Patents

Literature

58results about How to "Improve pulp fluidity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Efficient polycarboxylic acid water reducing agent with additional modified celluloses

InactiveCN105985052AGood dispersionReduce bleedingSolid waste managementPolyacrylamideSodium hydroxide

The invention discloses an efficient polycarboxylic acid water reducing agent with modified celluloses. The efficient polycarboxylic acid water reducing agent comprises, by weight, 240-250 parts of methyl-2-buten polyoxyethylene ether, 25.2-26.0 parts of acrylic acid, 1.6-1.65 parts of ammonium persulfate, 0.53-0.55 part of thioglycolic acid, 13-14 parts of lignin, an appropriate quantity of sodium hydroxide solution with the concentration of 10 wt%, an appropriate quantity of deionized water, 26-28 parts of graphene oxide, 5-7 parts of waste liquid from sugar factories, 7-8 parts of hydroxypropyl methyl celluloses, 2-3 parts of polyacrylamide, 3-4 parts of calcium chloride, 2-3 parts of triethanolamine, 5-6 parts of carbon black, 19-22 parts of building brick residues and 1-1.2 parts of silane coupling agents kh550. The efficient polycarboxylic acid water reducing agent has the advantages that components such as the hydroxypropyl methyl celluloses, the polyacrylamide and the carbon black are added into the efficient polycarboxylic acid water reducing agent in preparation procedures by the aid of a series of treatment processes, accordingly, the flowability and the frost resistance of concrete can be improved, and the dispersion resistance of products in water further can be improved.

Owner:ANHUI XINRUN NEW MATERIALS

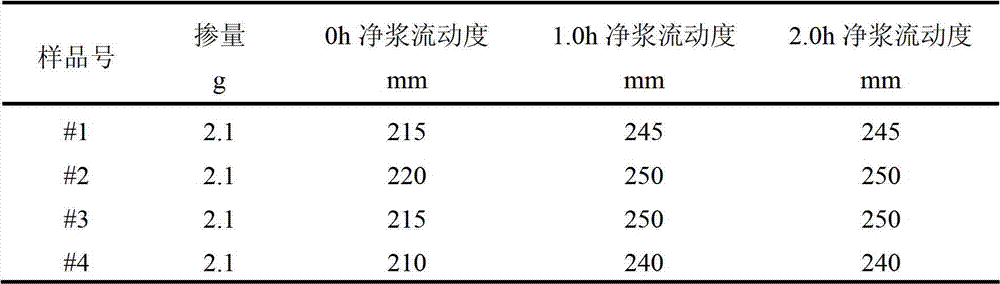

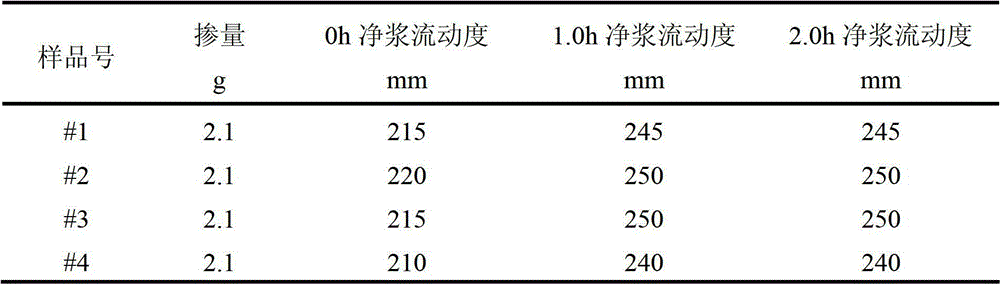

Preparation method for modified cyclodextrin water reducer

The invention relates to a preparation method for modified cyclodextrin water reducer. Beta-CD (cyclodextrin) originated from natural starch is utilized as raw materials, carboxylic groups are introduced onto beta-CD molecules modified by chloroacetic acid, and the beta-CD has fine dispersity, fluidity and slow setting by the aid of a cavity structure of the beta-CD and hydroxy and carboxylic radicals on the surface of the beta-CD, so that the beta-CD can be independently utilized and also utilized with polycarboxylate water reducer. The beta-CD independently utilized as the water reducer is stable in performance, high in adaptability to cement and good in compatibility with other additives, the cement paste fluidity can reach more than 240mm [W / C (water / cement)=0.35], the concrete water reducing rate can be up to 18-25%, and the slump retention time ranges from 5 hours to 7 hours. When the beta-CD is utilized with the polycarboxylate water reducer, the cement paste fluidity of the polycarboxylate water reducer can be increased by about 30mm, the slow setting and slump retention time can be prolonged by 3-5 hours, overflow, separation and the like of the polycarboxylate water reducer can be effectively prevented, and adaptability of the polycarboxylate water reducer to aggregate containing mud is enhanced.

Owner:SHAANXI UNIV OF SCI & TECH

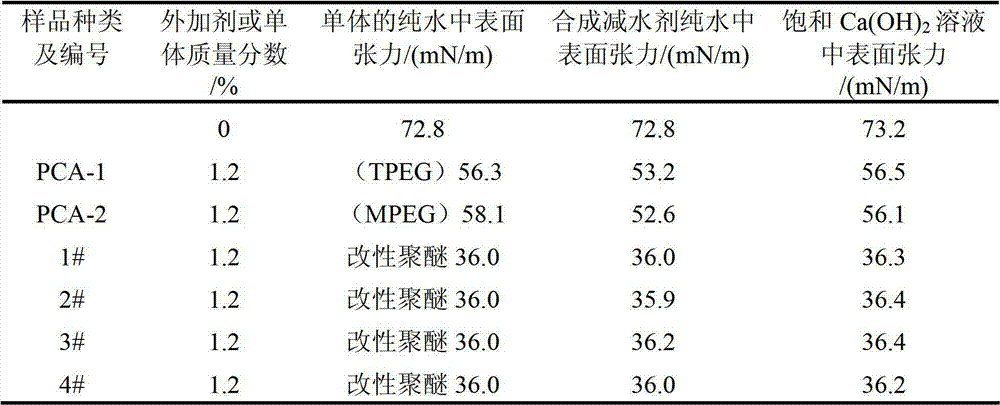

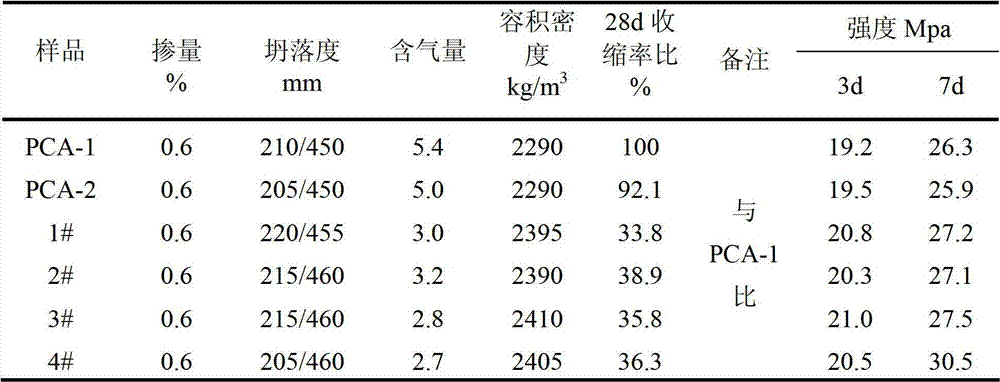

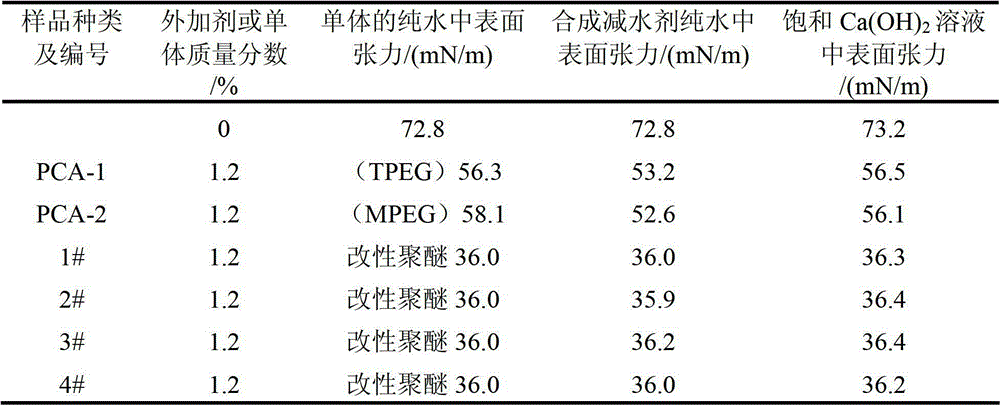

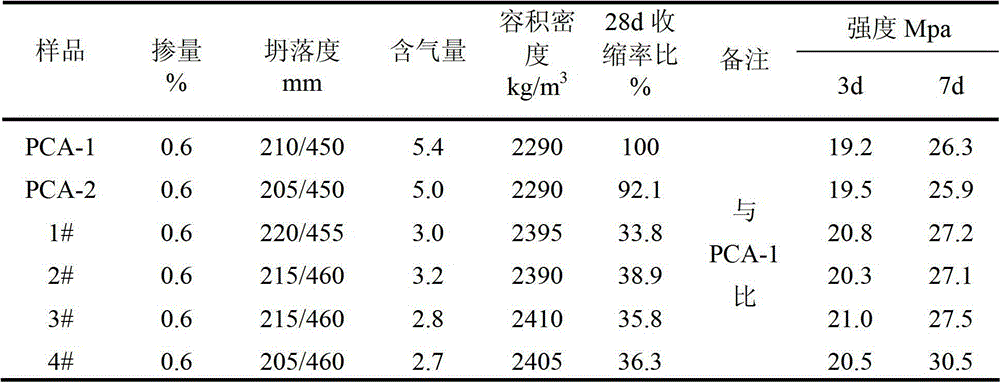

Low air leading reducing type polycarboxylic acid concrete water reducer and preparation method thereof

The invention relates to a low air leading reducing type polycarboxylic acid concrete water reducer and a preparation method thereof. The water reducer is formed by a single body A and a single body B in copolymerization according to the molar ratio of 1:3-3.5. The single body A is modified polyether TPEG, and the single body B is one or several of crylic acid, methyl acrylate, acrylamide, methacrylic acid, methyl methacrylate and methacrylamide. The preparation method includes first adding H2O2 into modified polyether TPEG water solution under the temperature of 50-55 DEG C, stirring the mixture for 10-15min, simultaneously dropping mixed water solution of ascorbic acid and a chain transfer agent and single body B solution respectively and continuously conducting reaction for 0.5-1.0 hour in heat insulation mode after dropping is finished to obtain the polycarboxylic acid water reducer after pH value adjustment. The water reducer has higher water reducing rate, has low air content and a certain reducing function if used for concrete and is the multifunctional high-efficiency water reducer integrating water reducing, reducing and low air leading.

Owner:山东华伟银凯建材科技股份有限公司

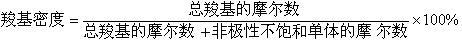

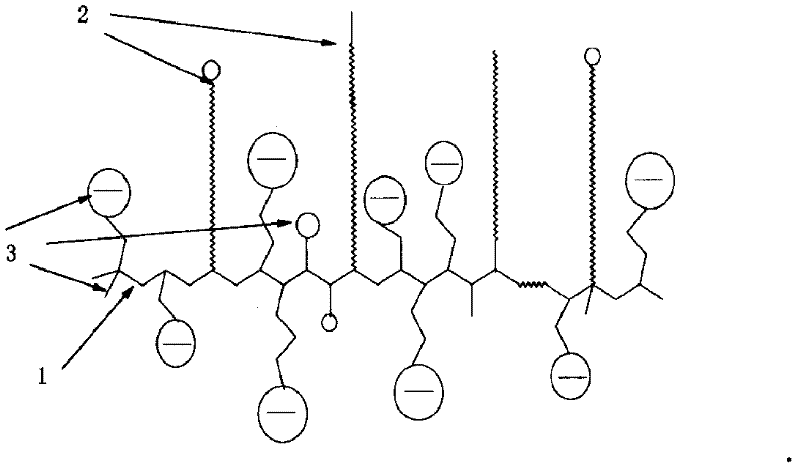

Main chain carboxy-density-adjustable high-efficiency polycarboxylic acid water reducing agent

InactiveCN102584093AImprove performanceAvoid the effects of a significant reduction in dispersing propertiesSolubilityDispersity

The invention discloses a novel main chain carboxy-density-adjustable high-efficiency polycarboxylic acid water reducing agent which has a comb-type structure. The main chain is mainly formed by randomly copolymerizing carboxy-containing unsaturated monomers and nonpolar unsaturated monomers; the side chain is long chain polyether; and the main chain and the side chain are connected through esterifying reaction to form the polycarboxylic acid water reducing agent. The nonpolar unsaturated monomers are used as the carboxy density regulator, and the consumption of the carboxy density regulator is regulated to effectively regulate the carboxy density in the water reducing agent main chain, thereby finely regulating the comprehensive properties of the water reducing agent. In addition, the unsaturated functional monomers containing sulfonic groups, amido groups or the like can be added according to needs to further improve the dispersity and solubility of the water reducing agent. The maximum water reducing rate of the water reducing agent is up to 42%; and when used in Portland cement or slag-base cementing material, the water reducing agent can obviously enhance the net slurry and mortar flowability of the product, the net slurry and mortar flowability retentivity, folding strength, compression strength and the like.

