Patents

Literature

34results about How to "Slow down the rate of condensation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

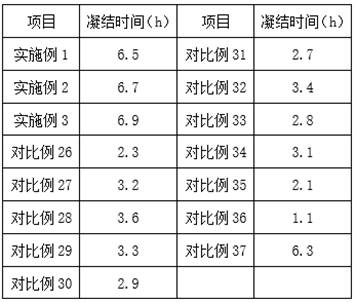

Retarder applicable to sulphate aluminum cement

The invention discloses retarder applicable to sulphate aluminum cement. The retarder is composed of, by weight, 7-60 parts of carbamide, 3-11 parts of sodium lignin sulfonate, 2-7 parts of dinaphthyl methane disulfonic acid sodium, 2-5 parts of water reducing agent and 30-70 parts of vermiculite. By means of the retarder, the coagulation speed of the sulphate aluminum cement can be effectively reduced, the flowability of sulphate aluminum cement slurry can be remarkably improved, and the water demand in the sulphate aluminum cement mixing process can be reduced. The carbamide is added into the retarder, the coagulation time of the sulphate aluminum cement can be prolonged, nitrogen nutrient elements required by the plant growth can be further released slowly after the cement slurry is hardened, and the nitrogen nutrient elements are supplied to plants in porous plant-growing concrete for meeting the plant growth requirements.

