Patents

Literature

108results about How to "Uniform spraying effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

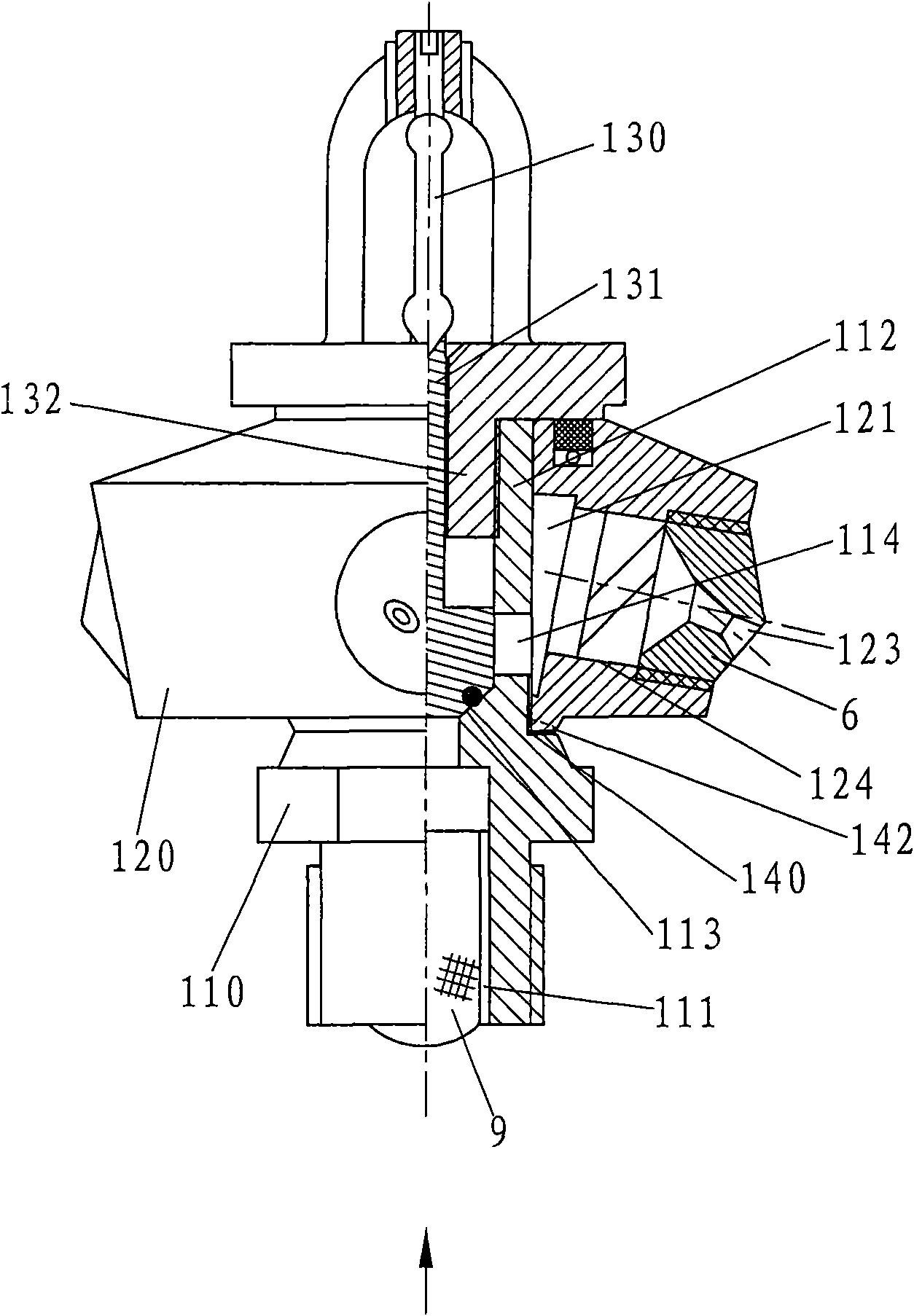

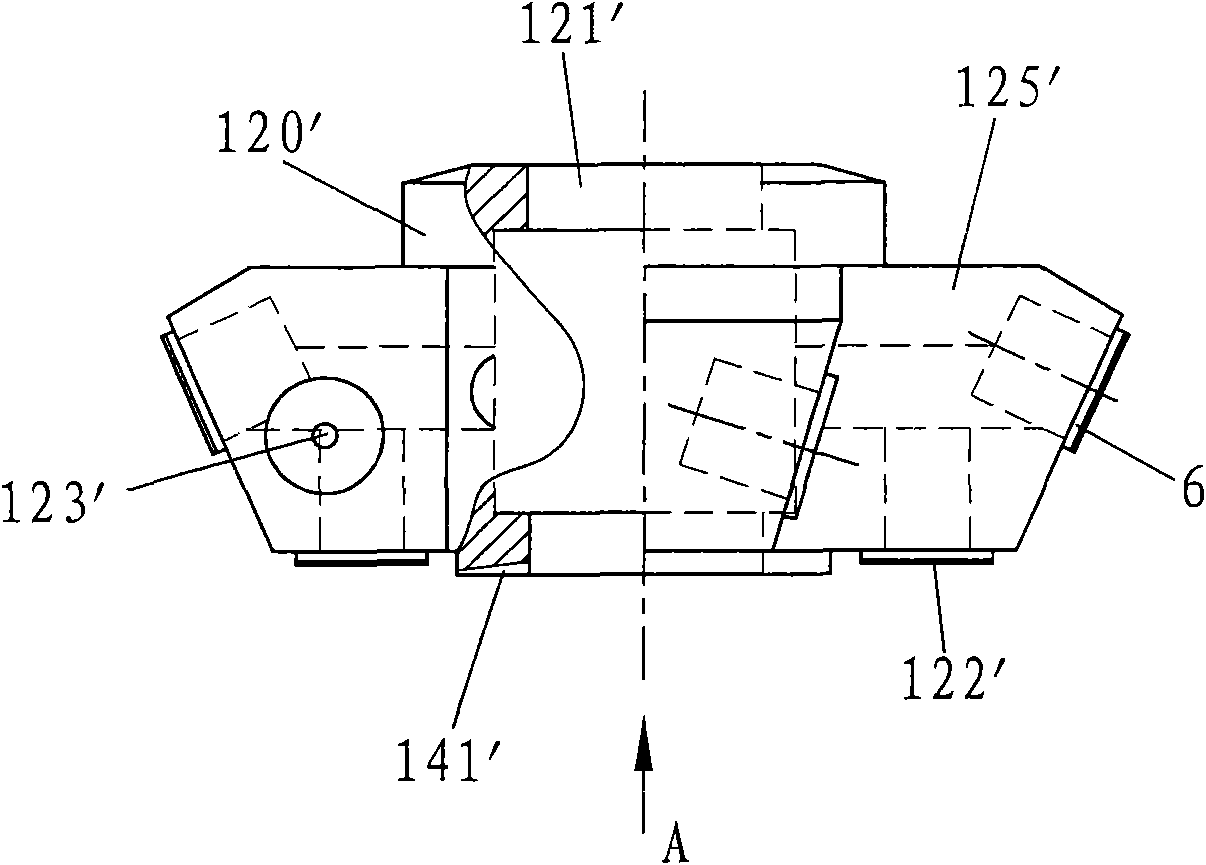

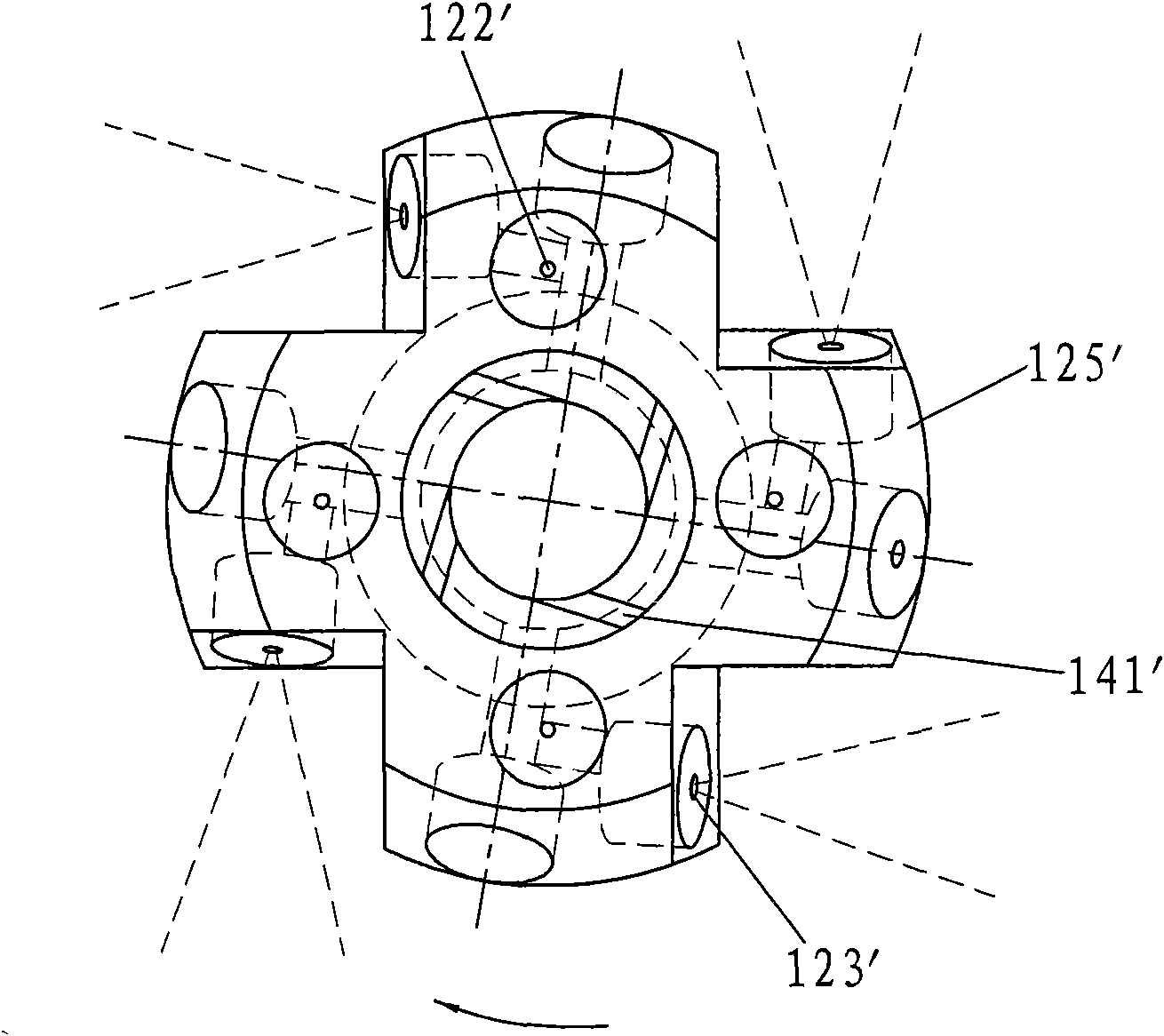

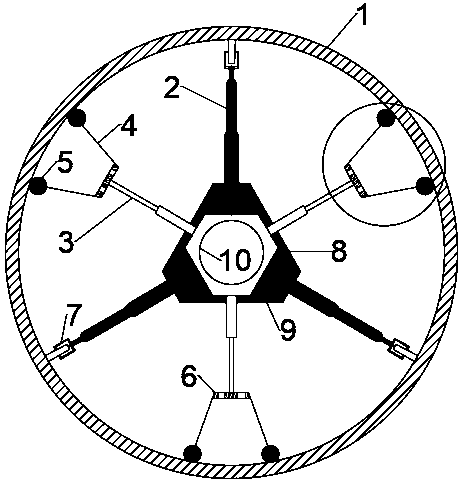

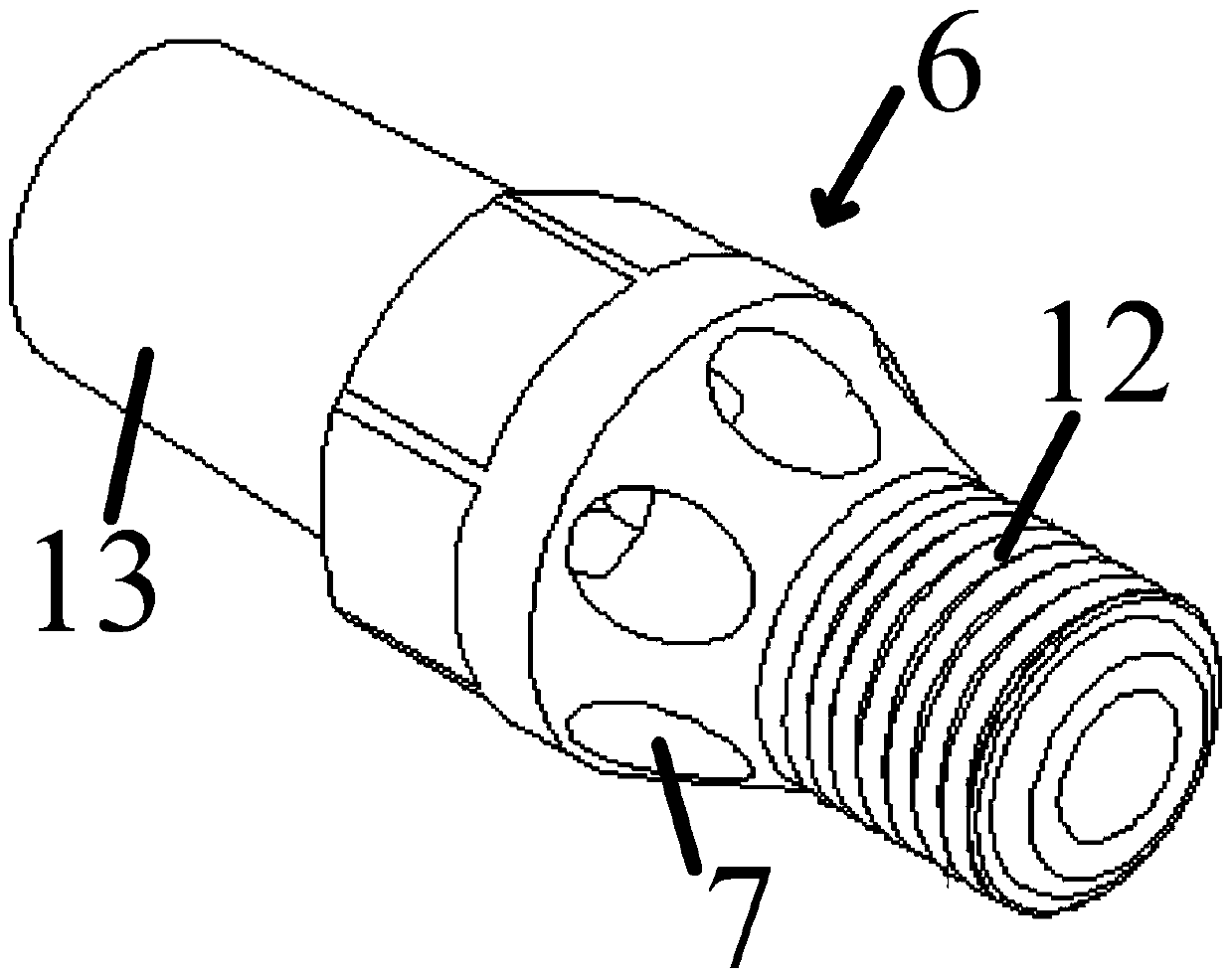

Jet-driven rotary type spraying head

InactiveCN101829638ASimple structureIncreased spray fire extinguishing capacityMovable spraying apparatusSpray nozzlesJet flowMechanical engineering

The invention discloses a jet-driven rotary spraying head, which comprises a hollow base and a spraying head body capable of rotating relative to the base, wherein a fluid passage is arranged inside the spraying head body, and spraying orifices are formed outside the spraying head body; each spraying orifice at least comprises two eccentric spraying orifices capable of generating eccentric spraying flows; the spraying flows of the eccentric spraying orifices rotate the spraying head body; and the setting direction of each eccentric spraying orifice should make the spraying head body rotate in the same direction. A rotary matching surface is arranged between the spraying head body and the base; the spraying head body drives the spraying orifices formed thereon to rotate together, a fluid permeating the rotary matching surface is used for lubricating the rotary matching surface; at least one matching surface gap, capable of leaking the fluid outwards, in the rotary matching surface is designed into a circular seam spraying orifice; and a small amount of the fluid joins in the spraying of the spraying head through the circular seam spraying orifice. The spraying head uses spraying jet flow reacting force of the eccentric spraying orifices to cause autorotation, and can also solve the problems of large-area uniform spraying and fine atomization while working at meddle and low pressures.

Owner:韩铁夫

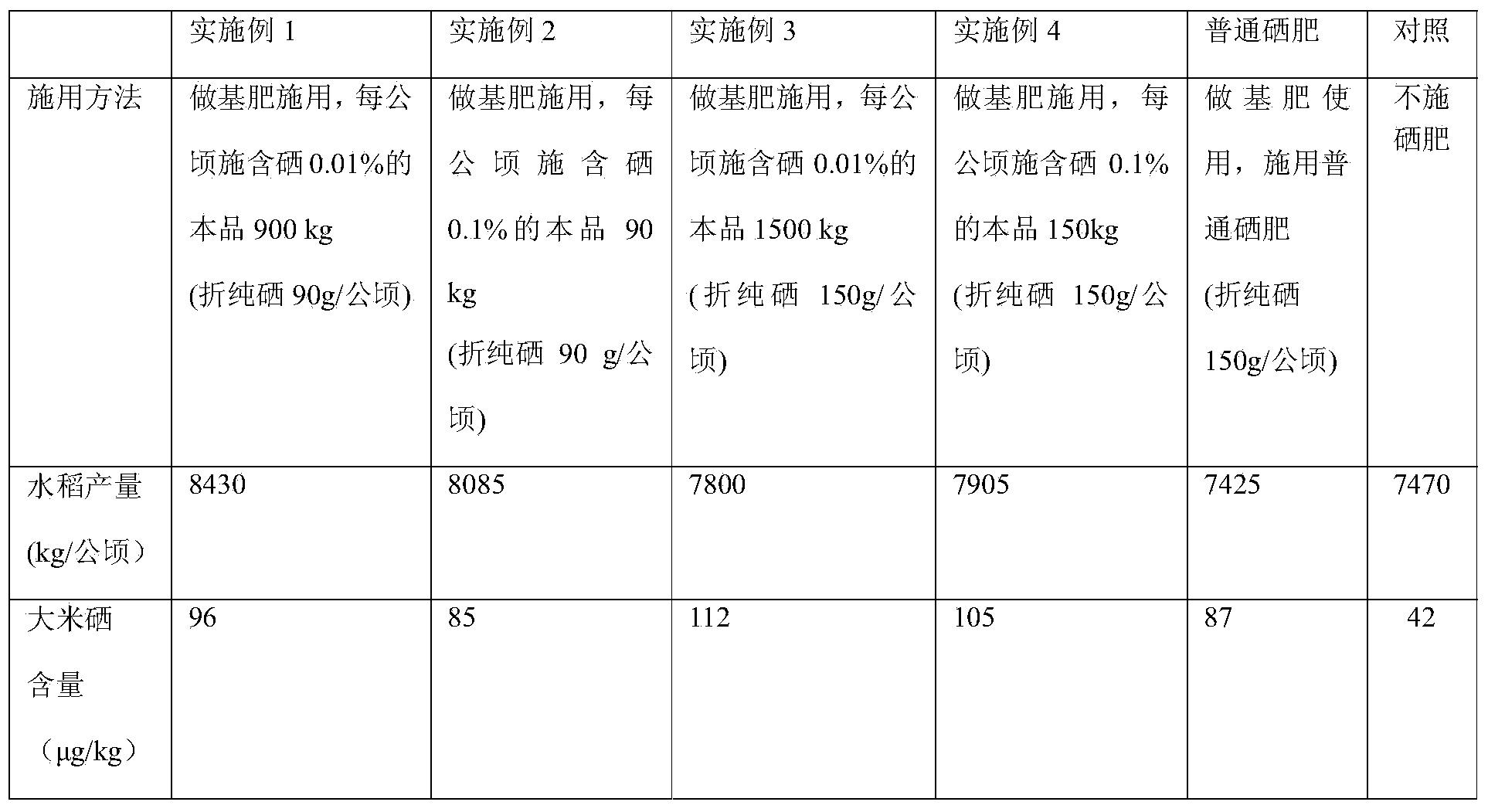

Stabilized selenium-enriched fertilizer and preparation method thereof