Owner:KUNMING UNIV OF SCI & TECH

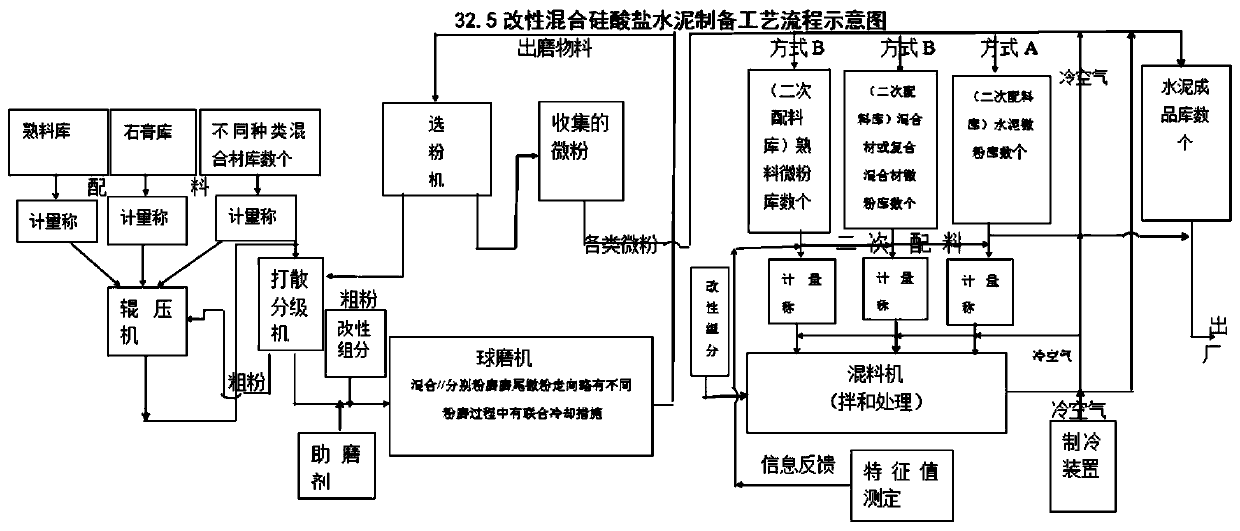

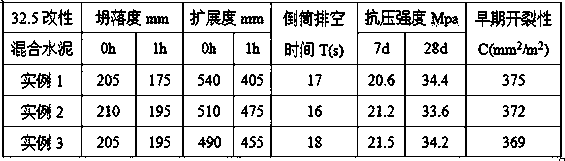

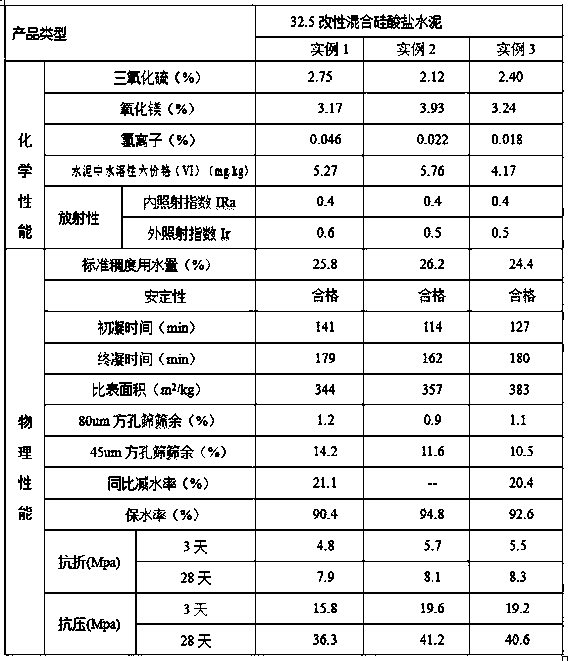

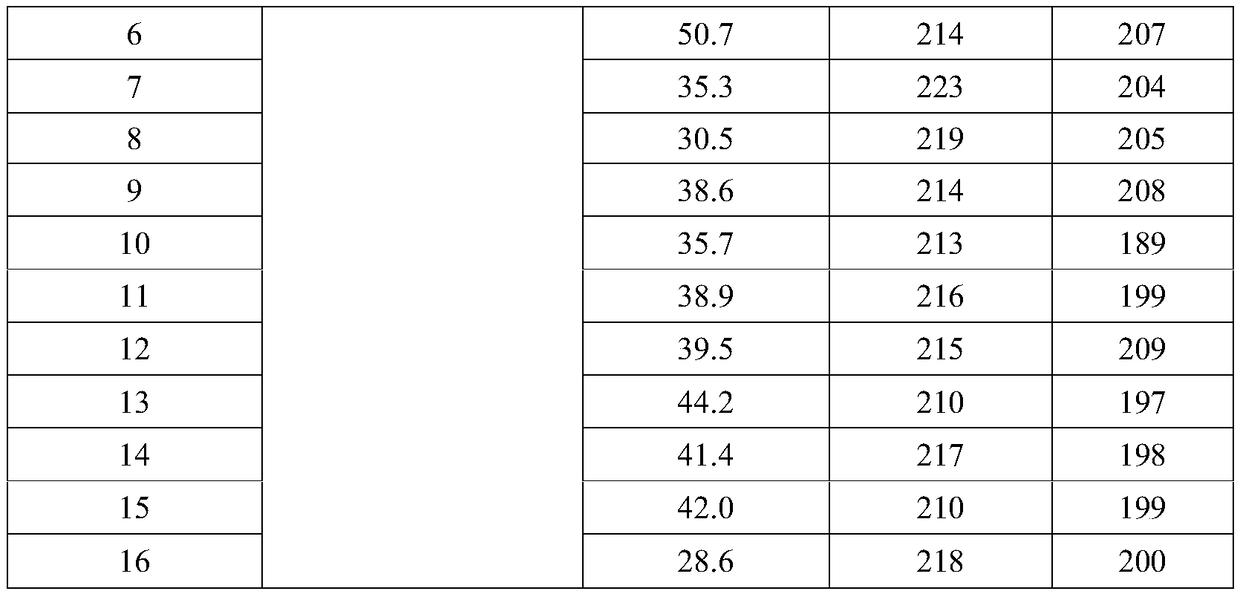

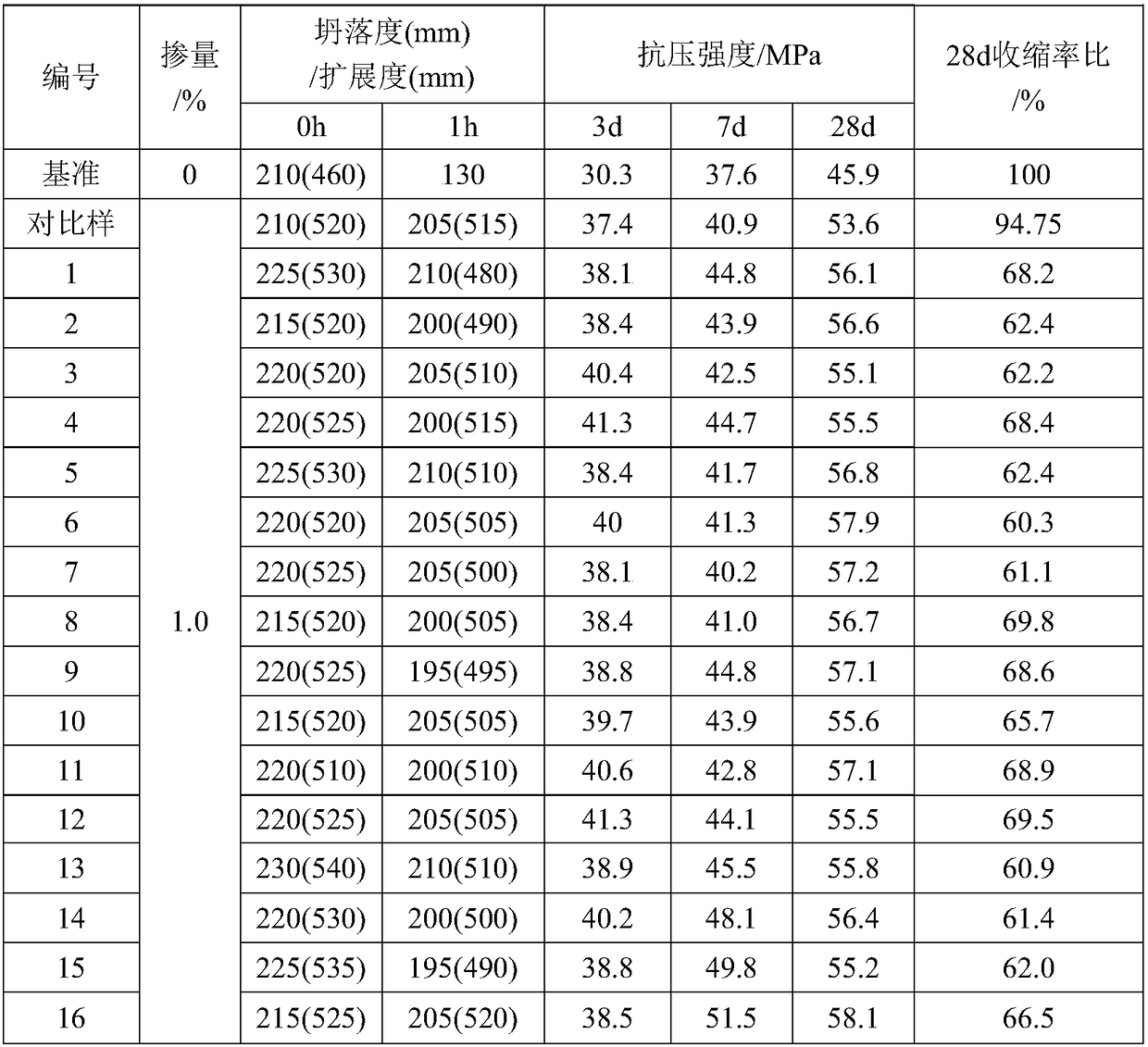

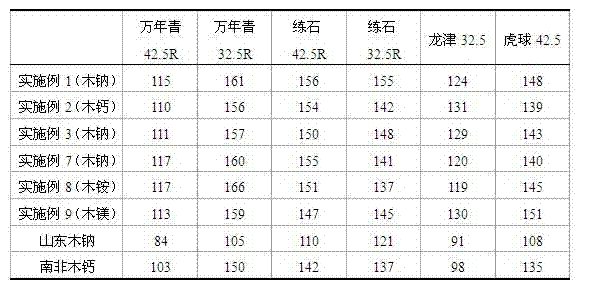

32.5 modified mixed Portland cement and preparation method thereof

The invention discloses a 32.5 modified mixed Portland cement and a preparation method thereof. The cement comprises, by mass, 45.0-68.0% of Portland cement clinker and gypsum, 5.0-25.0% of limestone,0-0.5% of a grinding aid and 0.02-5.5% of a modifying component, and also includes 5.0-45.0% of one or more of granulated blast furnace slag, granulated blast furnace slag powder, a vulcanic ash mixture and a fly ash-containing active or non-active mixture, and 8.0% or below of other incorporation-allowed waste slag. The raw materials have wide sources, and the preparation method is not complicated, relates to the fields of comprehensive utilization of cement, concrete, mortar and solid wastes, and meets the conditions of the process for preparing the cement product containing the modifyingcomponent. The cement improves the homogeneity, the workability, the durability and other performances of concrete and mortar prepared from the cement, increases the construction efficiency, and facilitates of comprehensive utilization of resources, energy saving and emission reduction.

Owner:程菲 +1

Preparation method of fluorine-containing shrink-reduced polycarboxylate water reducing agent

ActiveCN109280141AHigh water reduction rateLow plasticityShrinkage crackingOxidation-Reduction Agent

The invention discloses a preparation method of a fluorine-containing shrink-reduced polycarboxylate water reducing agent. The method particularly includes: 1) preparation of a polycarboxylate water reducing agent prepolymer: under effects of an initiator, a reducing agent and a chain transfer agent, performing a redox radical polymerization reaction to a carbonyl-containing monomer, an unsaturated acid monomer and an unsaturated macro-monomer to obtain a carbonyl-containing polycarboxylate water reducing agent prepolymer; 2) preparation of the fluorine-containing shrink-reduced polycarboxylate water reducing agent: performing a nucleophilic substitution reaction to the carbonyl-containing polycarboxylate water reducing agent prepolymer with a Prakash reagent (TMSCF3) to obtain the water reducing agent. The water reducing agent can significantly reduce surface tension and improve cement dispersibility, is high in shrinkage reducing performance on the basis of high water reduction, is good in compatibility with cement, is low in gas content when being applied to concrete, can effectively improve size stability of concrete and reduce shrinkage cracking and can improve the durabilityand service life of a concrete structure.

Owner:BEIJING UNIV OF TECH

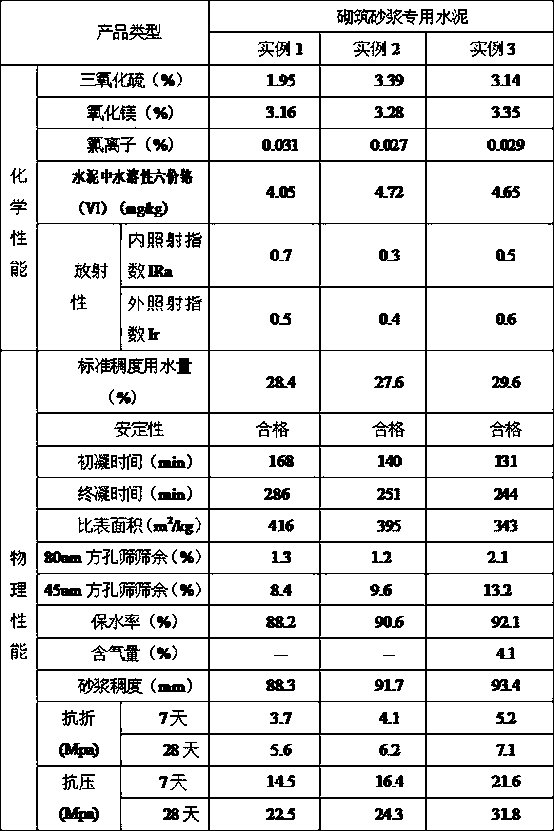

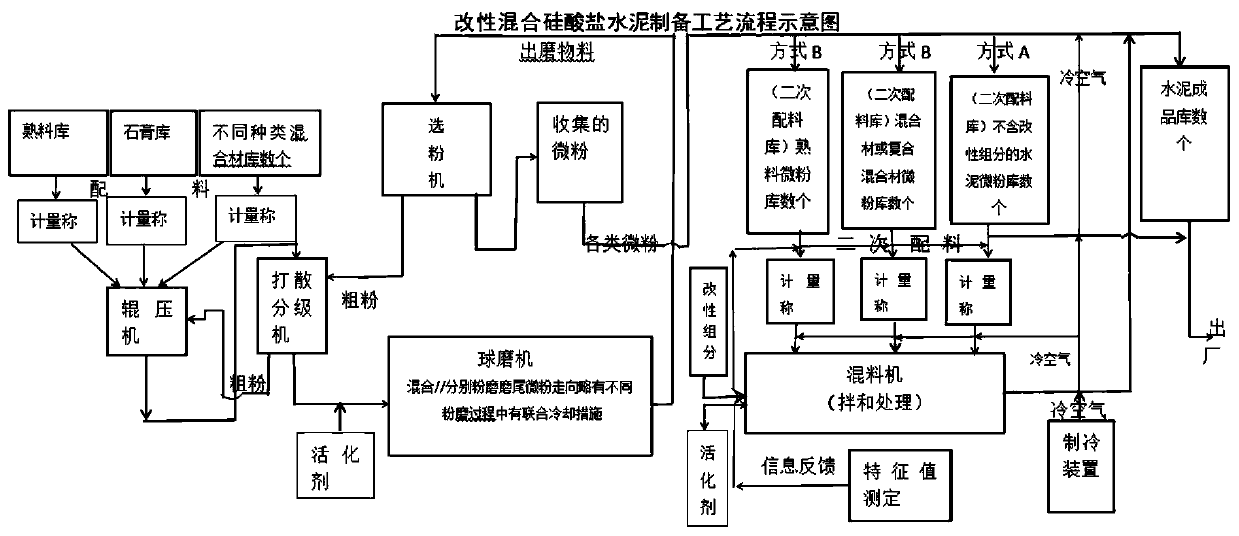

Special cement for masonry mortar and preparation method thereof

ActiveCN109851259APromoting energy saving, consumption reduction, emission reduction and waste utilizationSimple preparation processCement productionSlagCement mortar

A special cement for masonry mortar comprises the following raw materials in proportion: clinker, gypsum, limestone, grinding aid and modifying component, and also comprises one or more of active or inactive mixtures including granulated blast furnace slag, granulated blast furnace slag powder, pozzolanic mixture and fly ash and other waste slag is allowed to replace the active mixture. The invention also discloses a preparation method of a special cement for masonry mortar, and a secondary batching mixing and homogenizing system is adopted in the design. The method has a wide source of raw materials and relates to the field of cement mortar. The homogeneity of cementitious material system in mortar is improved and the properties and construction efficiency of mortar are improved without adding admixtures and additives when the special cement for masonry mortar is used to prepare masonry mortar.