Owner:UNIV OF JINAN

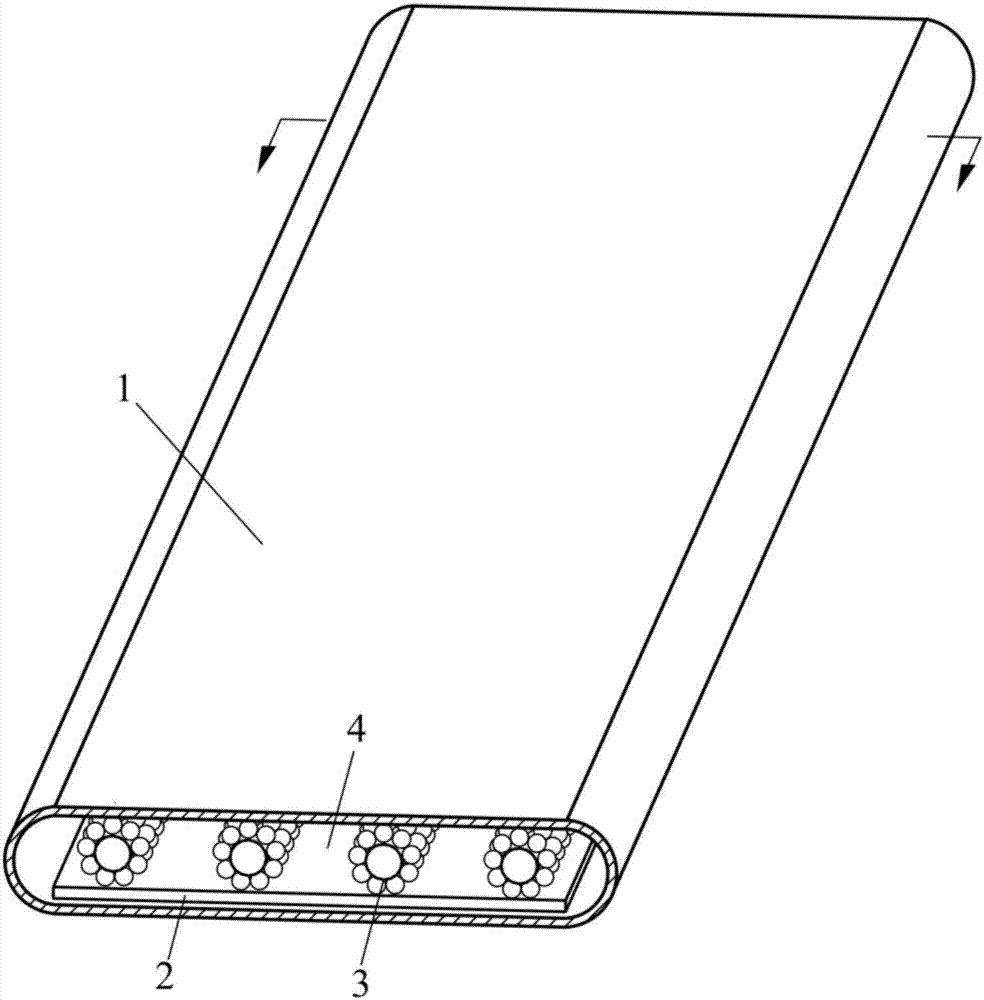

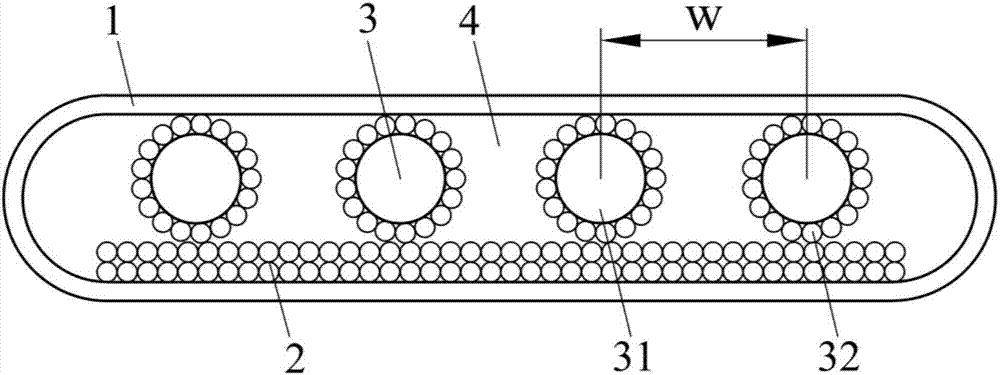

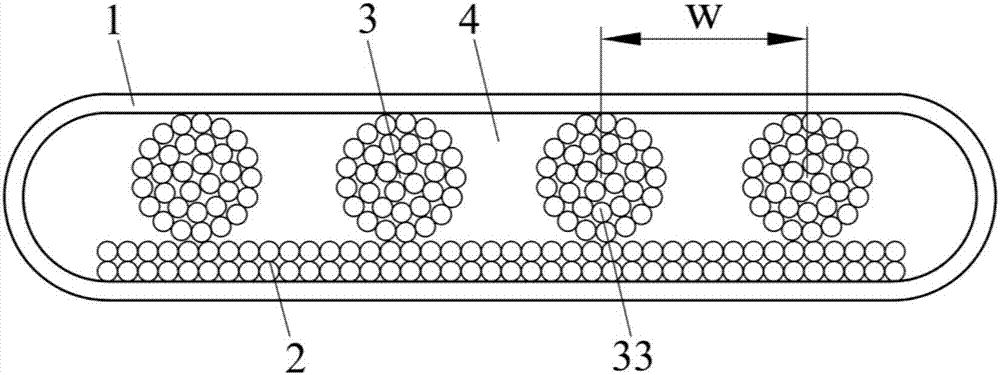

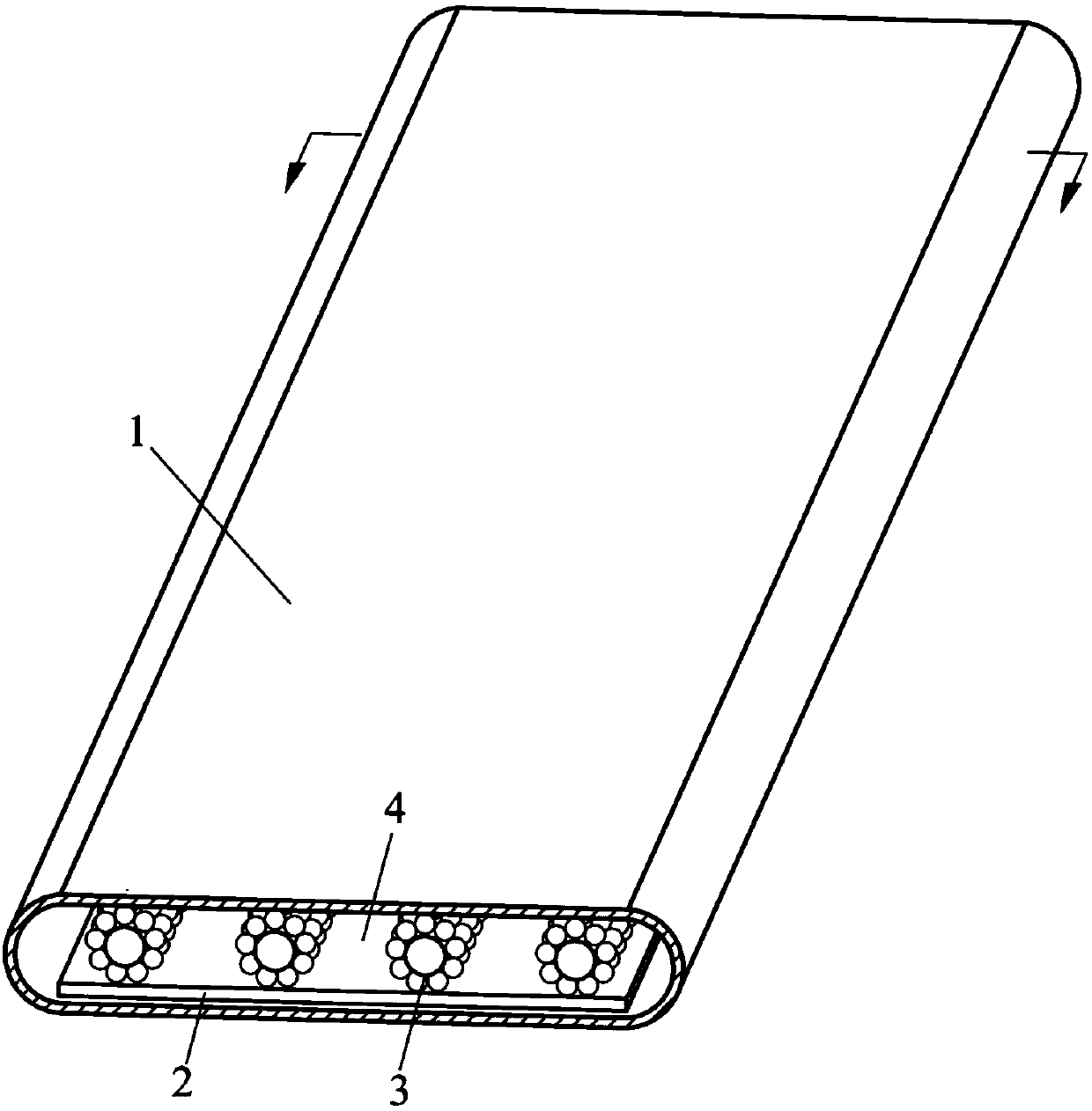

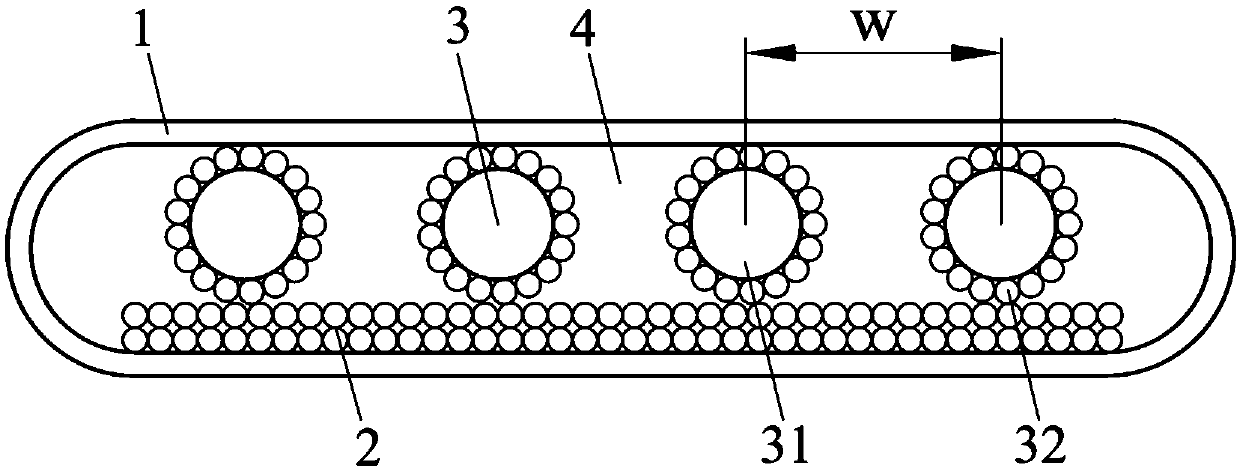

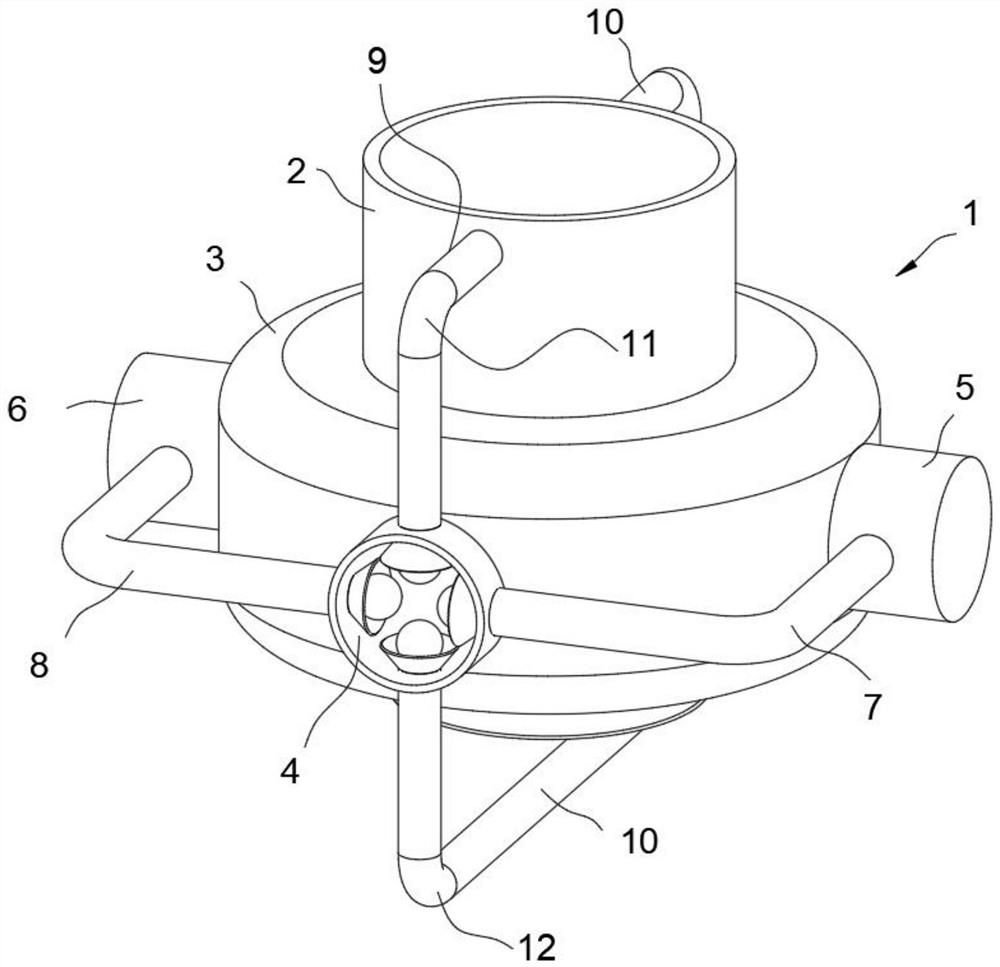

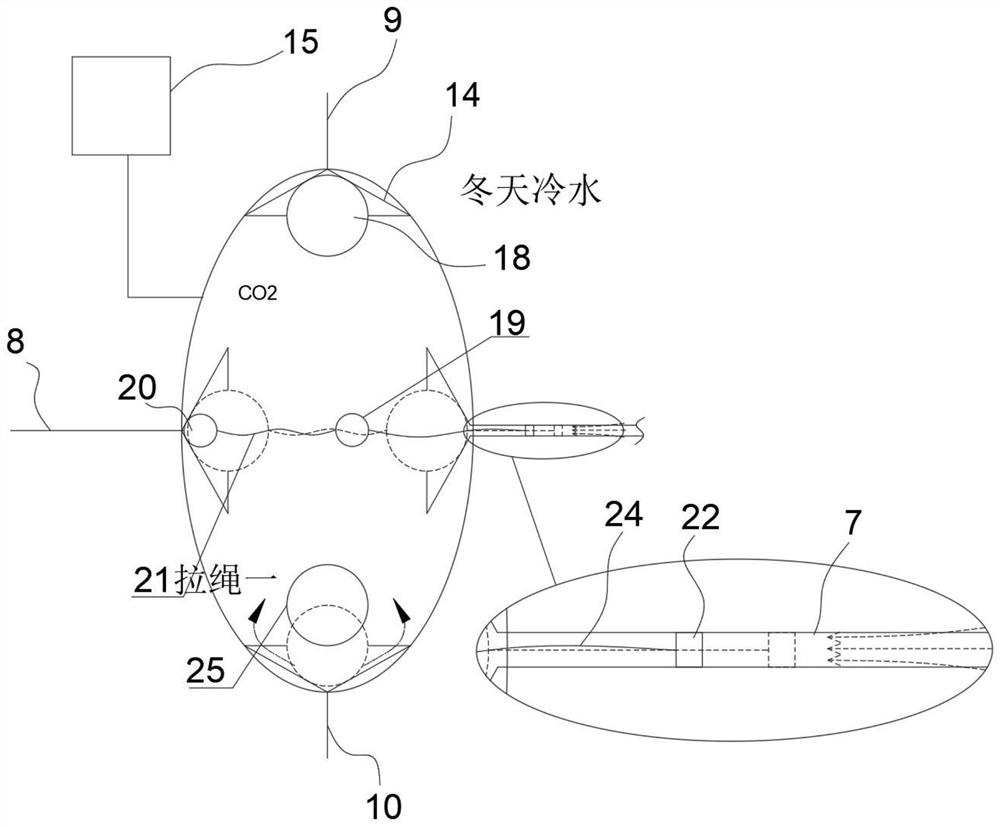

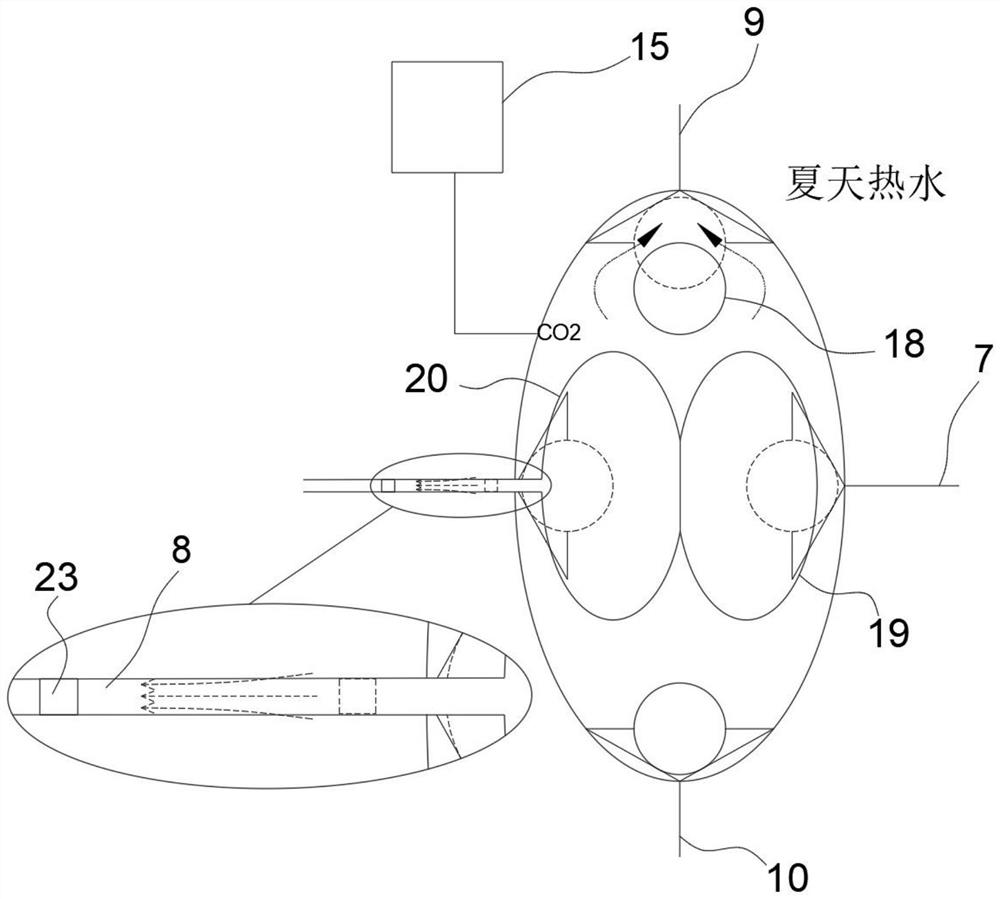

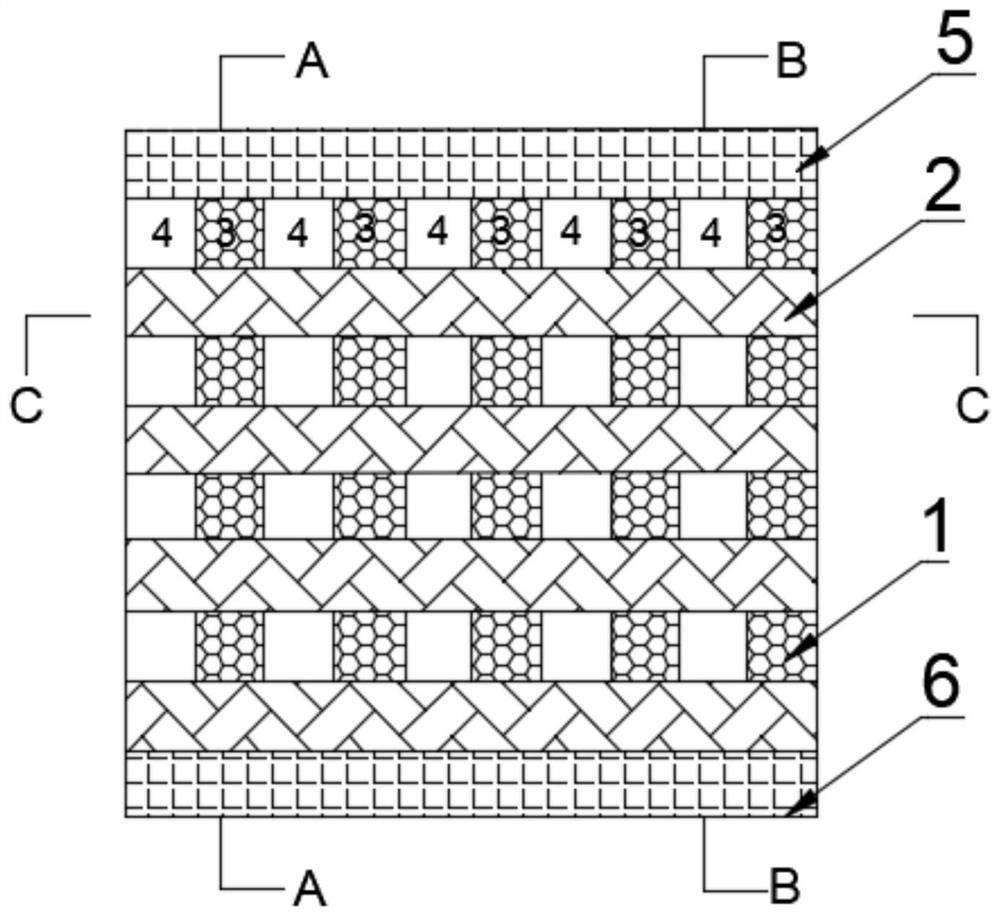

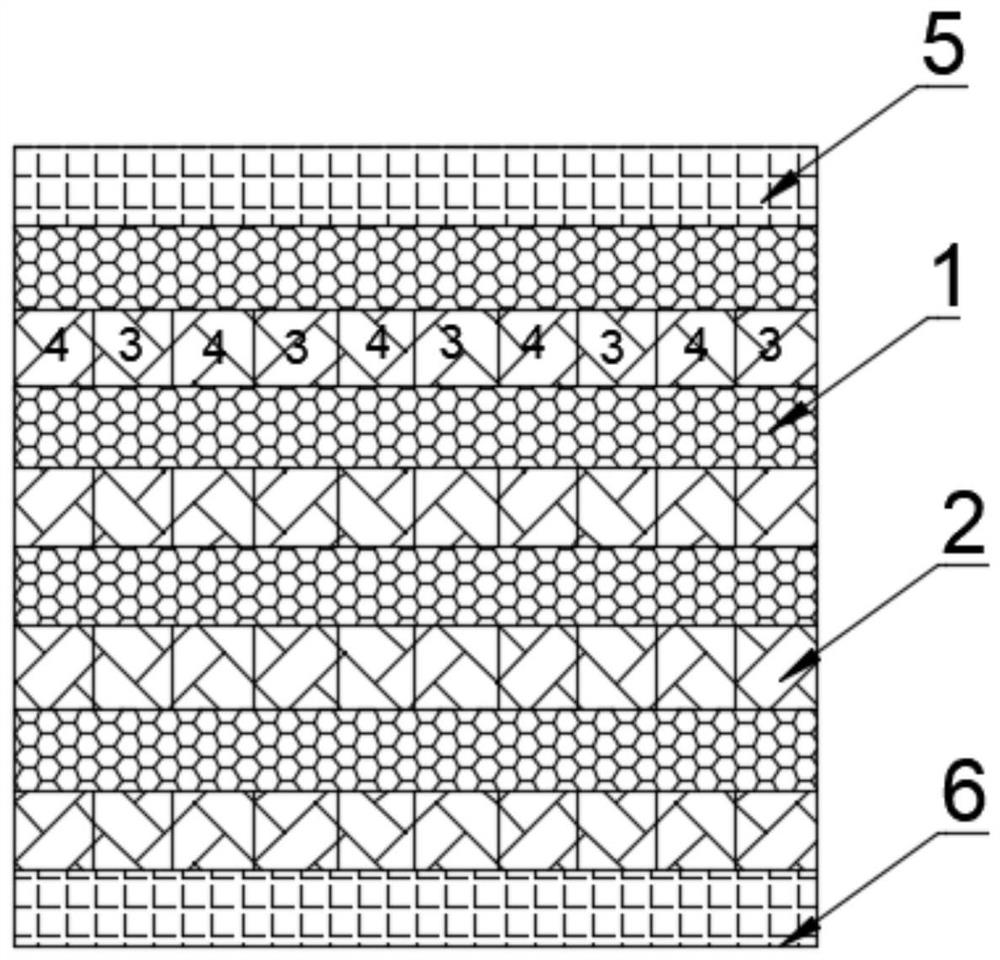

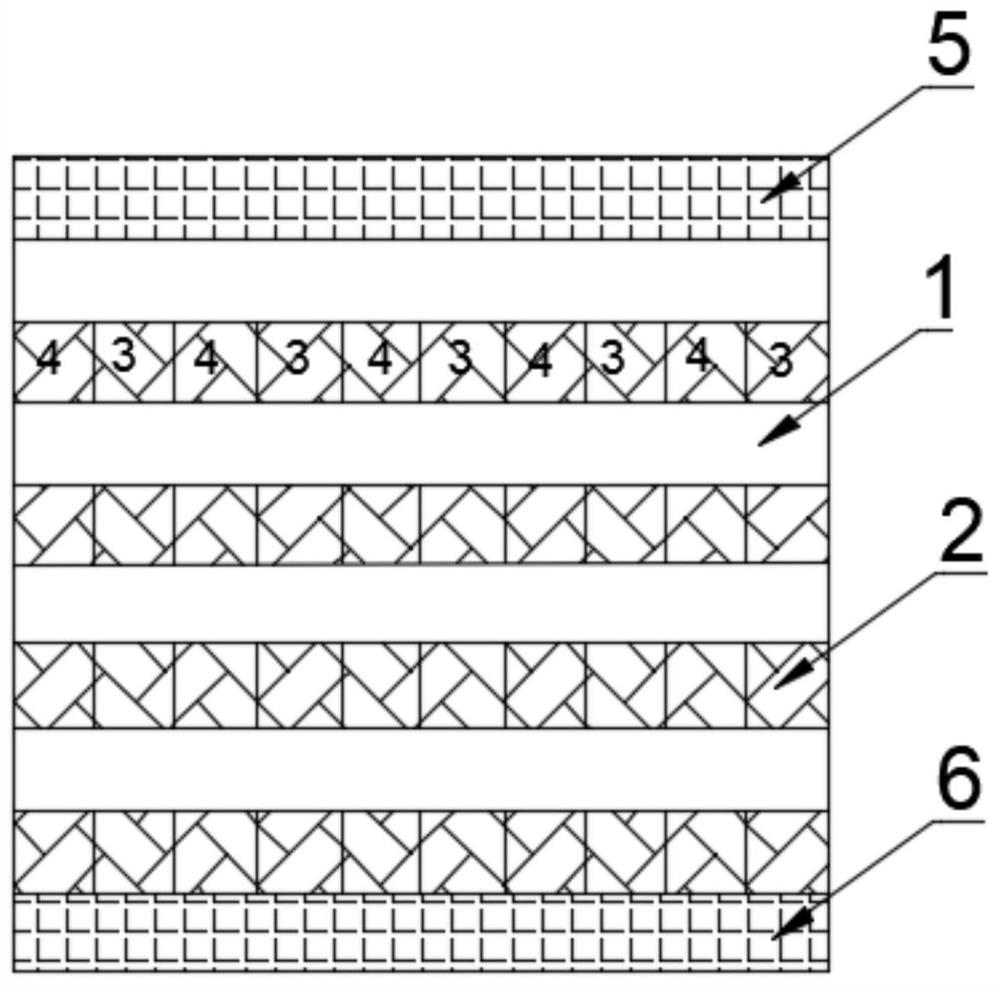

Ultra-thin flat panel heat pipe and manufacturing method thereof

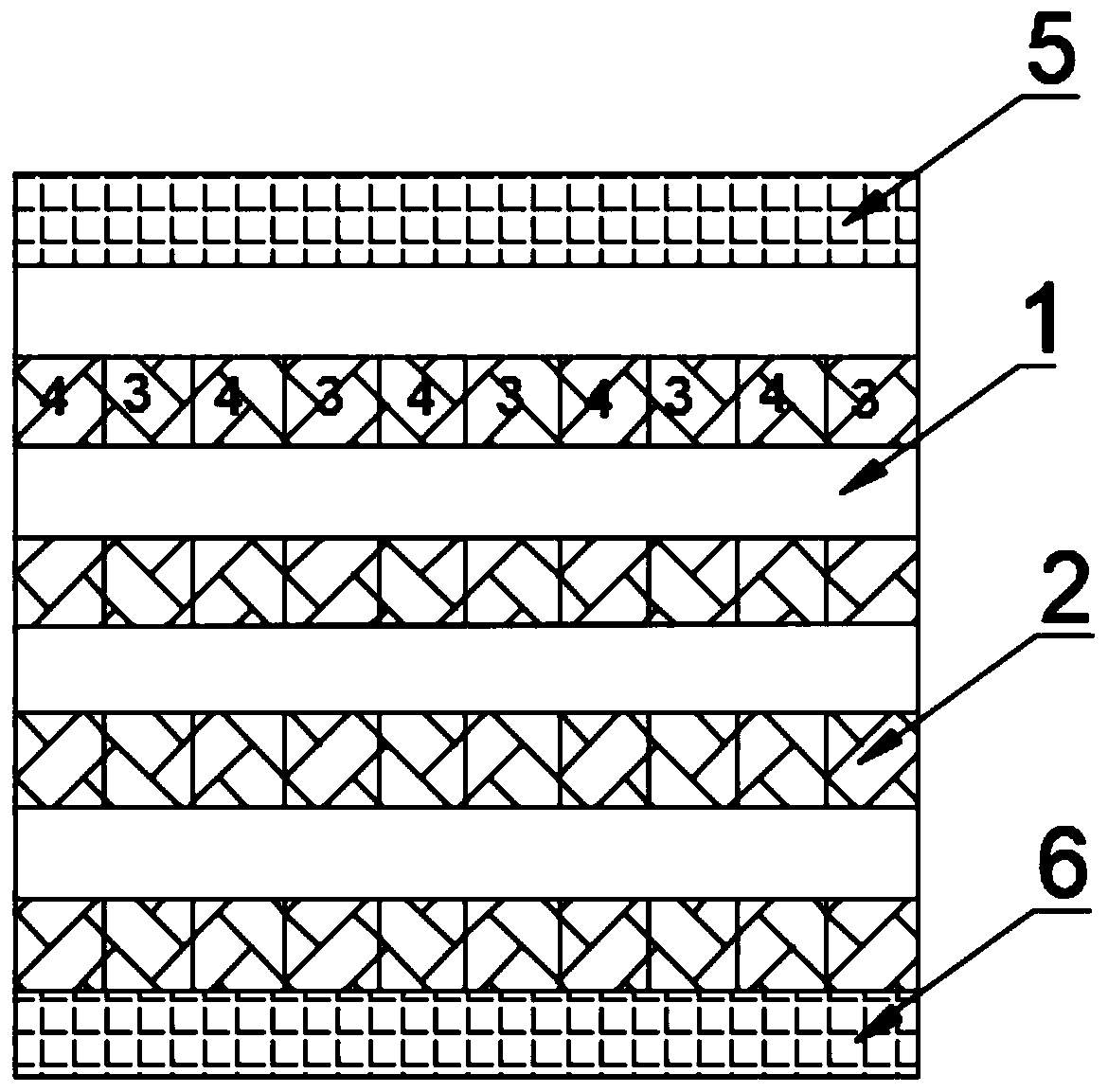

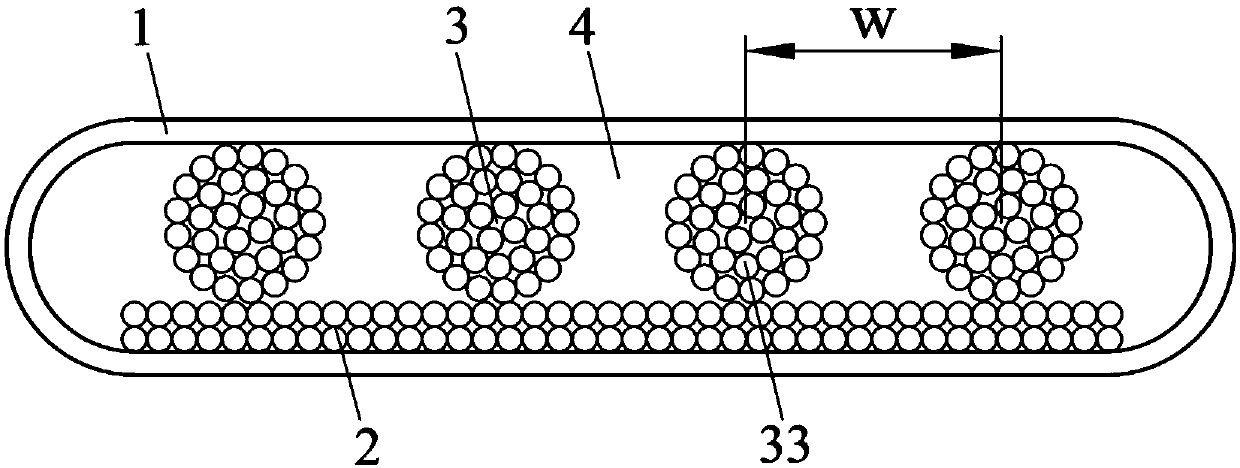

ActiveCN107167008AEasy to moveIncrease heat transfer limitIndirect heat exchangersVapor liquidHeat flux

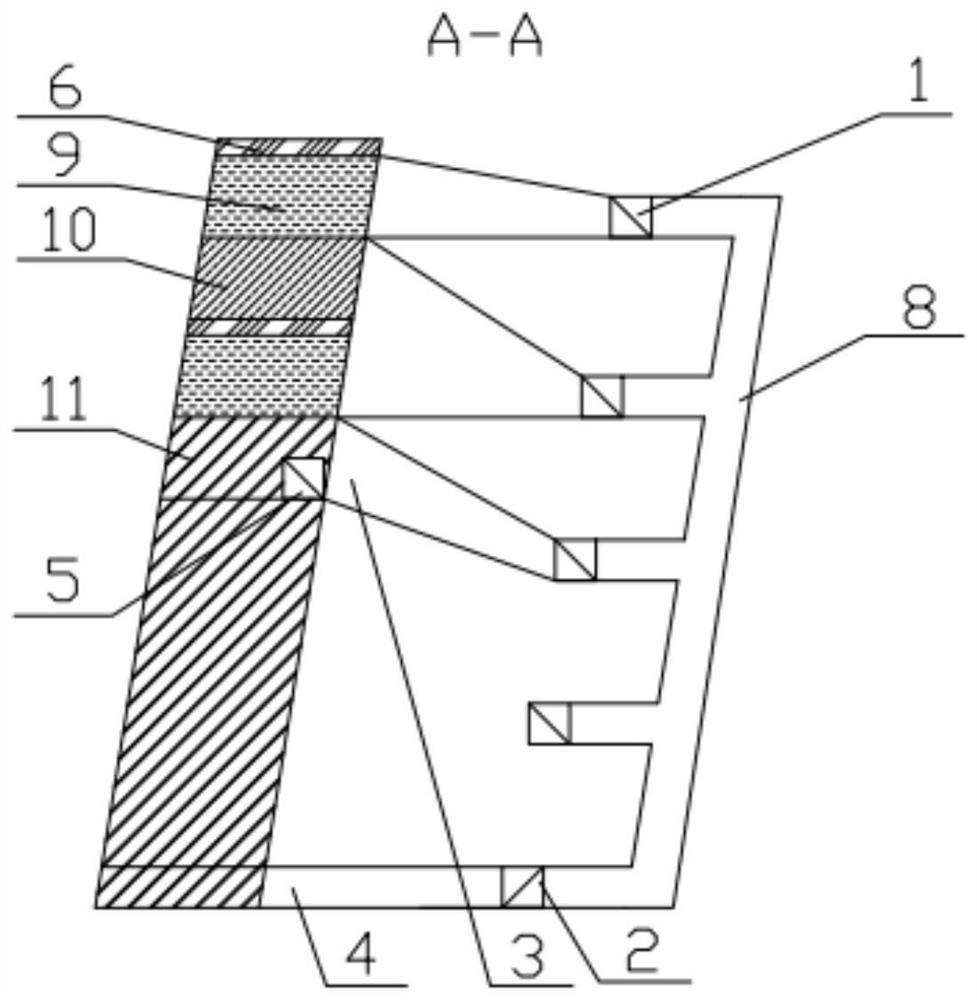

The invention relates to an ultra-thin flat heat pipe and a manufacturing method thereof. A wick comprises a porous medium bottom layer and a plurality of porous medium filaments arranged side by side; the porous medium filaments make contact with the top of a tube shell; the wick inside the heat pipe, a sharp angled area between the porous medium filaments and the upper surface of the tube shell, and a sharp angled area between the porous medium filaments and the porous medium bottom layer provide liquid return capillary driving force which is large enough in a limited space; spaces formed between the porous medium filaments provide steam flow channels, and the steam flow channels communicate with one another; and reasonable matching of vapor-liquid phase distribution is achieved, and steam and condensed liquid can flow easily. According to the ultra-thin flat heat pipe, efficient operation can be maintained at various angles, the performance of anti-gravity operation is excellent, the heat flux which can be borne by the heat pipe is high, and the heat transfer performance of the heat pipe is remarkably improved after further modification treatment.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

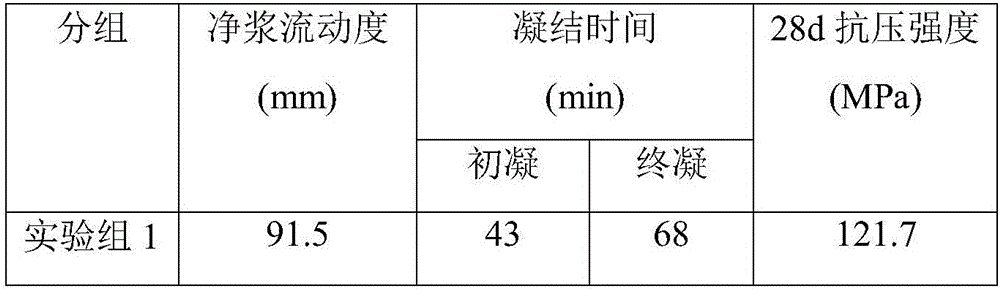

Retarder for sulphate aluminum cement and use method thereof

InactiveCN106746894AReduced hydration rateImprove the lubrication effectIsothiazolinonePolyethylene glycol

The invention discloses a retarder for sulphate aluminum cement and a use method thereof. The retarder is prepared from the following raw materials in parts by weight: 30-70 parts of polymer emulsion, 10-25 parts of metylchloro isothiazolinone, 2-10 parts of film-forming agent, 1-15 parts of water reducer and 5-15 parts of polyethylene glycol. The invention also discloses the use method for the retarder. The retarder disclosed by the invention can effectively reduce the coagulation speed of the sulphate aluminum cement; the initial setting time and the final setting time both can be prolonged for above 30min; the fluidity of the cement slurry can be obviously promoted; the fluidity of cement paste can be increased by above 15%. The retarder disclosed by the invention has no any adverse effect to the development of the cement strength, is low in cost, is high in performance stability and is easily stored and transported.