The invention relates to the field of crop fertilizers, in particular to a stabilized selenium-enriched fertilizer and a preparation method thereof. The stabilized selenium-enriched fertilizer comprises the raw materials including a selenium-containing substance, an amino acid substance, a soil enhancement substance, a stabilized substance and a coating substance, wherein the mass proportion of pure selenium in the selenium-containing substance, the amino acid substance, the soil enhancement substance and the stabilized substance is 1:(1-10):(20-50):(100-200), and the mixture obtained by pelleting 1 kg coating substance is added with 3-5ml of 3-5 percent coating solution. According to the stabilized selenium-enriched fertilizer, provided by the invention, in the respects of slow release, fixation prevention, absorption promotion and the like, after the stabilized selenium-enriched fertilizer is applied, the selenium enhancing ability of the crop is remarkably enhanced, and the output is remarkably improved. The invention further provides a preparation method of the stabilized selenium-enriched fertilizer, which is simple and easy to implement, and prepares the stabilized selenium-enriched fertilizer with good use effect.

Owner:INST OF AGRI RESOURCES & ENVIRONMENT GUANGDONG ACADEMY OF AGRI SCI

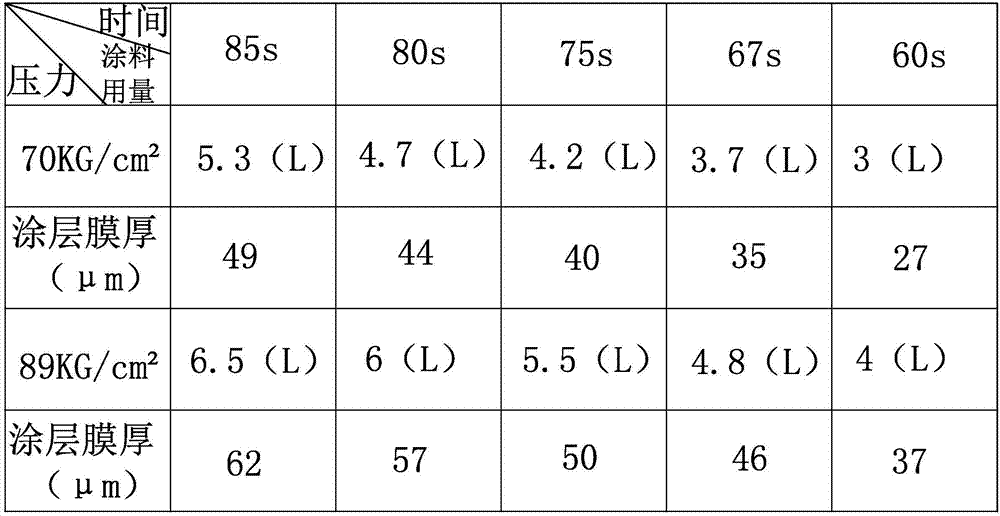

Stripable paint for laser impact treatment

This invention discloses a strippable coating for laser shock processing, which is composed of carbon powders 5-15 wt.%, bonding agent 50-70 wt.%, self-drying thinner 15-35 wt.% and additive 2-5 wt.%. The thickness of the coating layer is generally 60-150 mums. The strippable coating is manufactured by: (1) placing carbon powders in a reactor, and adding bonding agent, self-drying thinner and additive; and (2) stirring uniformly, and adjusting the pH value to 7.5 with 25% ammonia solution. The strippable coating can intimately adhere to the surface of metals, and cannot be stripped during continuous laser shock process, thus having a good shock effect.