Owner:王紫娴 +1

Lignin-graphene oxide composite modified polycarboxylic acid efficient water reducing agent

The invention discloses a lignin-graphene oxide composite modified polycarboxylic acid efficient water reducing agent. The water reducing agent is prepared by, by weight, 240-250 parts of TPEG, 25.2-26.0 parts of acrylic acid, 1.6-1.65 parts of ammonium persulfate, 0.53-0.55 part of thioglycolic acid, 13-14 parts of lignin, an appropriate amount of sodium hydroxide solution with the concentration being 10wt%, an appropriate amount of deionized water, 26-28 parts of graphene oxide, 20-23 parts of boiler slag, 5-7 parts of sorbitol, 2-3 parts of sodium nitrite, 2-3 parts of dodecyl dimethyl benzyl ammonium chloride, 4-5 parts of carbon black and 3-4 parts of microcrystalline wax. The lignin-graphene oxide composite modified polycarboxylic acid efficient water reducing agent has the advantages that components such as the carbon black and the dodecyl dimethyl benzyl ammonium chloride are added into the preparation of the water reducing agent, so that the dispersity of the water reducing agent in concrete can be increased; the industrial waste boiler slag is added into the water reducing agent, so that production cost is lowered; the sodium nitrite is added into the water reducing agent, and accordingly the early strength and later strength of the concrete are further increased.

Owner:ANHUI XINRUN NEW MATERIALS

Retarder for sulphate aluminum cement and use method thereof

InactiveCN106746894AReduced hydration rateImprove the lubrication effectIsothiazolinonePolyethylene glycol

The invention discloses a retarder for sulphate aluminum cement and a use method thereof. The retarder is prepared from the following raw materials in parts by weight: 30-70 parts of polymer emulsion, 10-25 parts of metylchloro isothiazolinone, 2-10 parts of film-forming agent, 1-15 parts of water reducer and 5-15 parts of polyethylene glycol. The invention also discloses the use method for the retarder. The retarder disclosed by the invention can effectively reduce the coagulation speed of the sulphate aluminum cement; the initial setting time and the final setting time both can be prolonged for above 30min; the fluidity of the cement slurry can be obviously promoted; the fluidity of cement paste can be increased by above 15%. The retarder disclosed by the invention has no any adverse effect to the development of the cement strength, is low in cost, is high in performance stability and is easily stored and transported.

Owner:UNIV OF JINAN

Modified polycarboxylate water reducer capable of improving strength of concrete

The invention discloses a modified polycarboxylate water reducer capable of improving strength of concrete. The modified polycarboxylate water reducer is prepared from, by weight, 240-250 parts of TPEG, 25.2-26.0 parts of acrylic acid, 1.6-1.65 parts of ammonium persuflate, 0.53-0.55 parts of thioglycolic acid, 13-14 parts of lignin, proper amounts of sodium hydroxide solution of 10wt% in concentration and deionized water, 26-28 parts of grapheme oxide, 2.5-3 parts of sodium pyrophosphate, 2-3 parts of waterborne epoxy resin, 8-10 parts of nano alumina, 5-6 parts of carbide slag, 2-3 parts of microcrystalline wax and 3-4 parts of sodium citrate. The modified polycarboxylate water reducer is scientific and reasonable in ingredient proportion, the water reducer which is prepared from a series of processing steps is high in water reducing rate and good in dispersity in the concrete, early strength and later strength of the concrete are improved obviously, and the water reducer is excellent in working performance, high in durability and low in bleeding rate and has good economic benefit and social benefit.

Owner:ANHUI XINRUN NEW MATERIALS

High-flowing micro-expansion anti-dilution grouting agent

InactiveCN102180611AImprove liquidityImprove pourabilitySolid waste managementCeramicwareWater immersionSlurry

The invention relates to a high-flowing micro-expansion anti-dilution grouting agent used for cement concrete pavement slab suspending, which consists of 0-85% of fine sand, 14-85% of fly ash, 0.5-1.5% of water reducing agent, 0-1% of early strength agent, 0-25% of expansion agent and 0-5% of air-entraining agent. In the cement concrete pavement slab suspending, cement and water also need to be added in the high-flowing micro-expansion anti-dilution grouting agent, and evenly stirred for use, so that the grouting agent does not have bleeding lamination or shrinking, can compensate the shrinking of slurry or has certain expansion property, and serum is even, not easy to be diluted by moisture below a slab, and good in quality, and has the function of preventing water immersion, so as to enable 24-hour strength of a grouting material to reach above 3.5 MPa which is matched with the compressive strength of a base layer to be grouted, ensure a concrete face to obtain uniform support of a bottom plate again, and prolong the service life of the concrete face.

Owner:交通运输部公路科学研究院

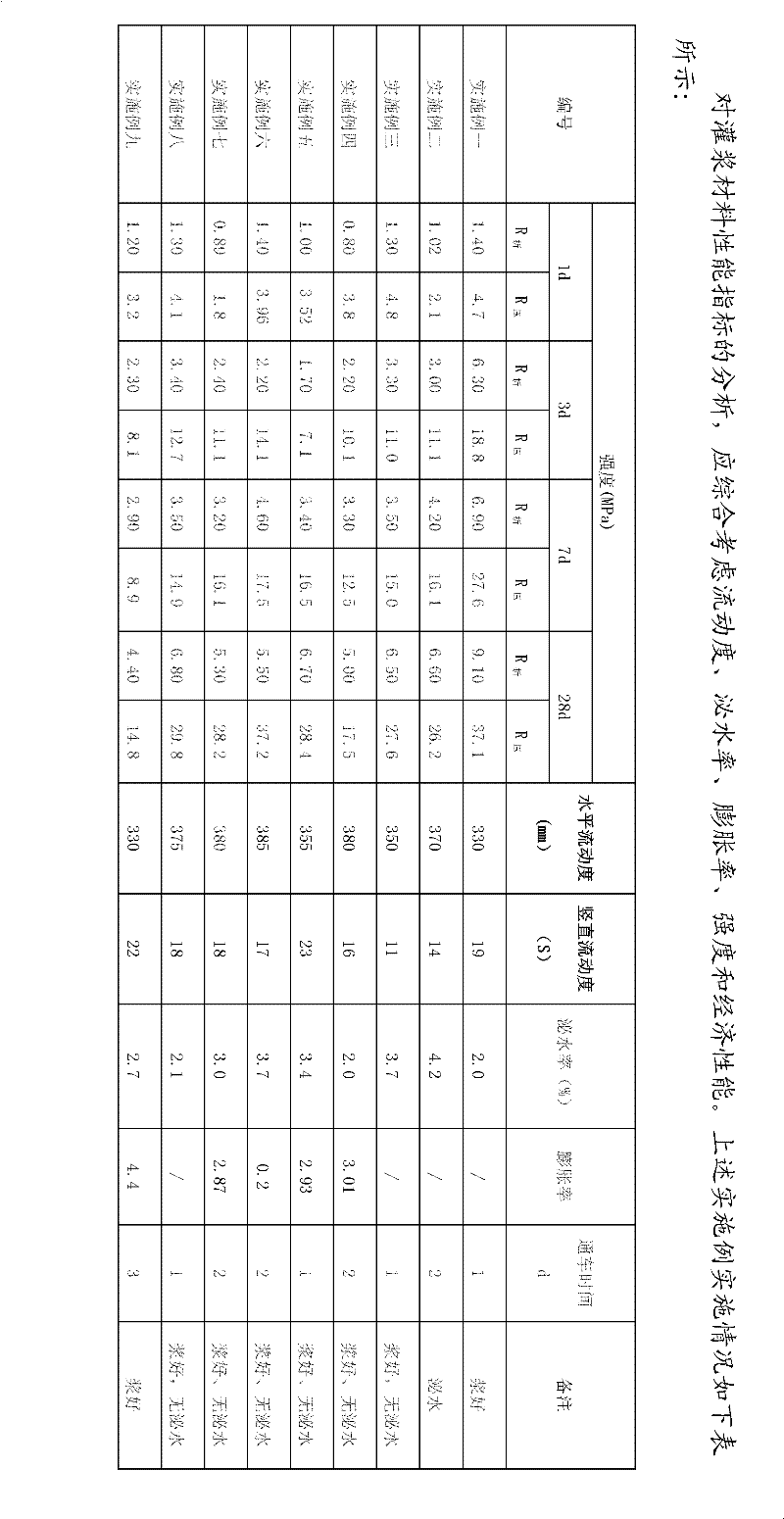

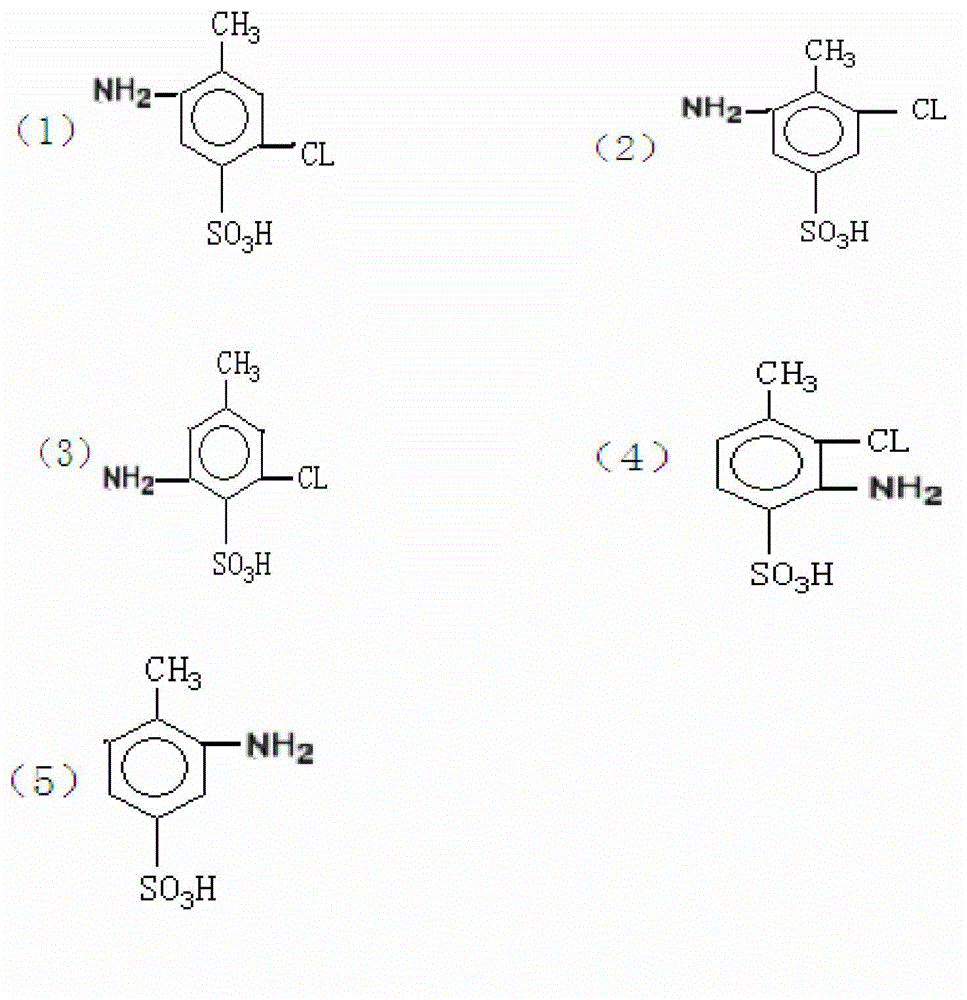

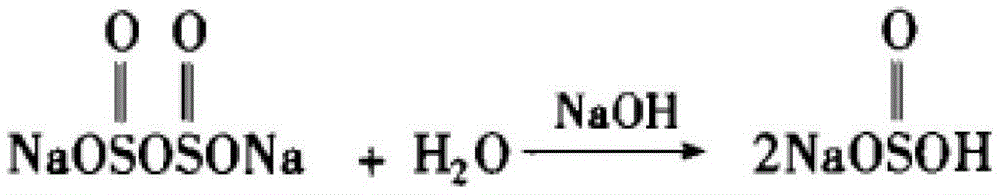

Method for preparing cement water-reducing agent by using byproduct of organic pigment intermediate CLT acid

The invention relates to a method for preparing a cement water-reducing agent by using a byproduct of an organic pigment midbody CLT acid. The method comprises the following steps of: adding raw materials into a reaction kettle according to a molar ratio of a mixture of various isomers of the CLT acid to sulfite to a ketone compound to water being 1: (1-8): (2-10): (10-20), raising the temperature to 40-60 DEG C, and refluxing for 0.5-3 hours; adding a caustic soda solution for adjusting pH to 10-14; adding an aldehyde compound, controlling the temperature to 50-75 DEG C, after dropwise addition is ended, raising temperature to 80-100 DEG C, reacting for 3-6 hours, and reducing to room temperature to obtain an aliphatic series high-effect water-reducing agent crude liquid; filtering to obtain an aliphatic series high-effect water-reducing agent liquid product with 30-40% of solid content; and compounding the water-reducing agent and a sulfamic acid high-effect cement water-reducing agent commonly used in market according to a weight ratio of (2-7):1 to obtain the novel high-effect cement water-reducing agent. According to the method, the pollution of an aminotoluene sulfonic acid isomer mixture on environment is avoided, and the production cost is effectively reduced; and the synthetic method is simple and can be implemented in the common reaction kettle.