Owner:UNIV OF JINAN

Low-water-absorption foamed cement

InactiveCN109265112AHigh strengthSlow down the rate of condensationCeramicwareFoaming agentFatty alcohol

The invention discloses low-water-absorption foamed cement. The low-water-absorption foamed cement is prepared from the following raw materials in parts by weight: 100 parts of cement, 1.8 to 2 partsof a foaming agent, 0.6 to 0.8 part of a foam stabilizer, 10 to 12 parts of a waterproof agent, 0.02 to 0.04 part of a naphthalene water reducer, 0.4 to 0.6 part of a reinforcing agent, and 45 to 50 parts of water, wherein the foaming agent is lauryl sodium sulfate and fatty alcohol polyoxyethylene ether sodium sulfate. The low-water-absorption foamed cement is good in waterproof performance, lowin water absorption rate and good in strength.

Owner:怀宁建国混凝土制品有限责任公司

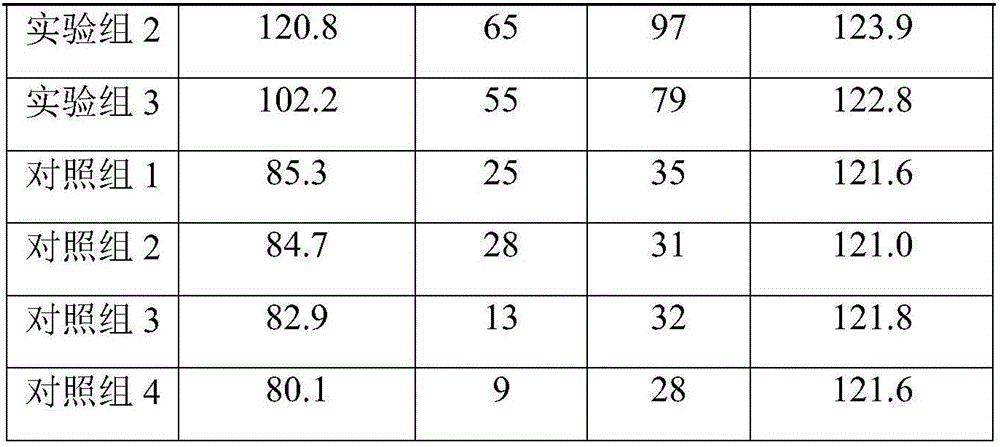

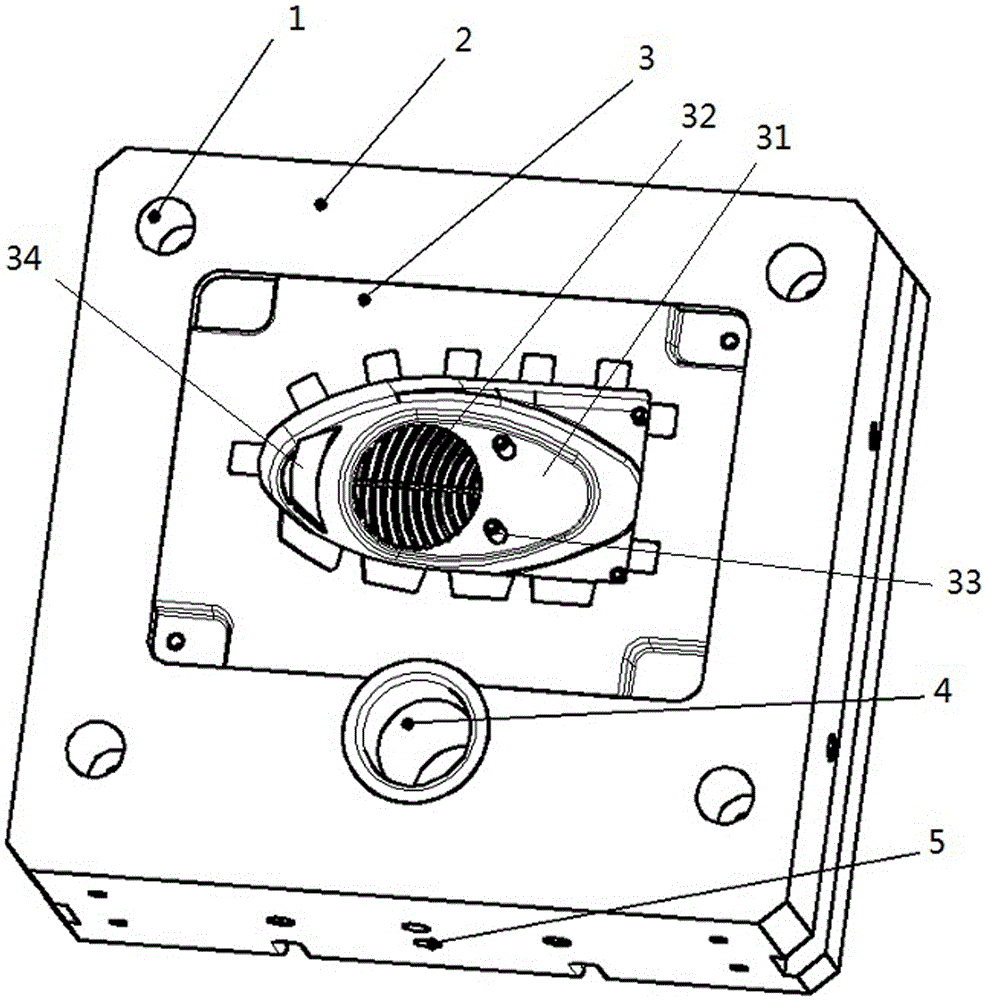

Lid mold structure with grill and diversion control device

InactiveCN105598386AQuality improvementEffective and smooth exhaustFoundry mouldsFoundry coresEngineering

The present invention relates to a lid mold structure with a grill and a diversion control device. The lid mold structure is characterized in that: a fixed mold frame is provided internally with a fixed mold core; a movable mold frame is provided internally with a movable mold core; the movable mold core is connected to a shunt sub; the fixed mold core is provided with a sprue bush; the center of the fixed core is provided with a molding recess; the molding recess is provided with a circular radiator grill; one side of the circular radiator grill is provided with two diversion control modules; the other side of the circular radiator grill is provided with a condensation control cavity; the center of the movable mold core is provided with an oval shaping boss; the center of the oval shaping boss is provided with a molding grill; one side of the molding grill is provided with a semicircular boss, and one side of the boss is connected to a guide column group; and shaping boss is equipped with a deceleration bump group. Dross outside the shaping boss and the circular radiator grill in the fixed mold core realize the more efficient and smooth gas exhaust, rapidly reduce local problems, improve the efficiency of coagulation, reduce the pores of the product, and improve the mold quality.

Owner:SHANGHAI YADELIN NONFERROUS METAL

Environment-friendly pollution-free concrete exposed-aggregate agent and preparation method thereof

InactiveCN107840630AImprove maintenance effectGood mixing effectHydroxypropylmethyl celluloseSodium silicate

The invention discloses an environmentally friendly and pollution-free concrete dew stone agent, which is made of the following materials in proportion by weight: hydroxypropyl methylcellulose, liquid sodium silicate, hydroxyl, carboxylate, protein, fatty acid, glucose, Urea, sodium carboxymethylcellulose, tricalcium silicate, dicalcium silicate, tricalcium aluminate, tetracalcium aluminoferrite, β-naphthalenesulfonate formaldehyde condensation product water reducer and pour point depressant; this type of concrete The dew stone agent has the advantages of low engineering cost, strong practicability, environmental protection, no pollution and stable effect.

Owner:夏放军

Downward access road filling mining method

ActiveCN111119894AEnsure safetyImprove mobilityUnderground miningSurface miningSlagMining engineering

The invention discloses a downward access road filling mining method which comprises the following steps: dividing a mining area into interval filling layers and complete filling layers alternately distributed in the vertical direction, adopting the downward access road layer-by-layer mining method, and alternately filling a high-strength quick setting filling material and a low-strength quick setting filling material in goafs of the interval filling layers and the complete filling layers, wherein the high-strength quick setting filling material is made of cement clinker, whole tailings, wasterock and an accelerator, and the low-strength quick setting filling material is made of cement, active slag, tailings and an accelerator, so that an upper-layer filling body is jointly supported by alower-layer high-strength filling body and a low-strength filling body to prevent the upper-layer filling body from collapse, the using quantity of cement in mining safe filling material is ensured,and the filling cost is reduced; and in addition, a small quantity of accelerator is added in the filling material to greatly shorten the time waiting for the filling material to reach the preset strength, so that the stoping time is shortened to greatly improve the mining efficiency.

Owner:NANHUA UNIV

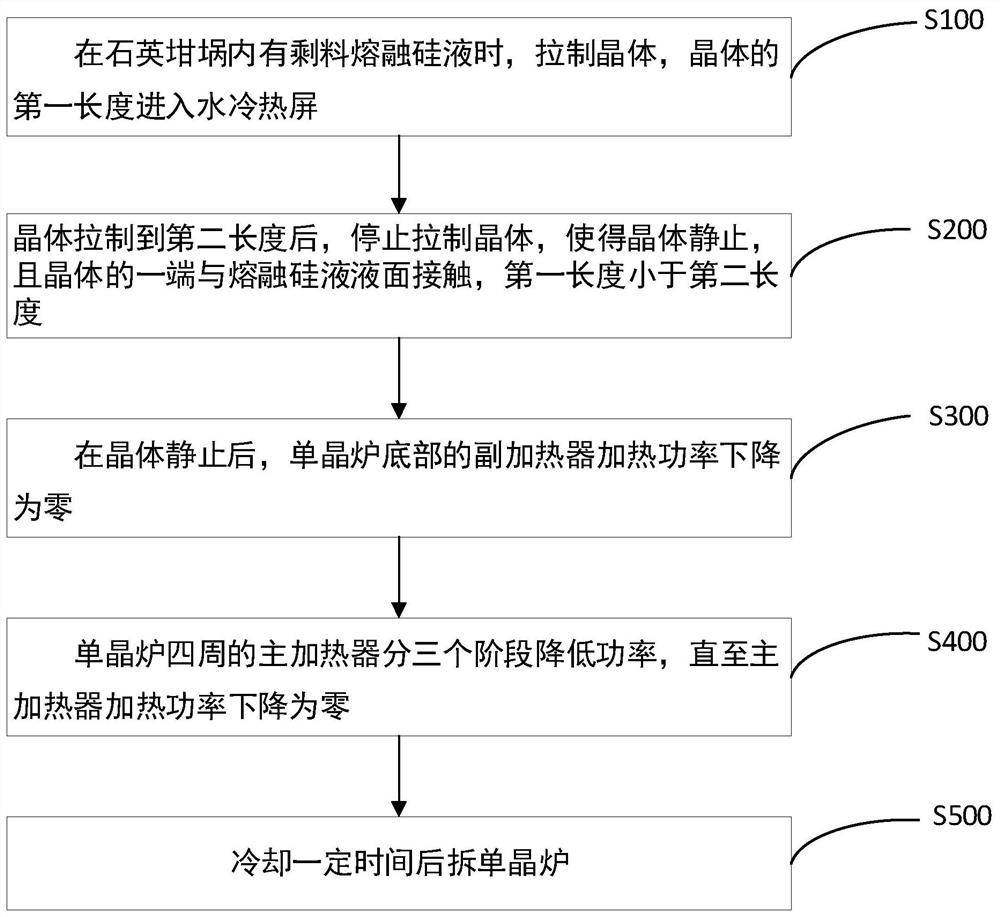

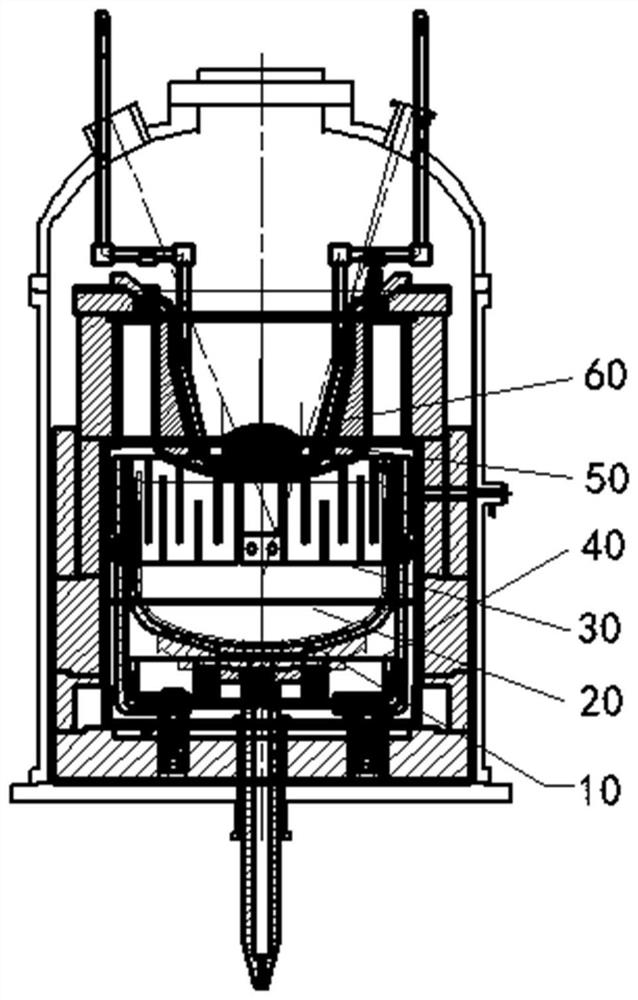

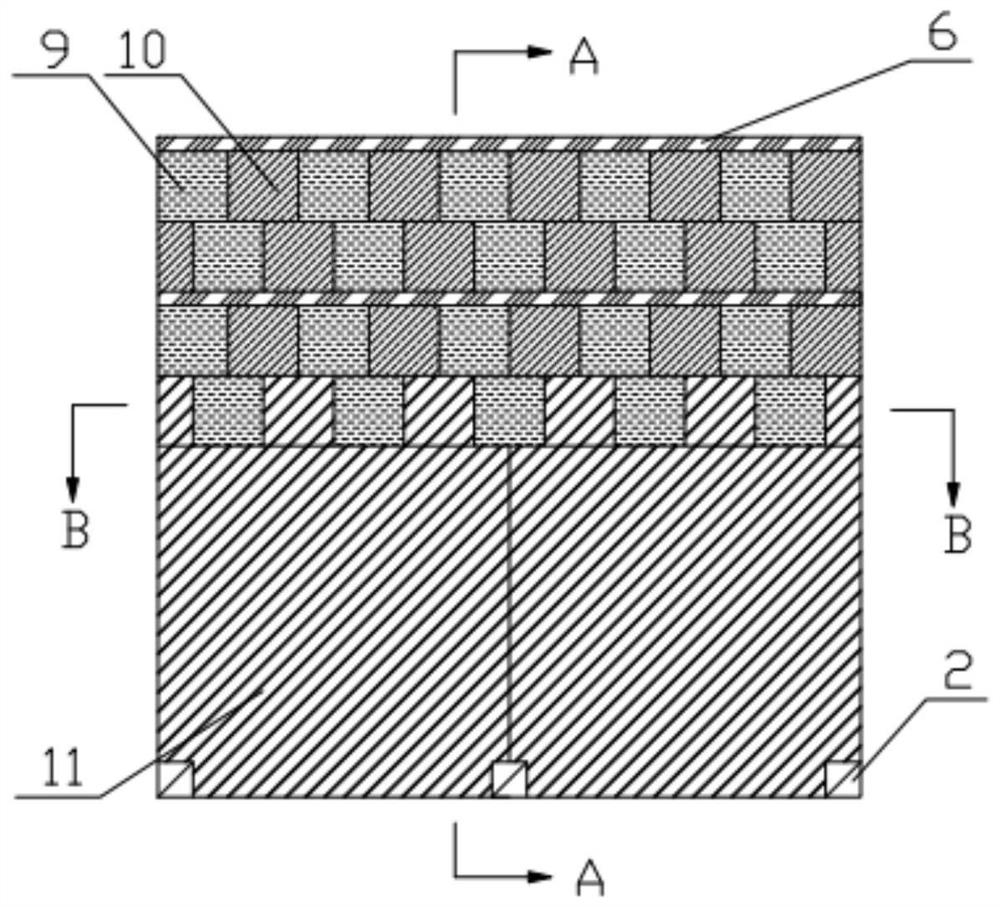

Single crystal furnace shutdown thermal field damage prevention method

PendingCN111826707AIncrease heat transfer volumeFast condensationPolycrystalline material growthBy pulling from meltMolten siliconHeating power

The invention provides a single crystal furnace shutdown thermal field damage prevention method which comprises the following steps of: 1, drawing a crystal when residual molten silicon liquid existsin a quartz crucible, and enabling the first length of the crystal to enter a water-cooling heat shield; 2, after the crystal is drawn to a second length, stopping drawing the crystal, and enabling one end of the crystal to be in contact with the liquid level of the molten silicon liquid; 3, after the crystal is static, reducing the heating power of an auxiliary heater at the bottom of the singlecrystal furnace to zero; 4, reducing the power of the main heaters around the single crystal furnace in three stages until the heating power of the main heaters is reduced to zero; and 5, cooling fora certain period of time, and disassembling the single crystal furnace. According to the method, a single crystal with a certain length can be drawn to increase the heat transfer volume, accelerate the condensation speed of molten silicon liquid in the middle of a quartz crucible and reduce the stress concentration ratio, a heater on the single crystal furnace stops heating in a stepped mode, thecondensation speed of silicon around the quartz crucible is reduced, a stress release area is reserved, and therefore the integrity of a thermal field is guaranteed to the maximum extent.

Owner:JA XINGTAI SOLAR CO LTD

A Downward Approach Filling Mining Method

ActiveCN111088979BPrevent collapseReduce usageUnderground chambersUnderground miningMining engineeringUltimate tensile strength

The invention discloses a mining method for filling downward approach, which includes ore block division, mining arrangement, stope mining and stope filling. Solidification filling materials and low-strength quick-setting filling materials are alternately filled in the goafs of adjacent ore blocks in each layered approach, thereby reducing filling costs while ensuring mining safety, shortening mining time, and improving mining efficiency. Through the above method, the present invention not only enables the upper filling body to be jointly supported by the lower high-strength filling body and the lower-strength filling body, prevents the upper filling body from collapsing, and ensures mining safety; While reducing the amount of cement used and reducing the filling cost, the strength of the filling body is improved, and the time spent waiting for the filling material to reach strength is shortened, so as to improve the mining efficiency. At the same time, the performance of the filling body can be adjusted according to the use requirements, and the application range is wide.

Owner:NANHUA UNIV

Dry-mixed ceramic tile adhesive mortar

The invention provides ceramic tile pasting mortar and a preparation method thereof. Waste tires are used for preparing machine-made sand, the existence of black garbage is effectively reduced, and meanwhile, the modified waste tire particles have very high ductility and excellent energy absorption performance, and can effectively prevent the dry shrinkage phenomenon of the mortar in the solidification process. A binding agent is added, the binding force of the mortar to the ceramic tile is increased, meanwhile, the binding agent is alkaline, the interface on the back face of the ceramic tile can be slightly reacted, the roughness of the interface is increased, and the binding agent can adhere and cure the mortar interface more easily. A modified retarder is added, so that the coagulation speed of the mortar is slowed down, the mortar does not react with groups outside modified waste tire particles and a binder, meanwhile, the modified retarder has the effect of a plastic stabilizer, the anti-sagging property of the mortar is improved, the micro-reaction inside the mortar is stabilized, and the bonding capacity of the mortar and a matrix interface is improved.