Owner:JIANGSU UNIV

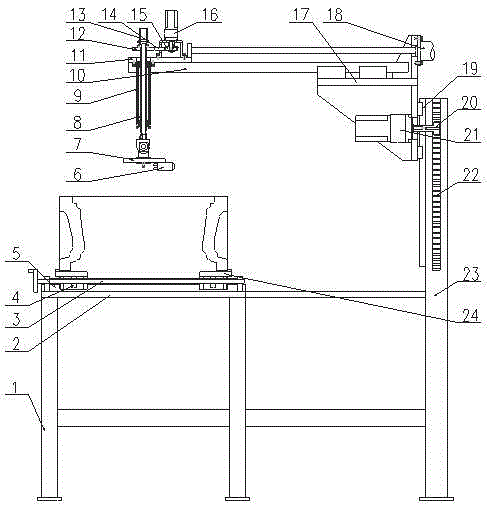

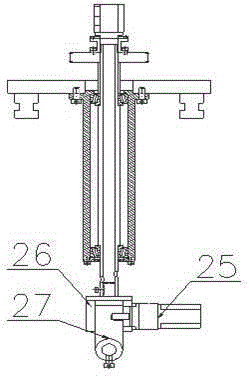

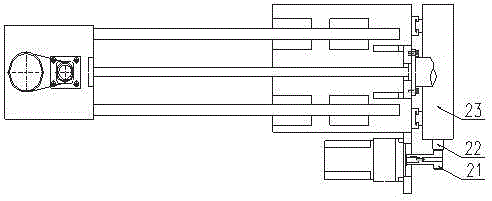

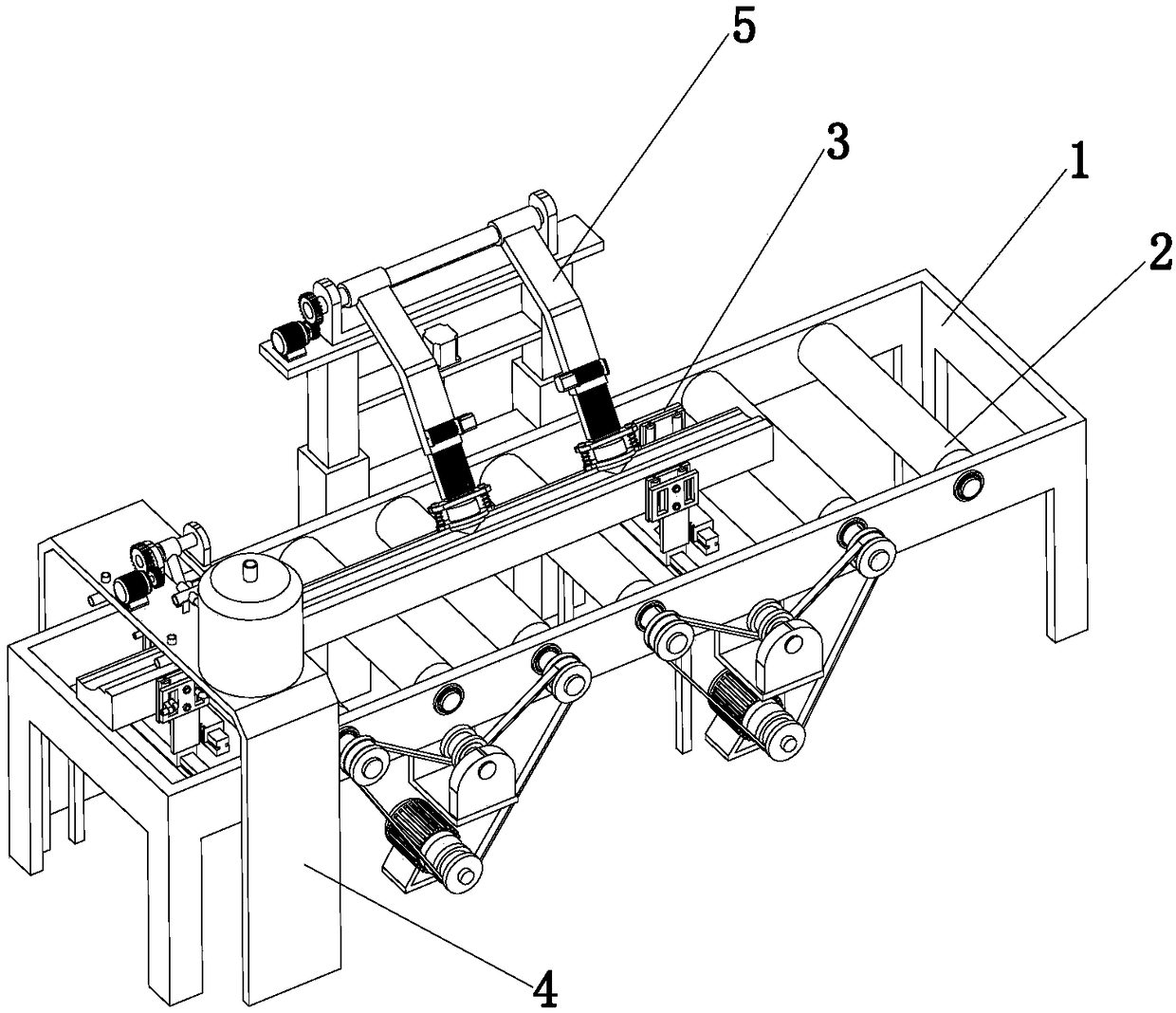

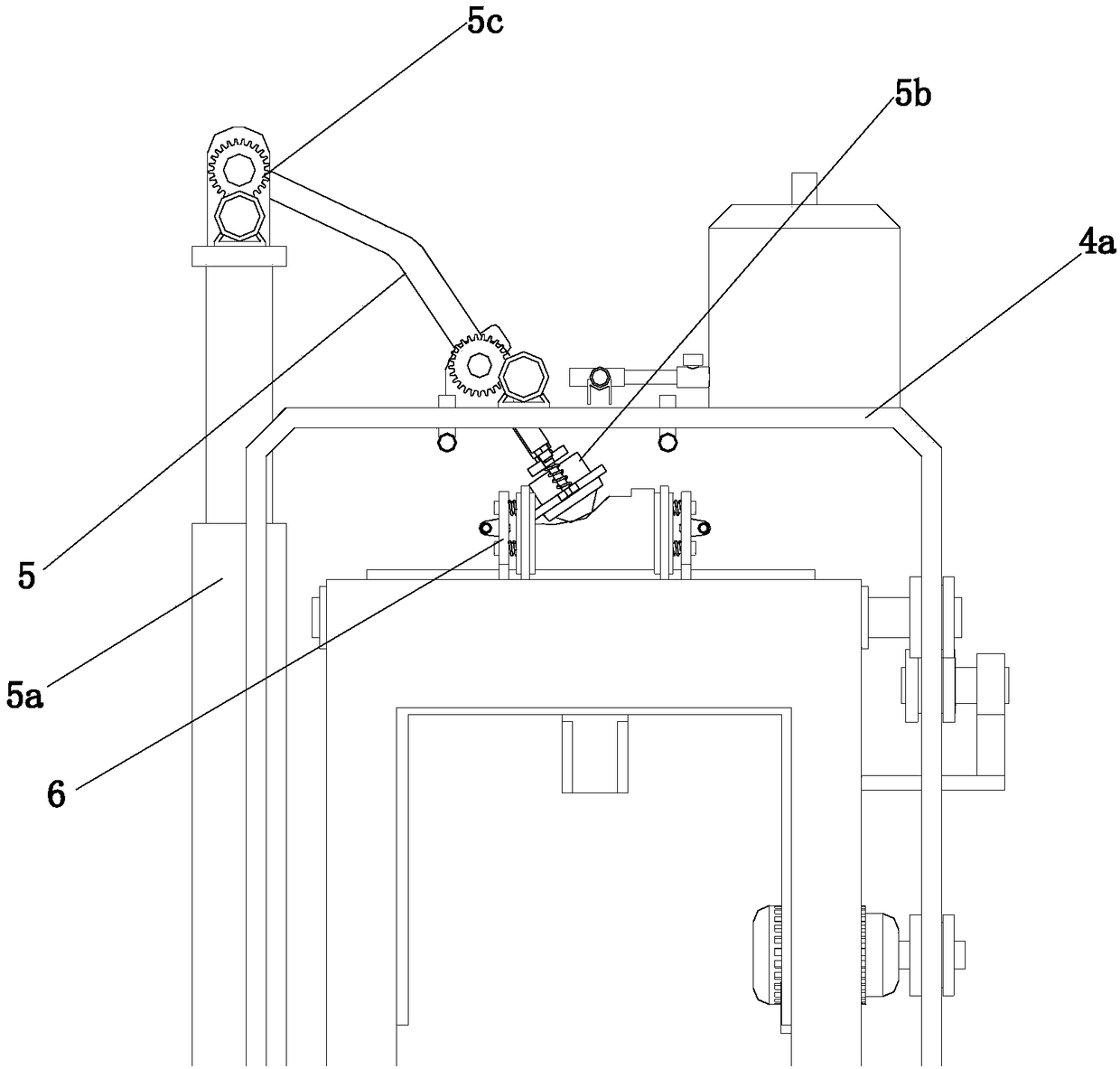

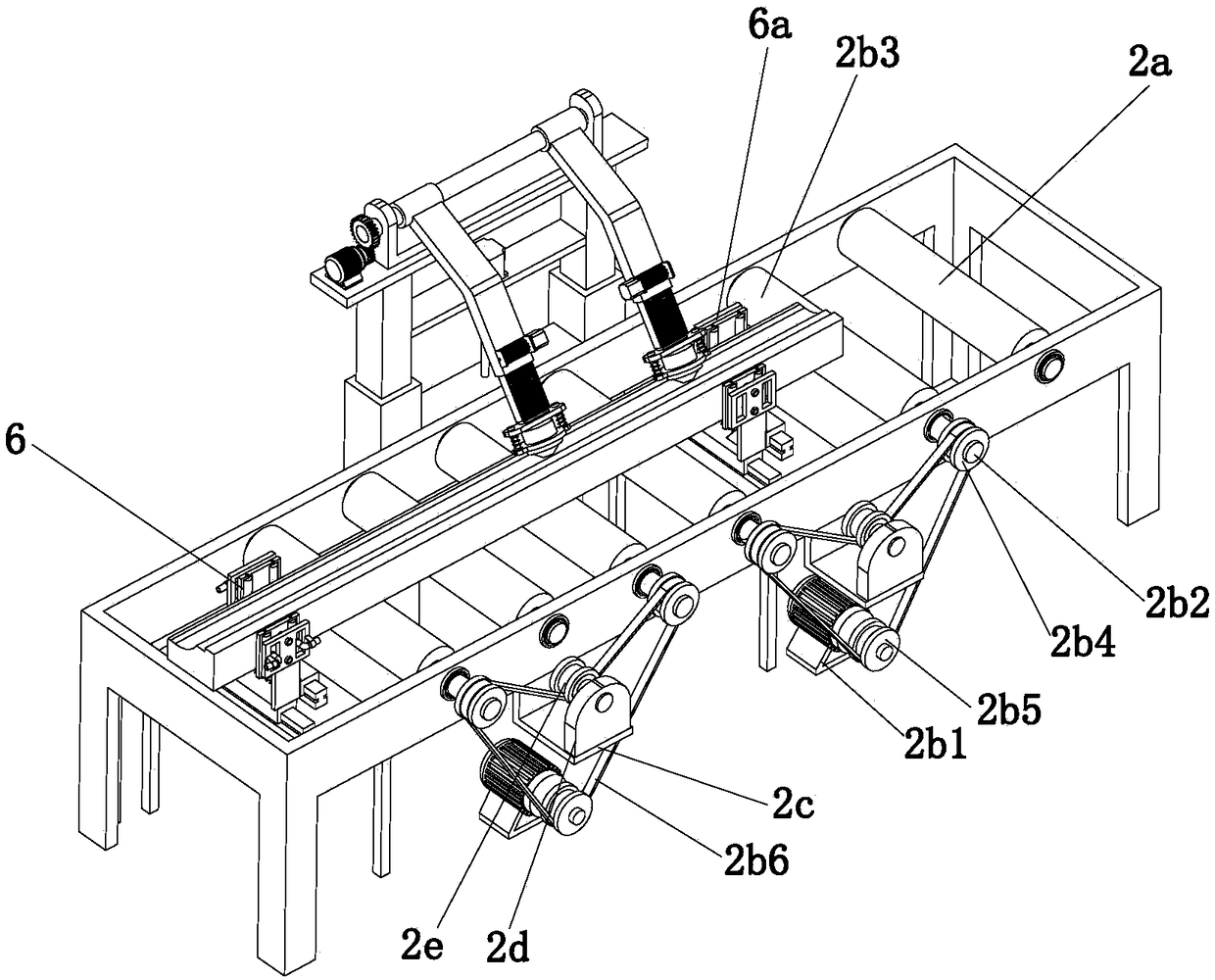

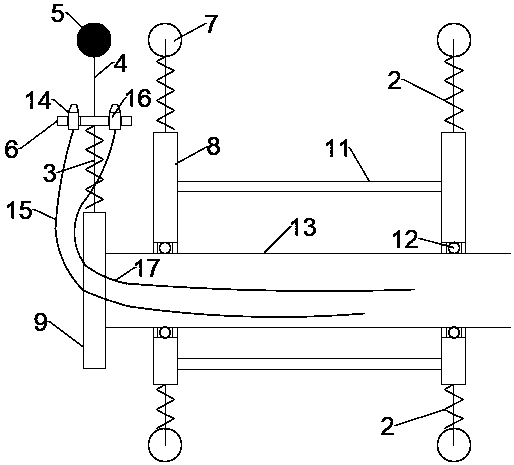

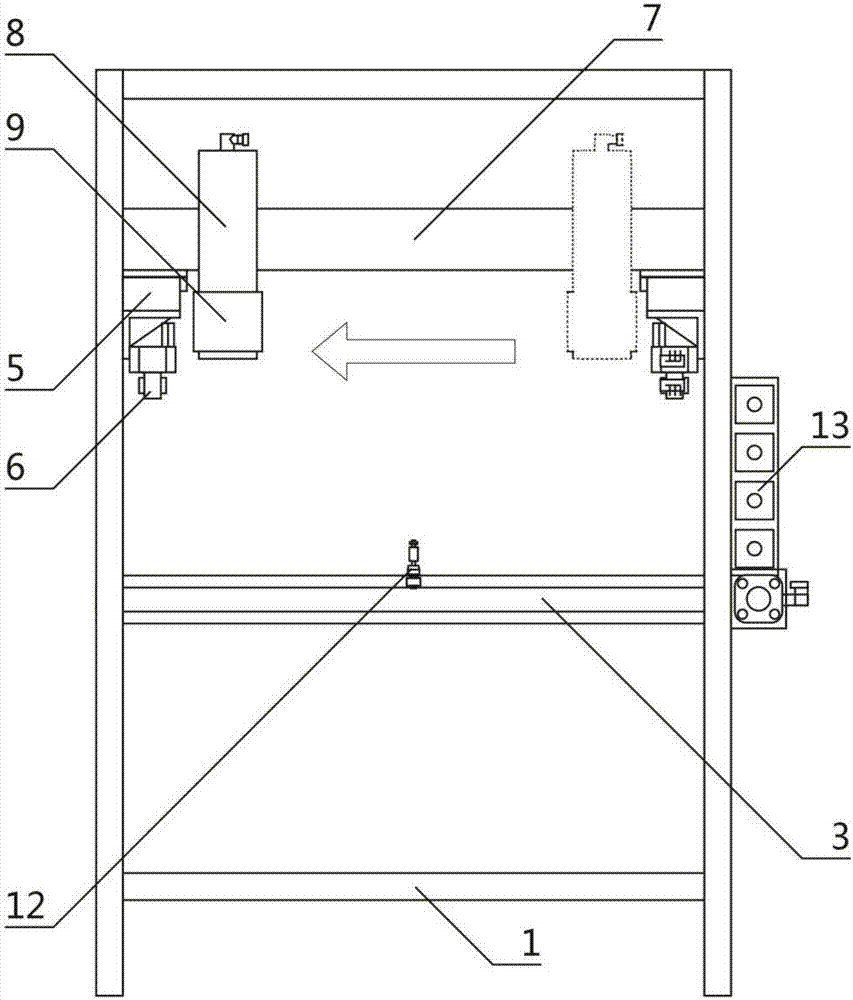

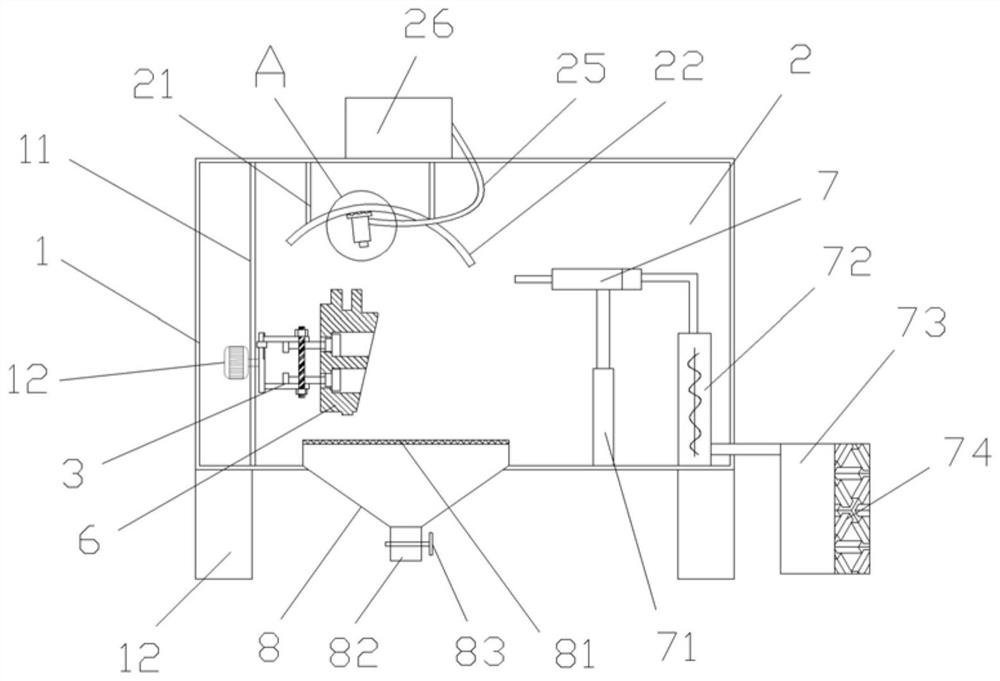

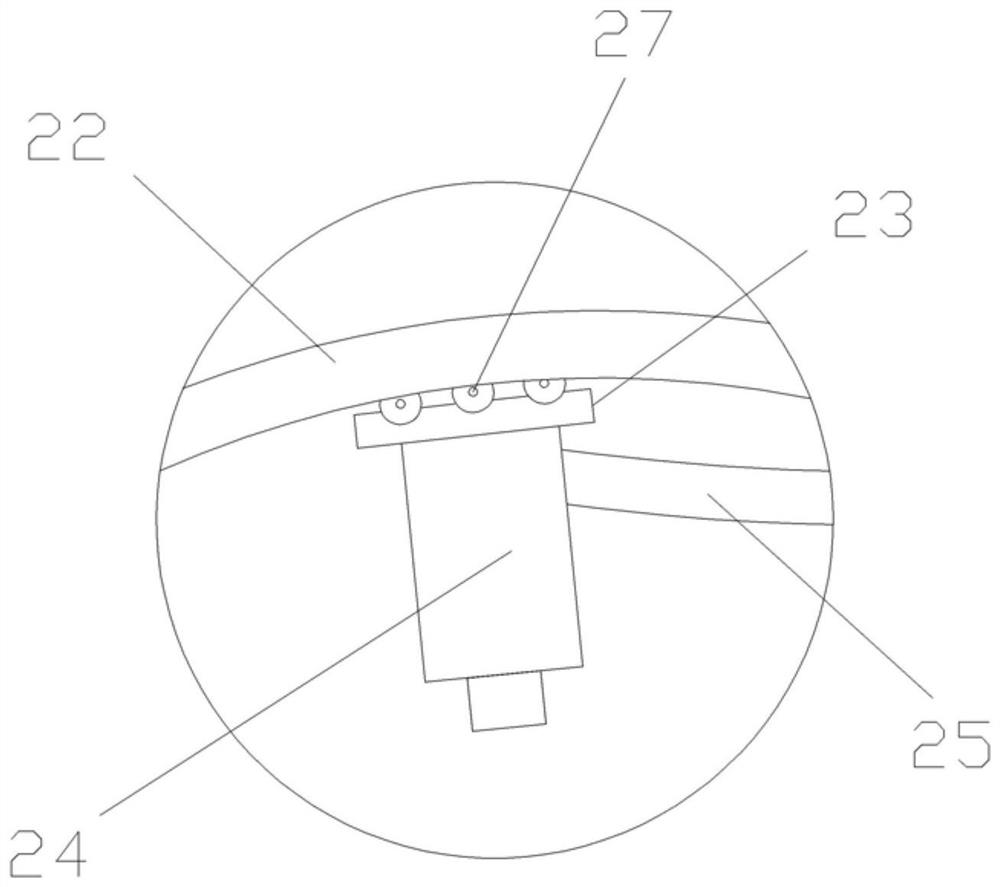

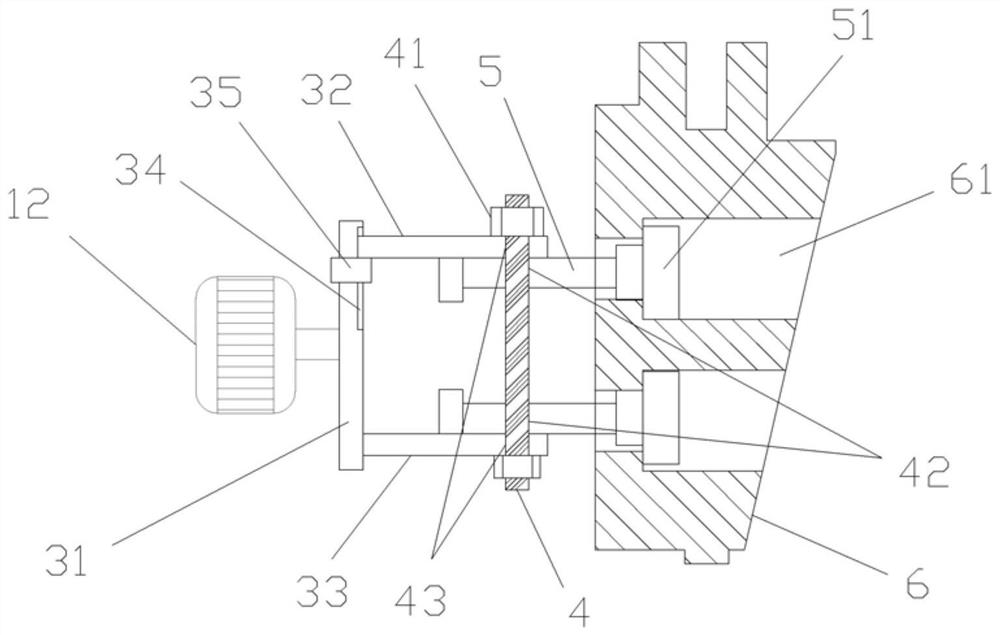

Wheel mold paint spraying device

The invention discloses a wheel mold paint spraying device. The wheel mold paint spraying device consists of a frame, servo motors, guide rails, a hollow shaft, nozzles and the like; four edge molds of a wheel are respectively put on four slide bases; rotating hand wheels adjust the slide bases to proper positions through lead screws and guide rails I; cylinders enable the nozzles to move to the left side to reach above the center positions of the four edge molds through guide rails II; a servo motor I enables the nozzles to rotate through belt wheels and synchronous belts; meanwhile, a servo motor II enables the nozzle s to downwards move through gears and racks; when the nozzles move below the edge molds, the paint spraying process can be finished; and angles of the nozzles can be adjusted through a servo motor III and a rotating frame. The wheel mold paint spraying device can realize automatic paint spraying process of four edge molds of the wheel, is uniform and consistent in spraying effect, can adjust the angles and parameters of the nozzles according to different wheel types, can relieve the labor intensity of workers and improve the operation environment thereof, and has such characteristics as simple structure, convenience for use and advanced process.