Owner:ZHEJIANG QINYAN TECH CO LTD

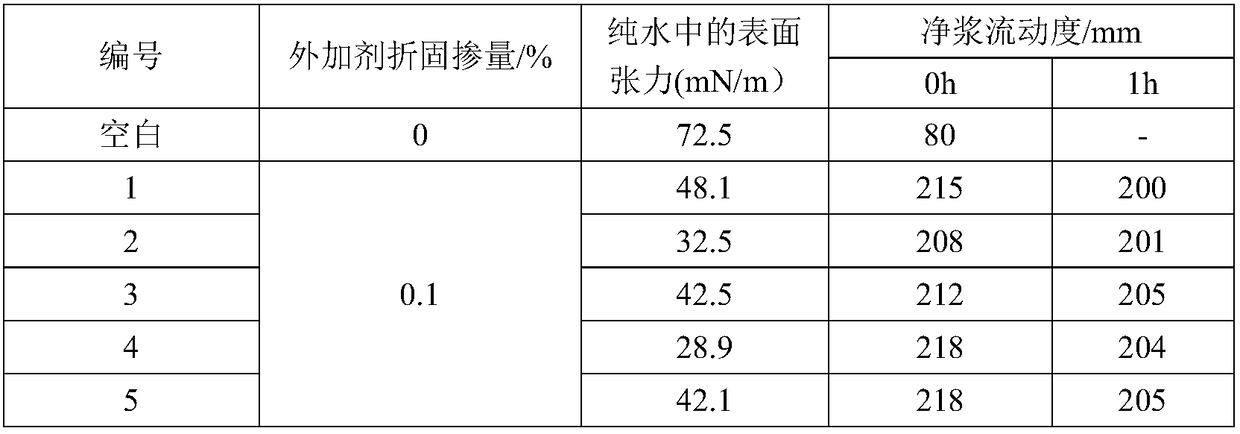

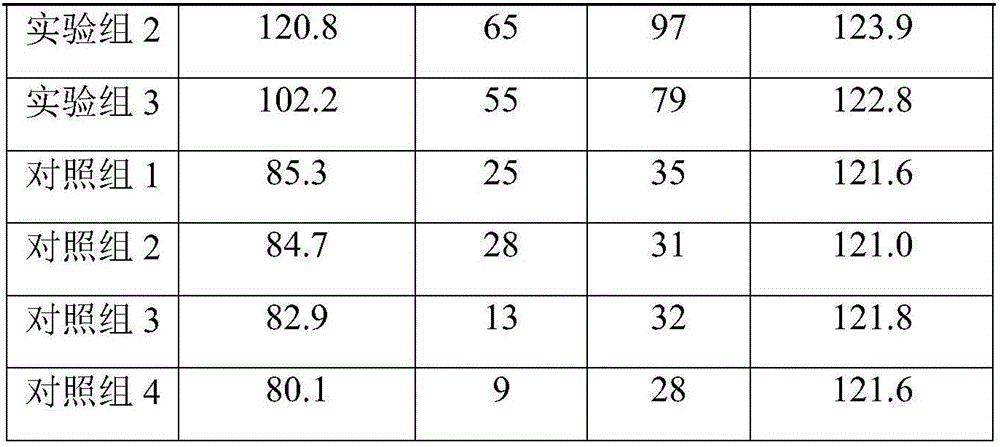

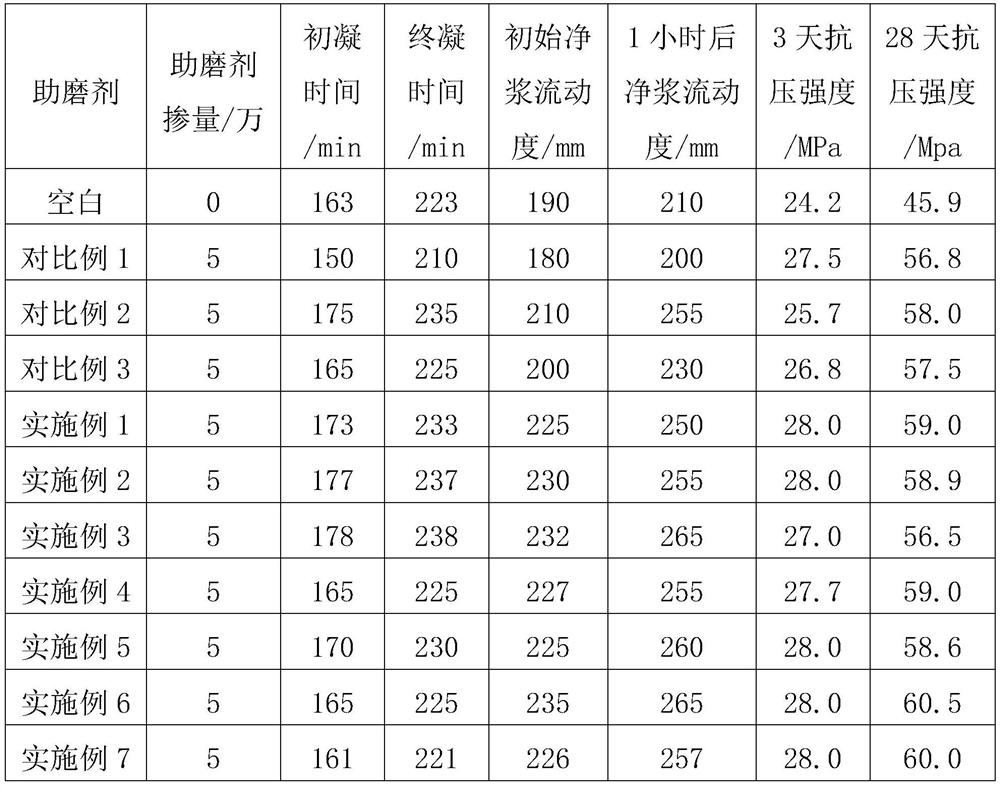

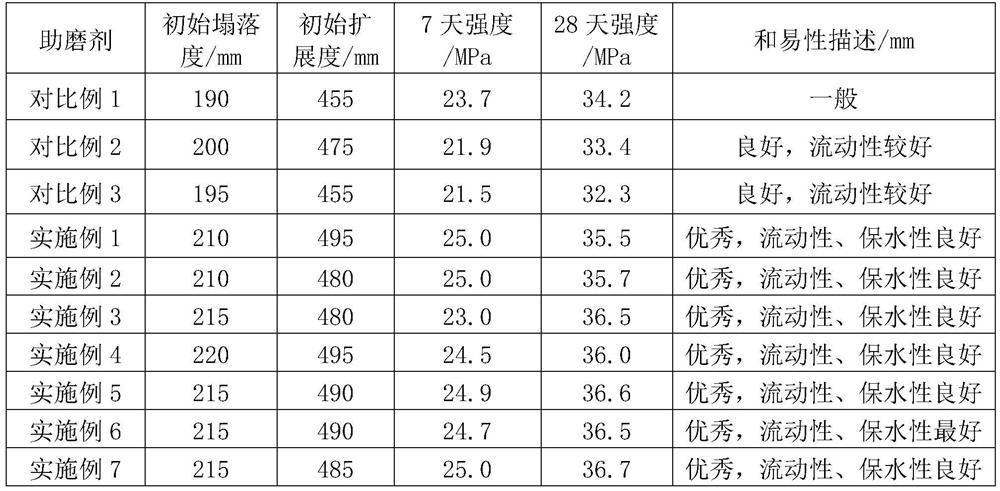

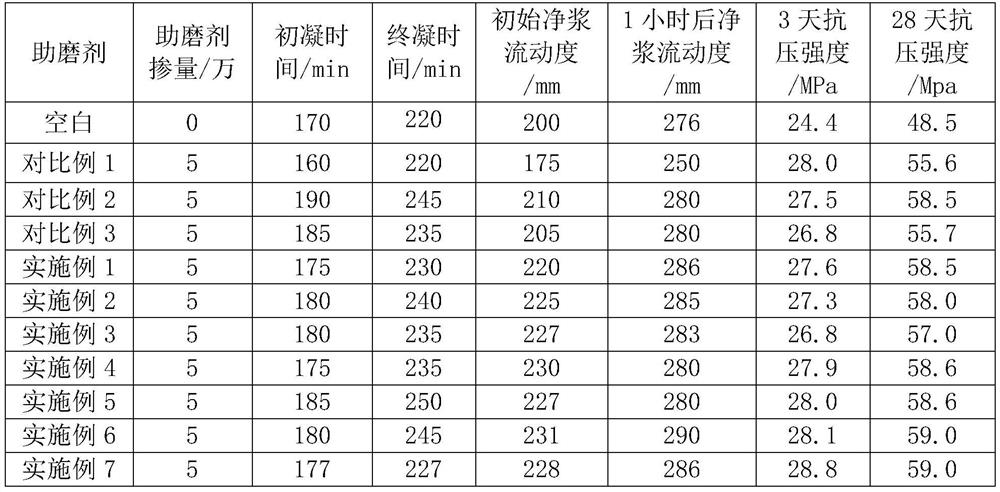

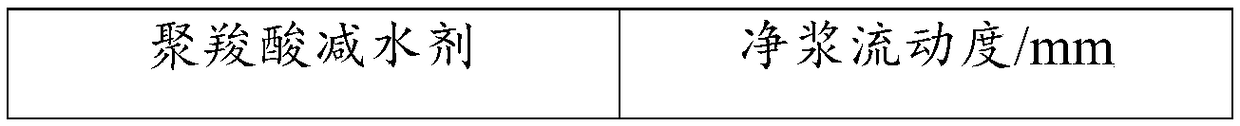

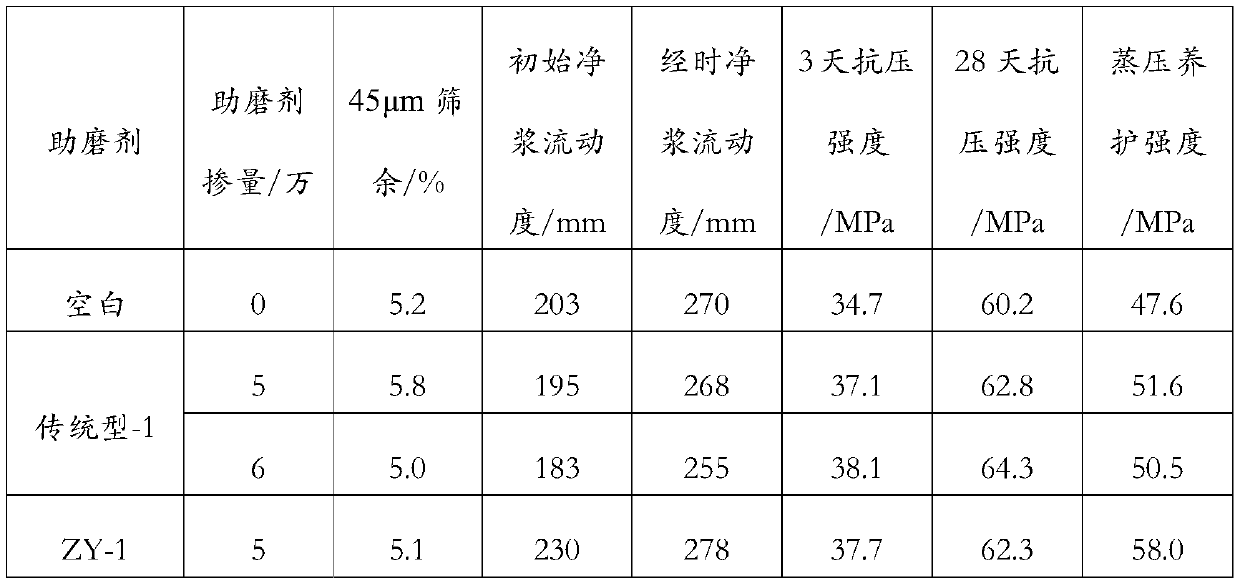

Grinding aid for improving adaptability of high-aluminum clinker cement admixture

The invention discloses a grinding aid for improving the adaptability of a high-alumina clinker cement admixture, and solves the technical problems that a grinding aid in the prior art causes lowadaptability of high-alumina clinker cement to the admixture and reduces the early strength of the high-alumina clinker cement. The grinding aid comprises: 3%-20% of dimer glycerol; 10%-27% of monoethanol diisopropanolamine; 2%-7% of hydroxyethylidene diphosphonic acid; 0.1%-0.25% of polyacrylamide; and the balance of water. Compared with a traditional grinding aid, the grinding aid for improving the adaptability of the high-aluminum clinker cement admixture has higher admixture adaptability, the fluidity of neat paste is improved by 20 mm or above, the slump of C30 and C25 concrete is improved by 15 mm or above, and the expansion degree is improved by 15 mm or above; and the formula of the grinding aid is optimized to improve the 28-day strength of the high-alumina clinker cement concrete.

Owner:华润水泥技术研发(广西)有限公司

Concrete water-reducing agent and application thereof

The invention discloses a concrete water-reducing agent and the application of the concrete water-reducing agent. The concrete water-reducing agent comprises the components by weight ratio: 58-80 parts of polycarboxylate high-performance water-reducing agent and 20-42 parts of compound containing hydroxyl and carboxyl. According to the concrete water-reducing agent, the advantages of the polycarboxylate high-performance water-reducing agent can be developed and the adaptability of the polycarboxylate high-performance water-reducing agent can be improved, in addition, the dosage is reduced, resources are saved, energy consumption is reduced and the comprehensive application cost of the polycarboxylate high-performance water-reducing agent can be lowered.

Owner:TIANJIN BINHAI NEW AREA JINYU XINAO TECH DEV

Water reducing agent for shrinkage-compensating concrete

InactiveCN102992696AHigh water reduction rateGood slump retentionHydrocarbons.aliphaticConstruction industry

The invention discloses a water reducing agent for shrinkage-compensating concrete. The water reducing agent comprises the following components in percentage by weight: 70%-80% of naphthalene or homologue, 5%-7% of aliphatic compound, 1%-6% of sodium gluconate, 1%-3% of lauryl sodium sulfate, 0.1%-0.5% of cellulose formaldehyde, 0.1%-0.5% of hydroxypropyl methyl cellulose and the balance of water. The water reducing agent disclosed by the invention has no waste and dust, has no damage to a human body, has no pollution to the environment, and belongs to a green product in the construction industry; simultaneously, the early cracking can be reduced, and harmful cracks of the concrete can be reduced into harmless cracks.

Owner:SUZHOU CHENGHU CONCRETE CO LTD

Water reducer capable of improving adhesiveness of concrete

The invention discloses a water reducer capable of improving adhesiveness of concrete. The water reducer is prepared from, by weight, 240-250 parts of TPEG, 25.2-26.0 parts of acrylic acid, 1.6-1.65 parts of ammonium persulfate, 0.53-0.55 part of thioglycolic acid, 13-14 parts of lignin, proper amounts of sodium hydroxide solution of 10wt% in concentration and deionized water, 26-28 parts of grapheme oxide, 3-4 parts of polyethylene glycol, 4-5 parts of carbon black, 4-5 parts of metakaolin, 6-8 parts of superfine slag powder, 3-4 parts of polyvinyl alcohol, 2-3 parts of molasses and 3.5-4 parts of calcium lignosulfonate. Metakaolin after being calcined is added to prepare the water reducer, has certain adhesiveness and can improve viscosity and strength of the concrete after being used in the water reducer, so that consumption of cement is reduced; a proper amount of the superfine slag powder is added, so that working performance of the concrete is improved remarkably.

Owner:ANHUI XINRUN NEW MATERIALS

Preparation method of powdery carboxylic acid water reducing agent

The invention provides a preparation method of a powdery carboxylic acid water reducing agent. The preparation method includes the steps: (1) mixing a water reducing agent monomer and water, and heating and fusing mixture; (2) adding initiators, chain transfer agents and unsaturated carboxylic acid into a system fused in the step (1), performing mass polymerization reaction to generate a polycarboxylic acid water reducing agent precursor; (3) neutralizing and crushing the polycarboxylic acid water reducing agent precursor to prepare the powdery carboxylic acid water reducing agent. According the preparation method, water is added in the mass polymerization reaction, the water serves as a reactant to react with the water reducing agent monomer and the unsaturated carboxylic acid, the systemviscosity of the mass polymerization reaction is reduced, the powdery carboxylic acid water reducing agent with high performance is synthesized when effective generation of the mass polymerization reaction and generation of solid polycarboxylic acid water reducing agent are ensured, long-distance transportation of the water reducing agent is facilitated, transportation cost is reduced, and the application range of the polycarboxylic acid water reducing agent is widened, so that the water reducing agent is applicable to products such as dry-mixed mortar and high-performance concrete.