Owner:龙南县彩艺装饰材料厂

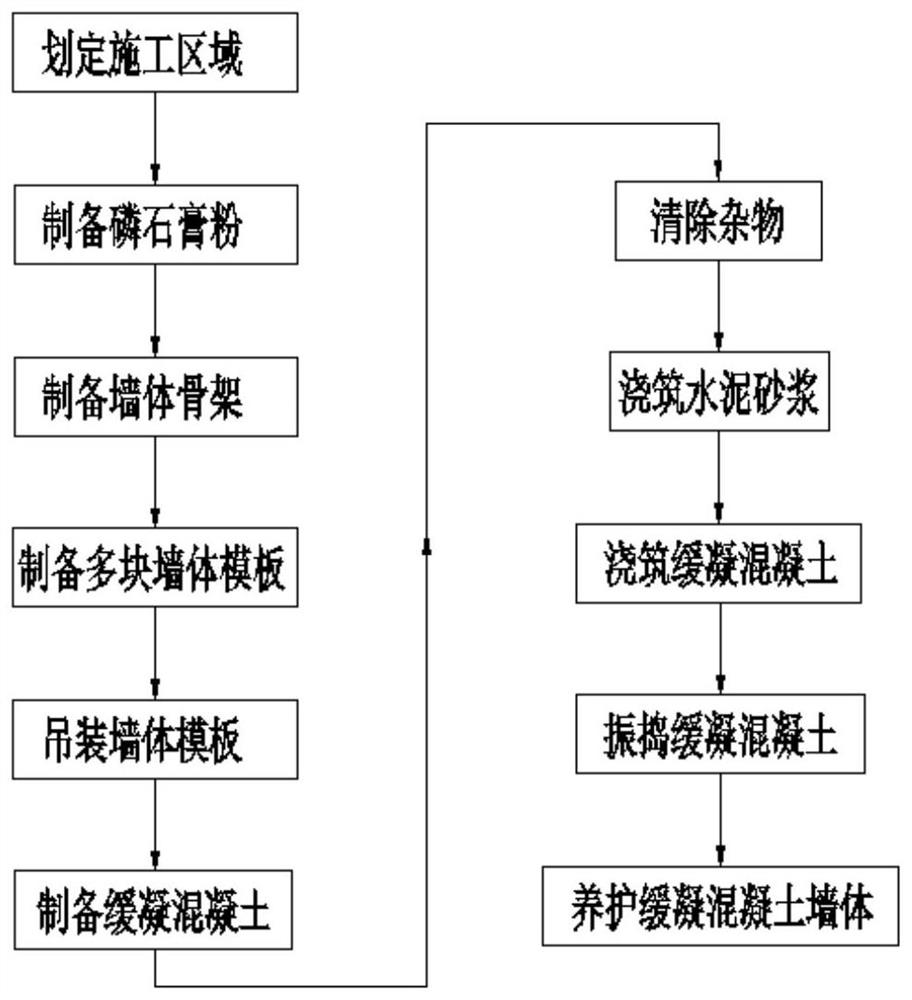

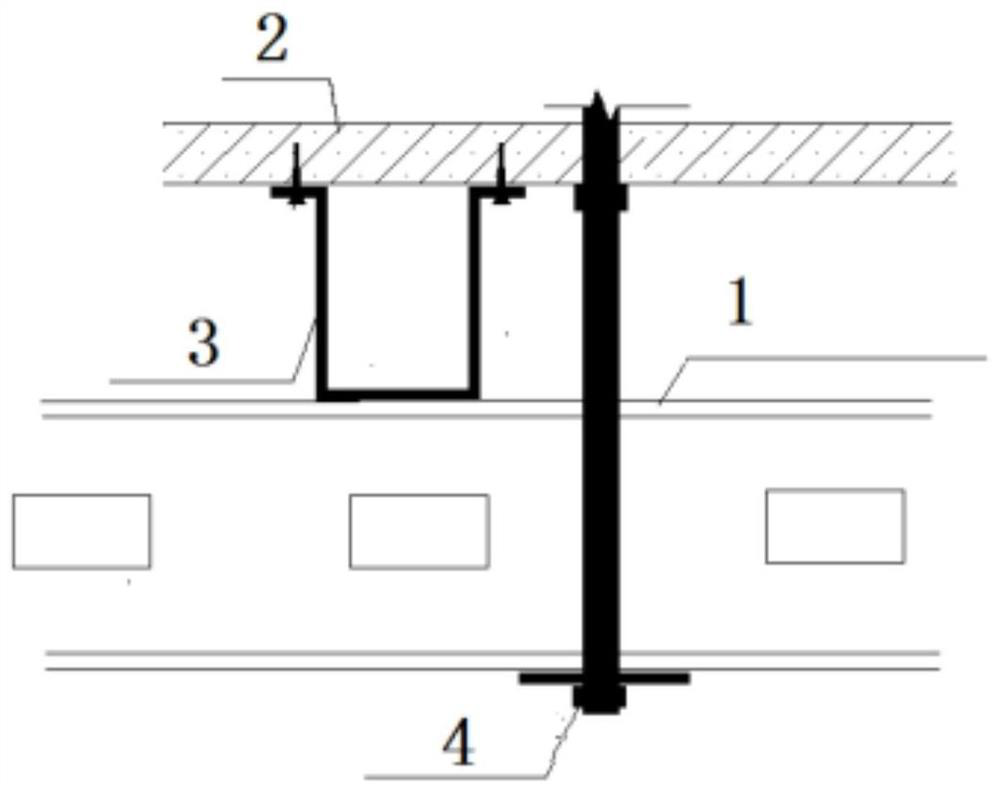

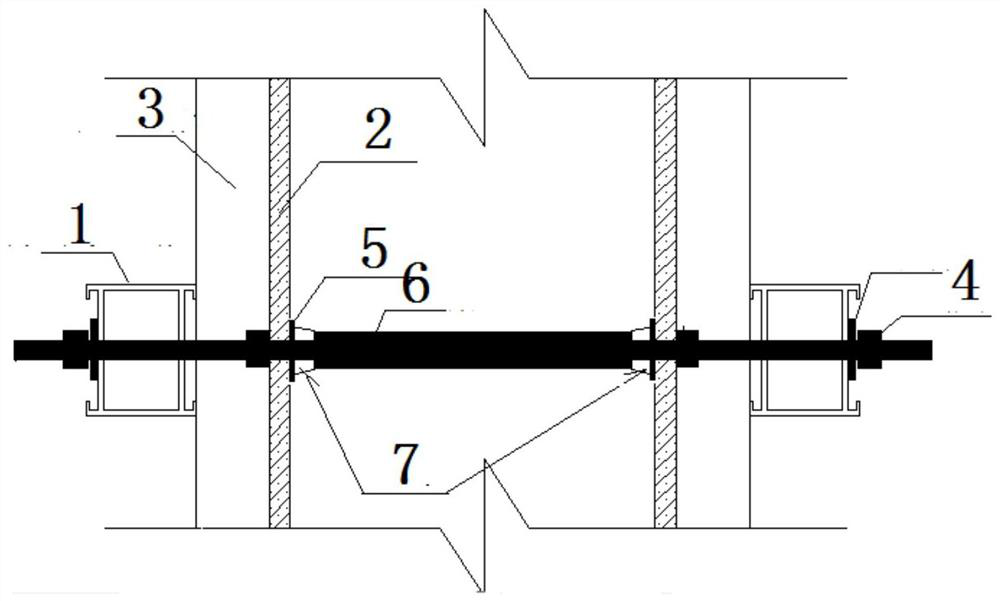

Construction process of retarded concrete wall body

InactiveCN112196152AImprove structural strengthReasonable structural designSolid waste managementWallsSupporting systemArchitectural engineering

The invention provides a construction process of a retarded concrete wall body. The construction process comprises the steps of defining a construction area on the ground, preparing ardealite powder,preparing a wall body framework, preparing a plurality of wall body formworks, hoisting the wall body formworks, preparing retarded concrete, removing all impurities in the wall body framework and thewall body formworks, pouring cement mortar, pouring the retarded concrete into the wall body framework in multiple times, vibrating the retarded concrete, maintaining the retarded concrete wall bodyand dismantling a protective material. According to the technical scheme, ardealite is adopted to replace natural gypsum to prepare the retarded concrete, the concrete setting speed is decreased, theconcrete setting strength is improved through sufficient vibration, and in addition, a large number of through-wall screws are adopted, so that the structural strength of an existing wall body formwork supporting system is greatly enhanced, the flatness of the two sides of a poured wall body is effectively guaranteed, and the construction process has the advantages that the wall body formworks areconvenient to install, the poured wall body is good in quality and low in cost, raw materials are saved, construction time is shortened, and environmental pollution is reduced.

Owner:NO 1 CONSTR ENG CO LTD OF GUIZHOU CONSTR & ENG GRP

Canned meat paste with low saturated fatty acids, and making technology of canned meat paste

InactiveCN108029987ASlow down the rate of condensationQuality improvementFood ingredient as taste affecting agentLipidic food ingredientsFood additiveVegetable oil

The invention discloses canned meat paste with low saturated fatty acids, and a making technology of the canned meat paste. Pork and food ingredients of a food additive, vegetable oil, gel and the like, in a unique compounding ratio, are made into flower-shaped meat sandwiches and emulsified fillings, wherein the flower-shaped meat sandwiches comprise 40-50 parts of the pork, 0.2168-0.2823 part ofthe food additive and 0.88-1.375 parts of a food flavoring agent; and the emulsified fillings comprise 20-30 parts of the pork, 12-16 parts of the vegetable oil, 0.72-1.157 parts of the gel, 3.38-8.143 parts of the food additive and 0.74-1.28 parts of the food flavoring agent; and after the flower-shaped meat sandwiches and the emulsified fillings are made into finished product fillings, the brand-new canned meat paste with low saturated fatty acids can be made. The canned meat paste with low saturated fatty acids has favorable distribution effects of flower-shaped fat sandwiches and low saturated fatty acid, is suitable for crowds suffering from high blood lipid to eat, and is suitable for the existing healthy consumption idea.

Owner:遂宁市三丰食品有限公司

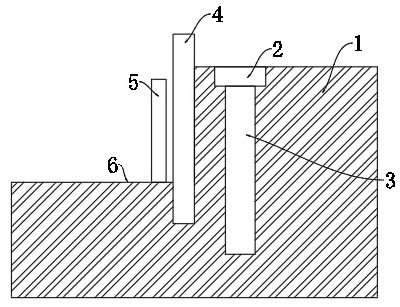

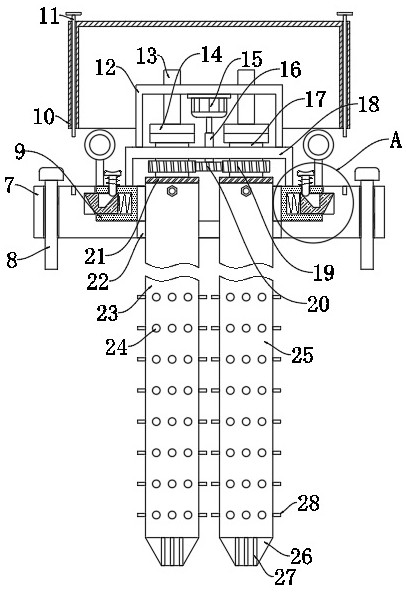

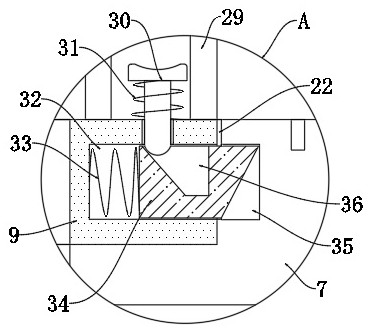

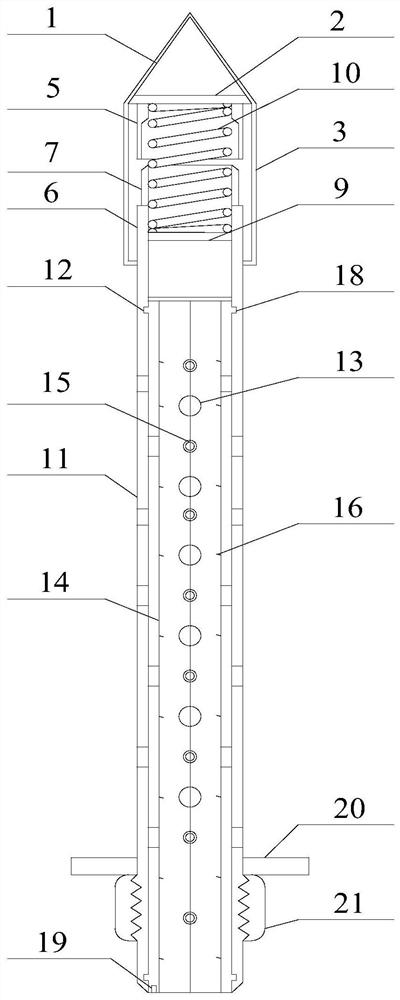

Foundation pit pre-embedded type double-liquid grouting leaking stoppage device

PendingCN113373930ASlow down the rate of condensationAvoid cloggingFoundation repairStructural engineeringPipe

The invention discloses a foundation pit pre-embedded type double-liquid grouting leaking stoppage device. The device comprises a preset hole formed in an original soil layer and close to a water stop wall, a containing groove is formed in the top of the preset hole, a containing plate is connected into the containing groove, a mounting groove is formed in the containing plate, a mounting plate is connected into the mounting groove, and the mounting plate is arranged in the mounting groove, mounting holes are formed in the two sides of the mounting plate, connecting mechanisms used for fixing the mounting plate to the containing plate are arranged in the mounting holes, an opening is formed in the middle of the mounting plate, a second mounting frame located above the opening is fixed to the upper end of the mounting plate, and two connecting sleeves are rotationally connected to the lower end of the second mounting frame; the lower ends of the two connecting sleeves are fixedly sleeved with a cement paste pipe and a water glass pipe correspondingly. The device has the effects of rapidly filling the collapsed position and preventing the ground of the original soil layer from collapsing, and the cement paste and the water glass are mixed more uniformly, so that the mixed condensation filling effect is improved.