Owner:CITIC DICASTAL

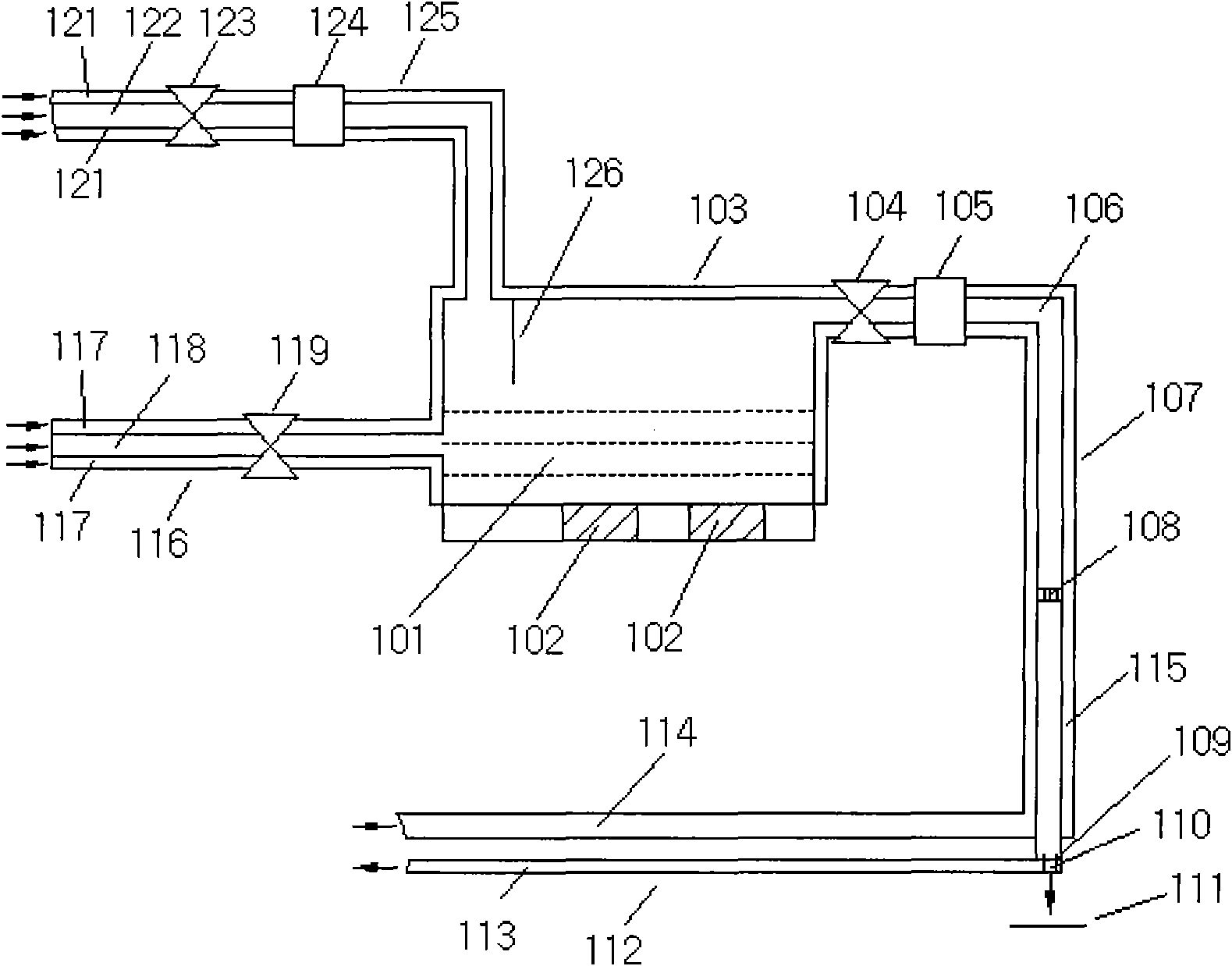

Spraying device of liquid material thin film and spraying method thereof

InactiveCN101813889AReduce wasteThe overall thickness is thinPhotomechanical coating apparatusSpray nozzleUltrasonic vibration

The invention relates to a spraying device of a liquid material thin film and a spraying method thereof, which belong to the technical field of semiconductor device production. The invention aims to solve the problem that sufficient atomization flow can not be ensured while enough thin ultrasonic atomization liquid particles are obtained. The spraying device comprises an atomization container, an ultrasonic vibration generator used for carrying out ultrasonic atomization operation, a liquid material input device used for introducing liquid raw materials, a carrier gas input device used for introducing carrier gas, a fog output device used for outputting fog and a spray nozzle used for receiving the fog and spraying the fog to a wafer to be sprayed, wherein the carrier gas is used for being mixed with the particles which is formed after the liquid materials are atomized to form the fog. The technical scheme has the characteristics that each functional module is independently installed in the scheme, and thereby, the overall work capacity and efficiency of the device are improved, and the waste of the liquid materials is greatly reduced, and then the environmental pollution is reduced; the thinner and evener spraying effect can be obtained, and a liquid thin film which is thinner and has better evenness can be generated; the spraying device can be used for spraying step surfaces.

