Autodensing concrete using polycarboxylic acid series additive and its technology

A technology of self-compacting concrete and polycarboxylate, which is applied in the field of concrete materials to achieve the effects of saving energy and manpower, eliminating noise, and maintaining good slump

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

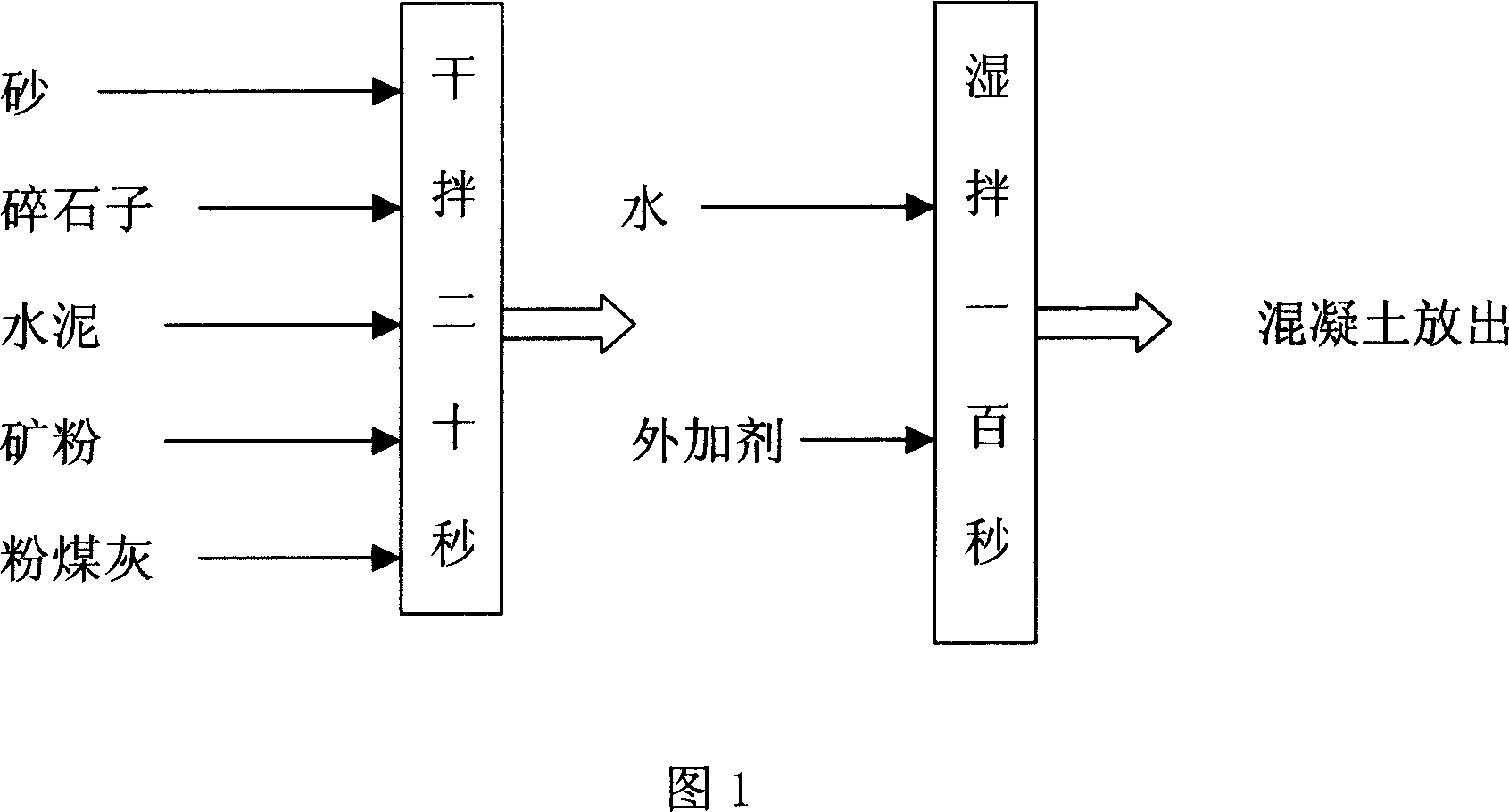

Method used

Image

Examples

Embodiment Construction

[0024] Below by embodiment the present invention will be further described

[0025] An embodiment of the present invention: the target of its concrete mix ratio design

[0026] Compressive strength: R28C60; slump: 220±20mm; expansion: 600±20mm; air content: ≤3%.

[0027] Raw material requirements for self-compacting concrete:

[0028] Cementitious material: Choose ordinary Portland cement with a strength grade of not less than 42.5, which has low water demand, and consider the compatibility with the polysalt admixture used. The composite effect of different admixtures is used to ensure the durability of concrete. For example, mineral powder has higher activity than fly ash, but poor segregation resistance. Fly ash has poorer carbonation resistance than mineral powder, but smaller shrinkage. Therefore, if slag powder and fly ash are mixed together in an appropriate proportion, then learn from each other.

[0029]Aggregate: The particle shape, size and gradation of the aggreg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum particle size | aaaaa | aaaaa |

| Chain length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com