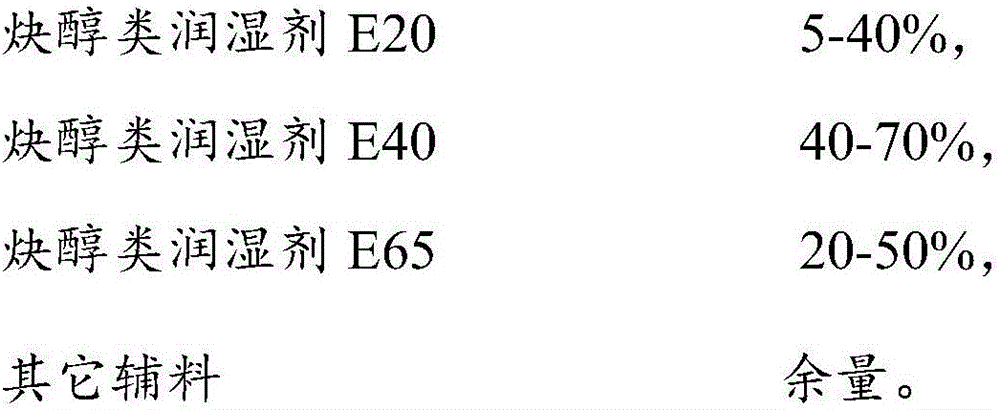

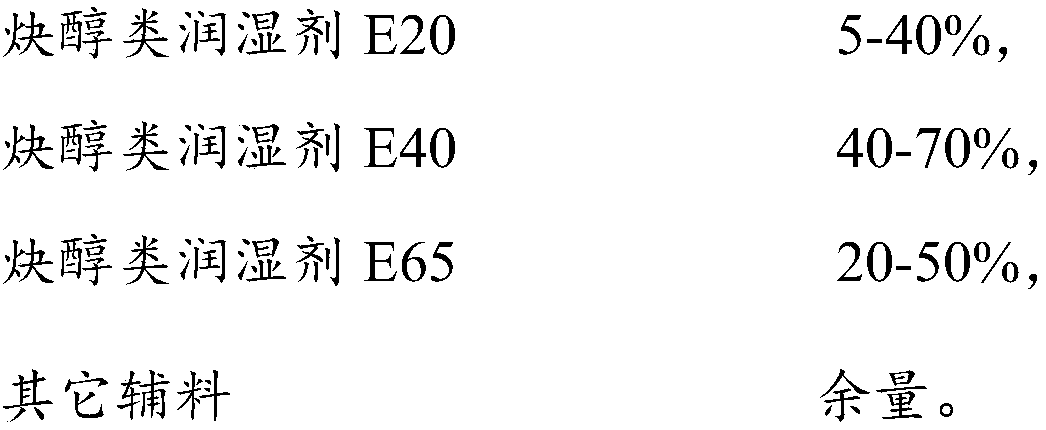

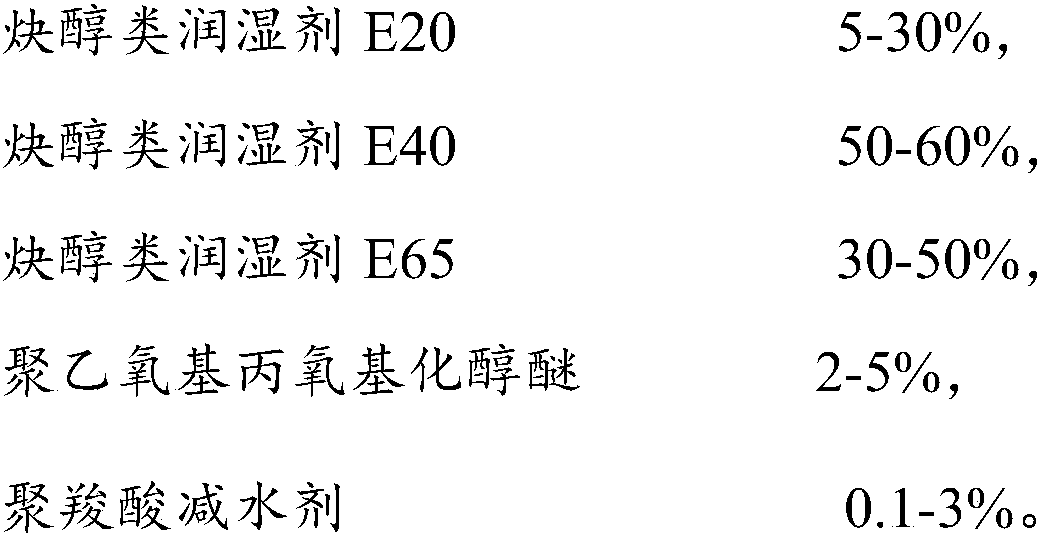

Foam control agent and air-entraining water reducing compounding agent and concrete prepared thereof

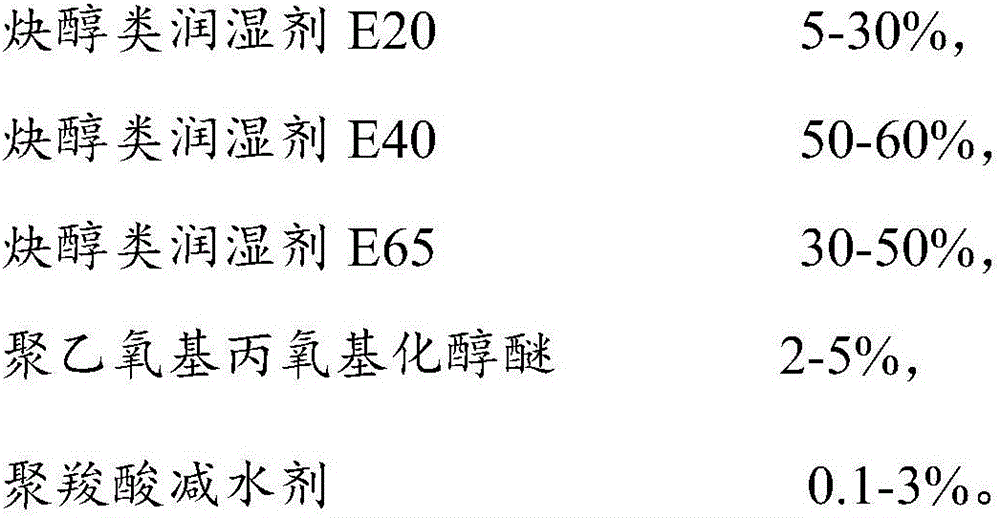

The invention provides a foam control agent and an air-entraining water reducing compounding agent and concrete prepared thereof. The foam control agent is mainly formed by compounding the following components by weight: 5-40% of an alkynol wetting agent E20, 40-70% of an alkynol wetting agent E40, 20-50% of an alkynol wetting agent E65, and the balance other accessories. The foam control agent has double technical effects of air entraining and foam control, can control the foam density and the foam size of a system, makes foams more uniform, eliminates big harmful foams, and makes the cement strength, stability and other properties improved.

Owner:岳阳凯门水性助剂有限公司

Preparation method of polycarboxylic acid water reducer

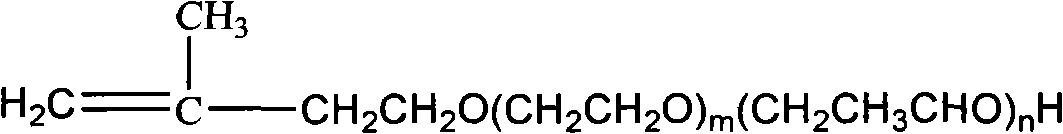

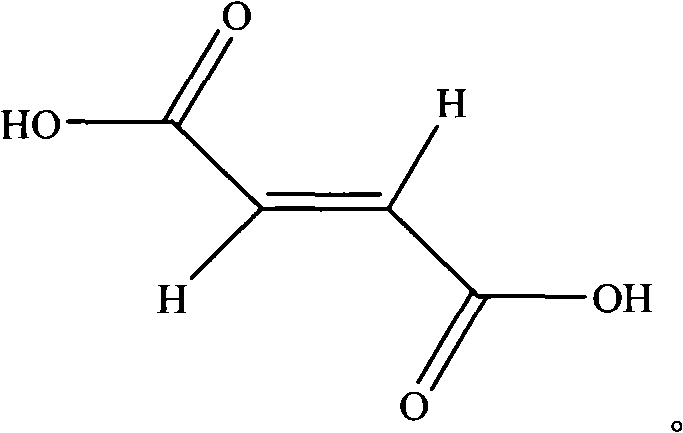

The invention discloses a preparation method of polycarboxylic acid water reducer, which is suitable in Gale Area of Xinjiang. The water reducer is prepared by polymerizing 20-60 percent of methyl and alkenyl polyoxyethylene polyoxypropylene ether (OXAB-501), 10-30 percent of acrylic acid (AA) and 20-60 percent of three monomers of fumaric acid as the raw materials under the action of H2O2-rongalite redox initiator. The concrete made out of the above water reducer has the advantages of favorable collapse performance, no environmental pollution, more effective ingredients and higher water reducing rate. Preparation method of the water reducer has the characteristics of simple operation and low cost, thereby providing the technical support for concrete construction in Gale Area of Xinjiang.