Owner:刘明杰

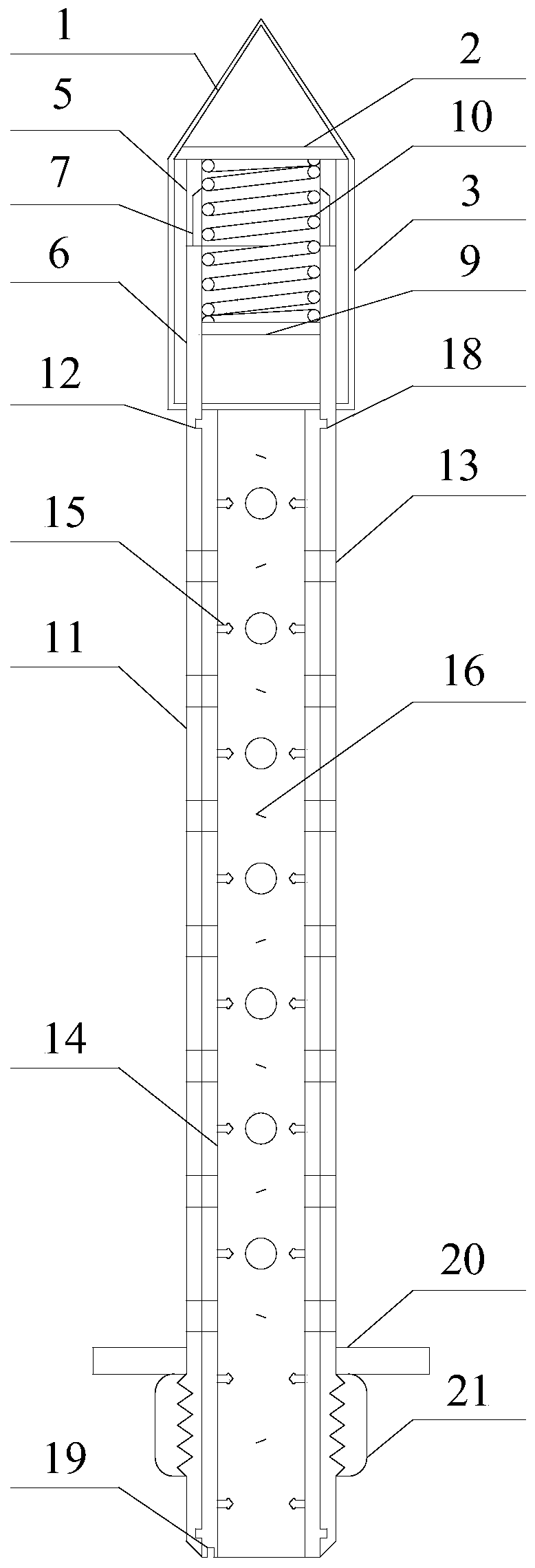

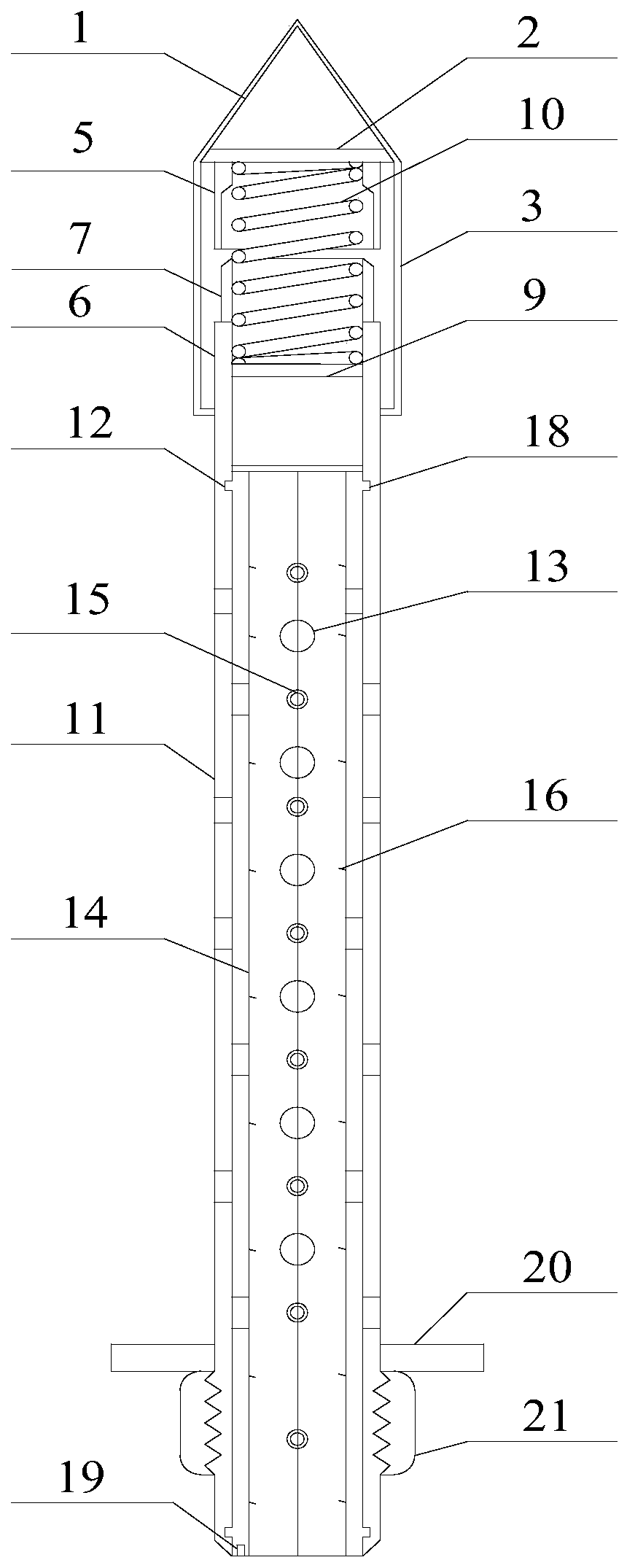

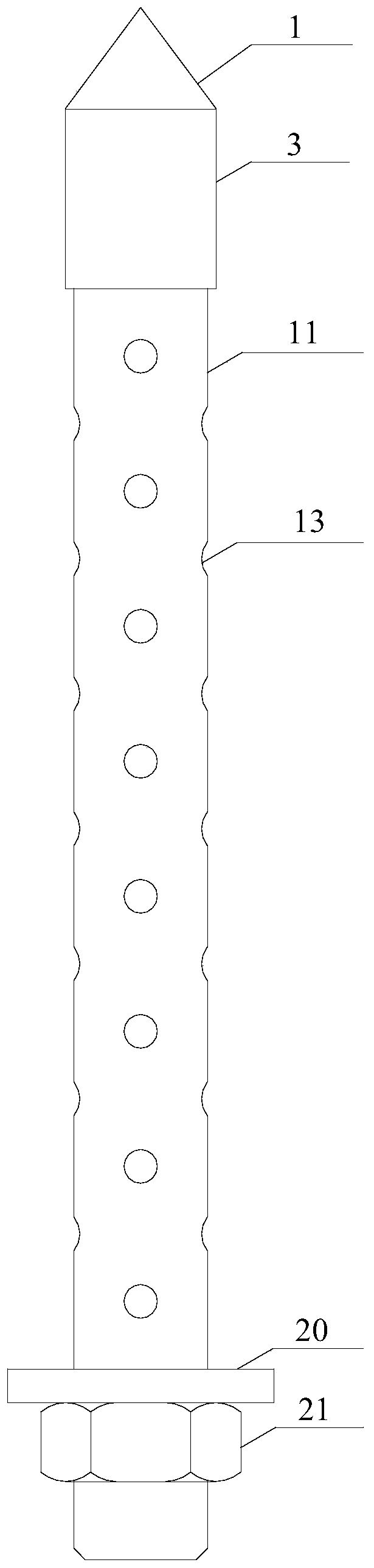

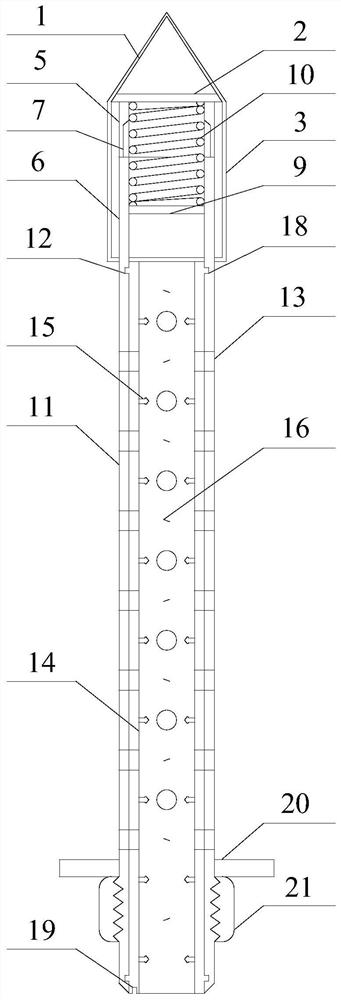

Recyclable advanced small guide pipe and use method thereof

The invention relates to the technical field of foundation pit construction advanced supports and discloses a recyclable advanced small guide pipe. The recyclable advanced small guide pipe comprises an end head ejection device and a sleeve type grouting device. The tail end of the end head ejection device is connected with the sleeve type grouting device. The end head ejection device comprises a conical pipe head, a pressure bearing plate, a cylindrical shell, an upper rotating pipe and a lower rotating pipe. The conical pipe head is connected to the cylindrical shell through the pressure bearing plate mounted at the bottom end of the conical pipe head. The upper rotating pipe is fixedly connected to the lower portion of the pressure bearing plate. The lower end of the upper rotating pipeis rotationally connected with the lower rotating pipe. The invention further comprises a use method of the recyclable advanced small guide pipe. The use method specifically comprises the following steps of assembling the advanced small guide pipe, fixing the assembled advanced small guide pipe on a rock soil body, rotating an outer steel pipe to enable an upper clamping shell and a lower clampingshell in the end head ejection device to be staggered after the advanced support is completed and extracting the small guide pipe from a rock-soil body drill hole. By the adoption of the recyclable advanced small guide pipe and the use method, the recovery and reuse of the advanced small guide pipe are facilitated.

Owner:RAILWAY NO 5 BUREAU GRP FIRST ENG CO LTD +1

Novel gypsum surface layer self-leveling material

The invention discloses a novel gypsum surface layer self-leveling material which is prepared from the following raw materials in parts: early strength ordinary Portland cement, quartz sand, anhydrite, low-viscosity hydroxypropyl methyl cellulose, a defoaming agent, water, high-alumina cement, ground calcium carbonate, redispersible latex powder, a water reducing agent and tartaric acid, wherein the proportion of the early strength ordinary Portland cement is 25%-40%, the proportion of the quartz sand is 5%-10%, and the proportion of the anhydrite is 4%-9%. According to the novel gypsum surface layer self-leveling material disclosed by the invention, the slurry can have ideal fluidity at a relatively low water cement ratio, and can be automatically unfolded and leveled only by virtue of the gravity of the slurry without external force, so that a flat mirror-like surface is obtained. By using the novel gypsum surface layer self-leveling material manufactured according to proportion, it is guaranteed that hollowing and cracking phenomena caused by different materials are avoided between different working procedures in the using process, and the construction technology is simple.

Owner:苏州金世晟建筑装饰工程有限公司

A kind of ultra-thin flat heat pipe and its manufacturing method

ActiveCN107167008BEasy to moveImprove mechanical propertiesIndirect heat exchangersVapor liquidHeat flux

The invention relates to an ultra-thin flat heat pipe and a manufacturing method thereof. A wick comprises a porous medium bottom layer and a plurality of porous medium filaments arranged side by side; the porous medium filaments make contact with the top of a tube shell; the wick inside the heat pipe, a sharp angled area between the porous medium filaments and the upper surface of the tube shell, and a sharp angled area between the porous medium filaments and the porous medium bottom layer provide liquid return capillary driving force which is large enough in a limited space; spaces formed between the porous medium filaments provide steam flow channels, and the steam flow channels communicate with one another; and reasonable matching of vapor-liquid phase distribution is achieved, and steam and condensed liquid can flow easily. According to the ultra-thin flat heat pipe, efficient operation can be maintained at various angles, the performance of anti-gravity operation is excellent, the heat flux which can be borne by the heat pipe is high, and the heat transfer performance of the heat pipe is remarkably improved after further modification treatment.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Roadway road foundation filling composition and preparation method thereof

The invention belongs to the technical field of concrete materials, and in particular relates to a roadway road foundation filling composition and a preparation method thereof. The composition includes by mass: 32.5- 47.8% of a binder, 63.3- 82.4% of a coarse aggregate, 32.2- 44.5 of a fine aggregate, 10.6-18.4% of gypsum, 4.5-8.7% of fatty alcohol polyoxyethylene ether sulfate sodium, 12.3-17.5%of polyvinyl chloride cement, 3.8-7.6% of a cellulose fiber, 4.4-9.7% of citric acid, 5.2-8.3% of tartaric acid, 2.7-6.5% of aluminite, 5.4-10.8% of quicklime, 3.3-7.2% of magnesium oxide, 1.2-5.5% of kyanite, 4.6-9.6% of calcium chloride, 4.8-8.2 % of ethylene glycol and 45.7-82.6 % of water. The roadway road foundation filling composition has the advantages of easy water seepage, freezing resistance, slow condensing speed and convenient transportation.

Owner:北京城建十六建筑工程有限责任公司

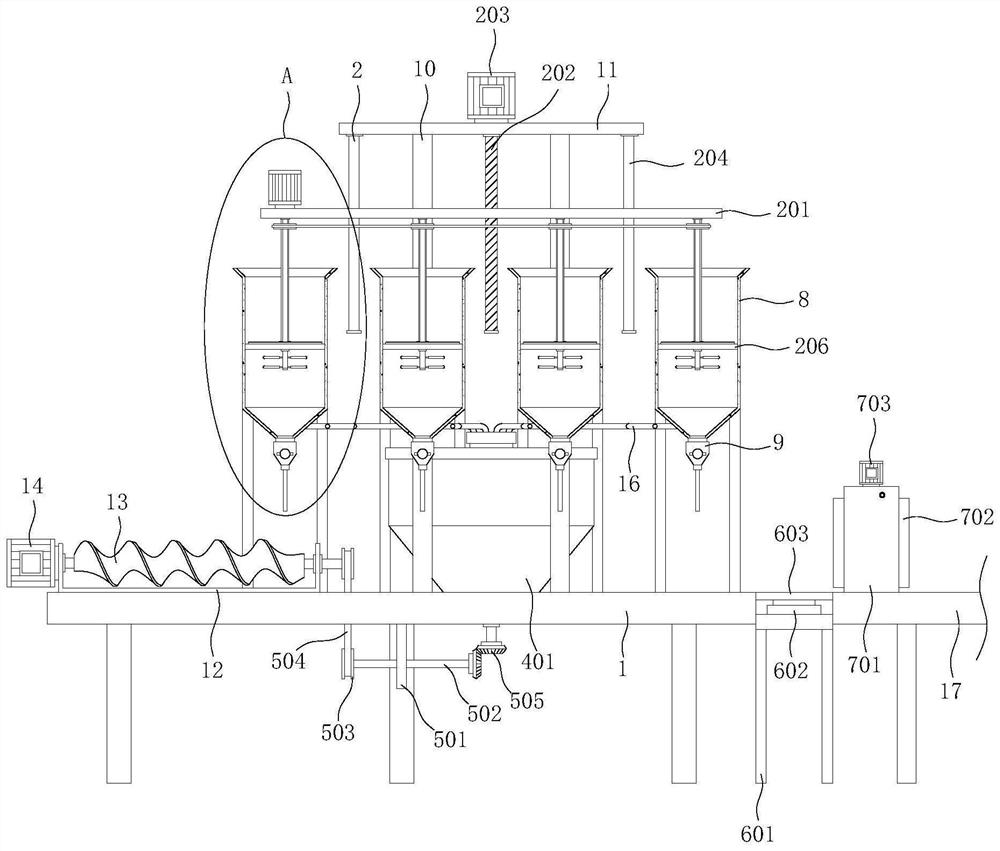

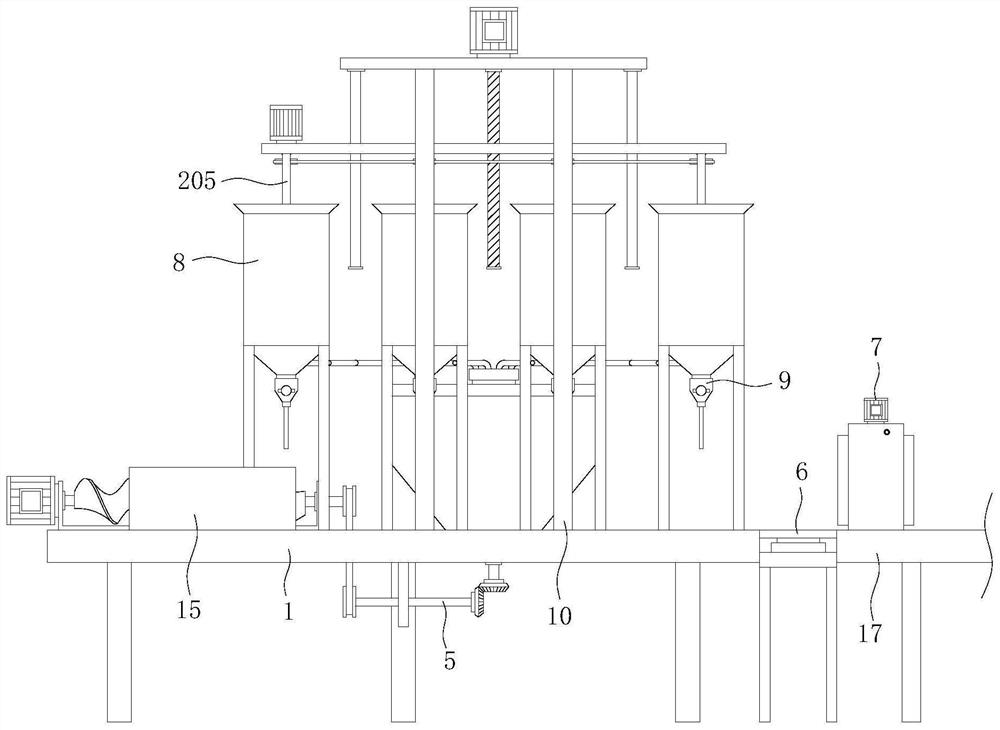

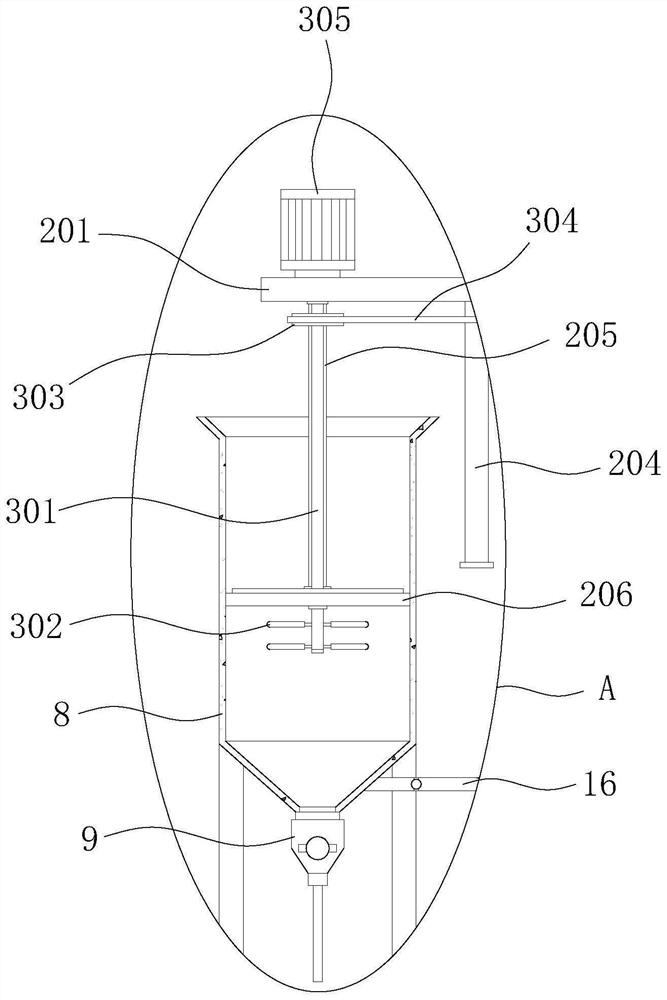

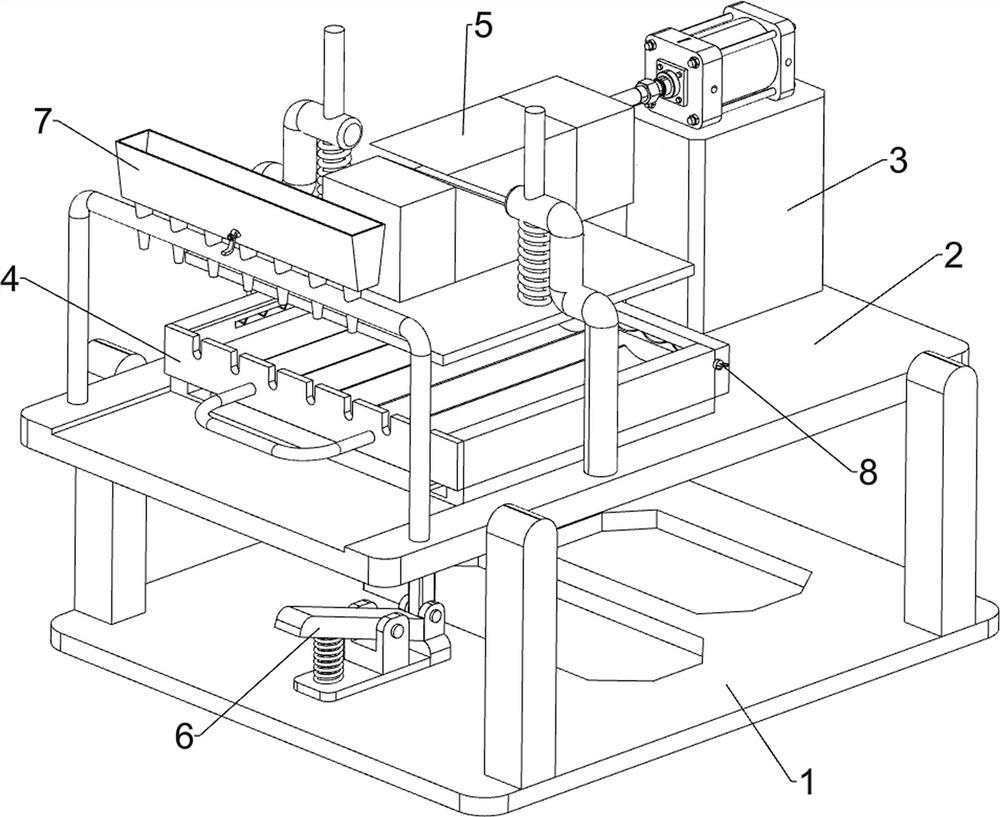

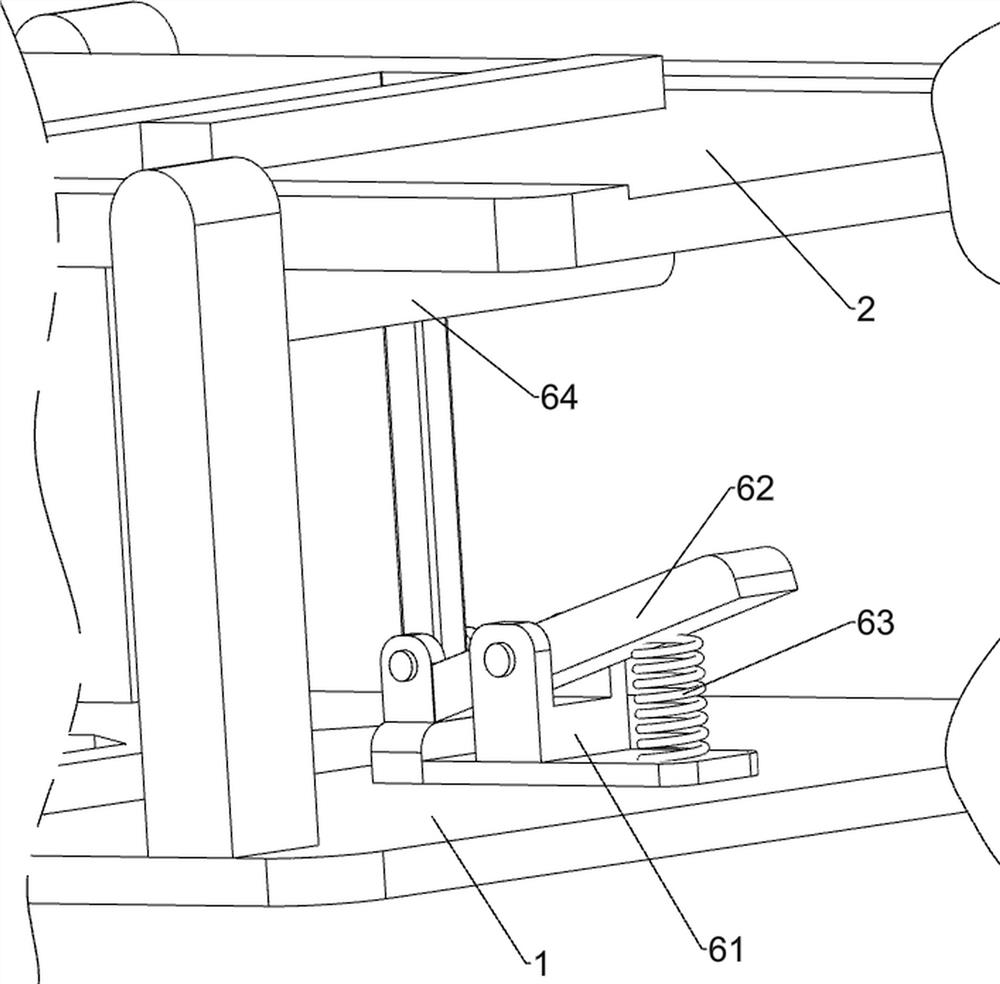

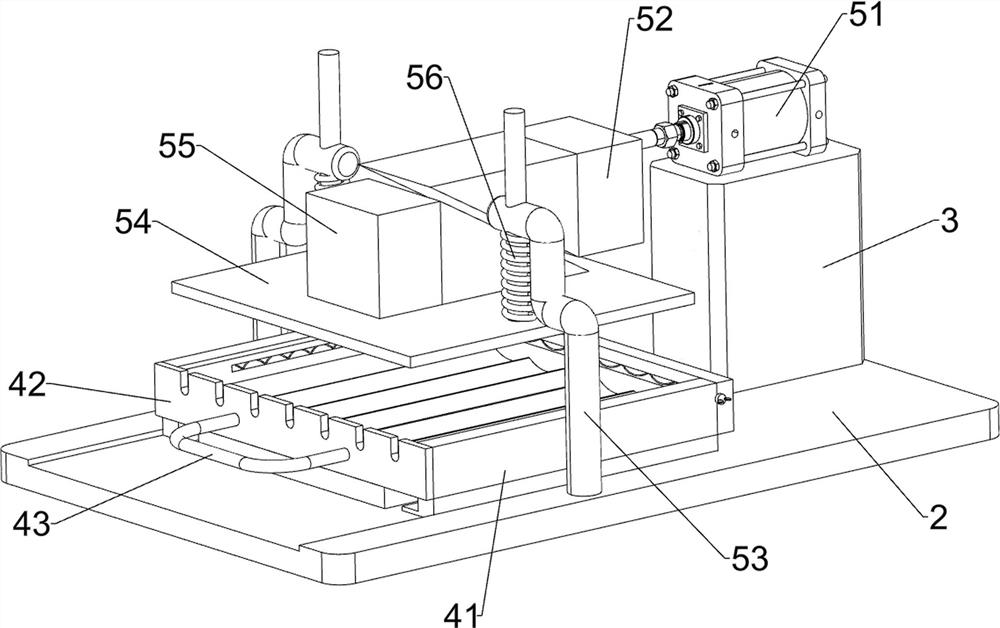

Batch weighing device for producing and processing paste products

ActiveCN112249384AIncrease productivityShorten the timeLiquid materialLiquid bottlingEconomic benefitsProcess engineering

