Preparation method of strengthening and toughening polycarboxylate water reducing agent

A polycarboxylate-based, strengthening and toughening technology, applied in the field of preparation of polycarboxylate-based water reducers, can solve the problems of large resource and energy consumption, environmental pollution, etc., and achieve improved compressive strength, good slump performance, High water reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

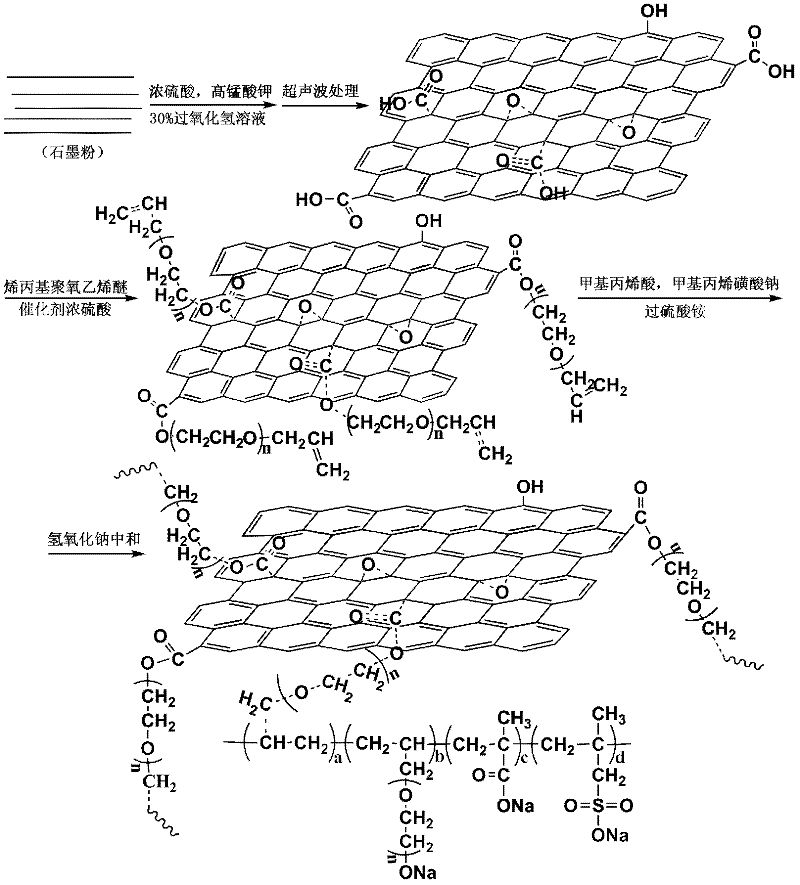

[0017] Embodiment 1: see figure 1 ,

[0018] 1) Add 6 parts of graphite powder with a particle size of <30 microns and 3 parts of sodium nitrate in parts by mass into 60 parts of concentrated sulfuric acid with a temperature of 5°C and a mass fraction of 98% under stirring, and slowly add 18 parts after stirring and mixing evenly. Parts of potassium permanganate, reacted at room temperature for 10 hours, slowly added 200 parts of deionized water, raised the temperature to 68°C and continued to react for 4 hours, then added dropwise 20 parts of hydrogen peroxide solution with a mass fraction of 30%, ultrasonically dispersed for 30 Minutes later, centrifuge, wash repeatedly to remove sulfuric acid, and dry at 60°C to obtain graphene oxide;

[0019] 2) Take 20 parts by mass of allyl polyoxyethylene ether, 0.5 parts of graphene oxide and 0.2 parts of concentrated sulfuric acid with a mass fraction of 98%, mix and stir to raise the temperature to 60 ° C, keep warm and ultrasonical...

Embodiment 2

[0024] 1) Add 6 parts of graphite powder with a particle size of <30 microns and 3 parts of sodium nitrate in parts by mass into 60 parts of concentrated sulfuric acid with a temperature of 5°C and a mass fraction of 98% under stirring, and slowly add 18 parts after stirring and mixing evenly. Parts of potassium permanganate, reacted at room temperature for 10 hours, slowly added 200 parts of deionized water, raised the temperature to 68°C and continued to react for 4 hours, then added dropwise 20 parts of hydrogen peroxide solution with a mass fraction of 30%, ultrasonically dispersed for 30 Minutes later, centrifuge, wash repeatedly to remove sulfuric acid, and dry at 60°C to obtain graphene oxide;

[0025] 2) Take 24 parts by mass of allyl polyoxyethylene ether, 0.8 parts of graphene oxide and 0.4 parts of concentrated sulfuric acid with a mass fraction of 98%, mix and stir to raise the temperature to 63 ° C, keep warm and ultrasonically treat for 1.2 hours to obtain oxidize...

Embodiment 3

[0030] 1) Add 6 parts of graphite powder with a particle size of <30 microns and 3 parts of sodium nitrate in parts by mass into 60 parts of concentrated sulfuric acid with a temperature of 5°C and a mass fraction of 98% under stirring, and slowly add 18 parts after stirring and mixing evenly. Parts of potassium permanganate, reacted at room temperature for 10 hours, slowly added 200 parts of deionized water, raised the temperature to 68°C and continued to react for 4 hours, then added dropwise 20 parts of hydrogen peroxide solution with a mass fraction of 30%, ultrasonically dispersed for 30 Minutes later, centrifuge, wash repeatedly to remove sulfuric acid, and dry at 60°C to obtain graphene oxide;

[0031] 2) Take 28 parts by mass of allyl polyoxyethylene ether, 1.2 parts of graphene oxide and 0.8 parts of concentrated sulfuric acid with a mass fraction of 98%, mix and stir to raise the temperature to 68 ° C, keep warm and ultrasonically treat for 1.3 hours to obtain oxidize...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com