Owner:ANHUI ZHONGTIE ENGINEER MATERIAL SCI & TECH CO LTD

Polycarboxylic acid water reducer prepared from running water and preparation method of polycarboxylic acid water reducer

The invention relates to the technical field of concrete admixtures, and particularly relates to a polycarboxylic acid water reducer prepared from running water and a preparation method of the polycarboxylic acid water reducer. According to the method, with unsaturated polyoxyethylene ether and acrylic acid as monomers and hexamethylene tetramine as a water clarifying agent, through adjusting the mixture ratio of an oxidant, a chain transfer agent and each monomer, the polycarboxylic acid water reducer, which is high in water-reducing rate and fluidity and good in slump hold ability is prepared from running water at room temperature. The polycarboxylic acid water reducer can be synthesized by running water at room temperature, and the preparation method is simple in process, and short in reaction time; hexamethylene tetramine added in the reaction can play a water purification effect and also has the anticorrosion ability; and the synthesized water reducer is good in effect, and has good economic benefits.

Owner:ANHUI XIN SOLID ENVIRONMENTAL CO LTD

Preparation method and application of viscosity-reducing polycarboxylate water reducer

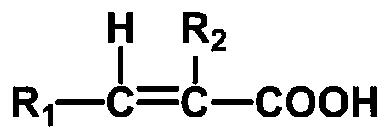

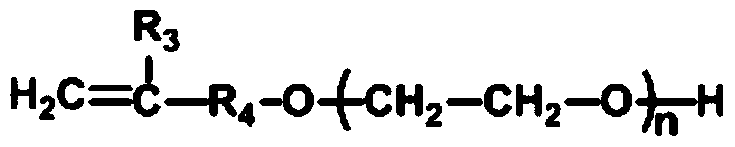

The invention provides a preparation method of a viscosity-reducing polycarboxylate superplasticizer and an application thereof. The viscosity-reducing polycarboxylate superplasticizer can remarkably reduce the viscosity of concrete on the premise of guaranteeing high water reduction and high slump loss resistance; and the preparation method has the advantages of simple technology, low cost, little pollution and the like. In the preparation method, a specific unsaturated acid monomer, a specific unsaturated polyether macromonomer and N-(4-vinyl benzyl)-N, N-dialkylamine in a molar ratio of (2.5-6.5):1:(0.05-0.2) are subjected to free radical copolymerization reaction to obtain the viscosity-reducing polycarboxylate superplasticizer.

Owner:JIANGSU SOBUTE NEW MATERIALS +3

Method for synthesizing modified aminosulfonate superplasticizer from wastewater produced in K acid production process

InactiveCN105645819ALow raw material costReduce dosageWater contaminantsMultistage water/sewage treatmentSuperplasticizerWastewater

The invention relates to a method for synthesizing a modified aminosulfonate superplasticizer from wastewater produced in the K acid production process. According to the method, the modified aminosulfonate superplasticizer is prepared from wastewater produced in the K acid production process, sodium sulfanilate and a compound of phenolic hydroxyl. The synthesized modified sulfamic acid has higher concrete water-reducing rate and excellent slump maintaining performance, and more importantly, a new way for comprehensive utilization of wastewater of a dye intermediate is developed. The cost of raw materials of the superplasticizer is reduced, the environment pressure in the production process of the dye intermediate is also reduced, and the method has good economic and environmental benefits.

Owner:浙江五龙新材股份有限公司

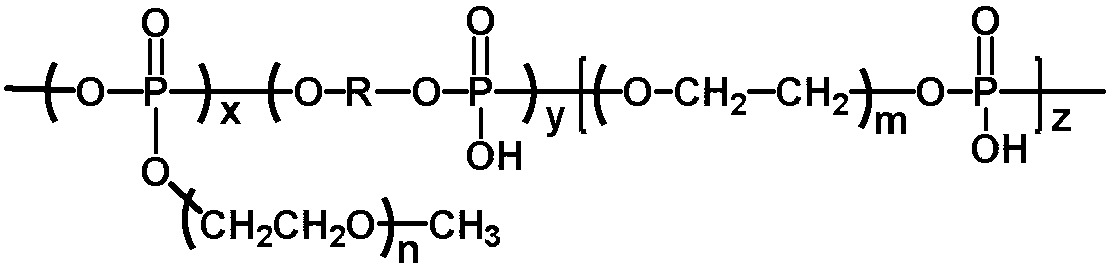

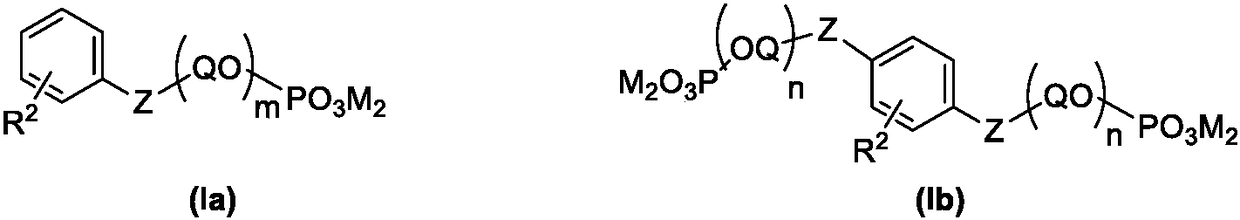

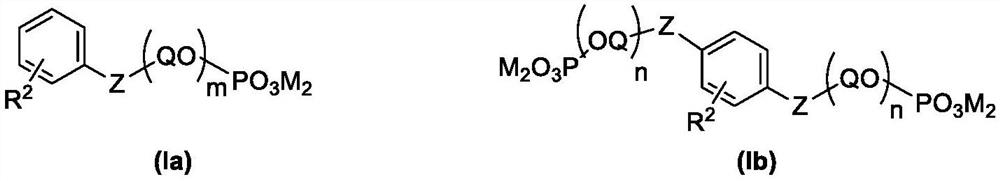

Method for preparing phosphate functional monomer by P2O5 dispersion method and application

InactiveCN107793447AGood dispersionImprove adaptabilityPhosphorus organic compoundsSimple Organic CompoundsFunctional monomer

The invention discloses a method for preparing a phosphate functional monomer by a P2O5 dispersion method and application. The invention relates to a method for synthesizing a phosphate functional monomer by feeding a polymerizable unsaturated organic compound dispersed P2O5, wherein a polymerizable unsaturated organic compound dispersing agent used in a synthesis process can participate in a subsequent polymerization reaction, thereby solving the problems of difficult separation and recovery of a low-boiling-point and toxic organic solvent adopted in a preparation process of an existing phosphate functional monomer and environmental pollution, and simultaneously simplifying the synthesis route of the phosphate functional monomer. The invention also discloses a method for preparing a high-performance polycarboxylate superplasticizer by taking a phosphate functional monomer solution with a polymerizable unsaturated organic compound as a solvent as a third monomer of a polycarboxylate superplasticizer, so that the problem of contradiction between dispersion capacity and slump retention capacity of an existing polycarboxylate superplasticizer is solved, and a method for preparing a high-performance polycarboxylate superplasticizer with high dispersion and slump retention capacity and strong cement adaptability is provided.

Owner:贵州中兴南友建材有限公司

Method for synthesizing a modified amino sulfonate water-reducing agent by utilizing wastewater generated in dye intermediate production process

InactiveCN105731858ALow raw material costReduce dosageWater contaminantsMultistage water/sewage treatmentSulfonateSulfamic acid

The invention relates to a method for synthesizing a modified amino sulfonate water-reducing agent by utilizing wastewater generated in the dye intermediate production process. The method comprises the step of preparing the modified amino sulfonate water-reducing agent by adopting the wastewater generated in the naphthalens series dye intermediate production process, sodium amino benzene sulfonate and a chemical compound containing a phenolic hydroxyl. Modified amino sulfonate synthesized by the method has higher concrete water-reducing rate and excellent slump retaining ability, and more importantly, a novel way for the comprehensive utilization of the dye intermediate wastewater is provided. While the raw material cost of the water-reducing agent is reduced, and the environmental pressure in the dye intermediate production process is reduced, therefore, the economic and environment-friendly benefits are good.