The invention discloses a batch weighing device for producing and processing paste products, and relates to the technical field of production and processing of the paste products. The batch weighing device for producing and processing the paste products comprises a first conveying frame. A pumping mechanism, a defoaming mechanism, a storage mechanism, a transmission mechanism, a weighing mechanism, a screening mechanism and four sets of feeding cylinders are arranged on the first conveying frame. Filling heads are installed at openings in the bottoms of the feeding cylinders in a threaded mode. Supporting legs are welded to the outer walls of the feeding cylinders, and the supporting legs are welded to the outer surface of the top of the first conveying frame. The batch weighing device forproducing and processing the paste products can weigh the filled products in batches, shortens the time consumed in the link, further improves the production efficiency of the whole process, brings about higher economic benefits, and can automatically screen out unqualified products. And the practicability and consistency of the device are further improved.

Owner:浙江霄腾智能科技有限公司

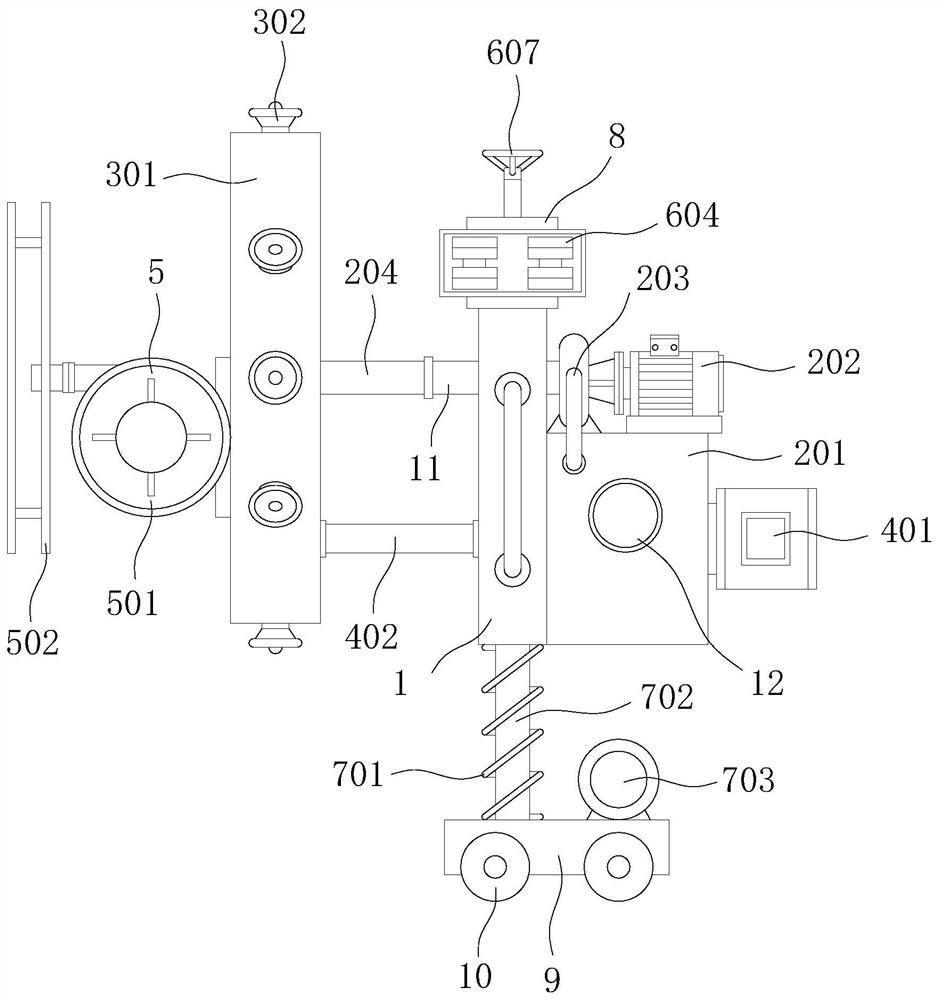

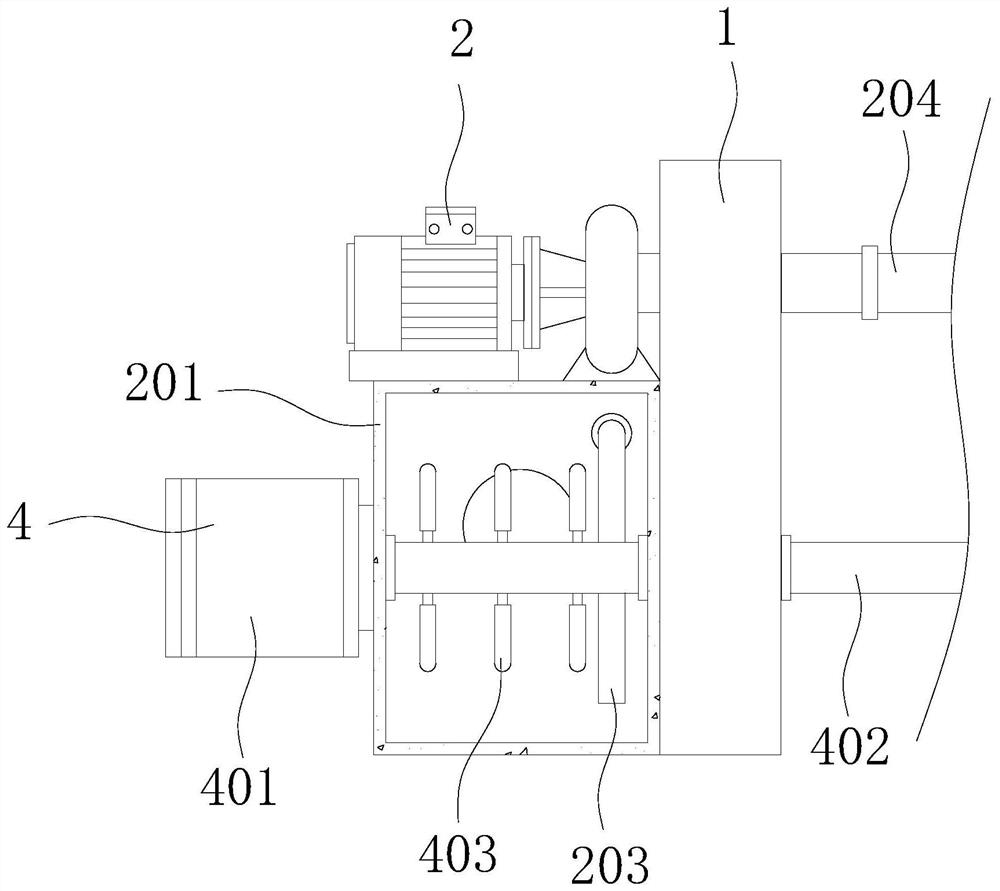

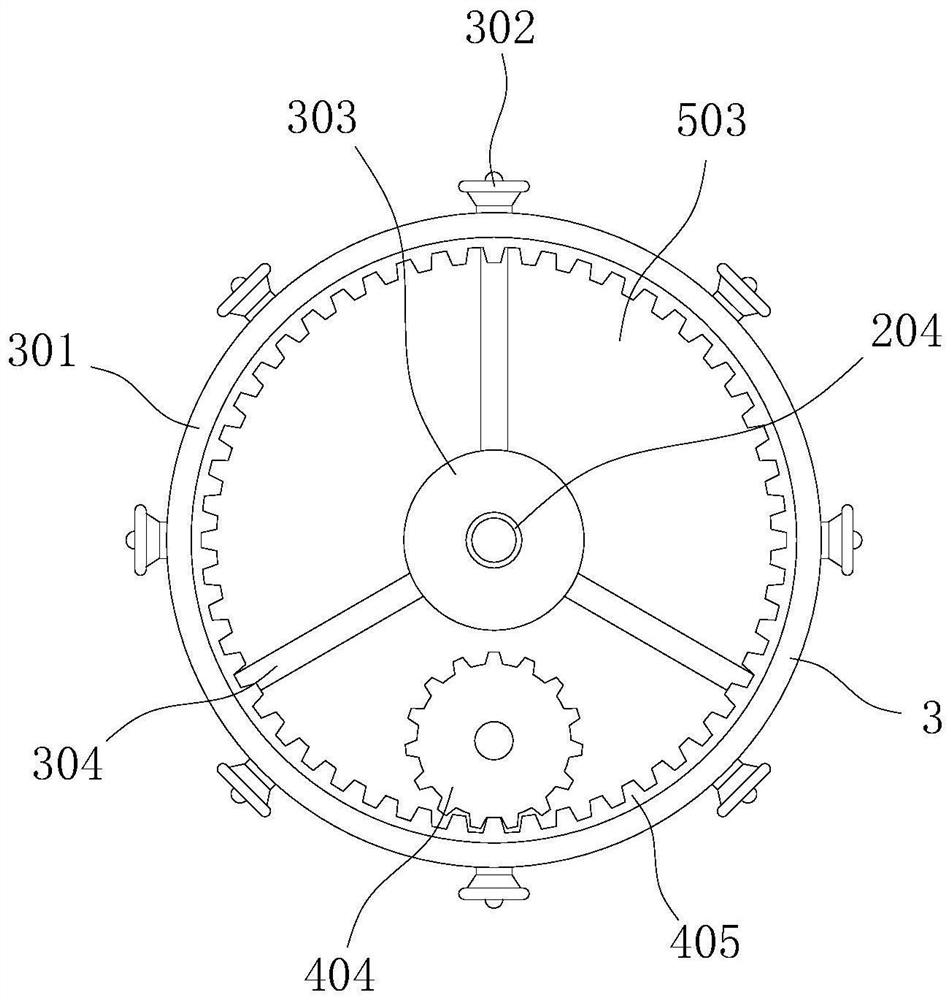

Powder feeding device for pipeline anticorrosion processing production line

InactiveCN112193838AUniform spraying effectImprove practicalityRotary stirring mixersBulk conveyorsProduction lineProcess engineering

The invention discloses a powder feeding device for a pipeline anticorrosion processing production line, and relates to the technical field of pipeline processing. The powder feeding device for the pipeline anticorrosion processing production line comprises a mounting table, wherein a feeding mechanism, a spraying mechanism, a driving mechanism, a drying mechanism, an abutting sliding mechanism and a walking driving mechanism are arranged on the mounting table, and a mounting cylinder is welded to the outer surface of the top of the mounting table. According to the powder feeding device for the pipeline anticorrosion processing production line, it is guaranteed that the spraying mechanism of the device is located in the center of the pipeline, compared with the device with part of a spraying part deviating from the center of a pipeline, the powder feeding device is more uniform in spraying effect; meanwhile, the device can conduct powder feeding spraying operation on the pipelines of different specifications, so that the application range of the device is widened; and the walking driving mechanism can further drive the whole device to walk in the pipeline, and compared with the device adopting a long pipe to extend into the pipeline for spraying, the device is higher in practicability and integrity.

Owner:湖州中福人管业科技有限公司

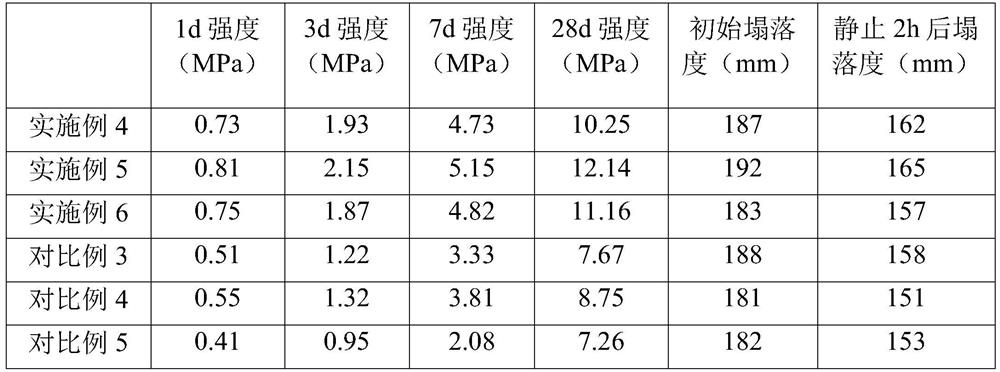

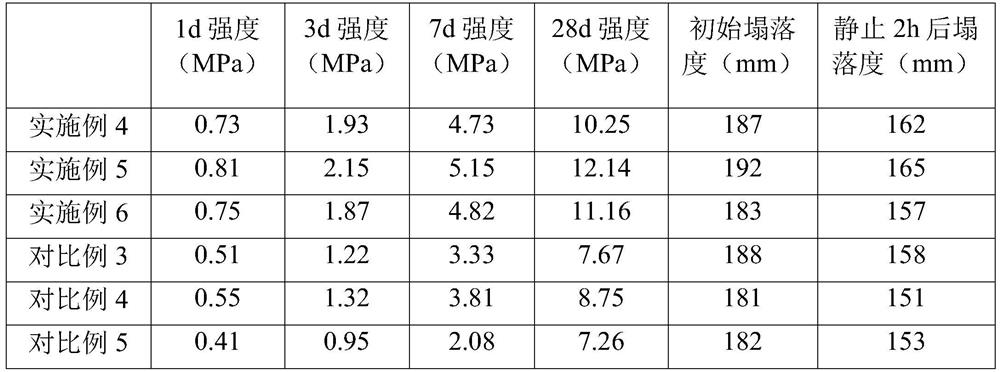

Paste filling cementing material and paste filling slurry

The invention relates to the technical field of mining engineering, and particularly discloses a paste filling cementing material and a paste filling slurry. The paste filling cementing material is prepared from, by mass, 55-65% of high alite Portland cement clinker, 25-35% of steel slag, 2-5% of nano SiO2, 2- 3% of nano CaCO3, 2-6% of modified gypsum and 0.1-0.5% of a compound additive. The industrial solid waste steel slag is used as the raw material, the process is simple, the production cost is greatly reduced, a guarantee is provided for green mining of mines, and a new way is provided for comprehensive utilization of industrial solid wastes. The paste filling cementing material is used for preparing paste filling slurry, and the problems that the paste filling material is low in early strength, poor in slurry fluidity, high in cost and energy consumption and the like are solved.