Owner:佳化化学(抚顺)新材料有限公司

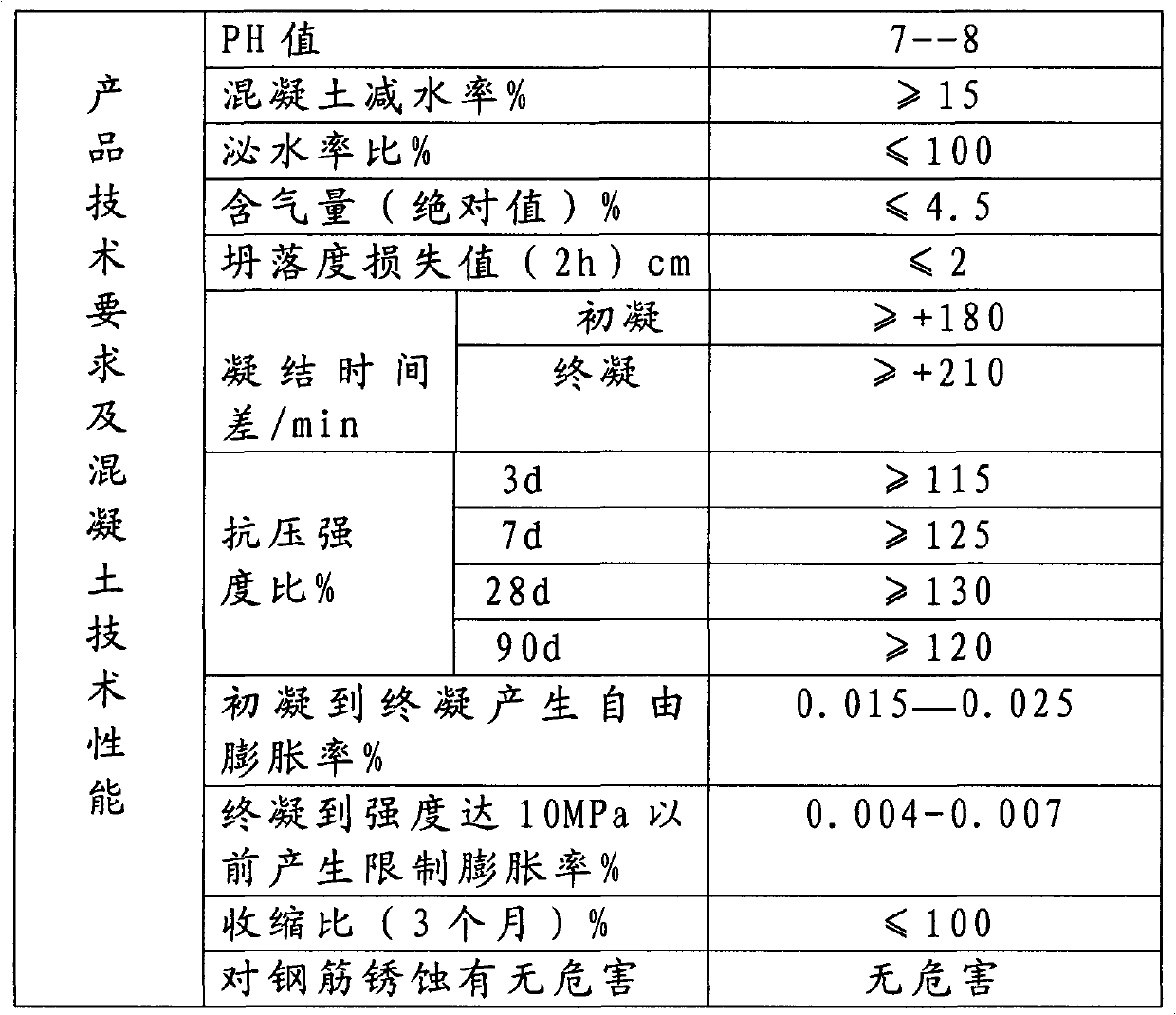

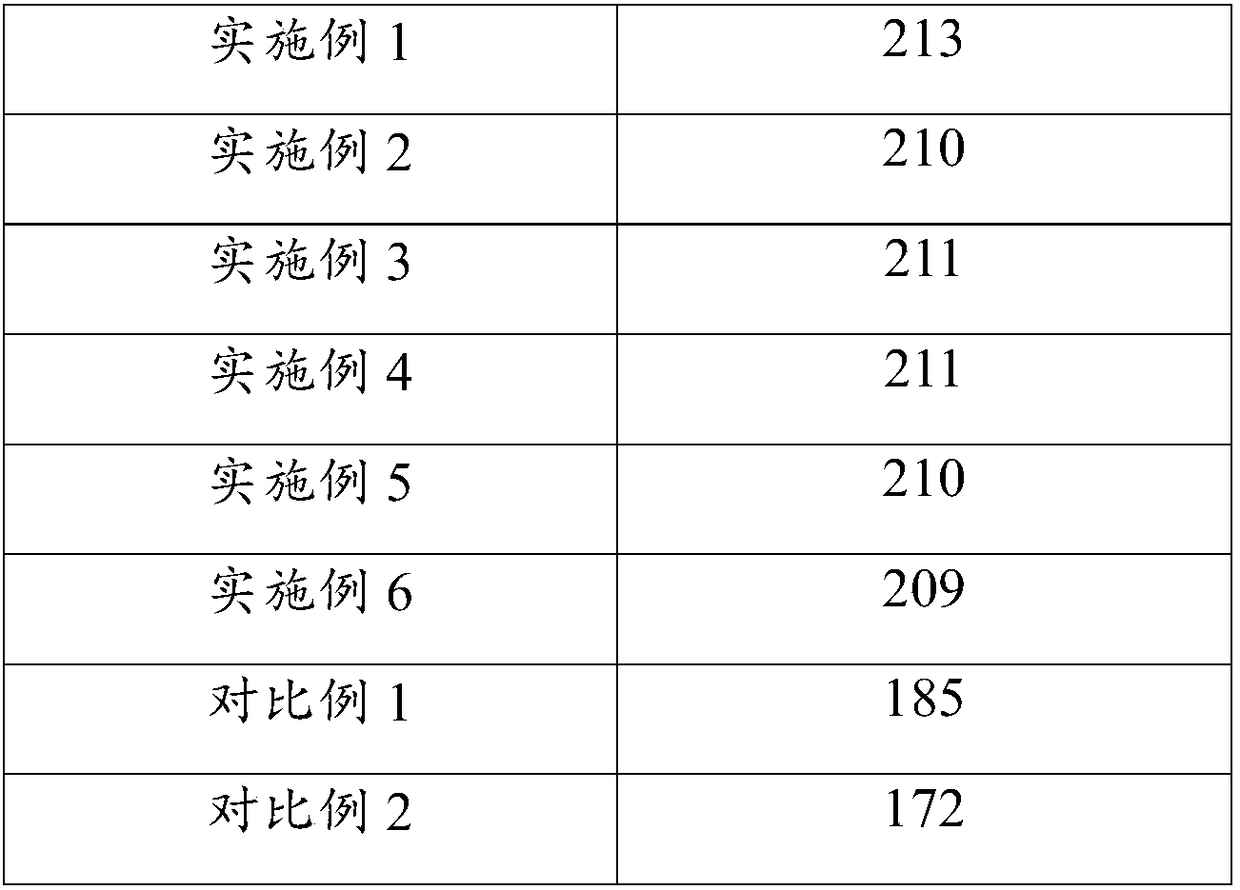

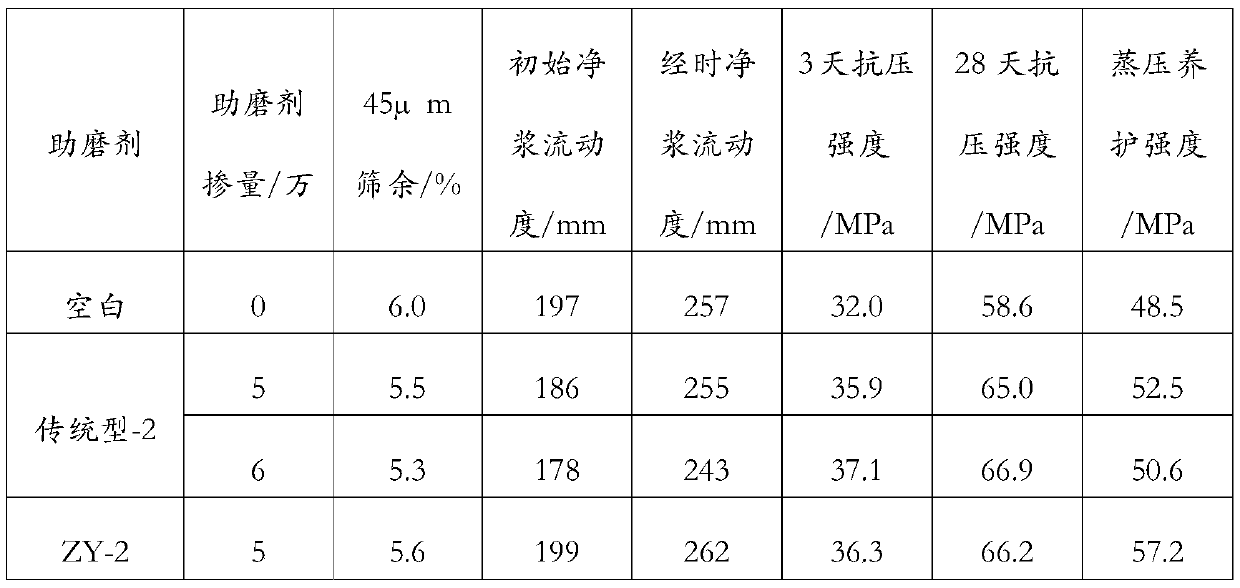

Cement grinding aid and application thereof in improving autoclaved curing strength of high-alumina clinker cement

InactiveCN110981267ALow alcohol amine contentEnhanced effect of high autoclaved curingInorganic saltsGlycerol

The invention discloses a cement grinding aid and application thereof in improving autoclaved curing strength of high-alumina clinker cement. The grinding aid comprises the following components in percentage by mass: 30 to 35% of grinding aid components, 5 to 10% of sodium metaaluminate, 6 to 10% of other inorganic salts, 10 to 15% of sodium gluconate, and 0.1 to 0.5% of sodium polyacrylate, withthe balance being water, wherein the grinding aid components are composed of dimer glycerol and monoethanol diisopropanolamine. The grinding aid disclosed by the invention has a relatively high autoclaved curing strengthening effect, and compared with a traditional grinding aid, the autoclaved curing strength is improved by 3 MPa or above. The grinding aid provided by the invention also has good additive adaptability, and compared with the traditional grinding aid, the fluidity of neat paste is improved by 20 mm.

Owner:华润水泥技术研发(广西)有限公司

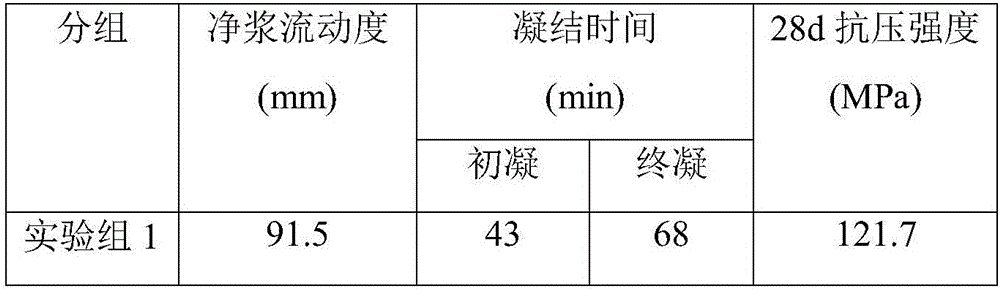

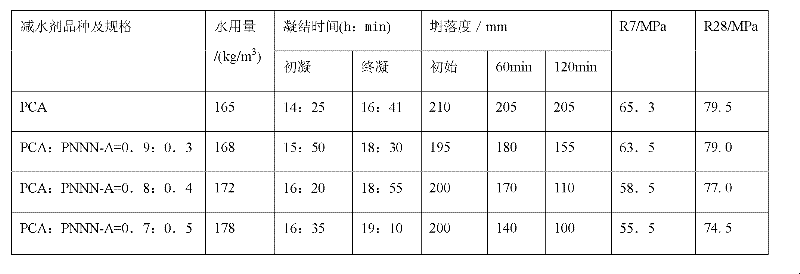

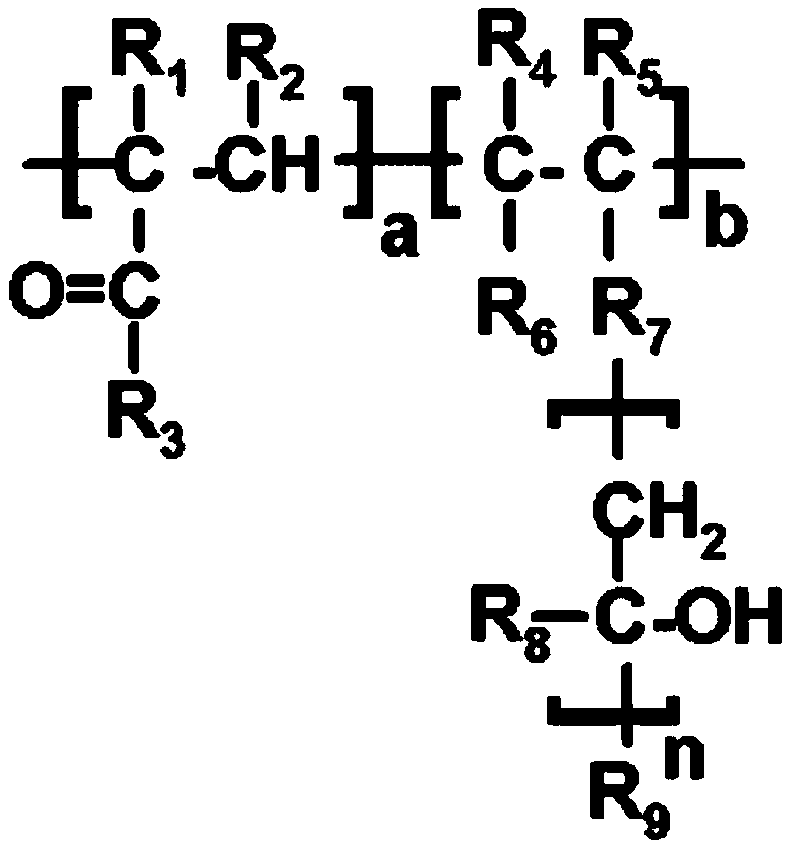

Method for preparing delayed coagulation type super plasticizer through atom transfer radical polymerization

ActiveCN109942754AProlong clotting timeIncrease late strengthSide chainAtom-transfer radical-polymerization

The invention relates to a method for preparing a delayed coagulation type super plasticizer through atom transfer radical polymerization. The method comprises the steps of with a delayed coagulationtype monomer and a carboxylic acid small monomer as main reaction raw materials, sequentially carrying out atom transfer radical polymerization (ATRP), alcoholysis and copolymerization so as to prepare the delayed coagulation type super plasticizer, namely that carrying out atom transfer radical polymerization (ATRP) on the delayed coagulation type monomer as a reactant under the system formed byan unsaturated initiator, transition metal halide and a ligand so as to obtain an unsaturated macromonomer, carrying out alcoholysis so as to obtain a delayed coagulation type macromonomer, and copolymerizing with the carboxylic acid small monomer, so as to obtain the delayed coagulation type super plasticizer. According to the method, a functional side chain consisting of delayed coagulation typestructural monomers is innovatively designed and synthesized by virtue of a controllable polymerization technical measure, a traditional polymer side chain structure is replaced, the super plasticizer presents excellent capacities of dispersing element purified slurry, and the coagulation time of the element purified slurry can be remarkably delayed, so that the later-period strength of concreteis improved, and multiple effects of high water reduction, slump resistance and delayed coagulation are achieved.