Owner:浙江五龙新材股份有限公司

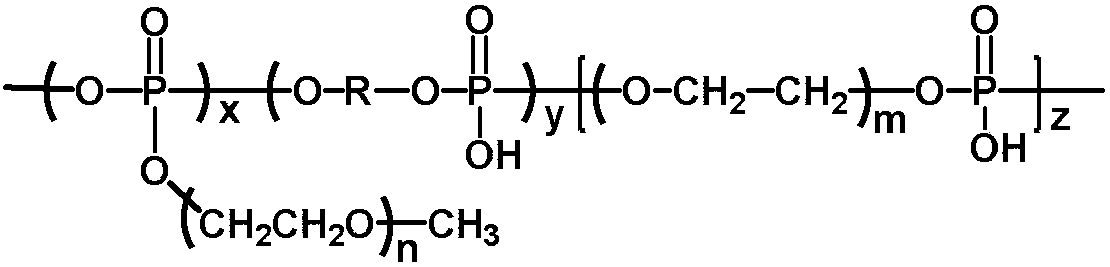

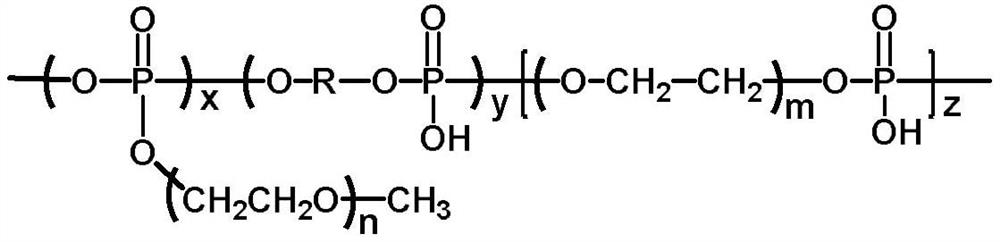

Polyphosphoric acid water reducing agent and preparation method thereof

ActiveCN111302692ARaw materials are cheap and easy to obtainSimple production processO-Phosphoric AcidAcid water

The invention discloses a polyphosphoric acid water reducing agent and a preparation method thereof. The polyphosphoric acid water reducing agent is prepared by carrying out an esterification dehydration reaction on phosphoric acid polyether, polyethylene glycol, alkyl diol, a phosphoric acid compound B and a water carrying agent, wherein the phosphoric acid polyether is prepared by carrying out an esterification reaction on polyethylene glycol monomethyl ether and a phosphoric acid compound A according to a molar ratio of 1:(1.05-1.2), and the molar ratio of the phosphoric acid polyether to the polyethylene glycol to the alkyl diol to the phosphoric acid compound B is 1:(1.5-3):(0.2-2):(1-4). According to the invention, the production process of the water reducing agent is simple, raw materials are cheap and easy to obtain, equipment investment is low, industrial large-scale production is easy, pollution in the reaction process is small, the water carrying agent can be recycled, and alarge amount of transportation cost is saved; and the water reducing agent has strong water reducing and slump retaining capabilities, can improve the workability of concrete, has good adaptability to concrete materials in different regions, has strong tolerance to sandstone aggregate with high clay and high sulfate content, and has a wide market application prospect.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

Slow-release high-efficiency polycarboxylate water reducer and preparation method thereof

Owner:SHIJIAZHUANG CHANGAN YUCAI BUILDING MATERIALS

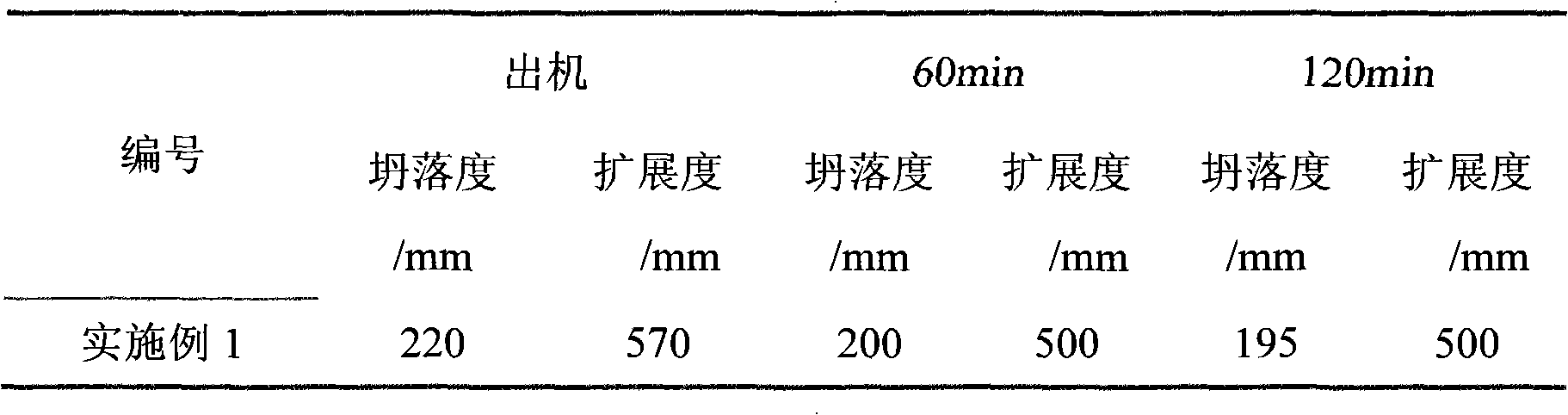

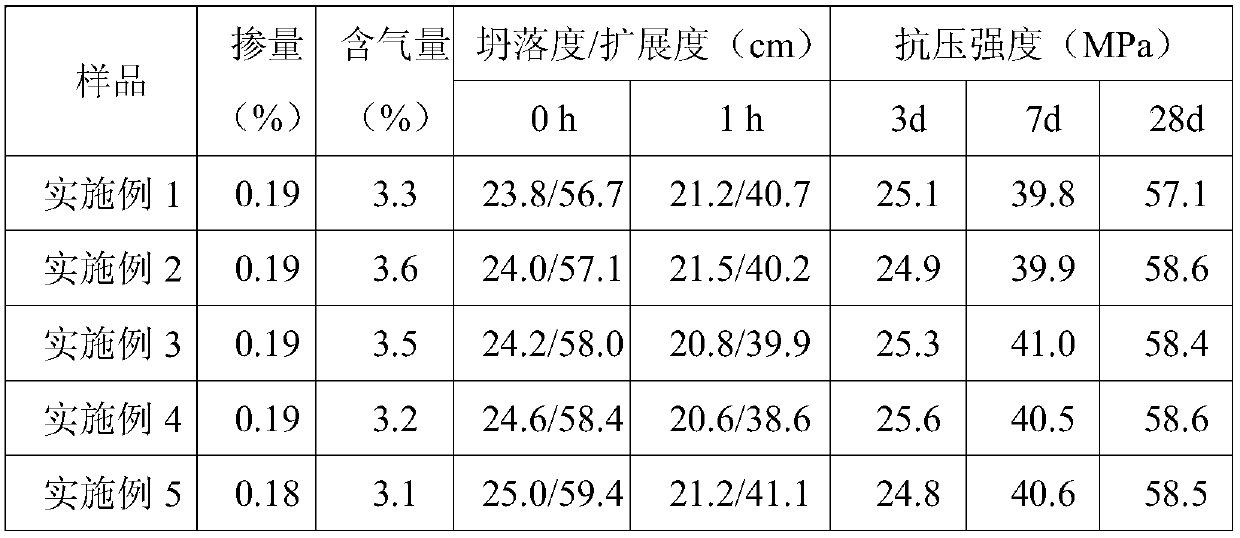

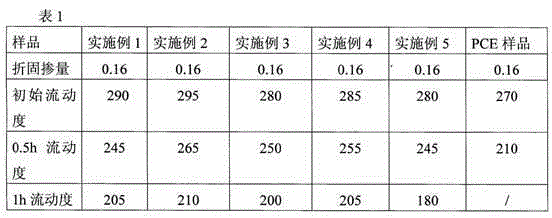

A kind of foam control agent and the air-entraining water-reducing compound agent thereof, concrete

The invention provides a foam control agent and an air-entraining water reducing compounding agent and concrete prepared thereof. The foam control agent is mainly formed by compounding the following components by weight: 5-40% of an alkynol wetting agent E20, 40-70% of an alkynol wetting agent E40, 20-50% of an alkynol wetting agent E65, and the balance other accessories. The foam control agent has double technical effects of air entraining and foam control, can control the foam density and the foam size of a system, makes foams more uniform, eliminates big harmful foams, and makes the cement strength, stability and other properties improved.