Owner:河北充填采矿技术有限公司 +1

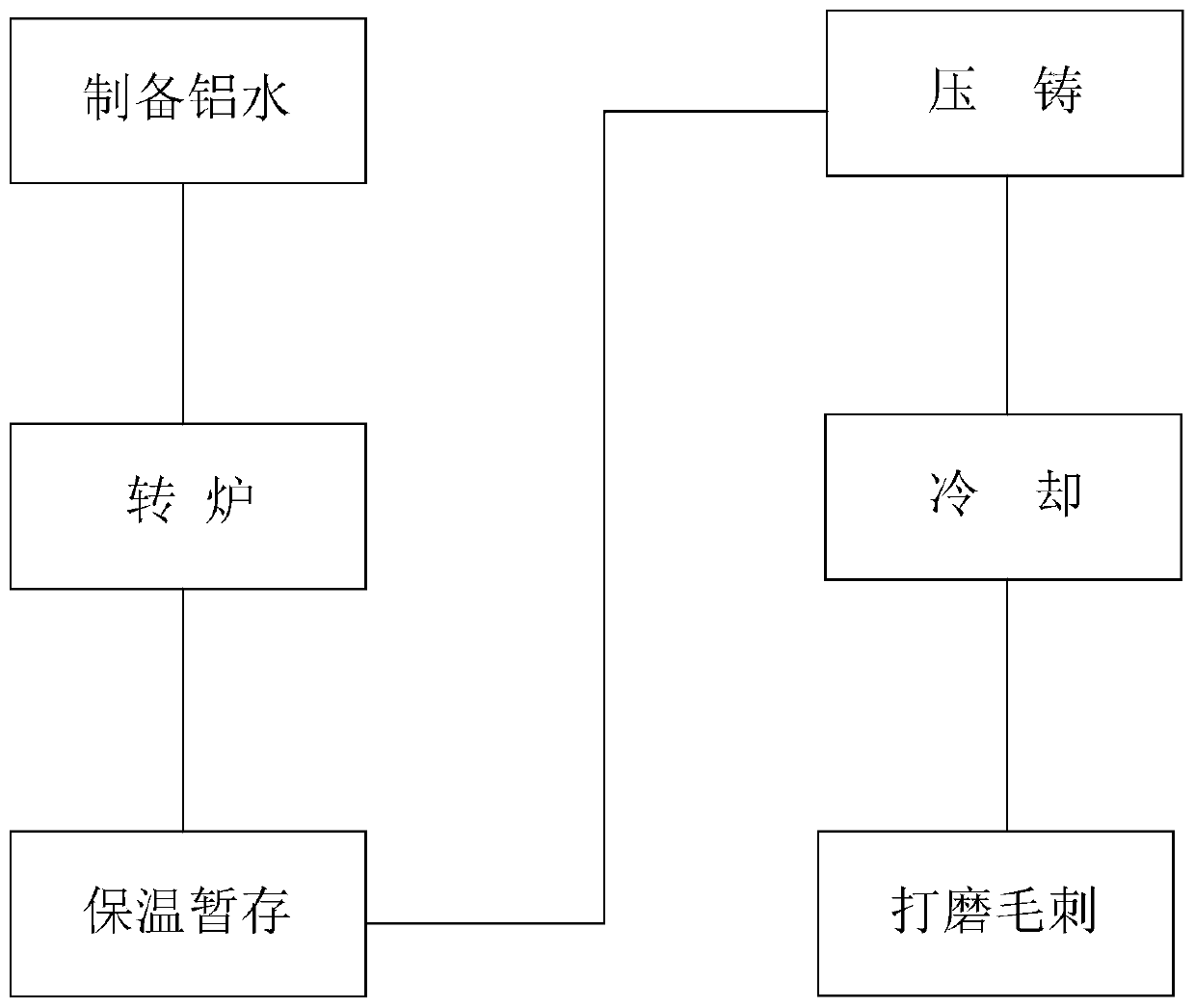

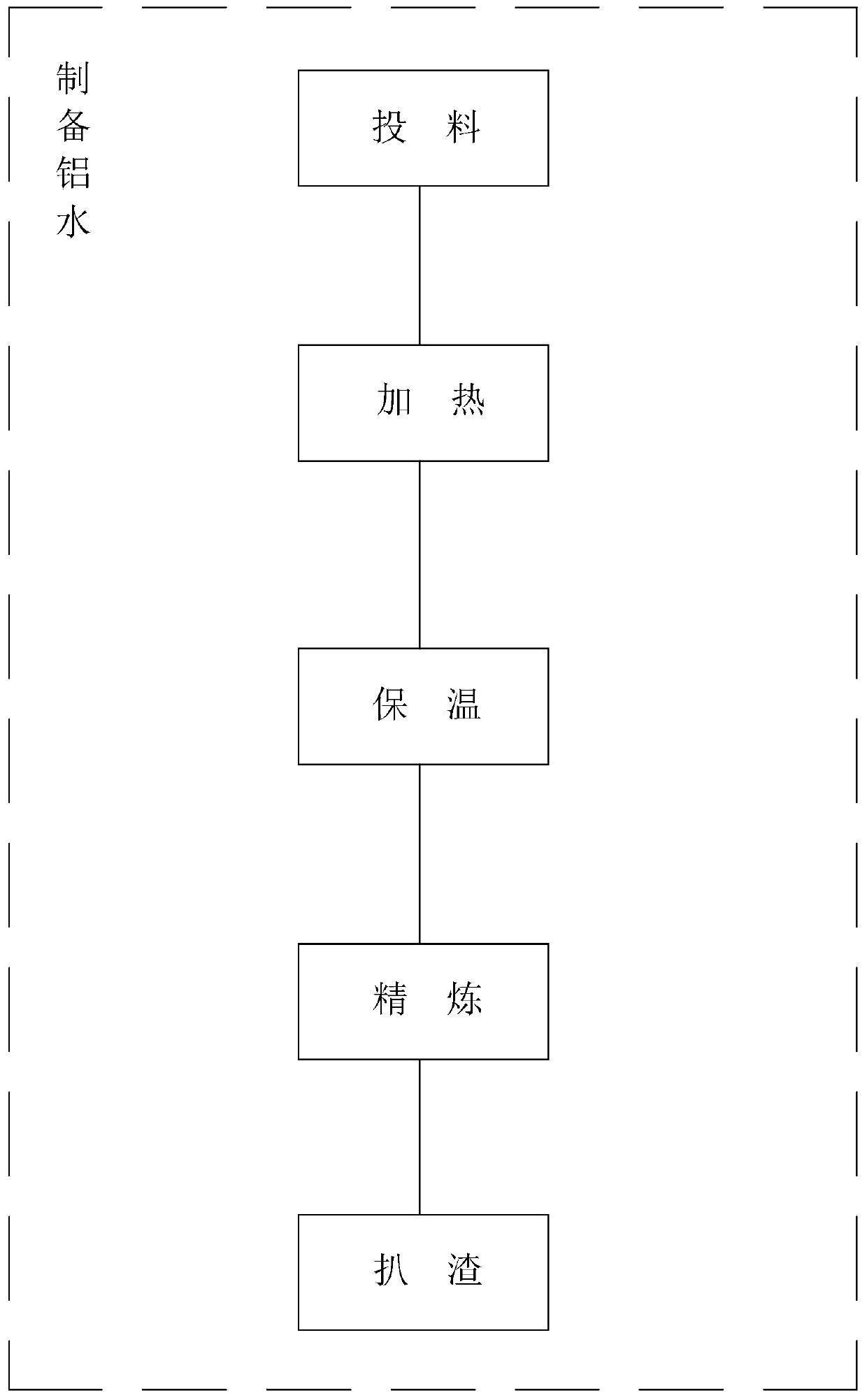

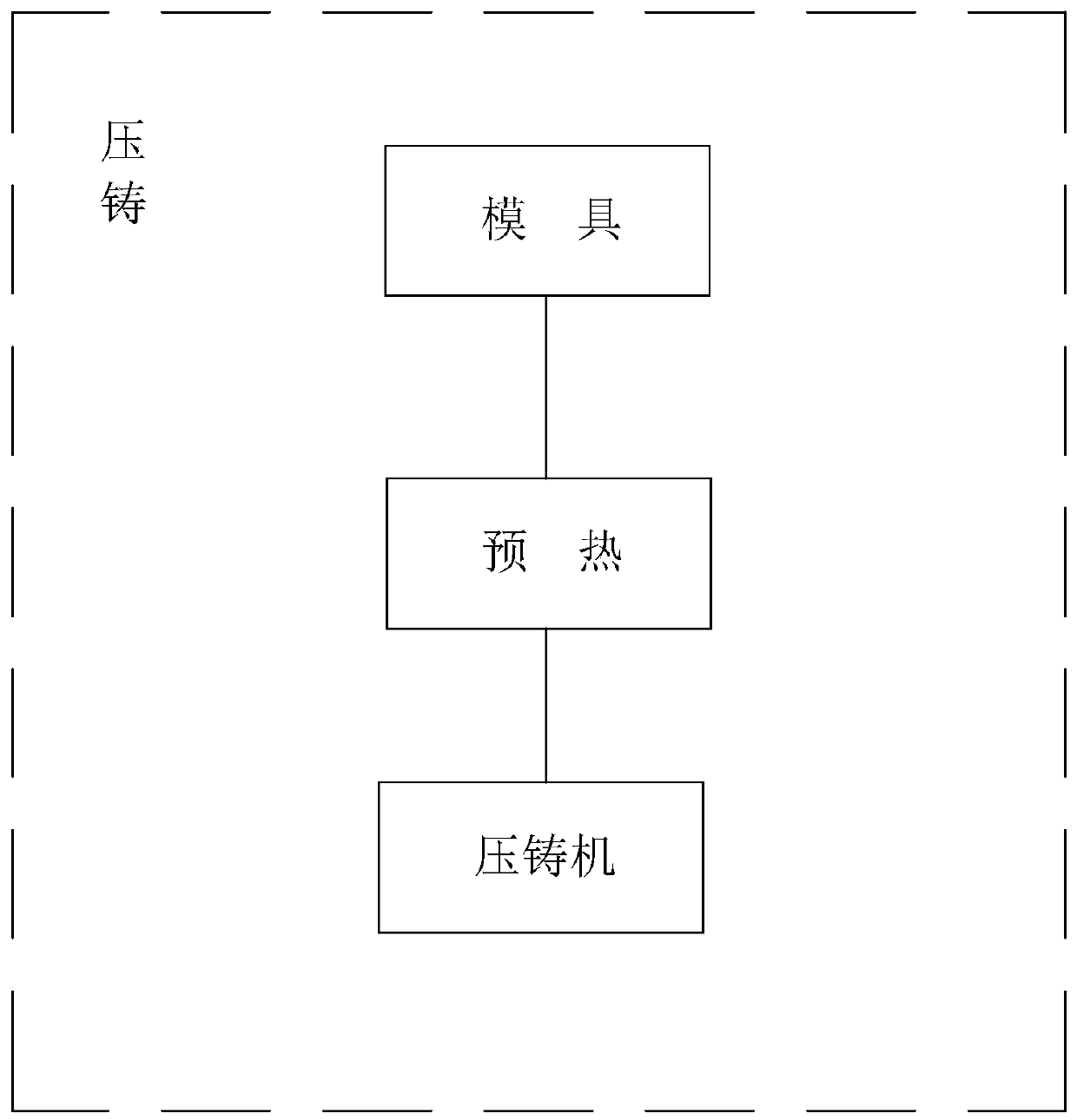

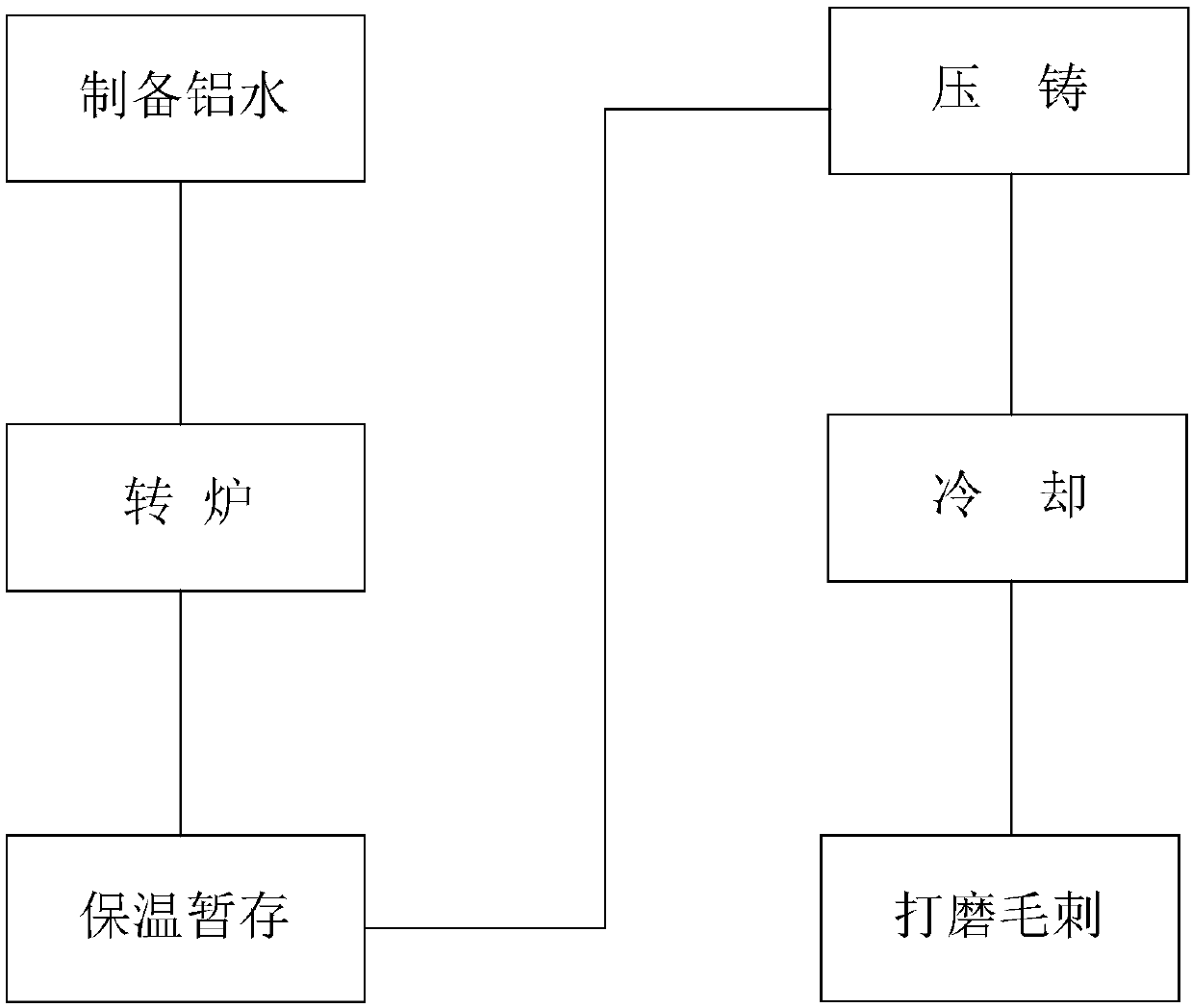

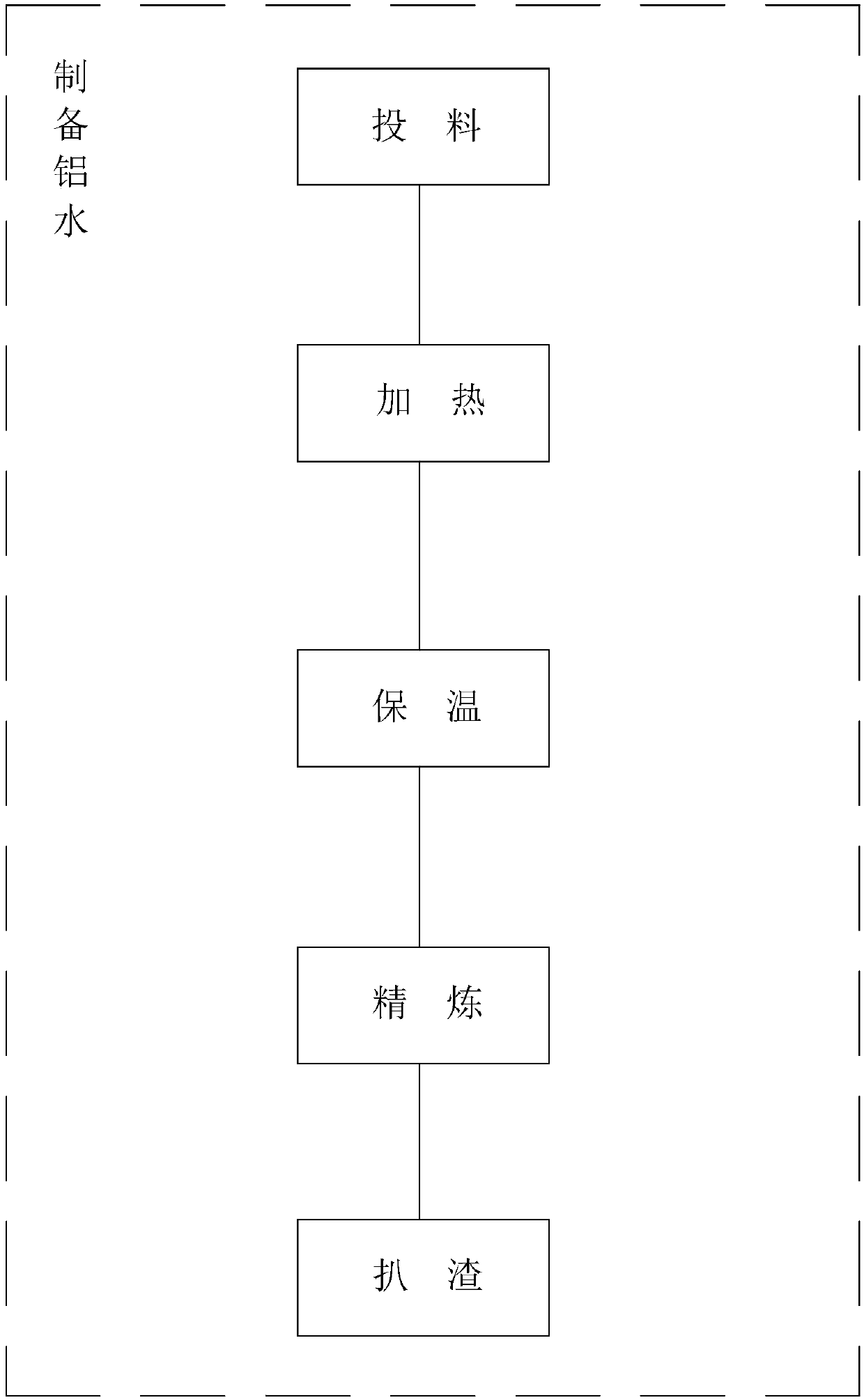

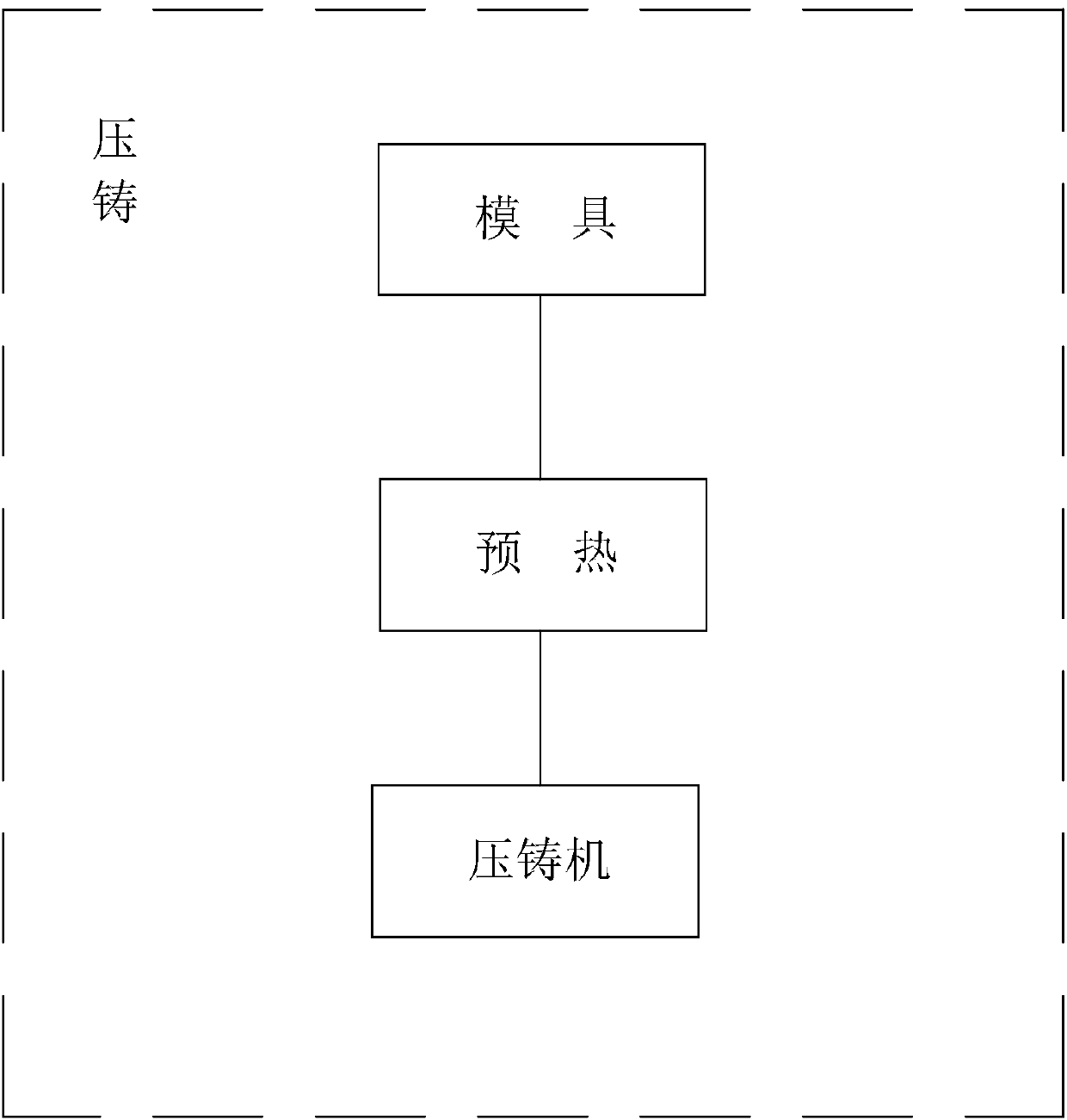

A kind of aluminum ingot blank making process

The invention discloses a blank making technology of an aluminum ingot, and relates to the technical field of aluminum ingot processing technologies for remelting. The blank making technology of the aluminum ingot comprises the following steps that S1, molten aluminum is prepared, and specifically, the aluminum ingot is put into an aluminum melting furnace and heated up to be transformed into themolten aluminum; S2, furnace transferring is carried out, and specifically, the molten aluminum is transferred into a holding furnace; S3, heat preservation and temporary storage are carried out, specifically, the temperature in the holding furnace is 700 DEG C-750 DEG C, the intensity of pressure in the furnace is 2-3 times as high as the standard atmospheric pressure, the humidity in the holdingfurnace is no more than 75%, and the heat preservation time is held for 10 min-20 min; S4, pressure casting is carried out, and specifically, the molten aluminum in the holding furnace is injected into a corresponding mould by a die-casting machine after insulation treatment; S5, cooling is carried out, specifically, the mould is taken down and is subjected to the cooling treatment, and the molten aluminum is gradually formed in the mould; and S6, burrs are polished, specifically, the mould is opened, castings are taken out and the burrs on the castings are polished manually, so that workblanks are obtained. According to the blank making technology of the aluminum ingot, quantity of air holes in the workblanks is reduced, and fracture of the workblanks is reduced, so that defective indexis reduced.