Owner:TSINGHUA UNIV

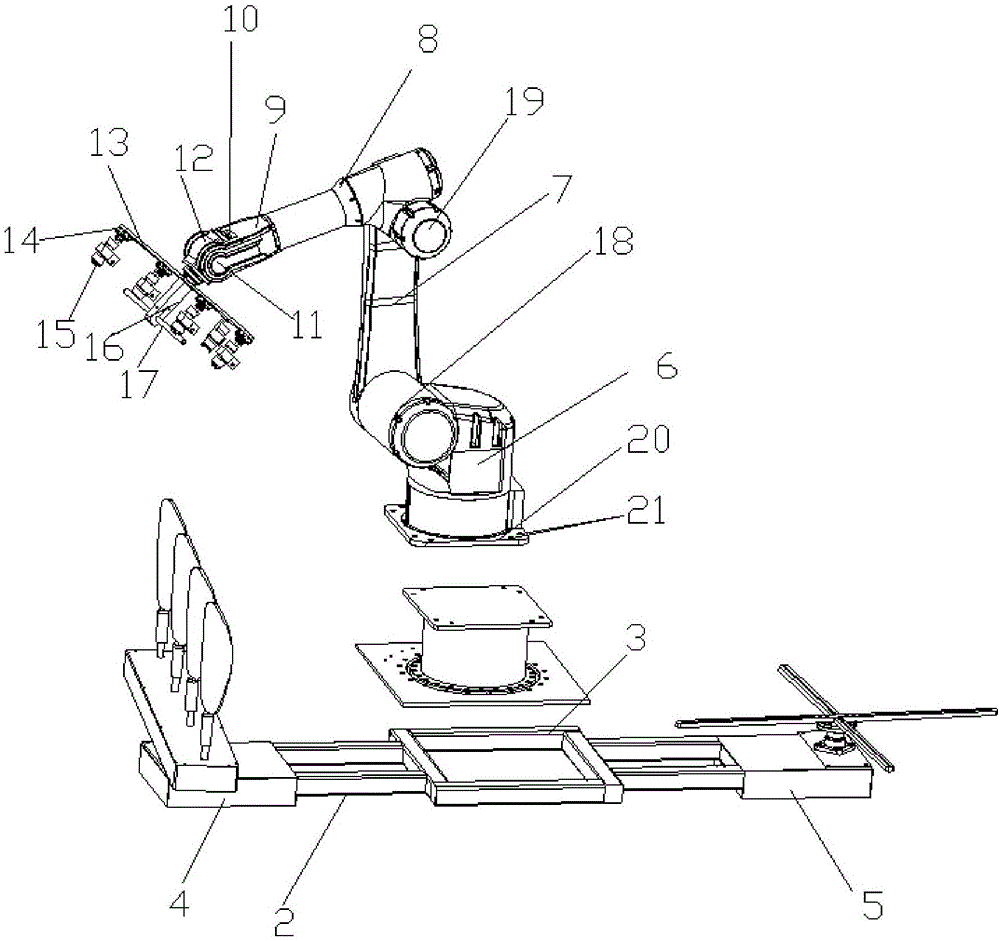

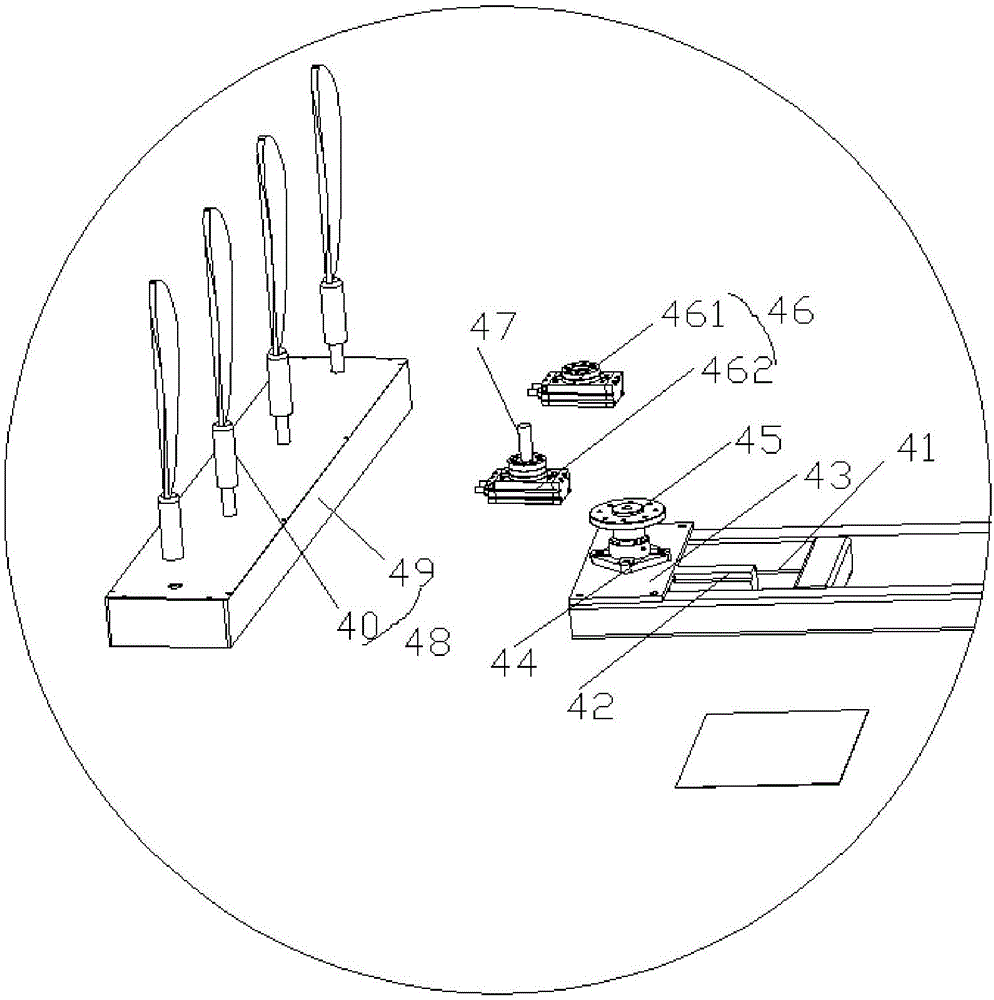

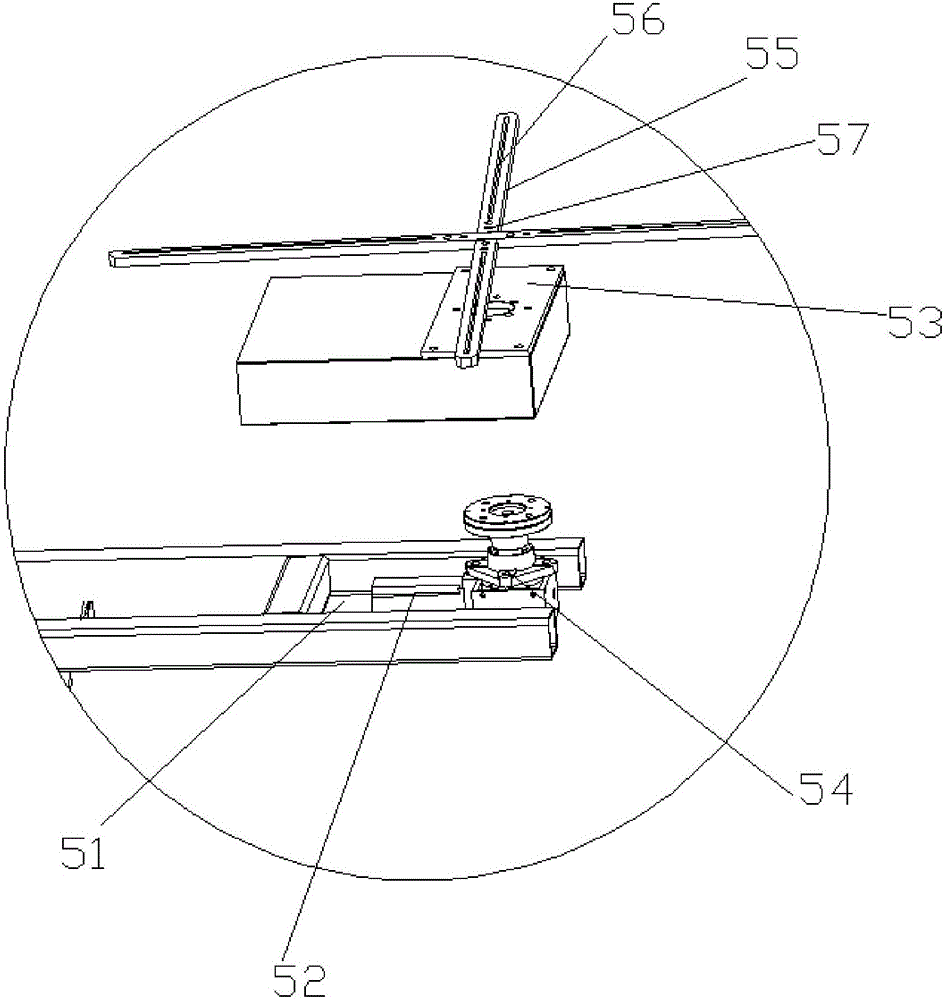

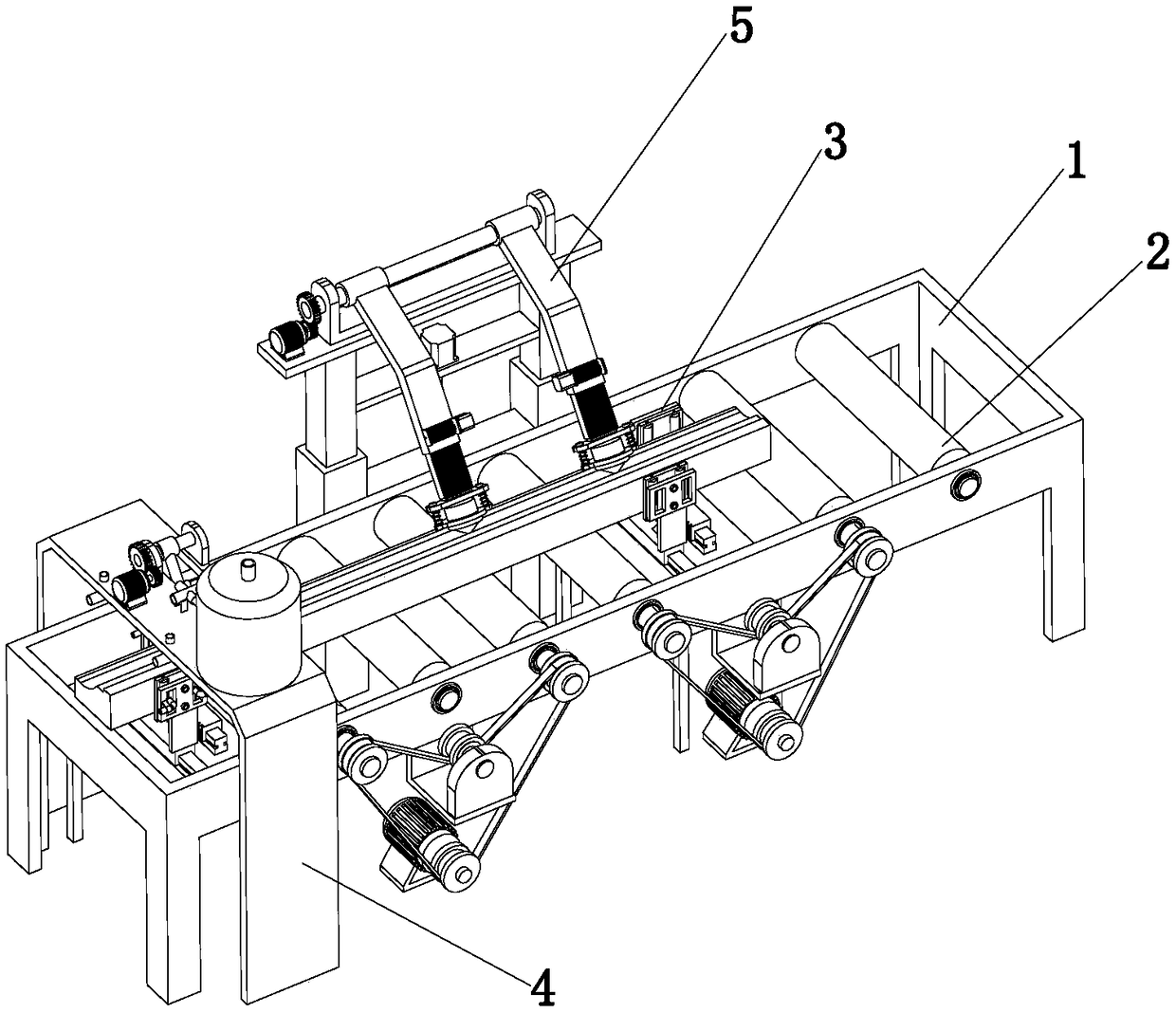

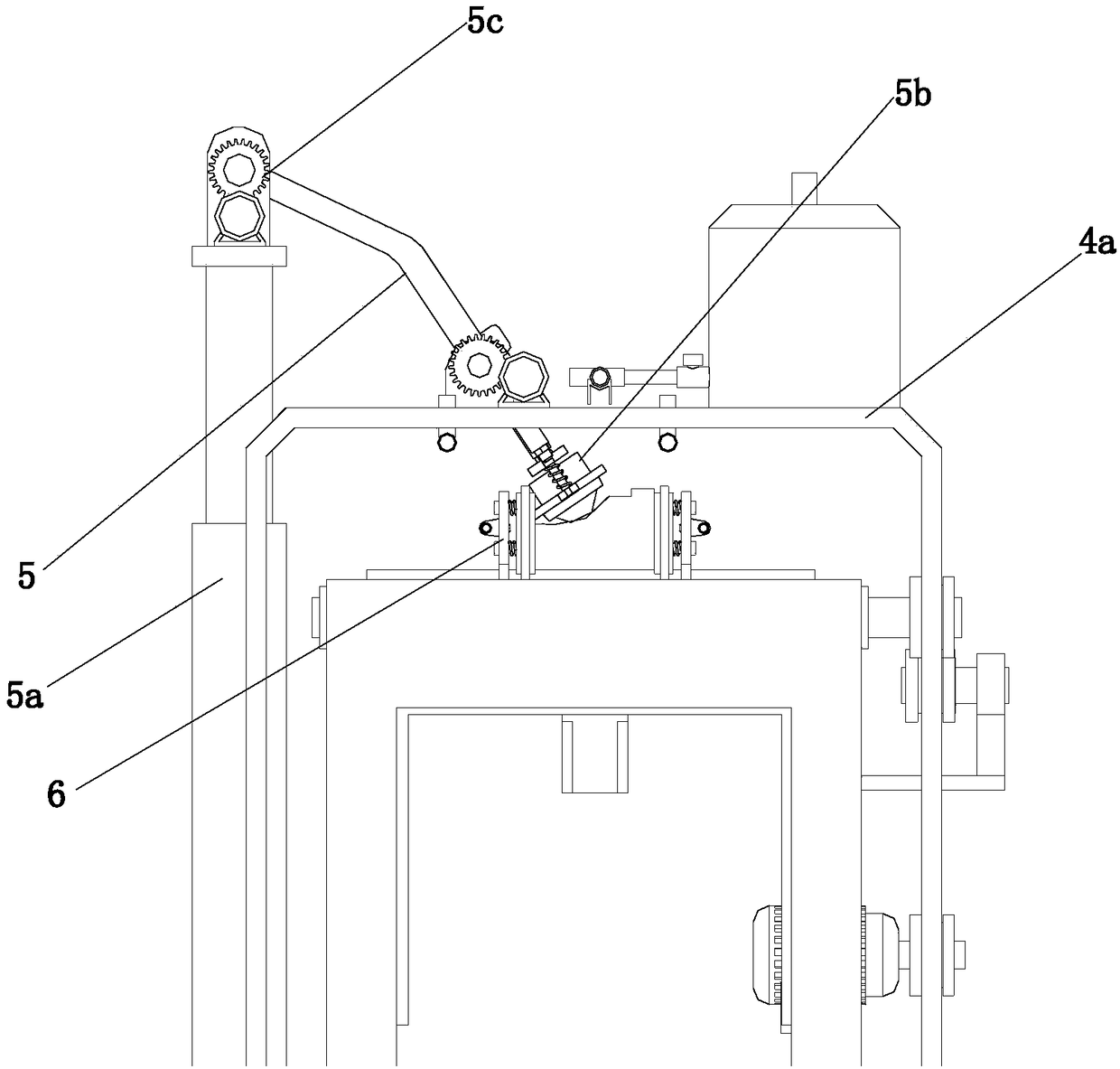

Spray manipulator device

The invention discloses a spray manipulator device. The spray manipulator device comprises a horizontal support table and a manipulator device, wherein a central frame is arranged in the middle of the horizontal support table, a product fixing and turning device for fixing upright products is arranged at one end of the horizontal support table, a horizontally placed product fixing and turning device for fixing horizontally placed products is arranged at the other end of the horizontal support table, a tail end manipulator arm is arranged at one end of the manipulator arm, a U-shaped notch is arranged in one end of the tail end manipulator arm, drive assemblies are arranged on two side arms of the U-shaped notch and control a drive rod to rotate, a spray motor is mounted on the drive rod, and an angle-rotatable spray head support is mounted on an output shaft of the spray motor. The spray manipulator device is simple in structure, facilitates manipulator spraying, requires no manual turning and side change and can realize turning spraying.

Owner:DONGGUAN LEBAOT ROBOT

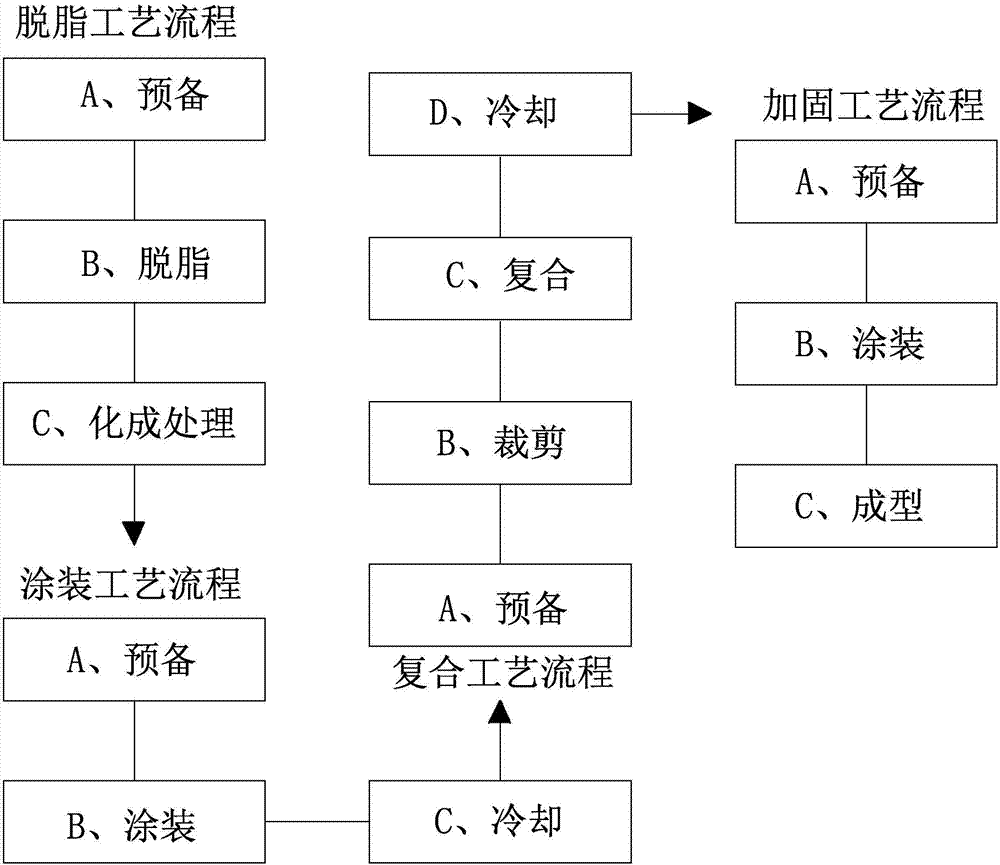