Owner:BEIJING UNIV OF TECH

Cement grinding aid and preparation method thereof

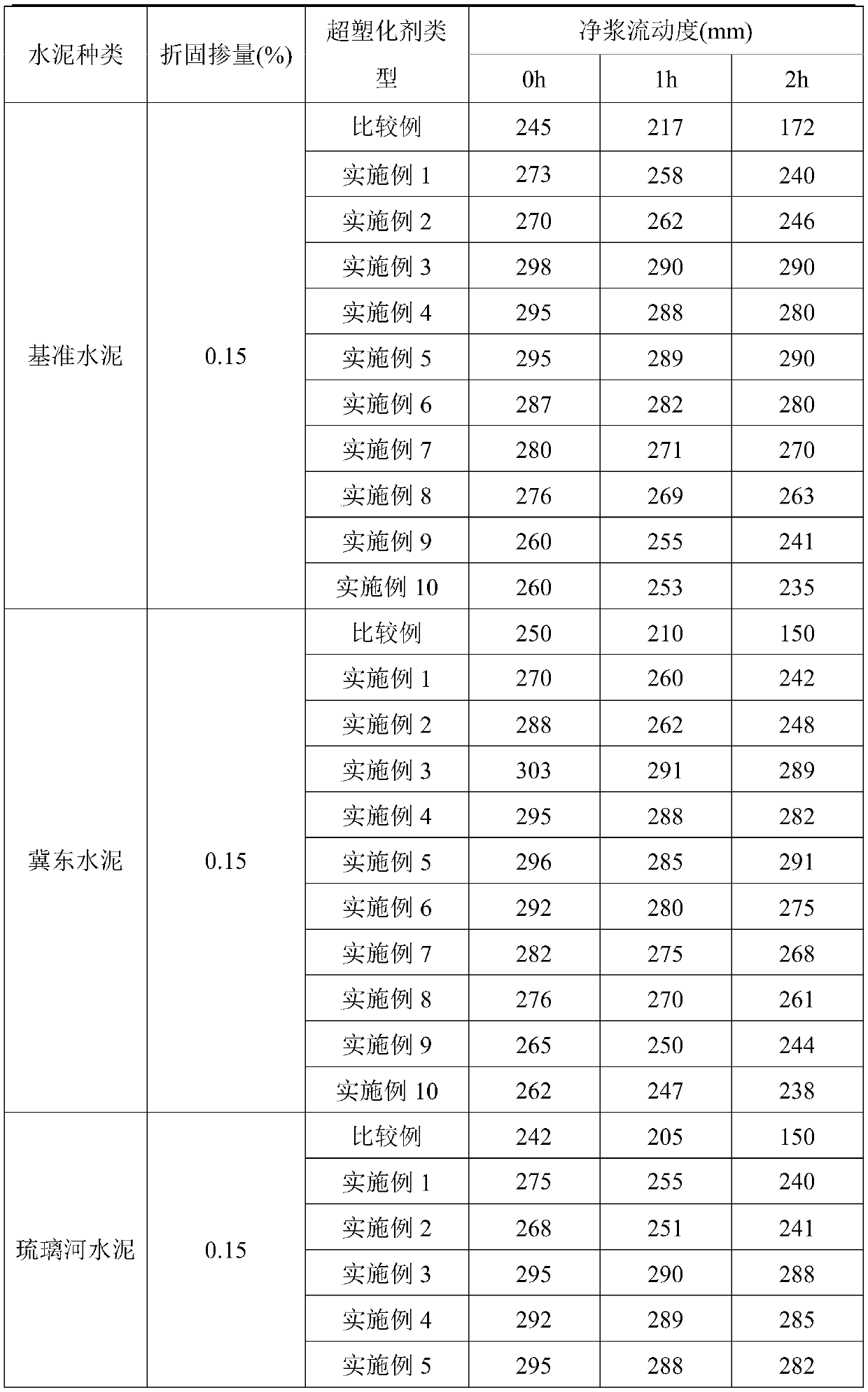

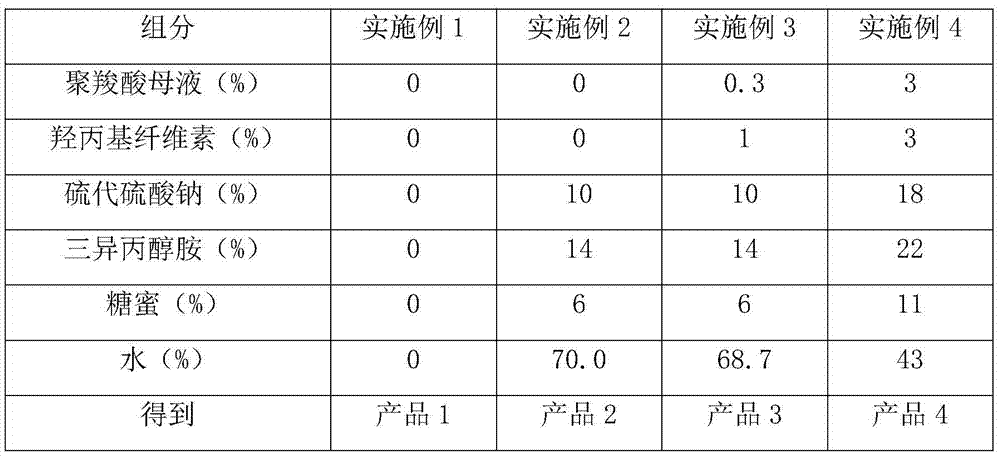

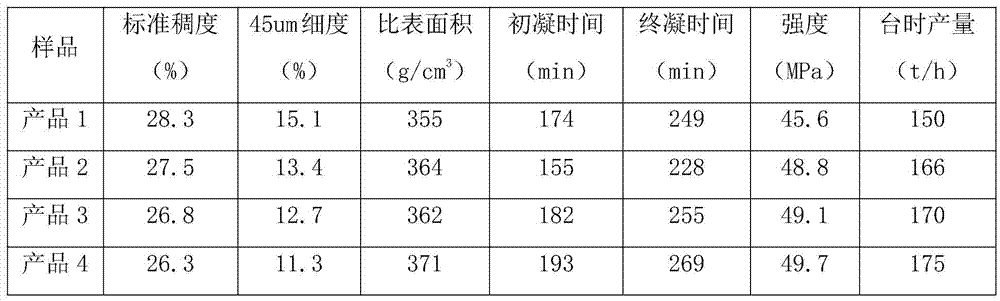

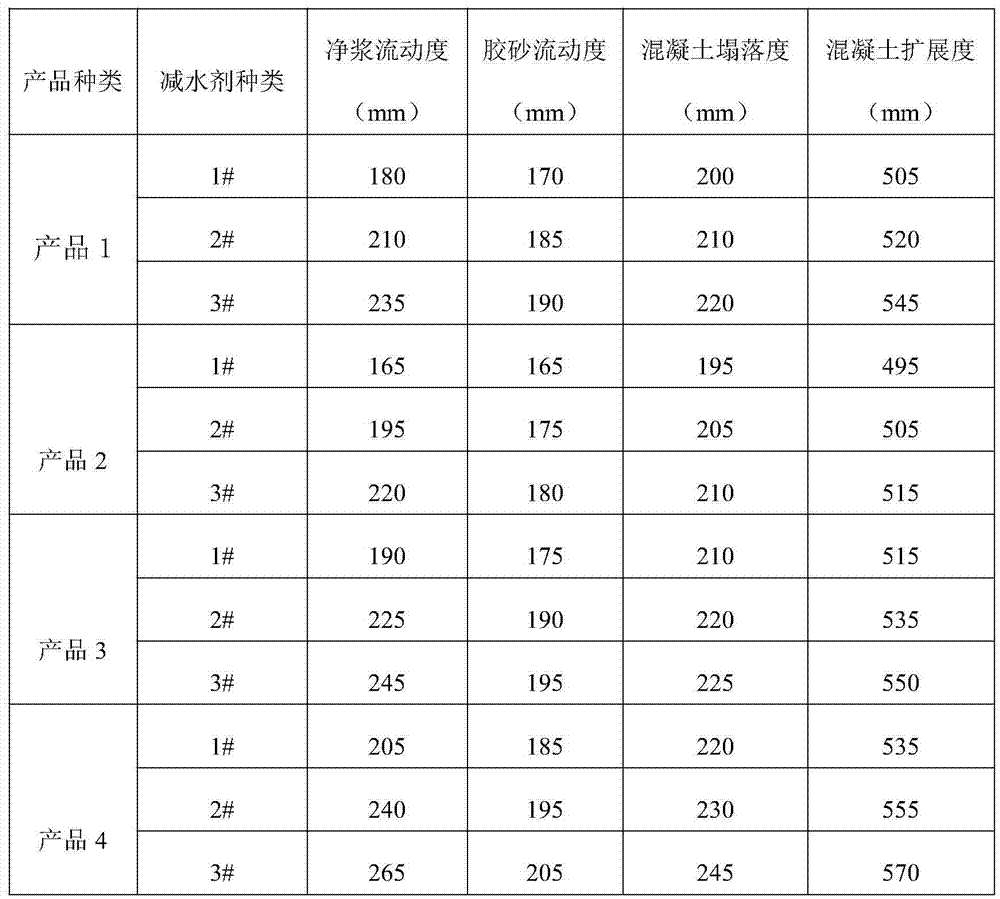

The invention provides a cement grinding aid and a preparation method thereof. The cement grinding aid is prepared from the following components in percentage by mass: 0.3-3 percent of polycarboxylic acid mother liquor, 1-3 percent of hydroxy propyl cellulose, 6-11 percent of molasses, 14-22 percent of modified diethanolisopropanolamine, 10-18 percent of sodium thiosulfate and the balance of water. The preparation method comprises the following steps: firstly, injecting water into a first pre-dissolution kettle, adding the hydroxy propyl cellulose under stirring, and stirring for 30 minutes to prepare a cellulose solution having a mass percentage of 3 percent for later use; and then, adding the polycarboxylic acid mother liquor and the sodium thiosulfate into the balance of water in a second reaction kettle under stirring according to the prescribed proportion, adding the molasses, the modified diethanolisopropanolamine and the hydroxy propyl cellulose solution, stirring for 20 minutes, filtering impurities by virtue of a stainless steel screen to prepare the cement grinding aid. According to the cement grinding aid, the setting time of cement and concrete can be remarkably improved, and the fluidity of cement paste, cement slump and slump flow can be improved.

Owner:HUNAN ZHONGYAN BUILDING MATERIAL TECH CO LTD

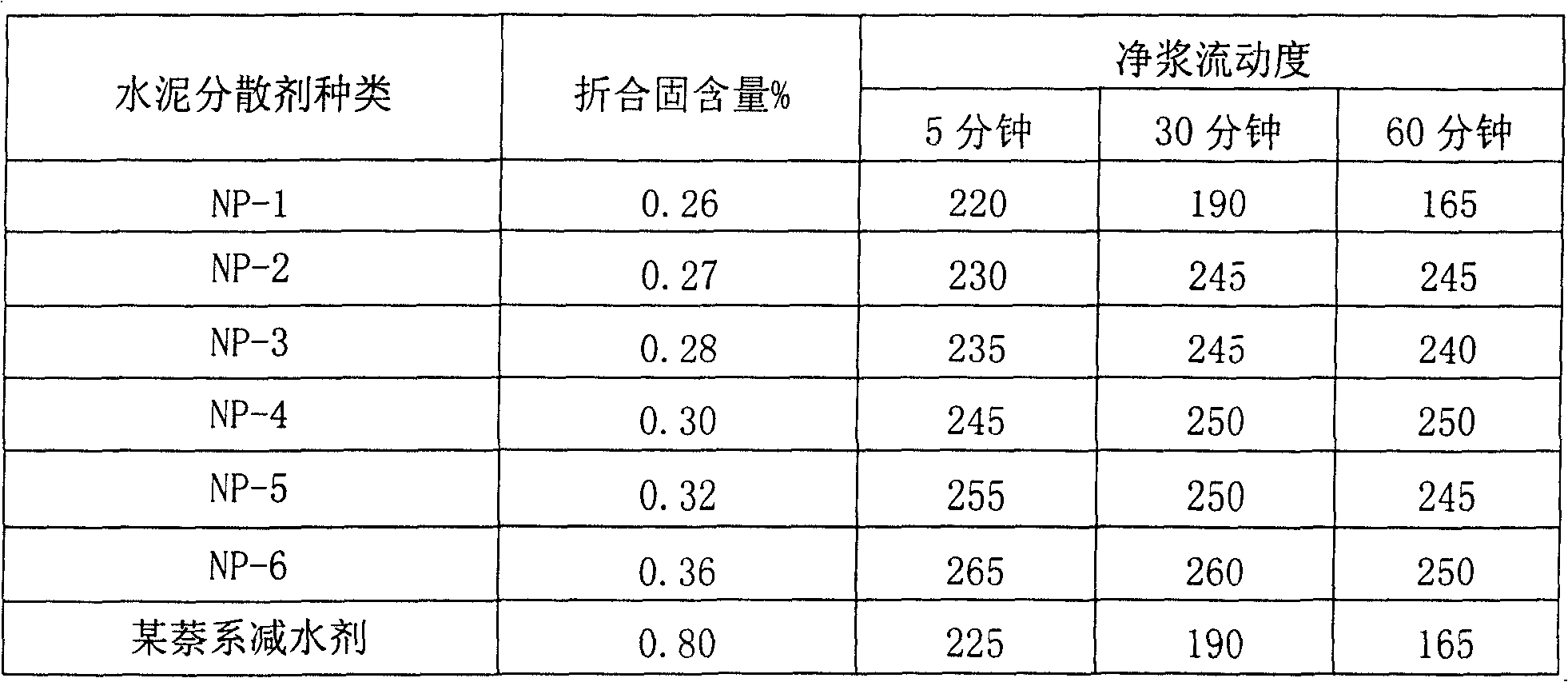

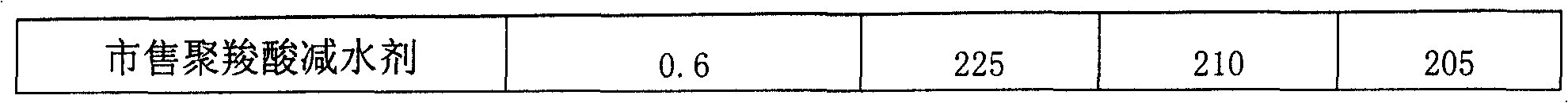

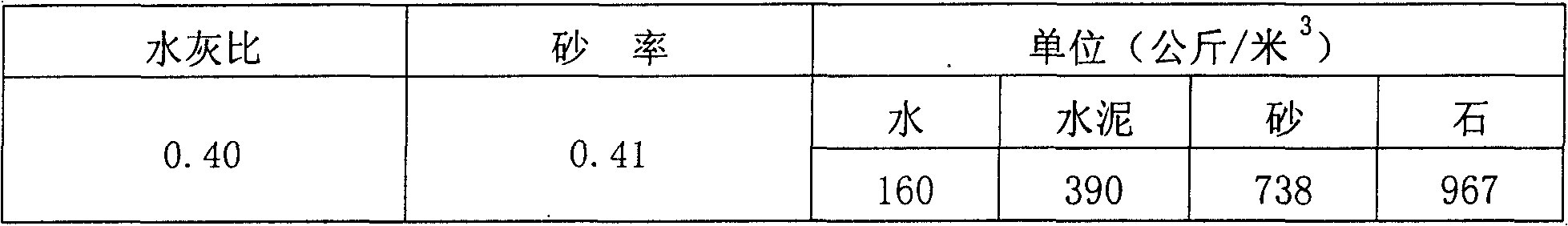

Method for preparing modified lignin poly-carboxylic-acid cement dispersant

This invention relates to preparation method of modified lignin poly carboxylic acid cement dispersant, belongs to concrete admixture. The process: whip amd heating-up lignin sulfonate to 50 to 80 deg, in turns add sodium dichromate 5 to 9 shares, polyvinyl alcohol 10 to 20 shares, acroleic acid 5 to 18 shares, initiator 0.1 to 3 shares, at temperature 80 to 100 deg, take reaction for 3 to 5 hours, gain modified lignin sulphonate water solution. The product brings the cement good consistency, not bleed air, without bleeding, good degree of fluidity and good flexibility.

