Retarder for sulphate aluminum cement and use method thereof

A technology of sulphoaluminate cement and retarder, which is applied in the field of cement admixtures, can solve inconsistencies, where water molecules are easy to penetrate into the interior of the wrapping film where the wrapping film is thin, the borax retarding effect is unstable, and the borax retarding effect is not stable. Unstable coagulation and other problems, to achieve the effect of prolonging the initial setting and final setting time, low price, and increasing fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

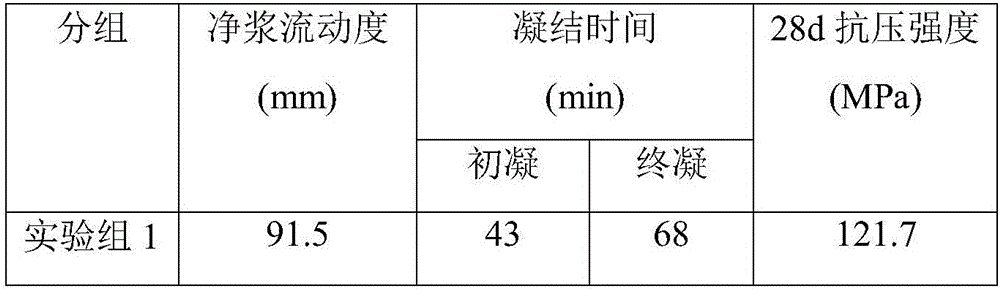

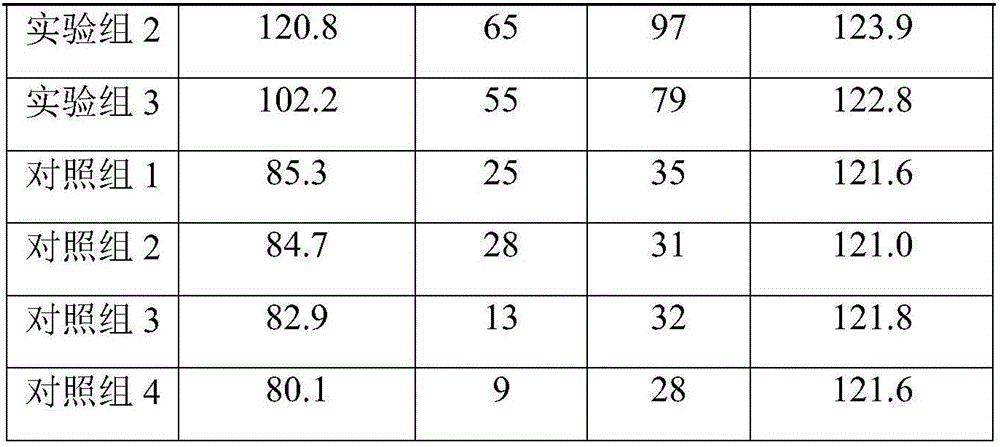

Examples

Embodiment 1

[0028] A retarder suitable for sulphoaluminate cement, which is prepared from the following raw materials in parts by weight: 70 parts of polymer emulsion, 10 parts of chloromethylisothiazolinone, 2 parts of film forming agent, and water reducer 1 part and polyethylene glycol 15 parts.

[0029] Said polymer emulsion is a silicone-modified acrylic emulsion with a solid content of 47-49%.

[0030] As mentioned, the film-forming agent is a non-ionic polyurethane emulsion with a solid content of 54%.

[0031] As mentioned above, the water reducer is sodium lignosulfonate powder, the sodium lignosulfonate content is >45%, and the sieve residue is ≤4%.

[0032] Described, polyethylene glycol is polyethylene glycol 300.

[0033] A method for using a retarder suitable for sulphoaluminate cement, comprising the following steps:

[0034] 1) Add sodium silicate to water, mix well, adjust the pH to 8, heat to keep the temperature at 40°C, and obtain an alkali solution;

[0035] 2) Wei...

Embodiment 2

[0043] A retarder suitable for sulphoaluminate cement is prepared from the following raw materials in parts by weight: 50 parts of polymer emulsion, 15 parts of chloromethylisothiazolinone, 6 parts of film forming agent, and water reducer 8 parts and polyethylene glycol 10 parts.

[0044] Described, polyethylene glycol is polyethylene glycol 600.

[0045] A method for using a retarder suitable for sulphoaluminate cement, comprising the following steps:

[0046] 1) Add sodium silicate to water, mix well, adjust the pH to 9, heat to keep the temperature at 35°C, and obtain an alkaline solution;

[0047] 2) Weighing the polymer emulsion, chloromethylisothiazolinone, film-forming agent, water reducer and polyethylene glycol by weight, and mixing to obtain a retarder;

[0048] 3) Add the retarder to the alkali solution and stir for 25 minutes to obtain the primary product;

[0049] 4) Mix the first product with mixing water evenly, then add defoamer and starch, mix well, and the...

Embodiment 3

[0056] A retarder suitable for sulphoaluminate cement is prepared from the following raw materials in parts by weight: 30 parts of polymer emulsion, 25 parts of chloromethylisothiazolinone, 10 parts of film forming agent, and water reducer 15 parts and 5 parts polyethylene glycol.

[0057] Described, polyethylene glycol is polyethylene glycol 1000.

[0058] A method for using a retarder suitable for sulphoaluminate cement, comprising the following steps:

[0059] 1) Add sodium silicate to water, mix well, adjust the pH to 10, heat to keep the temperature at 30°C, and obtain an alkaline solution;

[0060] 2) Weighing the polymer emulsion, chloromethylisothiazolinone, film-forming agent, water reducer and polyethylene glycol by weight, and mixing to obtain a retarder;

[0061] 3) Add the retarder to the alkali solution and stir for 30 minutes to obtain the primary product;

[0062] 4) Mix the first product with mixing water evenly, then add defoamer and starch, mix well, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com