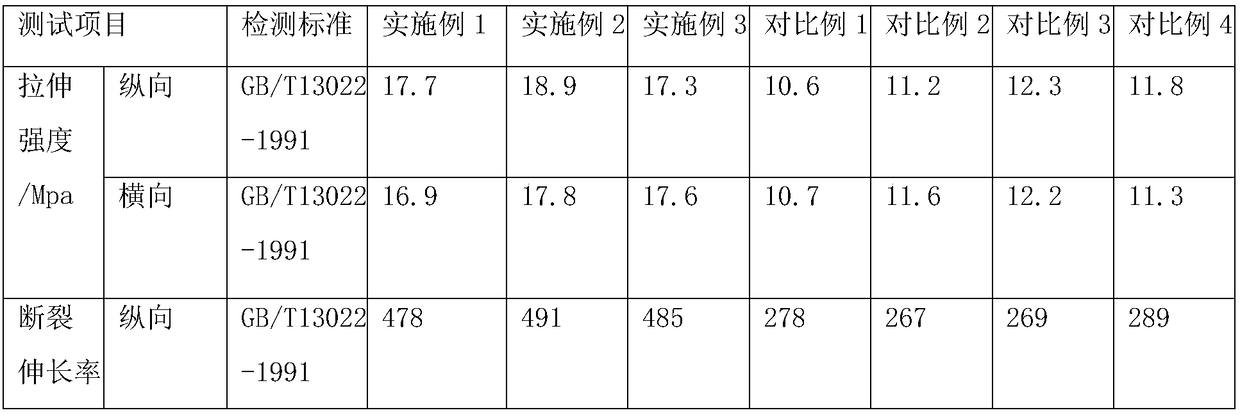

Production method of aluminum-plastic plate

InactiveCN107471807AReduce production process stepsSimple stepsCovering/liningsLamination ancillary operationsCorrosionMaterials science

The invention discloses a production method of an aluminum-plastic plate. The aluminum-plastic plate produced by the method has the effects of being good in corrosion resistance effect and plastic coating effect, and high in tensile strength. The aluminum-plastic plate is characterized by comprising an upper aluminum alloy layer, a middle layer and a lower aluminum alloy layer which are sequentially connected with one another, wherein the middle layer is prepared from flame-retardant material polyethylene (PE) plastic profiles; the upper aluminum alloy layer and the lower aluminum alloy layer are respectively sprayed with a flame-retardant coating; a filling ring groove is formed at the peripheral side of the middle layer and is positioned between the upper aluminum alloy layer and the lower aluminum alloy layer; the filling ring groove is internally filled with thermosetting resin. The production process comprises the following steps: (1) a degreasing process; (2) coating process; (3) compounding process; (4) strengthening process. The production method of the aluminum-plastic plate is suitable for the technical field of aluminum-plastic plate production.