Owner:武汉海德天物新材料有限公司

A hyperbranched glycoside polycarboxylate water reducer and its preparation method and application

ActiveCN105778018BGood three-dimensional spherical structureIncreased steric hindranceSolubilityGlycoside

The invention relates to a polycarboxylate superplasticizer and particularly discloses a hyperbranched glucoside polycarboxylate superplasticizer. The hyperbranched glucoside polycarboxylate superplasticizer is a star polymer with natural polyhydroxylated compound glucoside serving as a nucleus and polycarboxylate linear macromolecules serving as arms. Due to less molecular entanglement and a great quantity of hydrophilic groups and high branching of a molecular structure of the hyperbranched glucoside polycarboxylate superplasticizer, solubility, cement dispersion action and cement adaptability of the hyperbranched glucoside polycarboxylate superplasticizer are greatly enhanced. In addition, the hyperbranched glucoside polycarboxylate superplasticizer is high in water reducing rate, high in cement adaptability and high in cement paste fluidity and well meets the requirement of high-performance concrete workability.

Owner:GNSG ANHUI HONG SIFANG

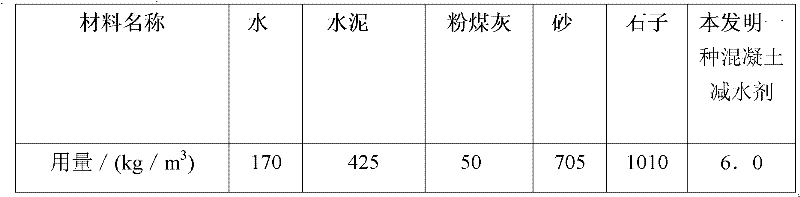

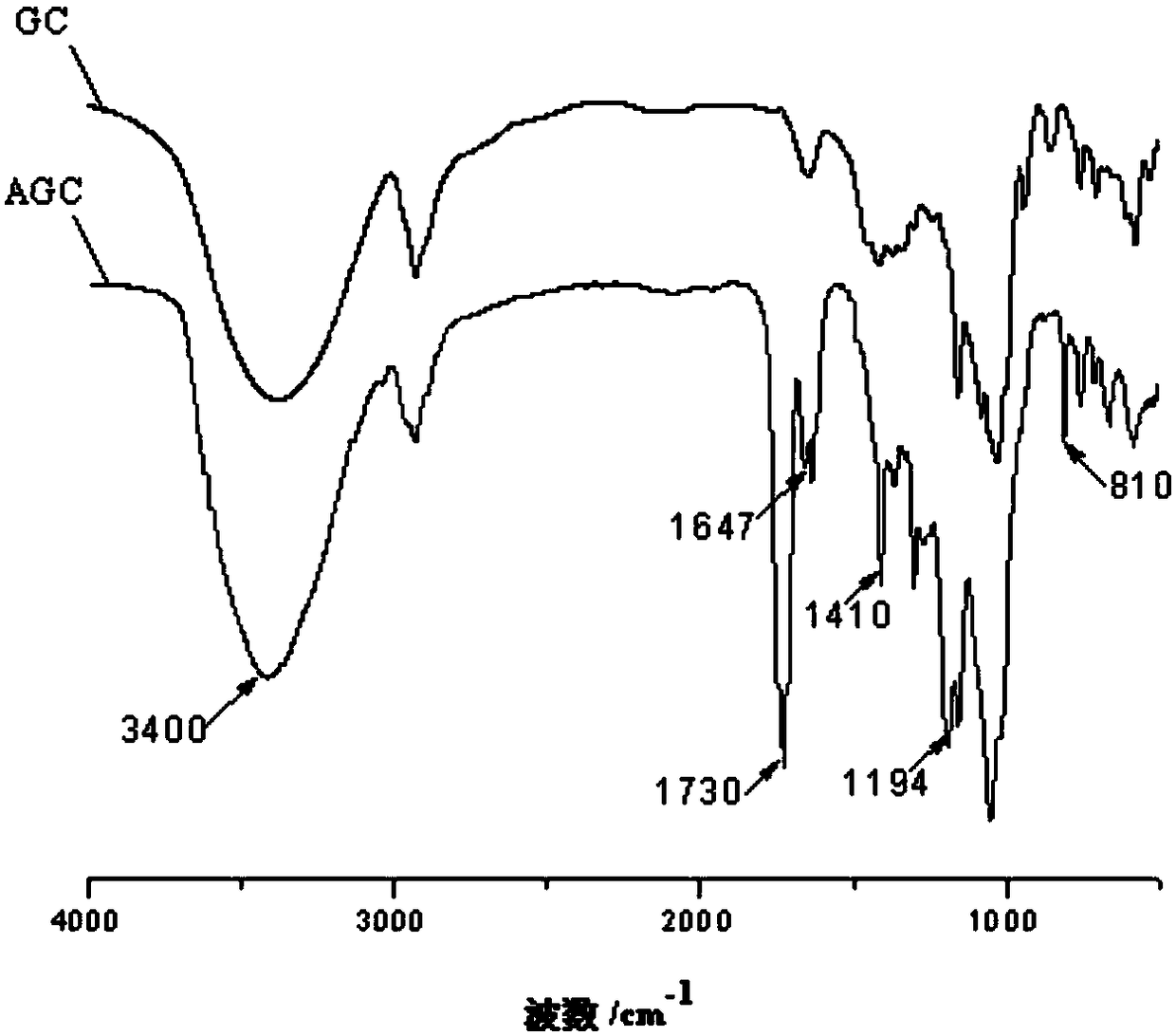

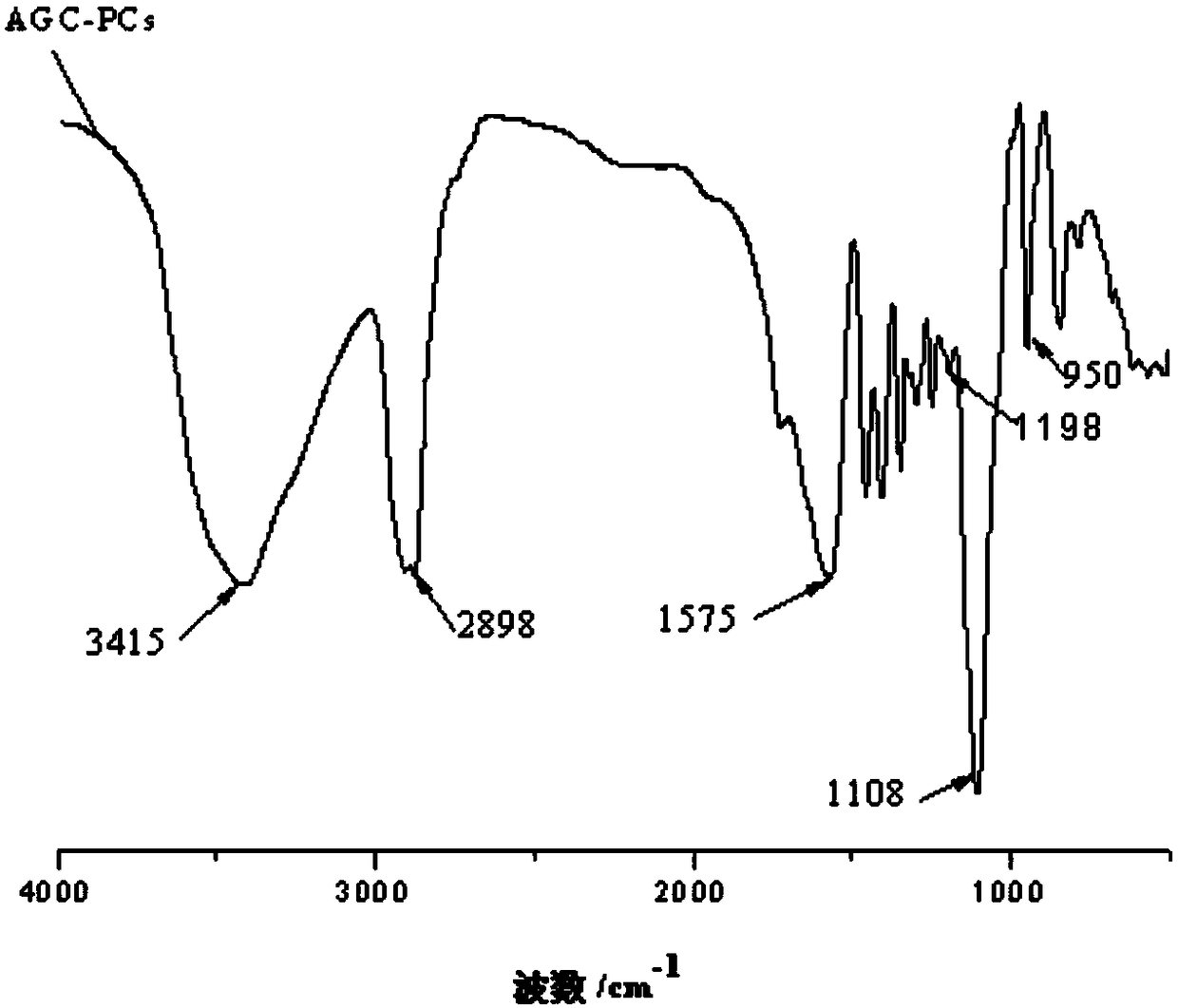

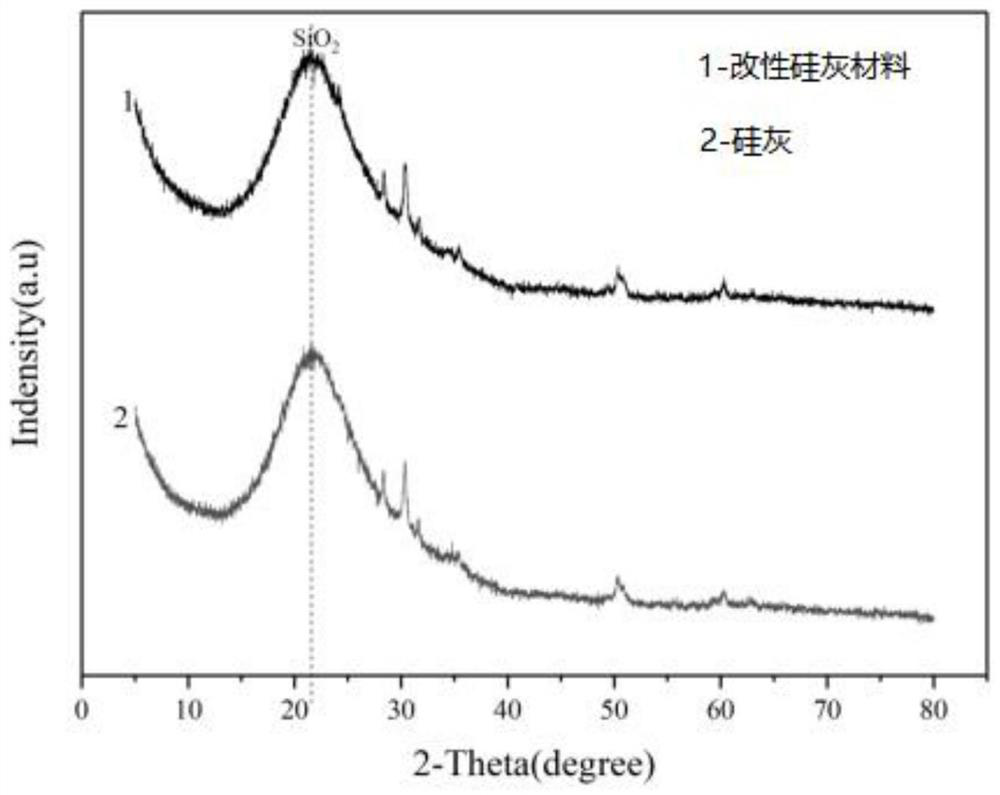

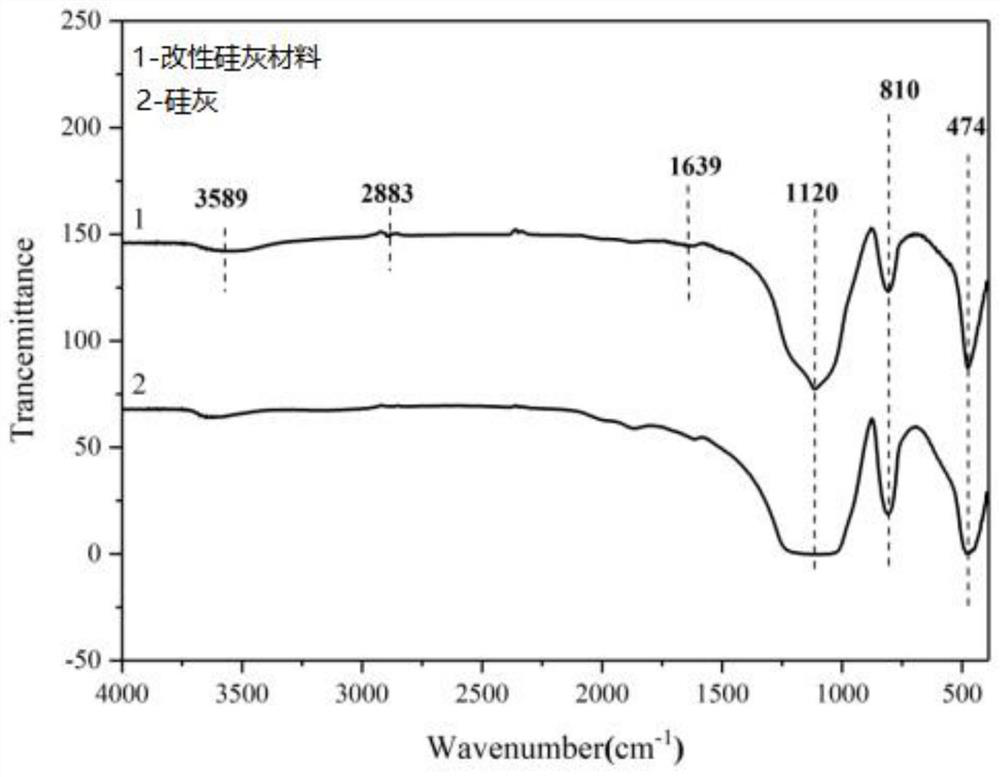

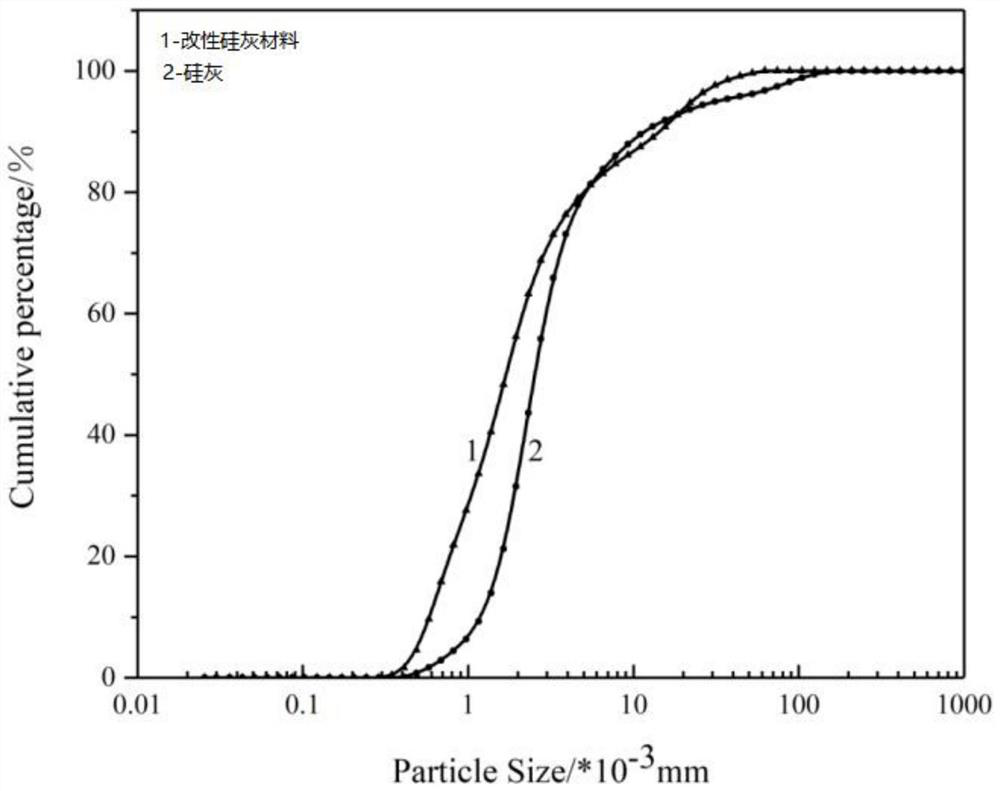

Preparation method and application of modified silica fume material

InactiveCN112939499AIncrease steric hindranceImprove pulp fluiditySolid waste managementCement productionAlcoholHydrolysate

