Water reducing agent for shrinkage-compensating concrete

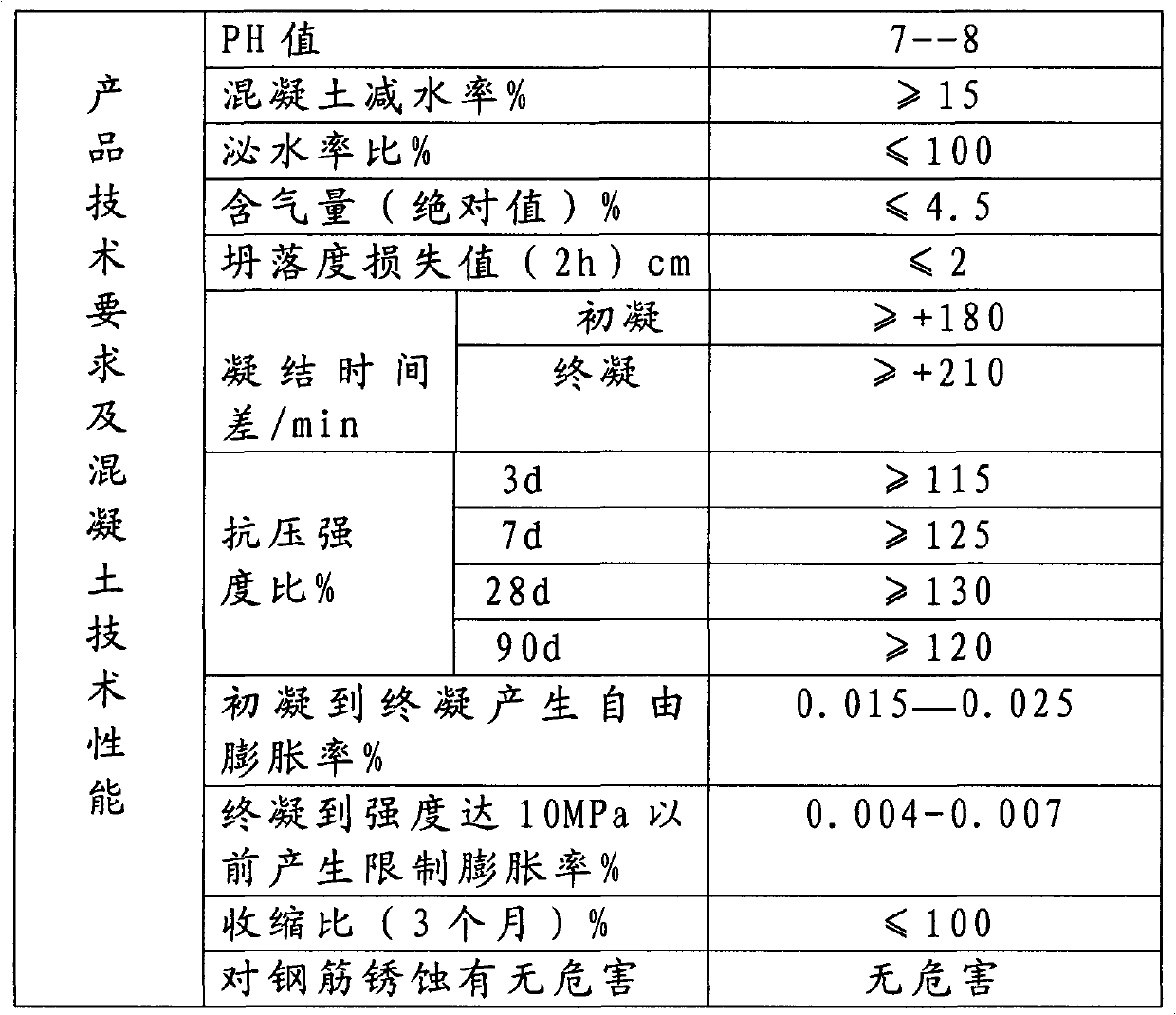

A technology for compensating shrinkage and concrete. It is applied in the field of water reducing agent for concrete. It can solve the problems of rapid slump loss, easy cracking, and increased concrete shrinkage rate, and achieves high water reduction rate, good slump retention, and early reduction of early cracking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0009] A shrinkage-compensating water reducer for concrete according to the present invention, comprising naphthalene or its homologues, aliphatic compounds, sodium glucocarbonate, sodium lauryl sulfate, formaldehyde cellulose, and hydroxypropylmethyl cellulose; wherein naphthalene Or homologues accounted for 70% by weight; aliphatic compounds accounted for 5% by weight; sodium glucocarbonate accounted for 3% by weight; sodium lauryl sulfate accounted for 1% by weight; formaldehyde cellulose The percentage by weight of hydroxypropyl methylcellulose is 0.2%; the percentage by weight of hydroxypropyl methylcellulose is 0.3%, and the rest is water.

Embodiment 2

[0011] A shrinkage-compensating water reducer for concrete according to the present invention, comprising naphthalene or its homologues, aliphatic compounds, sodium glucocarbonate, sodium lauryl sulfate, formaldehyde cellulose, and hydroxypropylmethyl cellulose; wherein naphthalene Or homologues accounted for 80% by weight; aliphatic compounds accounted for 7% by weight; sodium glucocarbonate accounted for 3% by weight; sodium lauryl sulfate accounted for 3% by weight; formaldehyde cellulose The percentage by weight of hydroxypropyl methylcellulose is 0.5%; the percentage by weight of hydroxypropyl methylcellulose is 0.5%, and the rest is water.

[0012] The shrinkage-compensating concrete water-reducing agent of the present invention has no waste, no dust, no harm to the human body, no pollution to the environment, and belongs to the green product in the construction industry; at the same time, the shrinkage-compensating concrete water-reducing agent of the present invention ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com