Owner:台州港邦建材有限公司

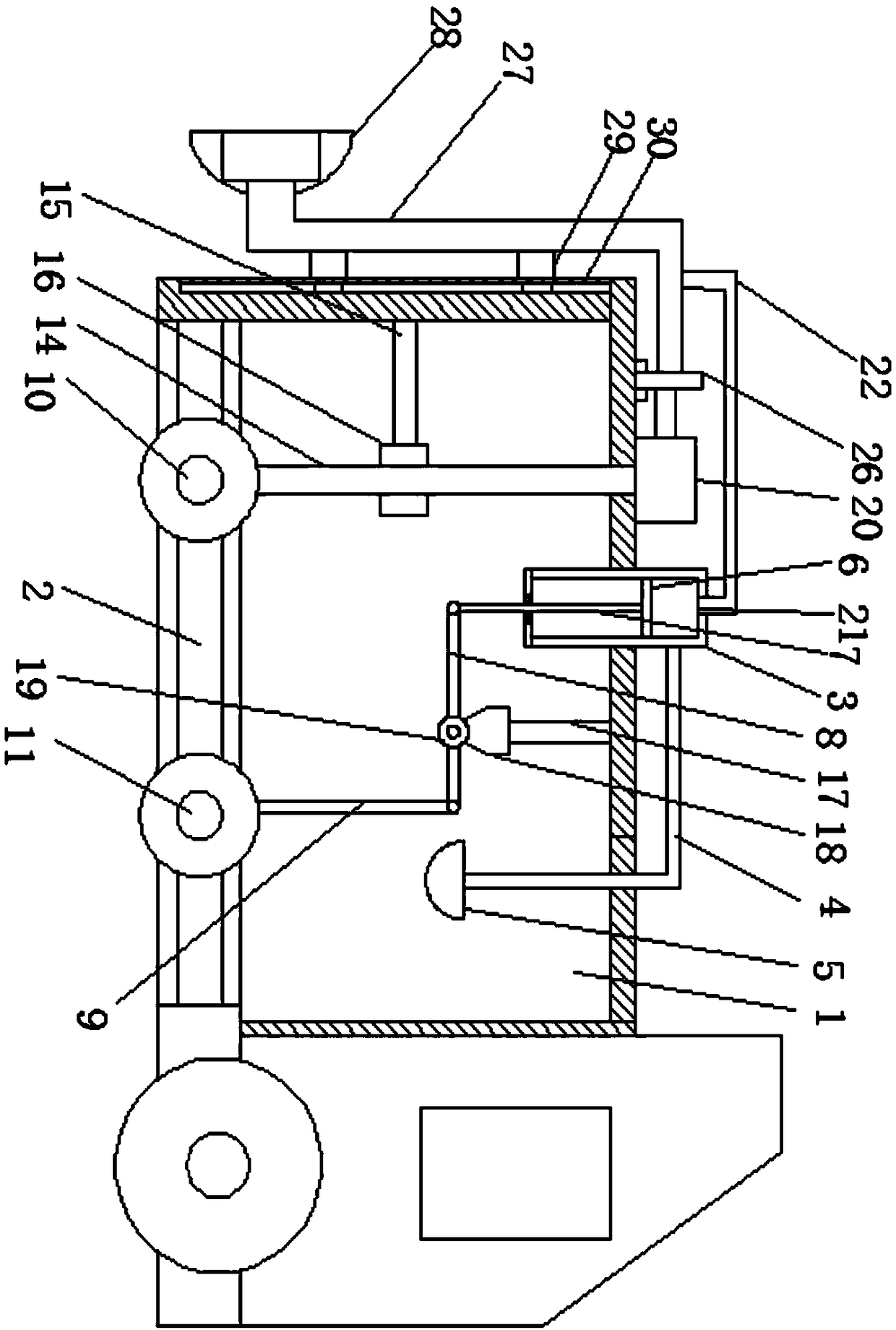

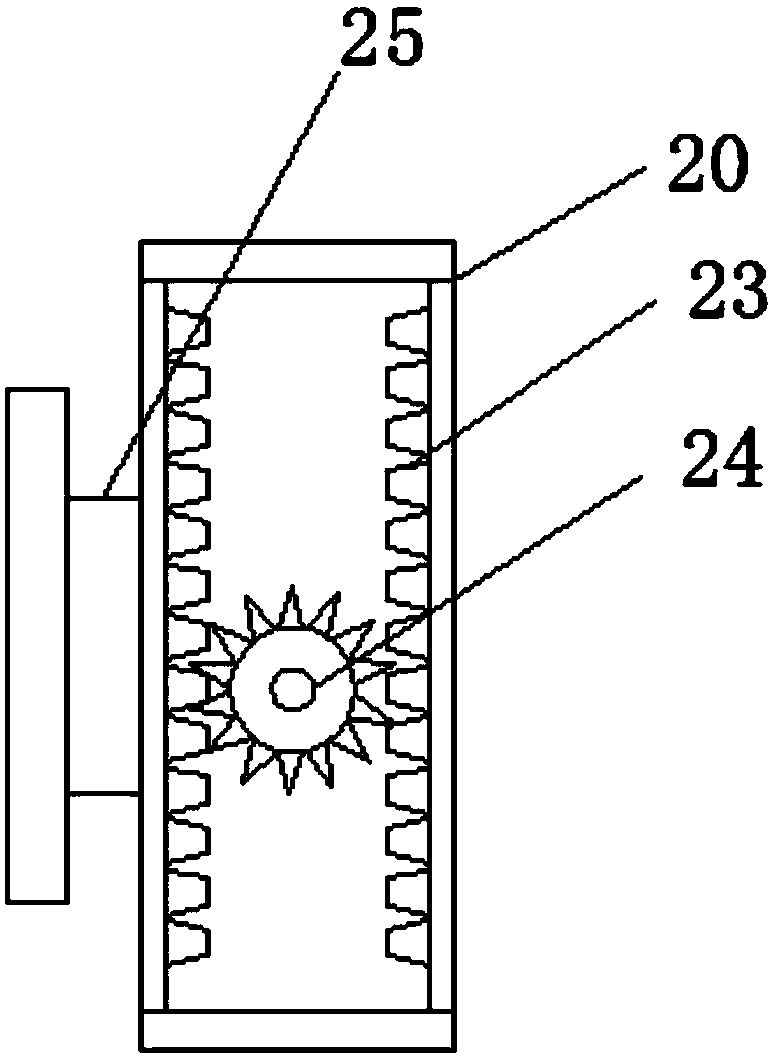

Working method of automatic building line strip spraying equipment

ActiveCN109433460AHigh degree of automationUniform spraying effectLiquid surface applicatorsSpraying apparatusEngineeringMoving parts

The invention relates to the field of building decoration line strip production equipment, in particular to automatic building line strip spraying equipment. The automatic building line strip sprayingequipment comprises a machine frame, a conveying mechanism, a line strip limiting mechanism and an automatic spraying mechanism, wherein the line strip limiting mechanism comprises a vertical limiting assembly, a first positioning assembly and a second positioning assembly, the first positioning assembly and the second positioning assembly are arranged at intervals and have the same structure, and each of the first positioning assembly and the second positioning assembly comprises a supporting frame, a material moving part and two abutting parts with the same structure. The automatic buildingline strip spraying equipment has the beneficial effects that the top surface and the side surface of a workpiece can be subjected to spraying operation through the automatic spraying mechanism, a worker does not need to additionally carry out spraying operation on the side surface of the workpiece; and line strips of different sizes can be limited through the line strip limiting mechanism in thevertical and transverse directions so that spraying operation on the line strips with different sizes can be achieved by adopting the equipment, and then the hidden danger of deviation of the line strips in the transportation process is avoided.