Owner:岳阳凯门水性助剂有限公司

Preparation method of high water-reducing rate branched chain type aliphatic series water reducing agent

InactiveCN103087270AHigh water reduction rateOvercome the problem of easy bleedingReaction temperatureAir content

The invention discloses a preparation method of a high water-reducing rate branched chain type aliphatic series water reducing agent. The preparation method comprises the following steps of: in parts by mass, adding 40-60 parts of sulfite and 220 parts of water into a reaction kettle; stirring for dissolving; adding liquid alkali to adjust the pH value of the solution to be 13; dropping 50-60 parts of acetone within 0.5-1 hour; controlling the reaction temperature to be 45-55 DEG C; preserving the temperature for 0.5 hour; dropping 170-190 parts of methanal within 1.5-2.5 hours; controlling the temperature to be less than or equal to 85 DEG C; adding a mixture solution prepared from 10-25 parts of polyoxyethylene ether macromonomer and 100 parts of water; dropping another mixture solution prepared from 2-5 parts of a water-soluble oxidation-reduction initiator and 40 parts of water into the system; preserving the temperature for 2-3 hours; and cooling to the room temperature so as to obtain the water reducing agent. The water reducing agent prepared by using the preparation method is greatly improved in water reducing rate, is enhanced in collapse-prevention function, and is high in air content good in air conduction capability; and the problem that bleeding is easy is overcome.

Owner:KZJ NEW MATERIALS GROUP CO LTD +3

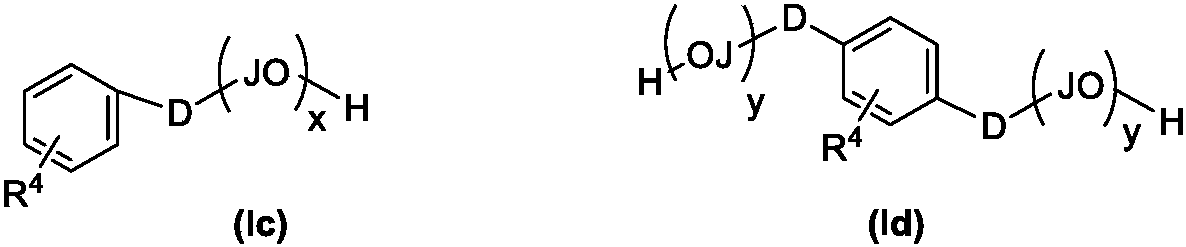

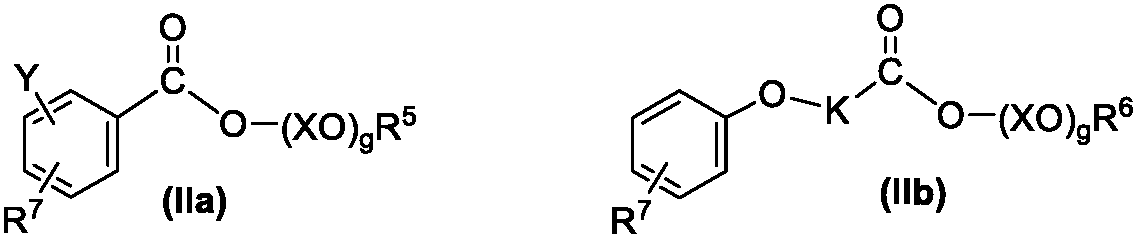

Preparation method and application of concrete plasticizer with improved clay adaptability

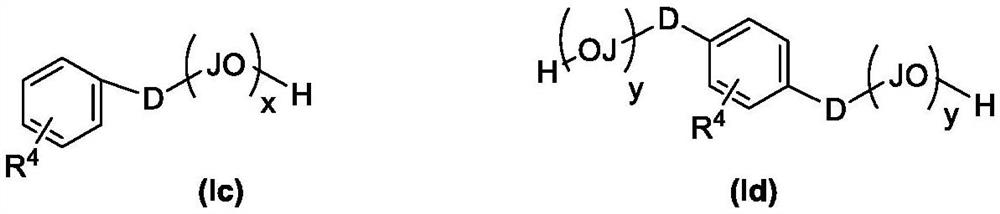

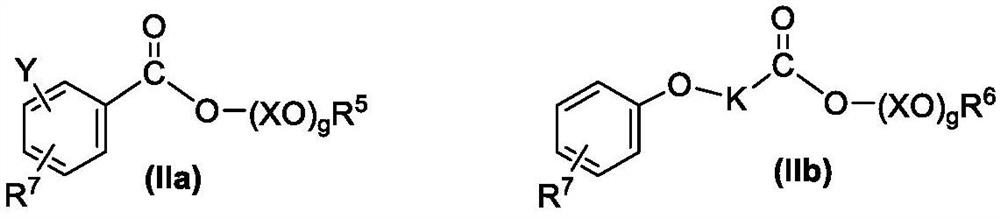

The invention provides a preparation method and an application of a concrete plasticizer with improved clay adaptability. The concrete plasticizer serves as a dispersing agent of water dispersion of ahydraulic binding agent and / or a potential hydraulic binding agent, and has good clay adaptability, better water reducing capability and higher slump loss resistance. The preparation method comprisesthe step of allowing an ingredient a, a monomer b, a monomer c and aldehyde d to give a copolycondensation under the condition of a combined catalyst e to form the concrete plasticizer. The weight-average molecular weight of the concrete plasticizer is 10000-40000; the ingredient a comprises an aryl polyether monomer a-1 with a terminal subjected to phosphonate esterification, and an optional aryl polyether monomer a-2 with hydroxyl as a terminal; the monomer b is an aryl monomer with a carboxylic ester group; the monomer c is an aryl monomer with COOH, SO3H or OPO3H2; and the combined catalyst e is a composition of protonic acid e-1 and non-protonic acid e-2.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

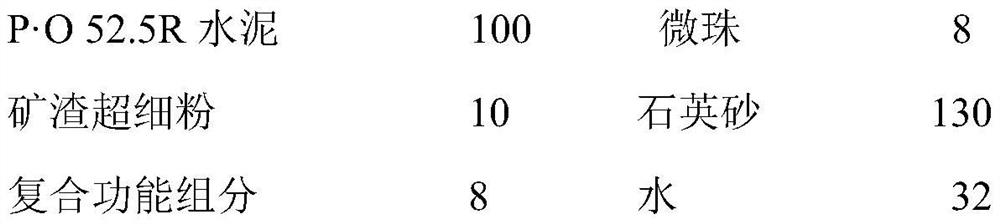

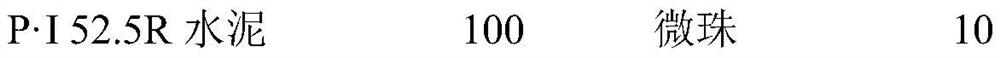

Slow-release grouting material for steel shell immersed tube grouting and construction method of slow-release grouting material

ActiveCN112592127AStrong slump retentionReduce lossesArtificial islandsUnderwater structuresSlagSlurry

The invention discloses a slow-release grouting material for steel shell immersed tube grouting and a construction method of the slow-release grouting material, and the slow-release grouting materialfor steel shell immersed tube grouting is composed of quick-hardening Portland cement, microbeads, superfine slag powder, quartz sand, a composite functional component and water. The composite functional components comprise an expanding agent, a slow-release water reducing agent, an early strength agent, a quick-acting defoaming agent, a rheological agent, a plastic expanding agent and a slump retaining agent, all the components (except water) are fully premixed into uniform dry powder in a professional factory, the grouting material dry powder and water are stirred in a container by a handheld stirrer according to a specified proportion, wherein the stirring time is not shorter than 3 min, uniform slurry is obtained by stirring, and after standing for not less than 5 minutes, and theuniform slurry can be pumped and grouted. The slow-release grouting material for steel shell immersed tube grouting has the characteristics of good fluidity, long fluidity retention time (more than or equal to 5 hours), accurate vertical expansion rate control, early strength, high strength and the like, and can be compactly filled in a gap between self-compacting concrete and a steel shell in a steelshell immersed tube.

Owner:江苏诺邦建材有限公司

Method for synthesizing modified sulfamate water reducer by utilizing wastewater generated in G salt production process

The invention relates to a method for synthesizing a modified sulfamate water reducer by utilizing wastewater generated in the G salt production process. In the method, the modified sulfamate water reducer is prepared by adopting the wastewater generated in the G salt production process, sodium sulfanilate and a compound of phenolic hydroxy. The synthesized modified sulfamic acid has a higher water-reducing rate of concrete and an excellent slump retaining property and more importantly opens up a new path of comprehensive utilization of dye intermediate wastewater. The method has the beneficial effects that the environmental pressure in the dye intermediate production process is reduced while the raw material cost of the water reducer is reduced; and therefore, the method has good economic and environmental protection benefits.

