Heat source-free short-time preparation method of controlled-release type polycarboxylic acid high-performance slump retaining agent

A slow-release polycarboxylic acid, high-performance technology, applied in the field of polycarboxylate water reducer, can solve the problems of insufficient slump retention capacity of the water reducer, and achieve the effects of simple equipment, good slump retention performance and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

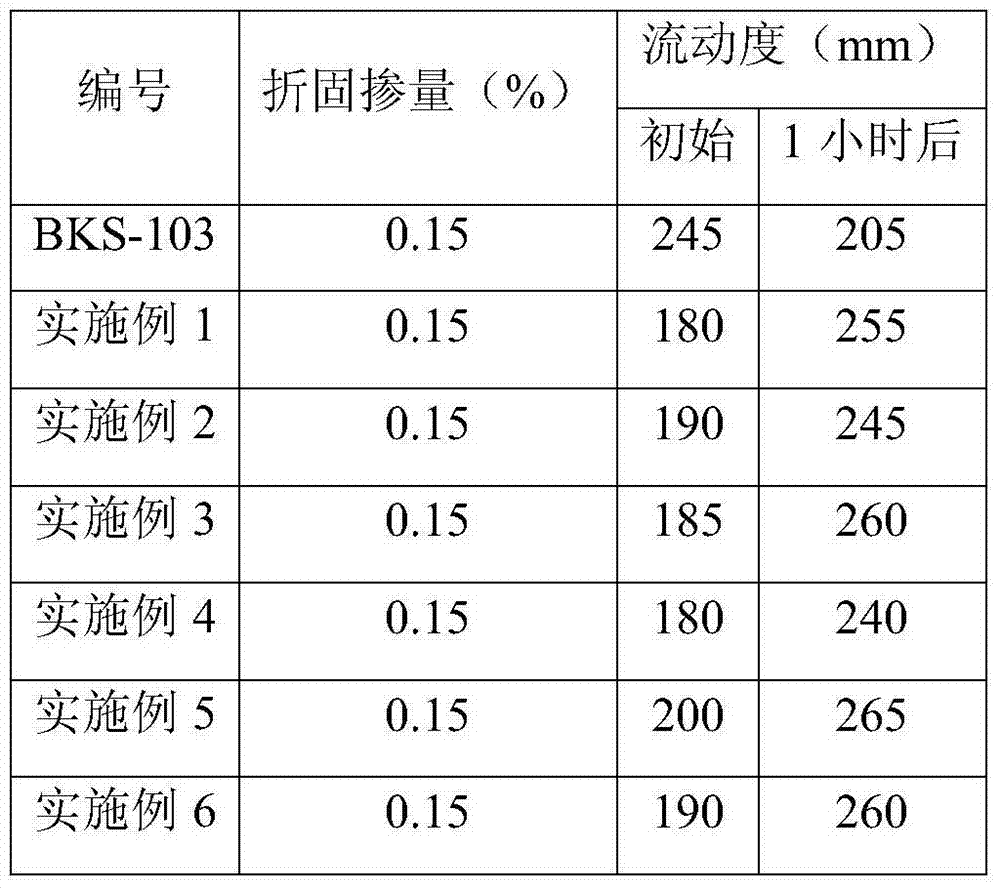

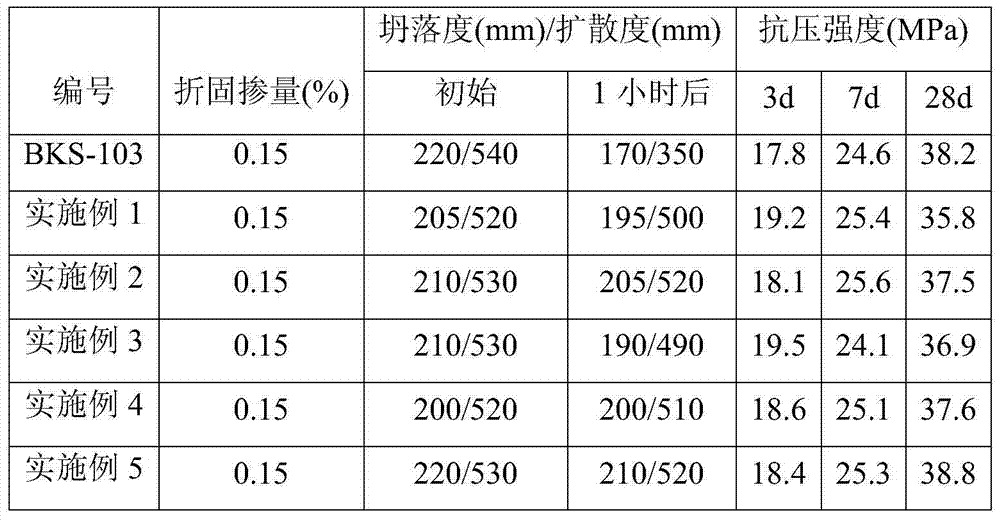

Examples

Embodiment 1

[0026] Put 330.5g of methallyl polyoxyethylene ether with a molecular weight of 2400 into a 1000m1 three-necked flask with an insulating jacket, add 330g of water, and stir for 0.5h; after the methallyl polyoxyethylene ether is completely dissolved, put in 3.5 g ammonium persulfate and 0.8 g sodium bisulfite, stir well for 2 min; simultaneously titrate the mixture containing 20 g of acrylic acid, 21 g of hydroxyethyl acrylate, 2.3 g of AMPS and 50 g of water, and the mixture of 2.1 g of thioglycolic acid and 80 g of water; 1 h at the same time After dripping, keep warm for 0.5h after titration; add a certain amount of lye to adjust the pH to 6-7, and add a certain amount of water to dilute to a solid content of 40%.

Embodiment 2

[0028] Put 330.5g of methallyl polyoxyethylene ether with a molecular weight of 2400 into a 1000m1 three-necked flask with an insulated jacket, add 330g of water, and stir for 0.5h; g ammonium persulfate, 0.5g sodium bisulfite and 0.4g vitamin C, stir well for 2min; simultaneously titrate the mixture containing 19g acrylic acid, 22g hydroxyethyl acrylate, 2.5g AMPS and 50g water and 2.6g thioglycolic acid and 80g water Mixed solution; 1h at the same time, keep warm for 0.5h after titration; add a certain amount of lye to adjust the pH to 6-7, and add a certain amount of water to dilute to a solid content of 40%.

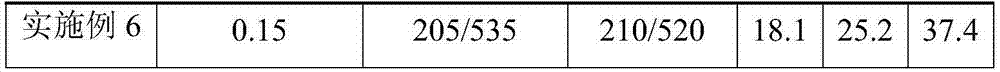

Embodiment 3

[0030] Put 330.5g of methallyl polyoxyethylene ether with a molecular weight of 2400 into a 1000m1 three-necked flask with an insulating jacket, add 330g of water, and stir for 0.5h; after the methallyl polyoxyethylene ether is completely dissolved, put in 3.2 1g ammonium persulfate and 0.83g hang white block, fully stirred for 2min; simultaneously titrate the mixed solution containing 19.5g acrylic acid, 20.5g hydroxyethyl acrylate, 2.1g AMPS and 50g water and the mixed solution of 2.2g thioglycolic acid and 80g water; 1h; At the same time, after the titration is completed, keep warm for 0.5h; add a certain amount of lye to adjust the pH to 6-7, and add a certain amount of water to dilute to a solid content of 40%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com