The invention relates to a preparation method of a modified silica fume material, which belongs to the technical field of building materials, and comprises the following steps: adding silica fume into absolute ethyl alcohol, and uniformly dispersing to obtain silica fume dispersion liquid; and adding a silane coupling agent into deionized water, adding the prepared silane coupling agent hydrolysate into the silica fume dispersion liquid, placing in a water bath at 60-80 DEG C, magnetically stirring, filtering after completion, cleaning filter residues with deionized water, and finally performing vacuum drying and grinding to obtain the modified silica fume material. The silane coupling agent is adopted to modify the silica fume, amino silane reacts with silicon hydroxyl on the silica fume, the Zeta potential on the surface of the silica fume changes, negative charges are changed into positive charges, the steric hindrance among silica fume particles is increased, the number of large particles of the modified silica fume is reduced, and particle size distribution is more concentrated; and after the modified silica fume is doped into the fly ash cement, the fluidity of fly ash cement neat paste is improved, the dispersity of the modified silica fume is improved, and the early strength of the fly ash cement is improved.

Owner:NANJING UNIV OF TECH

Set retarding superplasticizer making use of flue gas desulfurization ash

The invention discloses a set retarding superplasticizer making use of flue gas desulfurization ash. The set retarding superplasticizer is prepared from, by weight, 240-250 parts of TPEG, 25.2-26.0 parts of acrylic acid, 1.6-1.65 parts of ammonium persulfate, 0.53-0.55 part of mercaptoacetic acid, 13-14 parts of lignin, appropriate amount of sodium hydroxide solution with concentration being 10wt%, appropriate amount of deionized water, 26-28 parts of graphene oxide, 1.5-2 parts of texanol, 3-4 parts of dispersible adhesive powder, 0.9-1.2 parts of sodium hydroxide, 1.3-1.5 parts of sodium sulfate, 2-3 parts of triethanolamine, 7-8 parts of converter steel slag, 9-11 parts of flue gas desulfurization ash and 4-5 parts of sodium alginate. The set retarding superplasticizer has an excellent set retarding function and is capable of enhancing early strength of concrete, solid wastes are reduced, cement content is decreased, and land occupation of the solid wastes and pollutant generation in cement production are reduced simultaneously.

Owner:ANHUI XINRUN NEW MATERIALS

Rear earth tailing added polycarboxylate superplasticizer

The invention discloses a rear earth tailing added polycarboxylate superplasticizer. The polycarboxylate superplasticizer is prepared from, by weight, 240-250 parts of TPEG, 25.2-26.0 parts of acrylic acid, 1.6-1.65 parts of ammonium persulfate, 0.53-0.55 part of mercaptoacetic acid, 13-14 parts of lignin, appropriate amount of sodium hydroxide solution with concentration being 10wt%, appropriate amount of deionized water, 26-28 parts of graphene oxide, 2-3 parts of sodium dodecyl benzene sulfonate, 11-13 parts of rare earth tailings, 0.6-0.7 part of sodium hexametaphosphate, 0.3-0.4 part of sodium tripolyphosphate, 2-3 parts of cerous nitrate and 4-5 parts of EVA (ethylene-vinyl acetate) latex. The superplasticizer is capable of effectively improving grain boundary energy of cement products to improve compactness of an internal structure of concrete, and accordingly concrete strength is improved, durability is further improved, and defects caused by low strength in industrial production can be reduced.

Owner:ANHUI XINRUN NEW MATERIALS

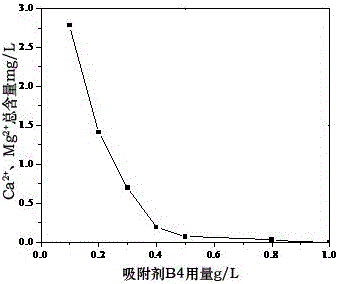

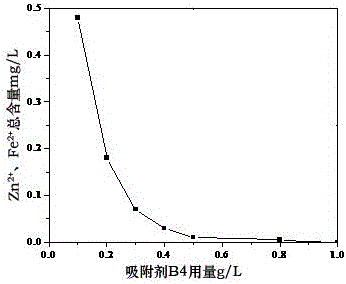

Adsorbent and preparation method and application thereof

ActiveCN106237991AImprove pulp fluidityQuality improvementOther chemical processesWater contaminantsSorbentMedicinal chemistry

The invention relates to an adsorbent and a preparation method and application thereof and belongs to the technical field of organic polymer compounds. The adsorbent is a mixture and is made mainly from a polymer chelating agent, modified chitosan, polyacrylamide, sodium metaaluminate and the like. The adsorbent synthesized in the application is used in the field of synthesis of water-reducing agents and can decrease the total content of Ca2+ and Mg2+ in water to 0.3 mg / L and below and the total content of Zn2+ and Fe2+ to 0.05 mg / L and below.

Owner:ZHEJIANG HUANGMA TECH

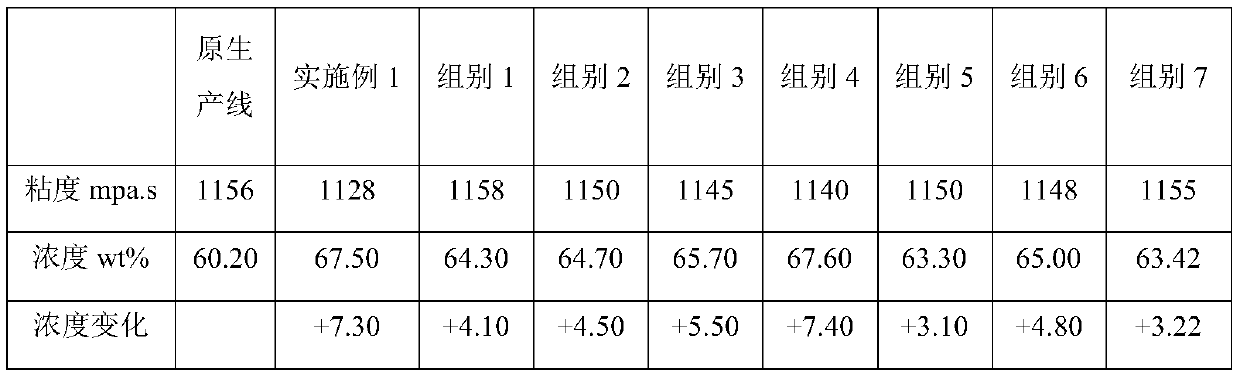

Method for improving fluidity and concentration of ore pulp

ActiveCN111594763AImprove pulp fluidityImprove liquidityPipeline systemsMineralogyMining engineering

The invention provides a method for improving the fluidity and concentration of ore pulp. The method comprises the following steps that a micron-sized component A is added into the ore pulp, and / or high-frequency vibration is performed, wherein the particle size dA of the component A is 20 microns or below. According to the method for improving the fluidity and the concentration of the ore pulp, the mineral substance component A with the quite high lubricity is added into the ore pulp of existing ore pulp preparation equipment so as to improve the fluidity of the ore pulp; meanwhile, high-frequency vibration is performed on the prepared ore pulp so as to increase the stacking density and then improve the concentration.

Owner:江苏丸九碳中和科技有限公司

Low air leading reducing type polycarboxylic acid concrete water reducer and preparation method thereof

The invention relates to a low air leading reducing type polycarboxylic acid concrete water reducer and a preparation method thereof. The water reducer is formed by a single body A and a single body B in copolymerization according to the molar ratio of 1:3-3.5. The single body A is modified polyether TPEG, and the single body B is one or several of crylic acid, methyl acrylate, acrylamide, methacrylic acid, methyl methacrylate and methacrylamide. The preparation method includes first adding H2O2 into modified polyether TPEG water solution under the temperature of 50-55 DEG C, stirring the mixture for 10-15min, simultaneously dropping mixed water solution of ascorbic acid and a chain transfer agent and single body B solution respectively and continuously conducting reaction for 0.5-1.0 hour in heat insulation mode after dropping is finished to obtain the polycarboxylic acid water reducer after pH value adjustment. The water reducer has higher water reducing rate, has low air content and a certain reducing function if used for concrete and is the multifunctional high-efficiency water reducer integrating water reducing, reducing and low air leading.

Owner:山东华伟银凯建材科技股份有限公司

Lignosulfonate prepared from ground wood pulp waste liquor and preparation process thereof

The invention relates to lignosulfonate prepared from ground wood pulp waste liquor and a preparation process thereof. The lignosulfonate has molecular weight of 15,000 to 80,000 and is a brownish black or brown liquid product; the pH (potential of hydrogen) value of the lignosulfonate is in the range of 7 to 9; or the product is subjected to spray drying to obtain yellowish-brown or nigger-brownpowder solid; and the preparation process of the lignosulfonate comprises the following step that the concentrate ground wood pulp waste liquor is subjected to etherification, sulfonation reaction and condensation reaction sequentially to obtain the lignosulfonate. The product is widely used for a concrete admixture, a dye dispersant, a coal water slurry additive and other industries. All the performances of the product can meet the requirements of related quality standards. The lignosulfonate product has high dispersion liquidity. The preparation process is simple. The condition is mild. Conventional equipment is adopted. The production cost is low. The aim of changing waste materials into things of value is fulfilled. No three wastes are discharged in the production process. The lignosulfonate has popularization and application value.

Owner:FUZHOU UNIV

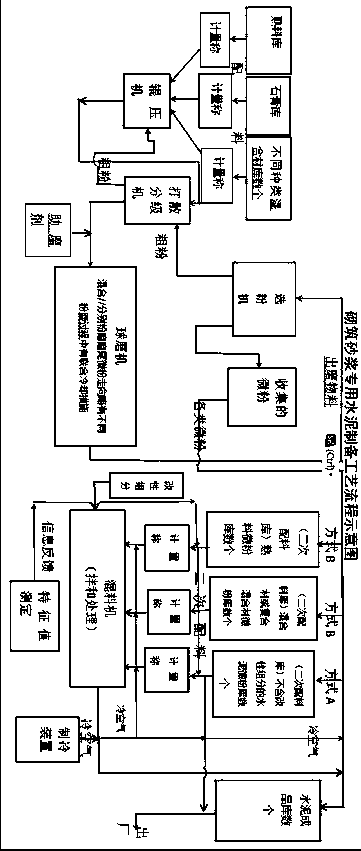

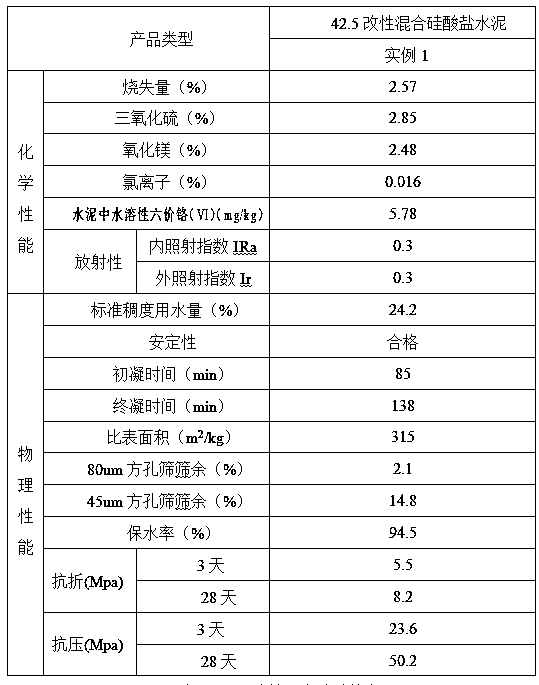

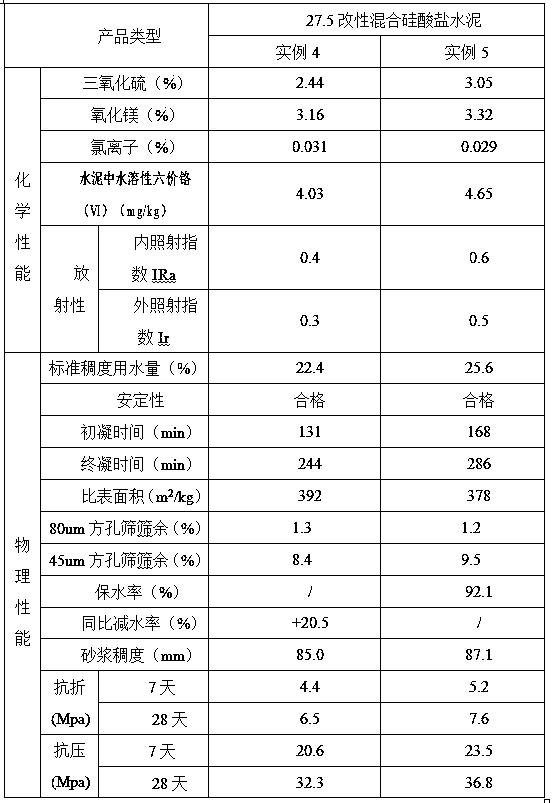

A kind of modified mixed Portland cement and preparation method thereof

ActiveCN109824283BPromoting energy saving, consumption reduction, emission reduction and waste utilizationImprove social and economic benefitsCement productionAutomatic controlSilicate Cement

The invention discloses modified mixed silicate cement and a preparation method thereof and relates to the field of cement and concrete production technologies and comprehensive utilization of solid wastes. Besides Portland cement clinker, gypsum, limestone and an activating agent, the composition of the cement also comprises one or more of granulated blast furnace slag, fly ash, a pozzolanic mixed material and the like, and the cement also includes other waste residues and modified components. The modified mixed silicate cement aims to solve the problems that since there are too many limits to existing production process conditions and existing cement temperature is high, it is difficult to add an admixture for concrete in cement production. According to the modified mixed silicate cement, a combined cooling device is adopted, the temperature of the cement can be controlled to be not higher than 60 DEG C, and the structure and effect of the modified components are prevented from beingdamaged; a secondary batching system, a uniformizing system and an automatic control system are added and optimized to satisfy the technical conditions for preparation of different varieties, products with modified components and the like. The modified mixed silicate cement can improve the uniformity, workability, durability, color and other properties of concrete and mortar, simplify construction operation and have a broad application prospect.

Owner:程菲 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com