Owner:浙江五龙新材股份有限公司

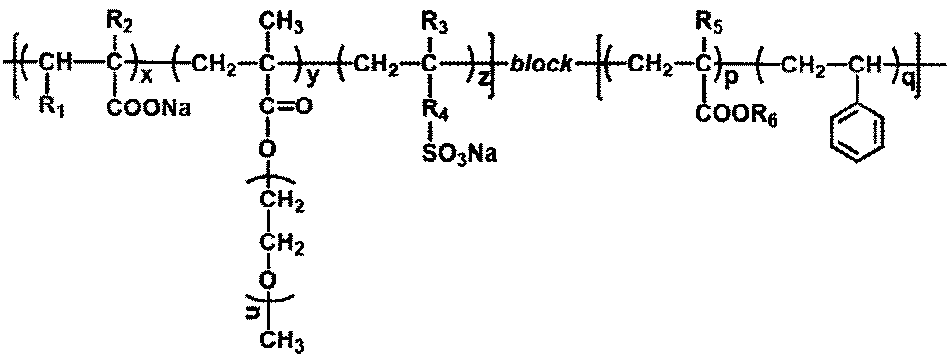

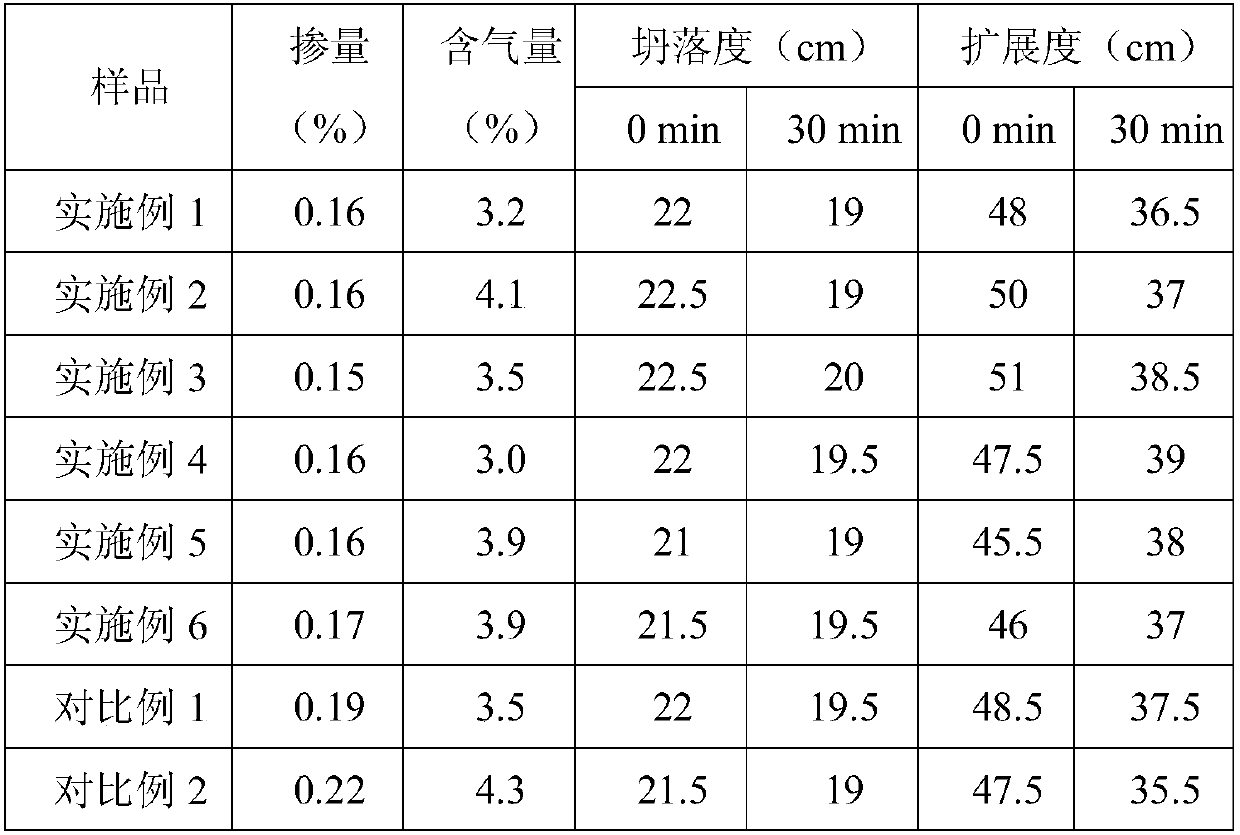

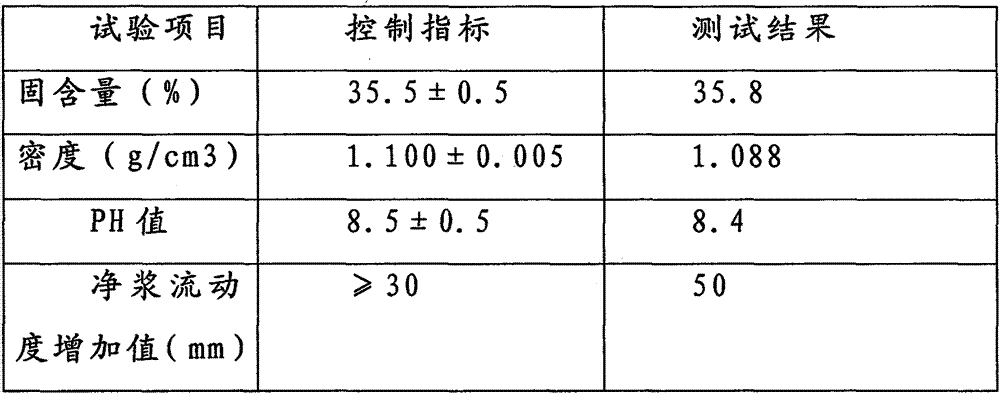

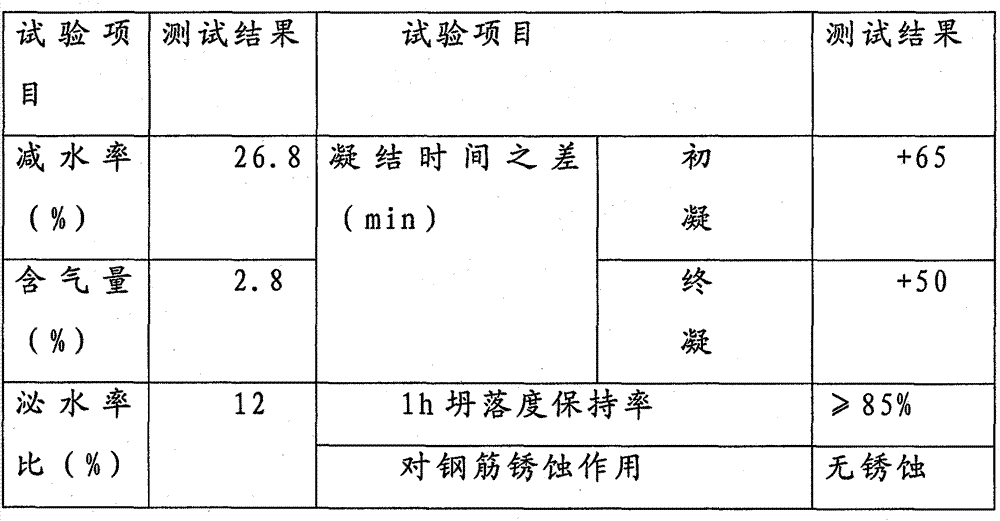

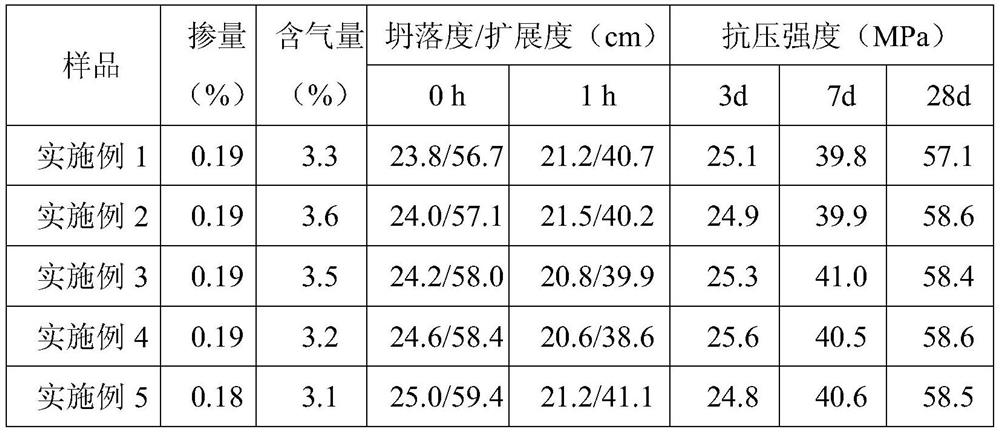

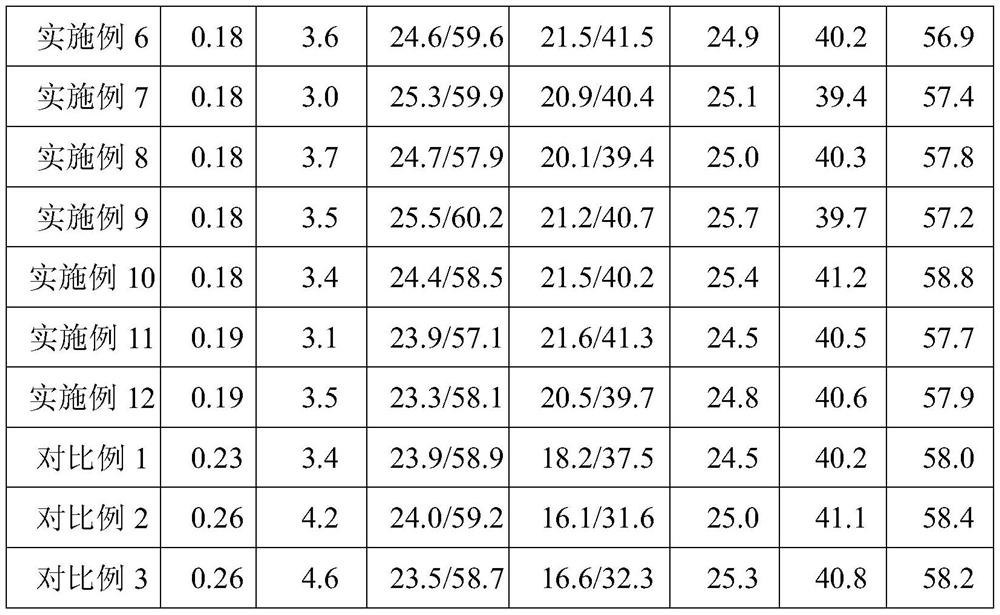

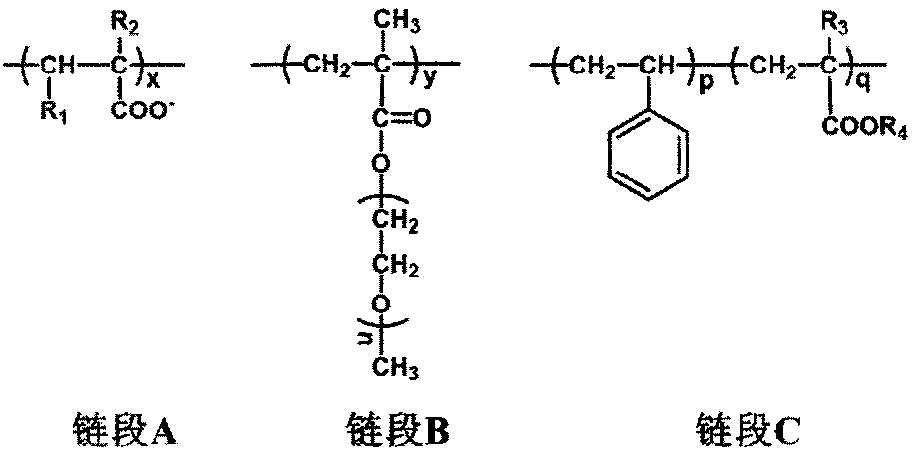

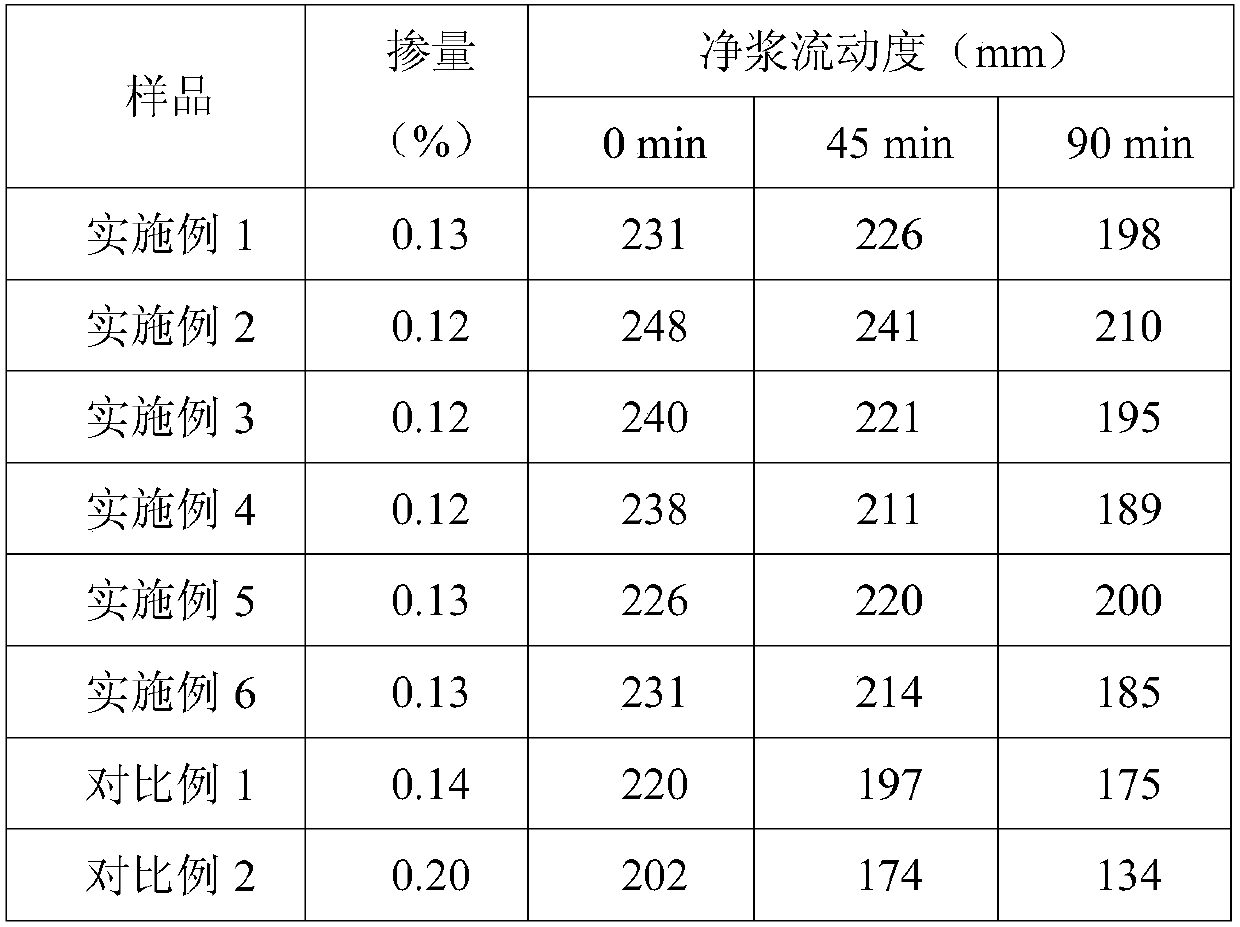

Preparation method of benzene ring-containing sulfonic block modified polycarboxylic acid slump retaining agent

InactiveCN111057198AGood adsorption and dispersion abilityGood fluidity retentionPolymer scienceSide chain

The invention relates to a preparation method of a benzene ring-containing sulfonic block modified polycarboxylic acid slump retaining agent. The polycarboxylic acid slump retaining agent is preparedby adopting a block polymerization method. The preparation method comprises the following steps: copolymerizing a benzene ring-containing monomer and a sulfonic acid monomer under certain conditions to obtain a benzene ring sulfonic block polymer i; the preparation method comprises the following steps: copolymerizing a polyether macromonomer and acrylic acid at normal temperature to obtain a blockpolymer ii, adjusting the ratio of the block polymer i to the block polymer ii, and opening double bonds to prepare the polycarboxylic acid slump retaining agent with the block copolymer by taking hydroxyethyl acrylate as a linking monomer. The polycarboxylic acid slump retaining agent prepared by the invention is prepared by adopting a block method for modification, strong anion groups such as steric hindrance and sulfo groups in a short side chain region are increased by benzene rings to provide anchoring groups, and unsaturated alkyl ester and acrylic acid are connected with a block polymer, so that the water reducing agent has relatively strong slump retaining performance and lasting slurry fluidity.