Owner:重庆嘉萌鸿业科技有限公司

Combined cooling process for aluminum alloy castings

The invention discloses a combined cooling process for aluminum alloy castings, and relates to the technical field of aluminum ingot machining processes for re-melting. The combined cooling process for the aluminum alloy castings comprises the following steps including S1. molten aluminummolten aluminum preparation: placing an aluminum ingot in an aluminum melting furnace and heating to transformthe aluminum ingot into molten aluminumthe molten aluminum; S2. furnace transfer: transferring the molten aluminummolten aluminum into a heat-insulation furnace; S3. heat-insulation temporary storage:a temperature in the heat-insulation furnace is 700-750 DEG C, a pressure in the furnace is 2-3 times of a standard atmospheric pressure, humidity in the furnace is not greater than 75%, and a heat-insulation time is 10 min-20 min; S4. die-casting: injecting the molten aluminum subjected to heat-insulation treatment into a corresponding die through a die-casting machine; S5. cooling: taking off the die and carrying out cooling treatment so as to gradually form the molten aluminum in the die; and S6. burr polishing: opening the die, taking out the castings and polishing burrs on the castings through manual treatment to obtain blanks. According to the scheme, the number of air holes in the blanks can be reduced, and the case of breakage of the blanks is reduced, so that the rejection rate is lowered.

Owner:重庆嘉萌鸿业科技有限公司

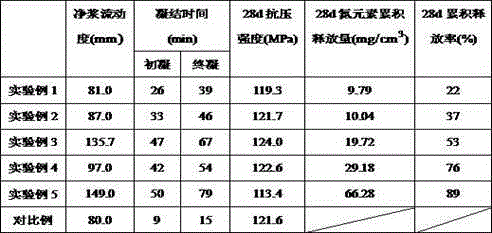

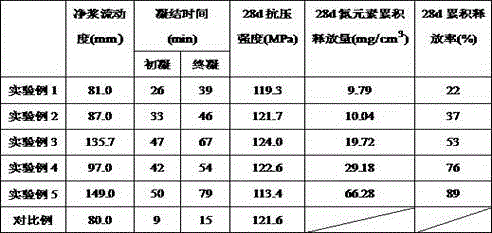

A retarder suitable for sulphoaluminate cement

ActiveCN105000819BSlow down the rate of condensationProlonged initial settingFertilizer mixturesSulfonateGrowth plant

The invention discloses retarder applicable to sulphate aluminum cement. The retarder is composed of, by weight, 7-60 parts of carbamide, 3-11 parts of sodium lignin sulfonate, 2-7 parts of dinaphthyl methane disulfonic acid sodium, 2-5 parts of water reducing agent and 30-70 parts of vermiculite. By means of the retarder, the coagulation speed of the sulphate aluminum cement can be effectively reduced, the flowability of sulphate aluminum cement slurry can be remarkably improved, and the water demand in the sulphate aluminum cement mixing process can be reduced. The carbamide is added into the retarder, the coagulation time of the sulphate aluminum cement can be prolonged, nitrogen nutrient elements required by the plant growth can be further released slowly after the cement slurry is hardened, and the nitrogen nutrient elements are supplied to plants in porous plant-growing concrete for meeting the plant growth requirements.

Owner:UNIV OF JINAN

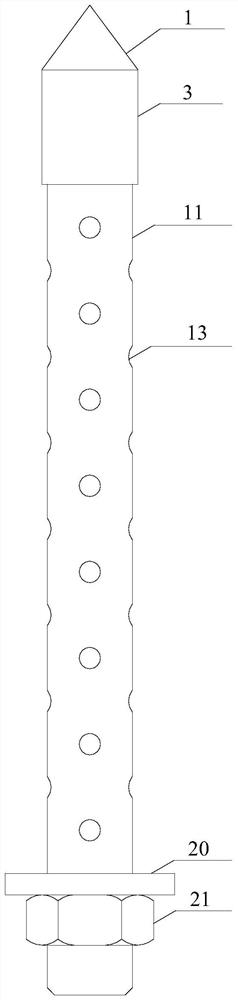

A kind of recoverable advanced small catheter and its use method

The invention relates to the technical field of advanced support for foundation pit construction, and discloses a recyclable advanced small conduit, which includes a terminal pop-up device and a sleeve-type grouting device, and the end of the terminal pop-up device is connected to the sleeve-type grouting device The end pop-up device includes a conical pipe head, a pressure plate, a cylindrical shell, an upper coil and a lower coil. The tapered pipe head is connected to the cylindrical shell through a pressure plate installed at the bottom of it. An upper coil is fixedly connected, and the lower end of the upper coil is rotatably connected with the lower coil. The present invention also includes a method for using the above-mentioned advanced small conduit, which specifically includes the following steps: assembling the advanced small conduit; fixing the assembled advanced small conduit on the rock and soil body; after the advanced support is completed, rotating the outer steel pipe so that the end The upper jamming and the lower jamming in the pop-up device are misaligned, and the small conduit is pulled out from the rock and soil mass borehole. The invention is beneficial to the recovery and reuse of the leading small catheter.

Owner:RAILWAY NO 5 BUREAU GRP FIRST ENG CO LTD +1

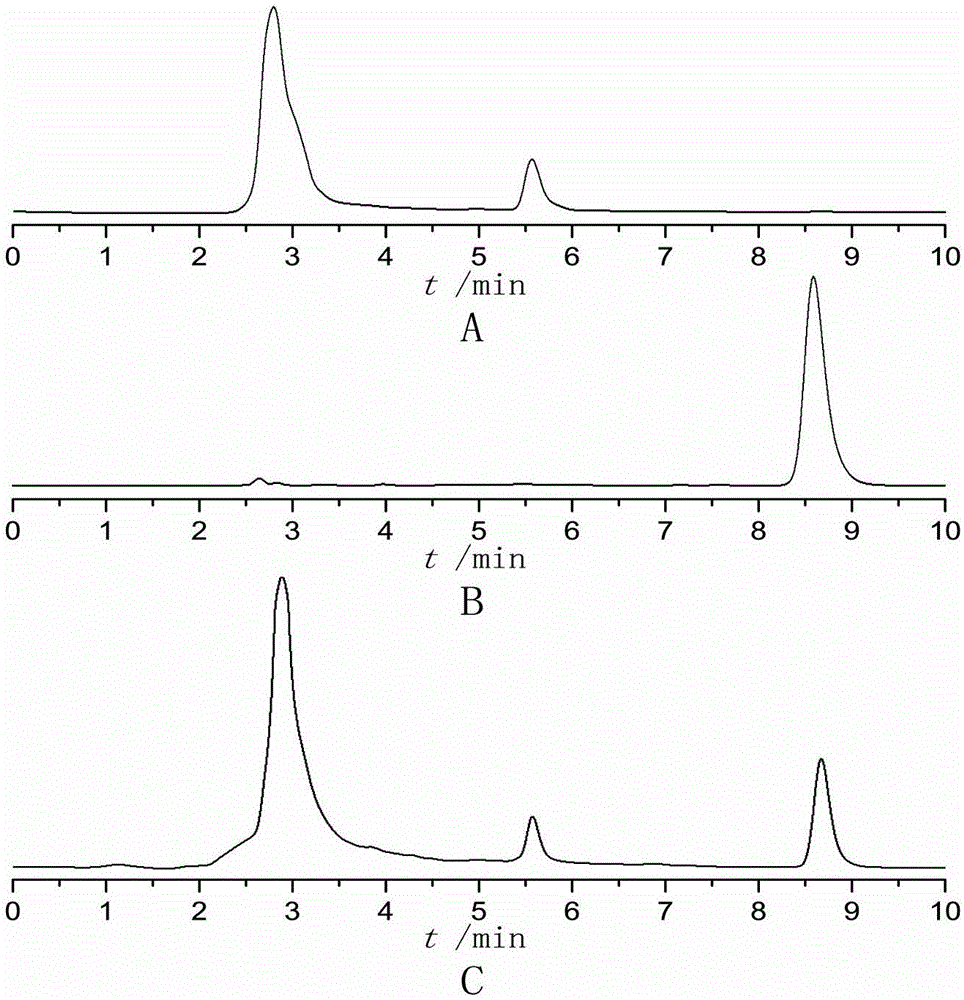

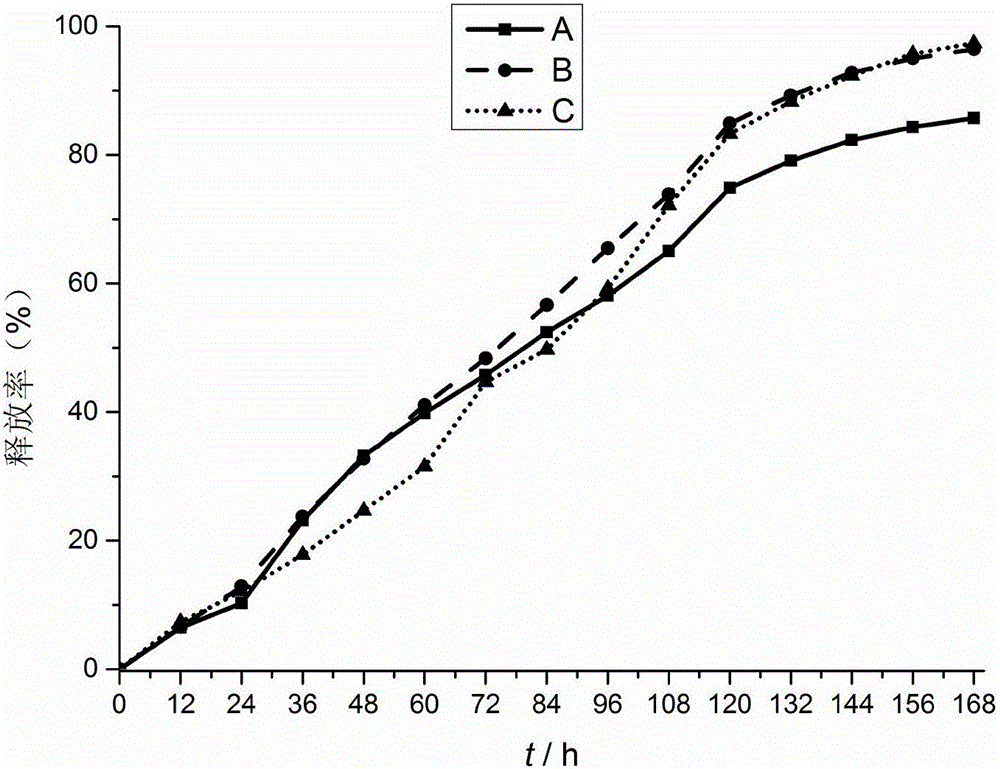

Biological protein glue-triamcinolone acetonide slow release agent as well as preparation method and application of slow release agent

InactiveCN106389393AWith adhesiveAvoid the need for secondary surgery to remove the problemOrganic active ingredientsAntipyreticLife qualityEsophageal stenosis

The invention provides a biological protein glue-triamcinolone acetonide slow release agent as well as a preparation method and application of the slow release agent. The slow release agent comprises biological protein glue, aprotinin and triamcinolone acetonide, wherein the biological protein glue is used as a medicine carrier, the aprotinin is used as a slow solvent, and triamcinolone acetonide is taken as an effective medicine component. The prepared biological protein glue-triamcinolone acetonide slow release agent is directly sprayed to a corresponding surgical region of a digestive tract by virtue of an endoscope and is capable of playing a durable anti-inflammatory role, so that the formation of postoperative scars is reduced, the postoperative esophageal stenosis is prevented, and the life quality of a patient is effectively improved.

Owner:THE FIRST AFFILIATED HOSPITAL OF THIRD MILITARY MEDICAL UNIVERSITY OF PLA

A construction device for producing super-long concrete structures

ActiveCN112692992BReduce limitationsLowering the freezing pointMixing operation control apparatusPretreatment controlStructural engineeringMechanics

Owner:江苏博拓新型建筑材料股份有限公司

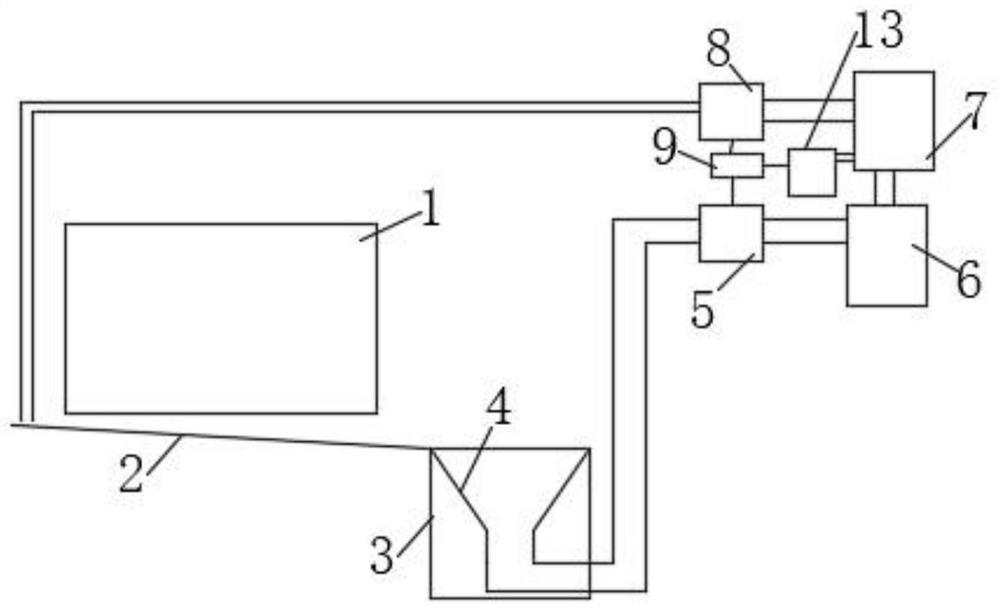

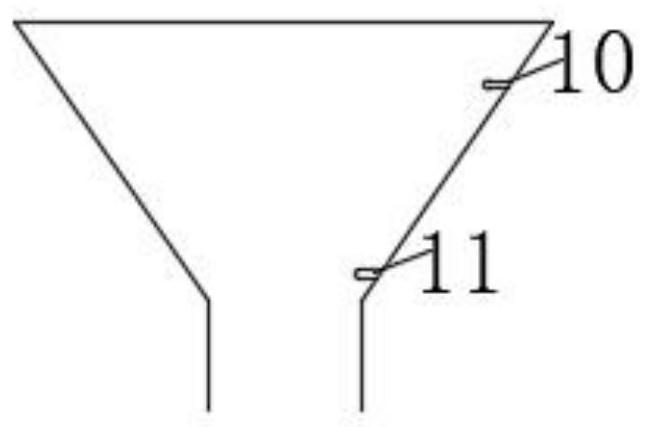

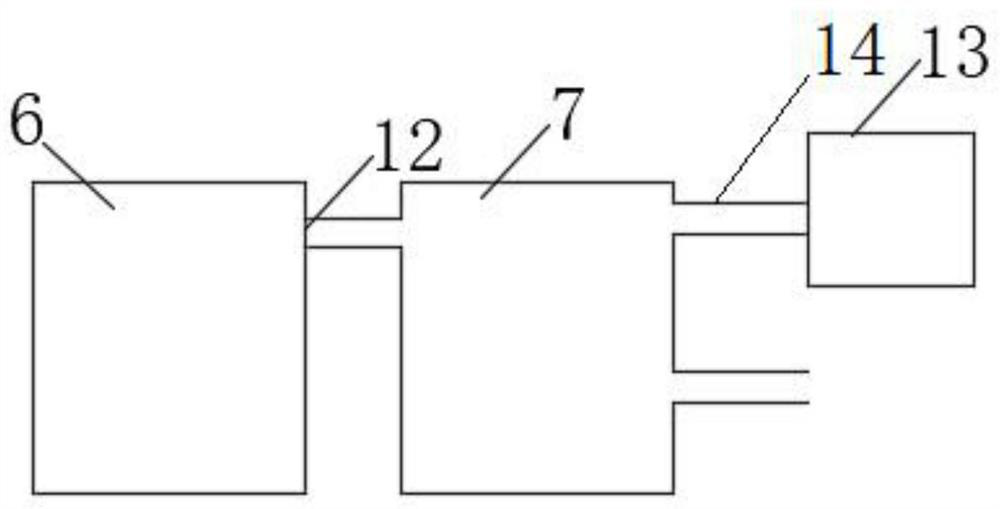

A water-stop curtain grouting production sewage recycling control system and method

ActiveCN110847180BReduce wasteReduce condensationFatty/oily/floating substances removal devicesSewerage structuresWater useControl system

The invention belongs to the technical field of sewage treatment, and discloses a water-stop curtain grouting production sewage recycling control system and method. The water-collecting funnel is arranged in the water-collecting well, and one end of the top of the water-collecting funnel is connected to a drainage channel, and the bottom of the water-collecting funnel is connected through a pipeline. The first water pump, the first water pump is connected to the sedimentation tank through the pipeline, the sedimentation tank is connected to the water collection tank through the pipeline, the water collection tank is respectively connected to the clean water tank and the second water pump through the pipeline, the second water pump, the first water pump and the third water pump, the second water pump is passed through The pipe is connected to the source of the drain. The invention reduces the waste of water resources and reduces engineering expenses by recycling water. The present invention is simple in structure, easy to implement, and suitable for popularization and use. By using the cement retarder to slow down the coagulation speed of cement, the cement coagulates in the sedimentation tank, reduces the coagulation of cement in other equipment, and reduces the cleaning workload. The low-temperature waterproof coating used, It can make the sedimentation tank clean the sedimented cement thoroughly, with high efficiency and saving labor cost.

Owner:SINOHYDRO BUREAU 1 CO LTD

Paste filling cementing material and paste filling slurry

The invention relates to the technical field of mining engineering, and specifically discloses a paste filling cementing material and a paste filling slurry. The paste filling cementing material includes the following components in terms of mass percentage: high-alite Portland cement clinker: 55% to 65%, steel slag: 25% to 35%, nano-SiO 2 : 2% ~ 5%, nano-CaCO 3 : 2% to 3%, modified gypsum 2% to 6% and compound admixture 0.1% to 0.5%. The invention uses industrial solid waste steel slag as raw material, has simple process, not only greatly reduces production cost, provides guarantee for green mining of mines, but also provides a new way for comprehensive utilization of industrial solid waste. The paste filling cementing material is used to prepare paste filling slurry, which solves the problems of low early strength of the paste filling material, poor slurry fluidity, high cost and energy consumption, and the like.

Owner:河北充填采矿技术有限公司 +1

Sugar-coated haw extruding device for food processing

PendingCN113317381AReduce workloadImprove work efficiencyConfectionerySweetmeatsManufacturing engineeringMechanical engineering

The invention relates to a sugar-coated haw extruding device, in particular to a sugar-coated haw extruding device for food processing. The technical problem to be solved is to provide the sugar-coated haw extruding device for food processing, which is simple to operate, reduces the workload of operators and improves the working efficiency. In order to solve the technical problem, the sugar-coated haw extruding device for food processing comprises a bottom plate, a supporting plate, a placing assembly and a pressing assembly; the top of the bottom plate is connected with an operation table; the supporting plate is connected to one side of the top of the operation table; the placing assembly is connected to the operation table; and the pressing assembly is connected between the operation table and the supporting plate. According to the device, through cooperation of the placing assembly and the pressing assembly, sugar-coated haws can be extruded, manual operation is not needed, the workload of the operators is relieved, and the working efficiency is improved.

Owner:陈小弟

A Downward Approach Filling Mining Method

ActiveCN111119894BPrevent collapseReduce usageUnderground miningSurface miningMining engineeringClinker (waste)

The invention discloses a downward approach filling mining method. The mining area is divided into alternately distributed interval filling layers and complete filling layers from the vertical direction, and the downward approach mining method is adopted layer by layer. The high-strength quick-setting filling materials made of clinker, full tailings, waste rock, and accelerators and the low-strength quick-setting filling materials made of cement, active slag, tailings, and accelerators are alternately filled in the interval filling layer and In the goaf of the completely filled layer, the upper filling body is jointly supported by the lower high-strength filling body and low-strength filling body, preventing the upper filling body from collapsing and ensuring mining safety; at the same time, it can effectively reduce the amount of cement used in filling materials , reduce the filling cost, and by adding a small amount of quick-setting agent to the filling material, the time required to wait for the filling material to reach the preset strength can be greatly shortened, so as to shorten the recovery time, thereby greatly improving the mining efficiency.

Owner:NANHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com