Preparation method of polycarboxylic acid water reducer

A technology of water reducing agent and polycarboxylic acid, applied in the field of preparation of polycarboxylic acid water reducing agent, can solve the problems of low polymerization activity, low conversion rate, unable to meet construction requirements, etc., and achieves strong environmental adaptability and effective ingredients. Increase and improve the effect of polymerization reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

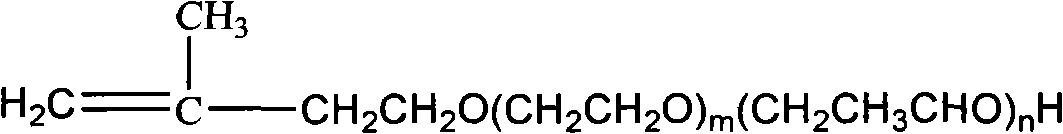

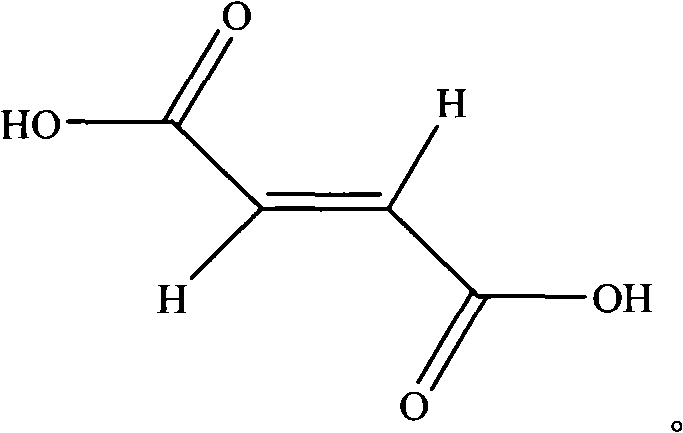

Method used

Image

Examples

Embodiment Construction

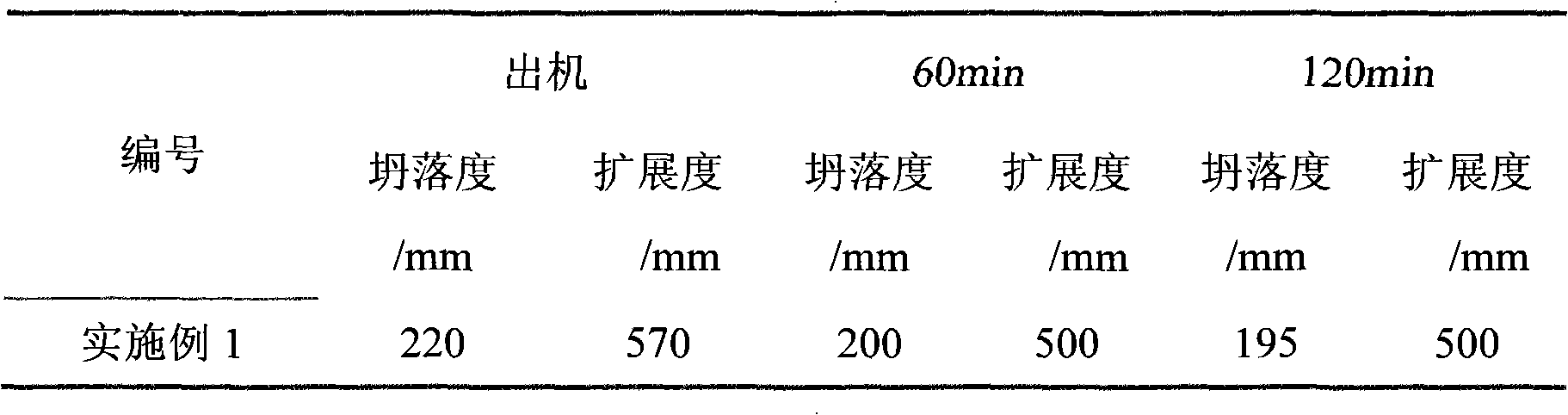

[0056] According to the requirements of high-performance concrete in the Bailifeng area of Xinjiang section of Lanzhou-Xinjiang Railway, C30 grade concrete was prepared. The cement is Tianshan low-alkali cement PO 42.5, the fly ash is II ash, and the sand is medium sand with a fineness modulus of 2.8 (3.5% mud content, 5-25mm continuous gradation mud content (1.5%) for stones, The water reducer dosage is 1.0% of the cementitious material consumption, and the air relative humidity is 20%. Experiments are carried out by the following mixing ratio: cement: fly ash: sand: stone: water: admixture=269: 145: 709: 1020: 160: 4.14 (unit: Kg); basic requirements for concrete: slump 220 ± 20mm, loss of no more than 15% in 2 hours, no segregation and bleeding of concrete. Trial mix of concrete shall be carried out according to the above requirements. The results are shown in Table 1.

[0057] Table 1 concrete performance test results

[0058]

[0059]

[0060] As can be seen fro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com