Owner:ZHEJIANG COLLEGE OF CONSTR

Concrete composite type superplasticizer

The invention discloses a concrete composite type superplasticizer, wherein the formula component comprises the following components in parts by mass: 20-35 parts of beta-naphthalene sulfonated formaldehyde condensate, 10-30 parts of polyacrylic acid ether polymer, 3-4 parts of sodium tripolyphosphate, 1-5 parts of potassium sodium tartrate, 1-2 parts of sucrose, 0.5-5 parts of cellulose ether, 2-4 parts of lignin sulfonate, 3-4 parts of acrylic acid, 30-75 parts of hydrogen peroxide and 2-4 parts of mirabilite. The beta-naphthalene sulfonated formaldehyde condensate and the polyacrylic acid ether polymer are set, and under the action of sodium tripolyphosphate, the two kinds of different water reducers are effectively mixed, the slump of concrete is improved and the setting time can be prolonged, and the cellulose ether is added, so that the polycarboxylic acid water reducer can be modified by introducing the cellulose ether-containing monomer and the stereo-hindrance effect of the water reducer can be improved. Meanwhile, the water retention property of cellulose ether can also help disperse cement particles to improve the fluidity of slurry.

Owner:江苏博思通新材料有限公司

Solid flaky polycarboxylate superplasticizer and method for preparing same by core-shell emulsion method

The invention provides a solid flaky polycarboxylate superplasticizer and a method for preparing the same by a core-shell emulsion method. The superplasticizer comprises the following components in parts by weight: 18-32 parts of a special methacrylate hydrophobic monomer for emulsification, 7-13 parts of a carboxylic hydrophilic monomer for emulsification, 0.33-0.68 parts of an emulsion initiator, 0.56-0.84 parts of a chain transfer agent for emulsification, 37-62 parts of a carboxyl small monomer, 53-76 parts of an unsaturated sulfonic small monomer, 790-830 parts of a polyether macromonomer, 4-9 parts of a weak chain transfer agent, 3.6-6.8 parts of an azo initiator, 4.2-7.6 parts of an initiator, 2.3-4.2 parts of a strong chain transfer agent, and 3.4-5.6 parts of a pH regulator. The method comprises the following steps: (1) preparing an emulsifier; (2) preparing a nuclear monomer emulsion; (3) preparing a shell monomer pre-emulsion; and (4) preparing the solid flaky polycarboxylate superplasticizer. The polycarboxylate superplasticizer prepared by the core-shell emulsion method has the advantages of single molecular weight, excellent performance, strong adaptability and easiness in storage, is prepared into solid sheets, and is lower in transportation cost and suitable for long-distance transportation.

Owner:HUBEI UNIV OF TECH

Preparation method and application of a concrete plasticizer with improved clay adaptability

The invention provides a preparation method and an application of a concrete plasticizer with improved clay adaptability. The concrete plasticizer serves as a dispersing agent of water dispersion of ahydraulic binding agent and / or a potential hydraulic binding agent, and has good clay adaptability, better water reducing capability and higher slump loss resistance. The preparation method comprisesthe step of allowing an ingredient a, a monomer b, a monomer c and aldehyde d to give a copolycondensation under the condition of a combined catalyst e to form the concrete plasticizer. The weight-average molecular weight of the concrete plasticizer is 10000-40000; the ingredient a comprises an aryl polyether monomer a-1 with a terminal subjected to phosphonate esterification, and an optional aryl polyether monomer a-2 with hydroxyl as a terminal; the monomer b is an aryl monomer with a carboxylic ester group; the monomer c is an aryl monomer with COOH, SO3H or OPO3H2; and the combined catalyst e is a composition of protonic acid e-1 and non-protonic acid e-2.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

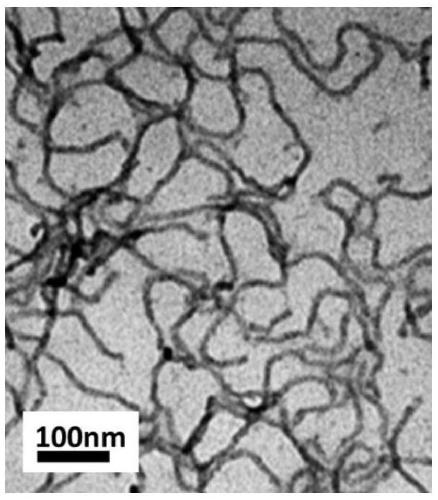

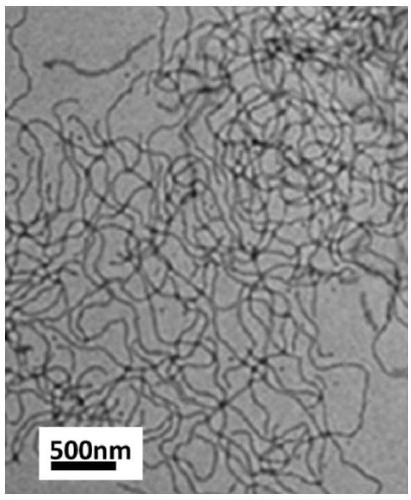

A kind of nano polycarboxylate water reducer and preparation method thereof

The invention provides a preparation method of polycarboxylic acid nanoparticles. The polycarboxylic acid nanoparticles are formed through copolymerizing a hydrophilic monomer unsaturated acid, a hydrophilic monomer polyethylene glycol monomethyl ether methacrylate, a hydrophilic monomer unsaturated sulfonate and a hydrophobic monomer styrene or (meth)acrylate, and have a linear microstructure in water. The water reducer applied to concrete has the advantages of low proportion, high water reduction, long slump retaining time and excellent mud resistance; and the polycarboxylic acids particles solves the water reducing and slump retaining problems of concrete without a super water reducer or an extra sacrificing agent when the mud content of aggregates is high, so the water reducer has good economic benefit.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

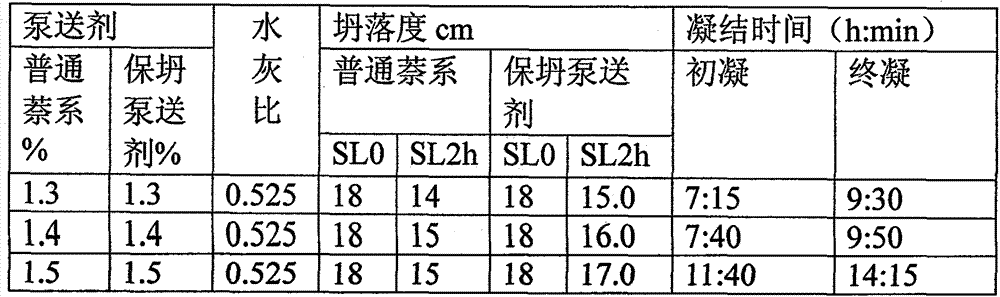

Slump-prevention-type concrete pumping aid

The invention discloses a slump-prevention-type concrete pumping aid, which comprises naphthalene or homolog thereof, aliphatic compounds, sodium gluconate, carboxylic acid grafted copolymers, lauryl sodium sulfate, formaldehyde cellulose, hydroxymethyl propyl cellulose, wherein the percentage by weight of the naphthalene or homolog thereof is 60%-80%; the percentage by weight of the aliphatic compounds is 6%-8%; the percentage by weight of sodium gluconate is 1%-5%; the percentage by weight of carboxylic acid grafted copolymers is 1%-5%; the percentage by weight of the lauryl sodium sulfate is 1%-3%, the percentage by weight of formaldehyde cellulose is 0.1%-0.5%, and the percentage by weight of the hydroxymethyl propyl cellulose is 0.1%-0.5% and the balance of water. According to the slump-prevention-type concrete pumping aid provided by the invention, on the basis of summarizing the common method of slump loss control, the carboxylic acid grafted copolymers are compounded into a naphthalene water reducer, and the slump-prevention-type concrete pumping aid has the characteristics of good dispersion property and high slump retaining capability, and solves the problem of rapid naphthalene doped pumping aid concrete slump loss.

Owner:SUZHOU CHENGHU CONCRETE CO LTD

A kind of preparation method of branched chain type aliphatic water reducing agent with high water reducing rate

InactiveCN103087270BHigh water reduction rateOvercome the problem of easy bleedingSuperplasticizerReaction temperature

The invention discloses a preparation method of a high water-reducing rate branched chain type aliphatic series water reducing agent. The preparation method comprises the following steps of: in parts by mass, adding 40-60 parts of sulfite and 220 parts of water into a reaction kettle; stirring for dissolving; adding liquid alkali to adjust the pH value of the solution to be 13; dropping 50-60 parts of acetone within 0.5-1 hour; controlling the reaction temperature to be 45-55 DEG C; preserving the temperature for 0.5 hour; dropping 170-190 parts of methanal within 1.5-2.5 hours; controlling the temperature to be less than or equal to 85 DEG C; adding a mixture solution prepared from 10-25 parts of polyoxyethylene ether macromonomer and 100 parts of water; dropping another mixture solution prepared from 2-5 parts of a water-soluble oxidation-reduction initiator and 40 parts of water into the system; preserving the temperature for 2-3 hours; and cooling to the room temperature so as to obtain the water reducing agent. The water reducing agent prepared by using the preparation method is greatly improved in water reducing rate, is enhanced in collapse-prevention function, and is high in air content good in air conduction capability; and the problem that bleeding is easy is overcome.

Owner:KZJ NEW MATERIALS GROUP CO LTD +3

A kind of polyphosphoric acid water reducing agent and preparation method thereof

ActiveCN111302692BRaw materials are cheap and easy to obtainSimple production processO-Phosphoric AcidPolyethylene glycol

Owner:JIANGSU SOBUTE NEW MATERIALS +1

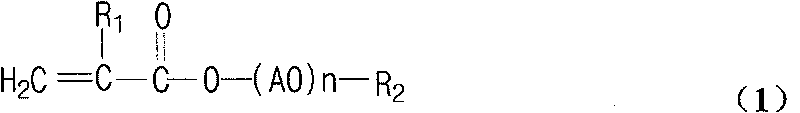

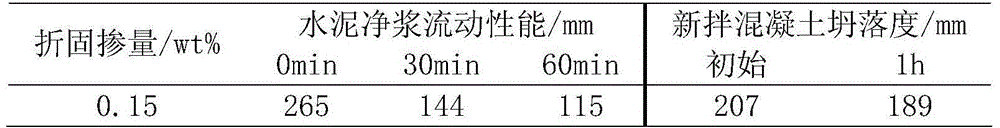

Method for preparing novel polycarboxylic acid retarded high-performance water reducer

The invention discloses a method for preparing a novel polycarboxylic acid retarded high-performance water reducer. The novel polycarboxylic acid retarded high-performance water reducer is prepared from a first reaction kettle, a second reaction kettle, methoxy polyethylene glycol, a methacrylic acid, a sulfuric acid (98%), phenothiazine,, hydroxyethyl acrylate, a crylic acid and the like as raw materials by esterification reaction, polymerization reaction and neutral reaction. The preparation method has the characteristics of simple process, good product dispersity, strong slump retention capacity, multiple variable factors of the molecular structure and the like, and is environmental friendly.

Owner:薛成明

Water-plastic retaining polycarboxylic acid water reducer and method for preparing same

The invention provides water-plastic retaining polycarboxylic acid water reducer and a method for preparing same, belonging to the technical field of the cement dispersant. The water-plastic retaining polycarboxylic acid water reducer is characterized by being prepared in nature through copolymerizing a big water-plastic retaining monomer and a small water-plastic retaining monomer, wherein the big water-plastic retaining monomer is prepared by mixing a big ester monomer with a small ester monomer. Prepared from the big water-plastic retaining monomer, the water-plastic retaining polycarboxylic acid water reducer can well retain the water and the plastic of concrete which is prepared through stirring different cement and different aggregate, and the ubiquitous problems of the segregation due to water bleeding and the quick slump loss are effectively solved. The water is used as solvent for the polymerization reaction, which is good for the industrial production and ensures the safe and environmental-friendly production process.

Owner:山东华伟银凯建材科技股份有限公司

a p 2 o 5 Method and application for preparing phosphate ester functional monomer by dispersion method

InactiveCN107793447BGood dispersionImprove adaptabilityPhosphorus organic compoundsPhosphoric Acid EstersSimple Organic Compounds

The invention discloses a method for preparing a phosphate functional monomer by a P2O5 dispersion method and application. The invention relates to a method for synthesizing a phosphate functional monomer by feeding a polymerizable unsaturated organic compound dispersed P2O5, wherein a polymerizable unsaturated organic compound dispersing agent used in a synthesis process can participate in a subsequent polymerization reaction, thereby solving the problems of difficult separation and recovery of a low-boiling-point and toxic organic solvent adopted in a preparation process of an existing phosphate functional monomer and environmental pollution, and simultaneously simplifying the synthesis route of the phosphate functional monomer. The invention also discloses a method for preparing a high-performance polycarboxylate superplasticizer by taking a phosphate functional monomer solution with a polymerizable unsaturated organic compound as a solvent as a third monomer of a polycarboxylate superplasticizer, so that the problem of contradiction between dispersion capacity and slump retention capacity of an existing polycarboxylate superplasticizer is solved, and a method for preparing a high-performance polycarboxylate superplasticizer with high dispersion and slump retention capacity and strong cement adaptability is provided.

Owner:贵州中兴南友建材有限公司

A kind of amphiphilic polycarboxylate cement dispersant and preparation method thereof

Owner:JIANGSU SOBUTE NEW MATERIALS +1

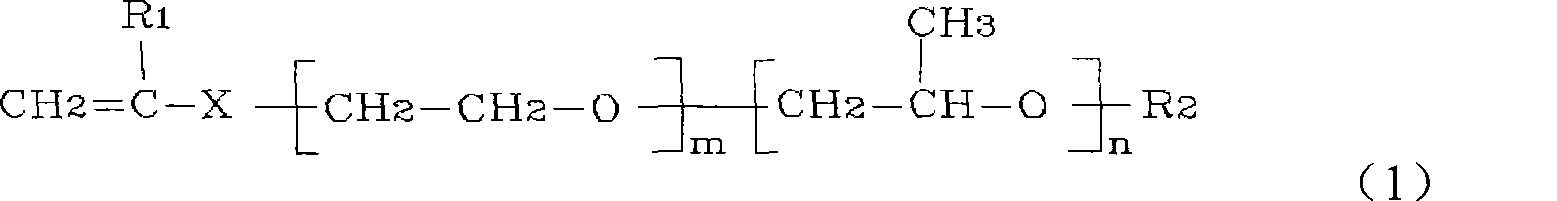

A kind of method of low temperature esterification synthetic comb type carboxylic acid polymer

ActiveCN104592528BHigh water reduction rateStrong slump retentionReaction temperaturePolyethylene glycol

The invention relates to a method for low temperature esterification synthesis of a comb-type carboxylic acid polymer. The method comprises the steps: under a vacuum condition, stirring evenly a monohydroxyl polyether and polyacrylic acid aqueous solution and a catalyst having the mass being 0.2-4 wt% of the monohydroxyl polyether and polyacrylic acid in reactant, and introducing nitrogen gas; and under a vacuum condition, adjusting the flow quantity of nitrogen gas to control the gas pressure, heating up to an esterification reaction temperature, then adding a solid acid catalyst with the mass being 0.1-2 wt% of the total mass of the monohydroxyl polyether and polyacrylic acid in reactant, carrying out esterification for 4-8 h, and synthesizing the comb-type carboxylic acid polymer. With use of the method for direct esterification of polyacrylic acid and polyethylene glycol monoether macromolecules to synthesize the polycarboxylic acid water reducing agent under catalysis of a high-catalytic-activity catalyst, the method has the characteristics of simple process, large molecular structure design freedom degree of the product, stable product quality, low reaction temperature, low energy consumption and low production cost.

Owner:JIANGSU CHINA RAILWAY ARIT NEW MATEIRALS CO LTD

A slow-release polycarboxylate water reducer and its preparation method and application

The invention discloses sustained-release polycarboxylate superplasticizer and a preparation method and application thereof.The sustained-release polycarboxylate superplasticizer is prepared from, by weight, 50-58 parts of polymethylacrylic acid, 22-30 parts of castor beans, 5-12 parts of menthone, 8-15 parts of chitosan, 1-5 parts of potassium ferrate and 33-40 parts of formic acid.The castor beans are dried, smashed and sieved, cyclohexane is added into the sieved castor bean powder, sealing heating is conducted, and supernatant liquid is extracted after filtering; the supernatant liquid and chitosan are mixed, sealing heating is conducted, and a mixture A is obtained; polymethylacrylic acid and formic acid are mixed, deionized water is added, heating and stirring are conducted, menthone is added, heating and stirring are conducted, and a mixture B is obtained; the mixture A and the mixture B are mixed, and after heating and stirring are conducted, potassium ferrate is added, heating is conducted, and the sustained-release polycarboxylate superplasticizer is prepared.The sustained-release polycarboxylate superplasticizer has sustained-release performance, the water reducing efficiency is higher, good water reducing performance and slump retaining performance are shown, the sustained-release polycarboxylate superplasticizer also has the defoaming function, sources of the raw materials are wide, the production technology is simple, cost is low, no environment pollution is caused, and the sustained-release polycarboxylate superplasticizer is suitable for industrial production.

Owner:SHANDONG JINGJIN NEW ENERGY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com