Owner:JIANGSU JINHUI CONSTR & INSTALLATION ENG

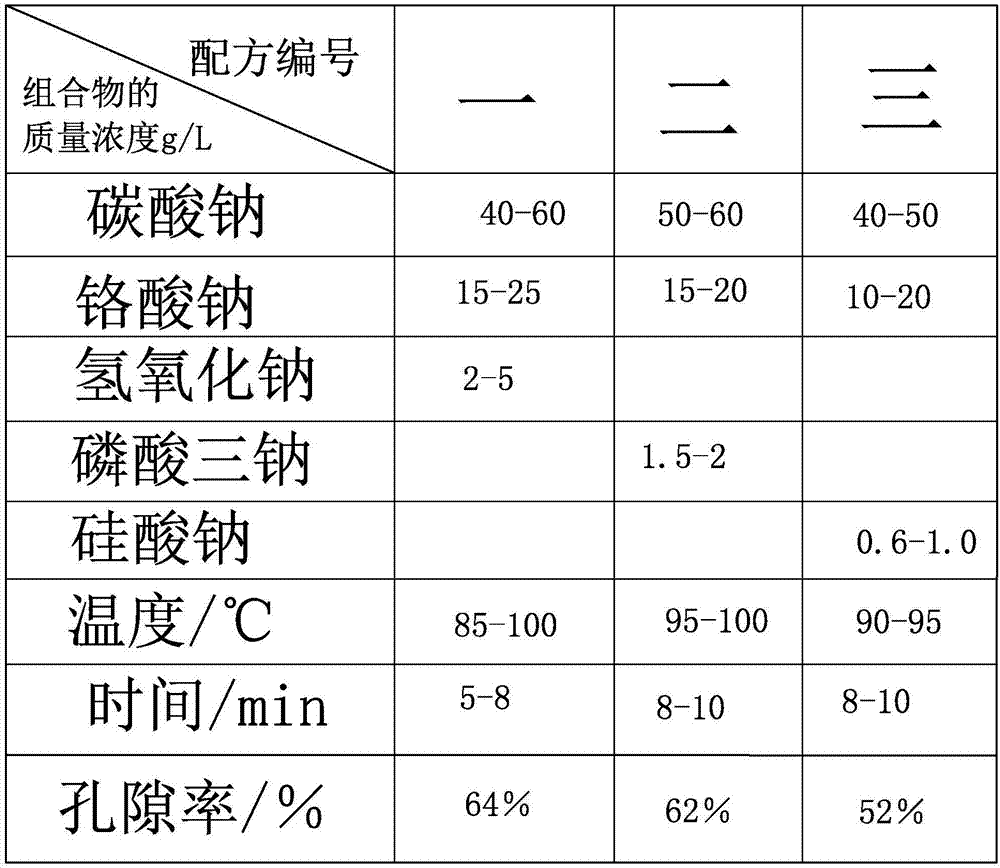

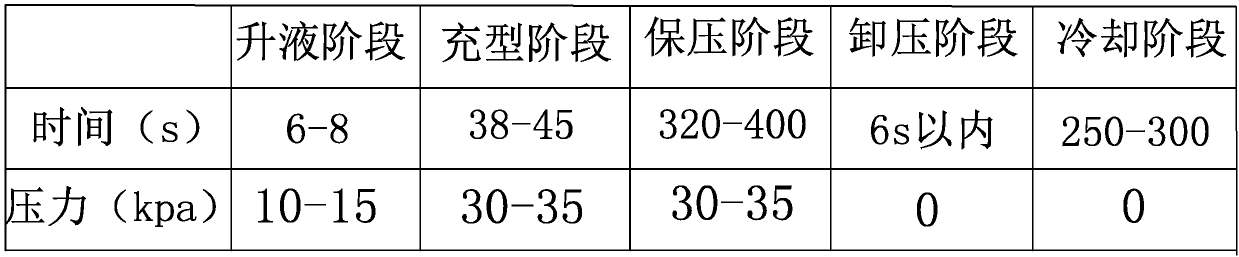

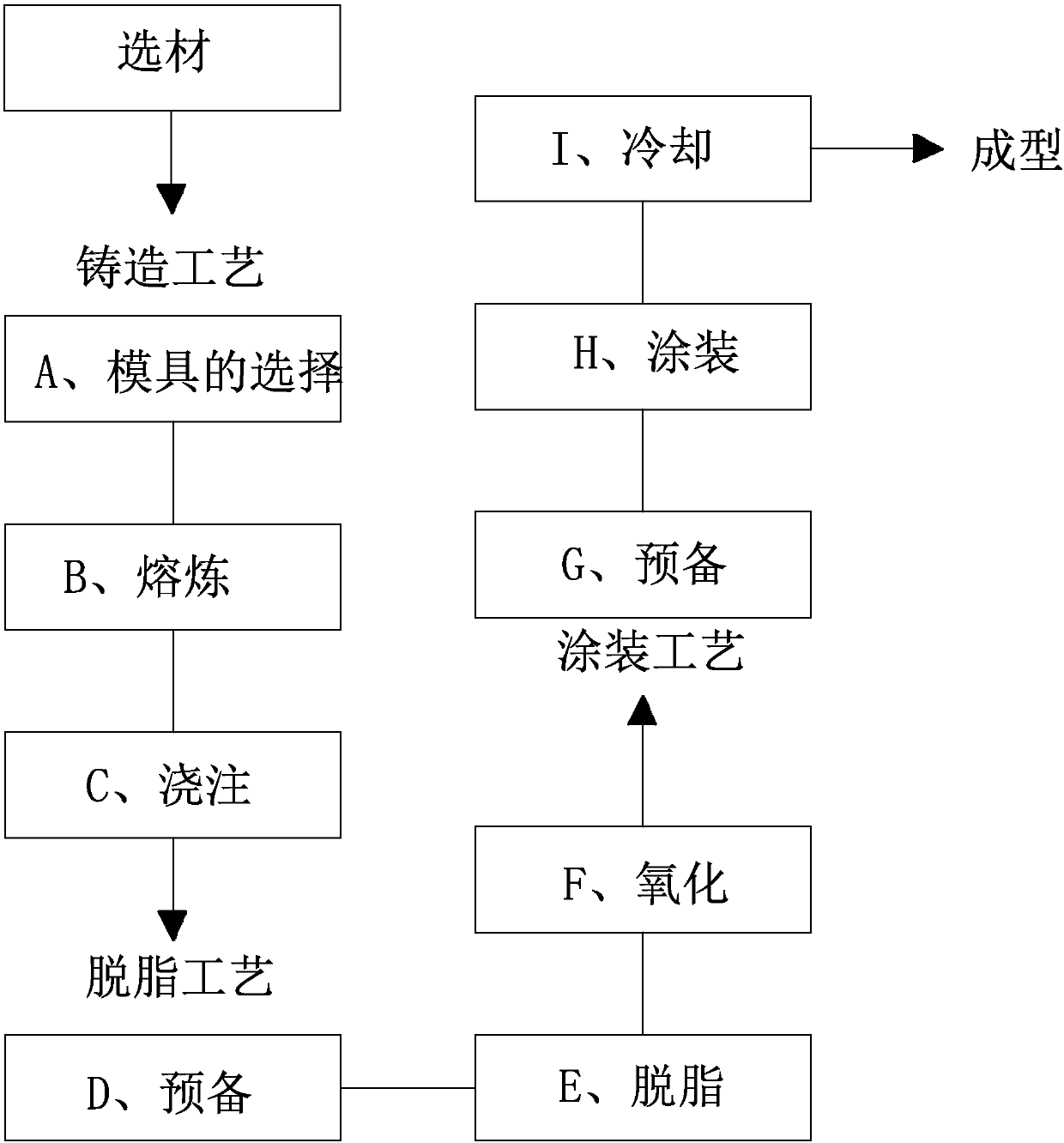

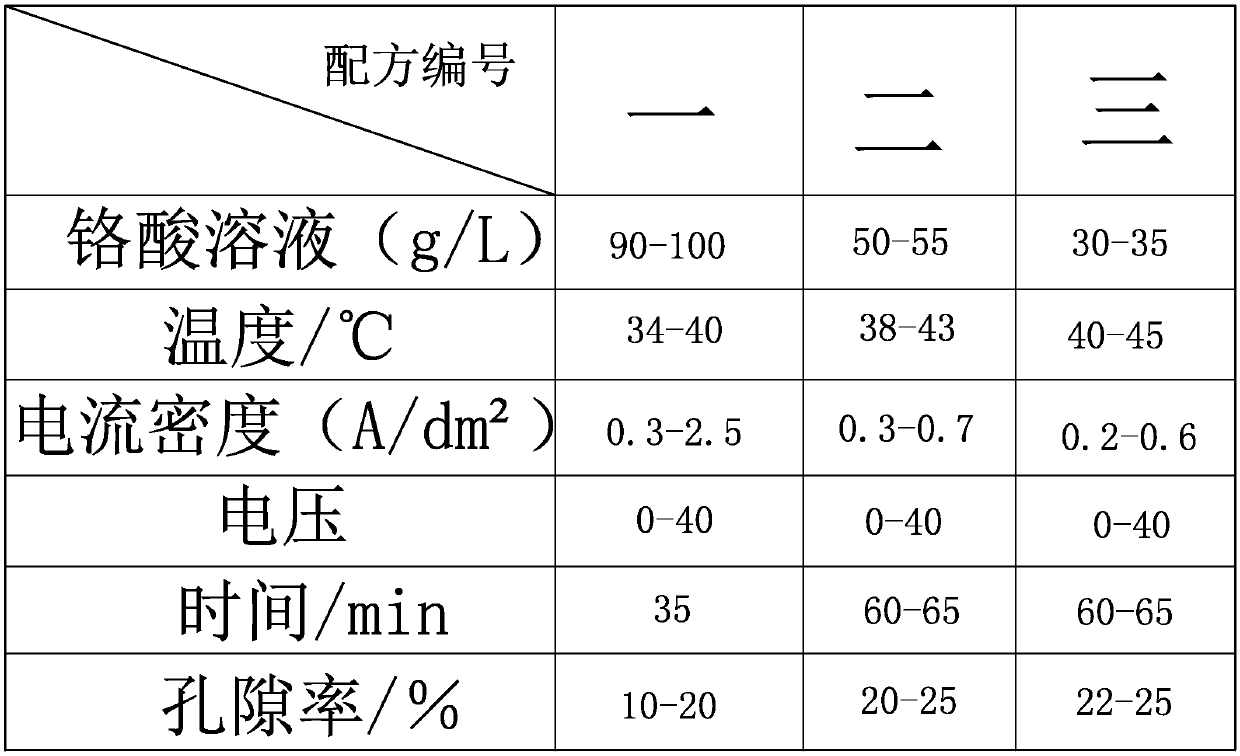

Production process for motor casing

ActiveCN107794417ASimplify processing stepsImprove liquidityAnodisationLiquid surface applicatorsCoatingIndustrial engineering

The invention discloses a production process for a motor casing. The production process for the motor casing aims at realizing convenient machining, a sufficient utilizing rate of materials, corrosionresistance and high practically. According to the technical scheme, the production process for the motor casing is characterized by comprising the following steps of (1) material selecting, (2) a casting process, (3) a degreasing process, (4) a coating process, and (5) forming. The production process is suitable for the motor casing.

Owner:新界泵业(浙江)有限公司

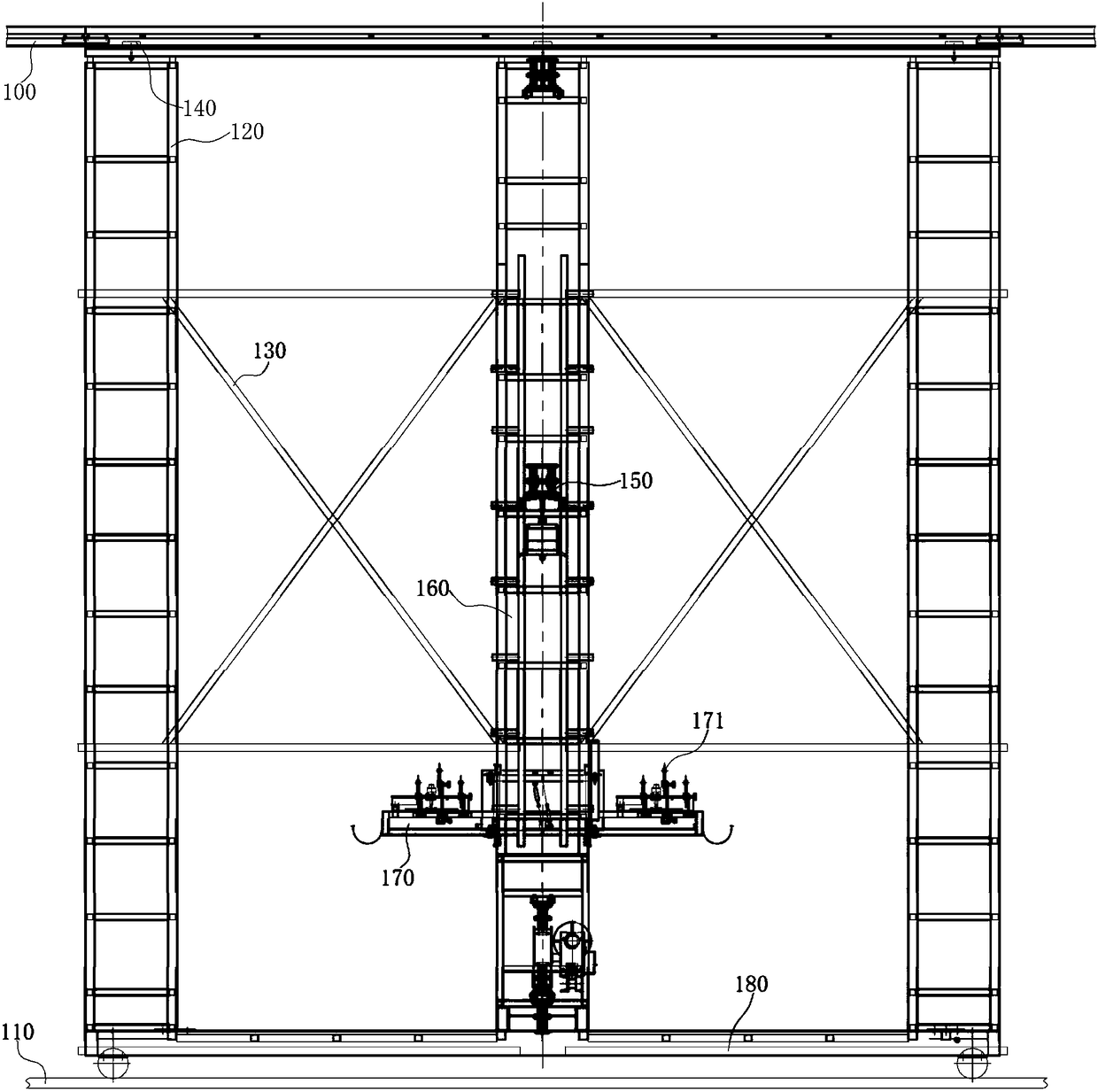

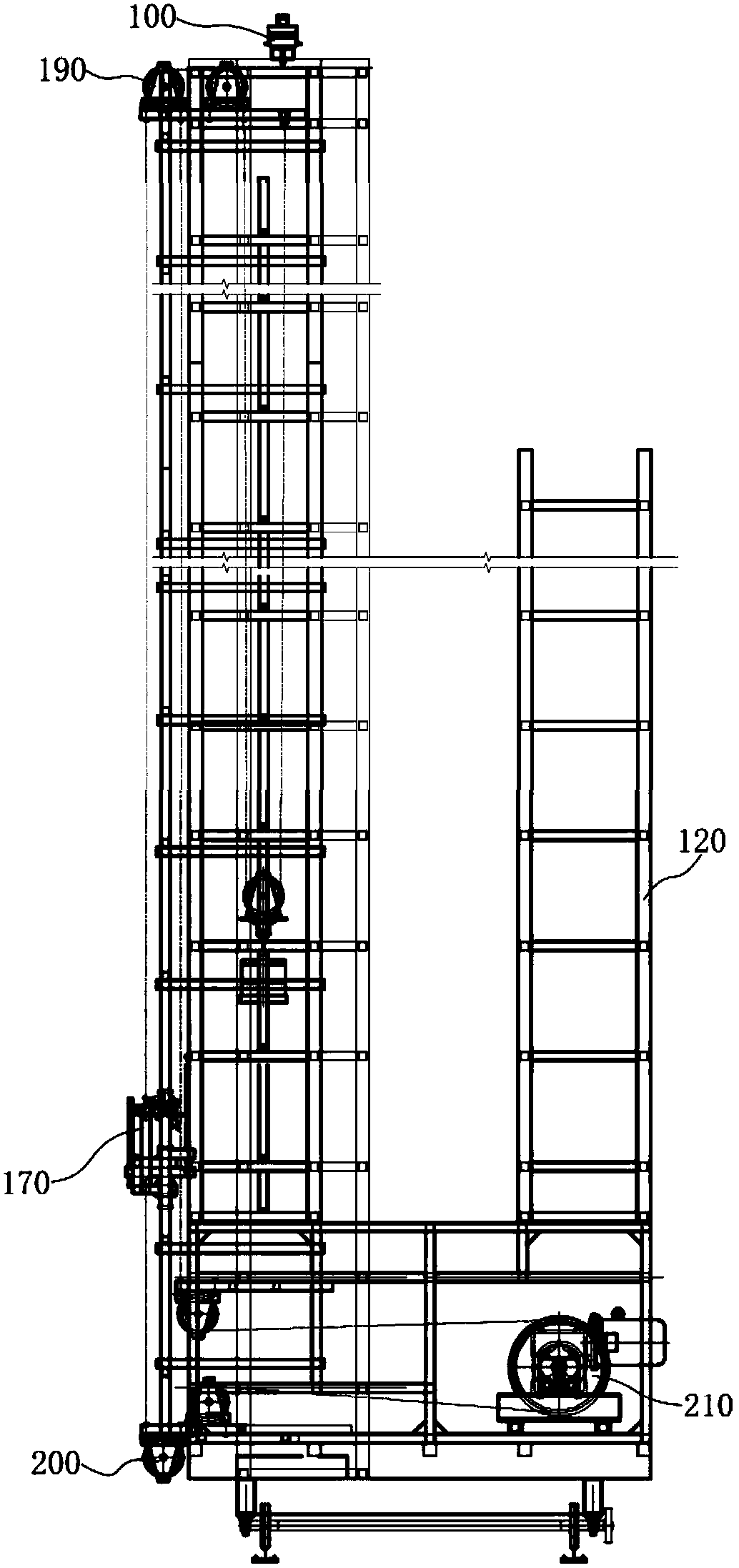

Projection screen optical coating spraying equipment

InactiveCN108273685APrecise positioningPrecise and controllable spray feedSpraying apparatusOptical coatingProjection screen

The invention discloses projection screen optical coating spraying equipment. The projection screen optical coating spraying equipment comprises spraying vertical frames. The bottoms of the spraying vertical frames are perpendicular to a spraying moving trolley which stably moves leftwards and rightwards. The tops of the three spraying vertical frames which are arrayed in a line shape on the sideof the spraying moving trolley are all provided with top rail guide wheels, and the top rail guide wheels are embedded into a top rail to pull the spraying vertical frames and enhance the stability and the overturning performance of the spraying vertical frames. By means of the spraying equipment, the uniformity of protection screen optical coating spraying and the appearance quality of coatings can be ensured, and the projection screen coatings reach the established projection optical index; according to a spraying process of the projection screen optical coating spraying equipment, the reliability and the adjustment flexibility are greatly improved, and the quality problems caused by the equipment in the production process are obviously reduced; and the equipment is suitable for production of various projection screens needing optical coating spraying, the design is novel, a very good innovation scheme is achieved, and great market popularization prospects are achieved.

Owner:WUHU STAR IMAX

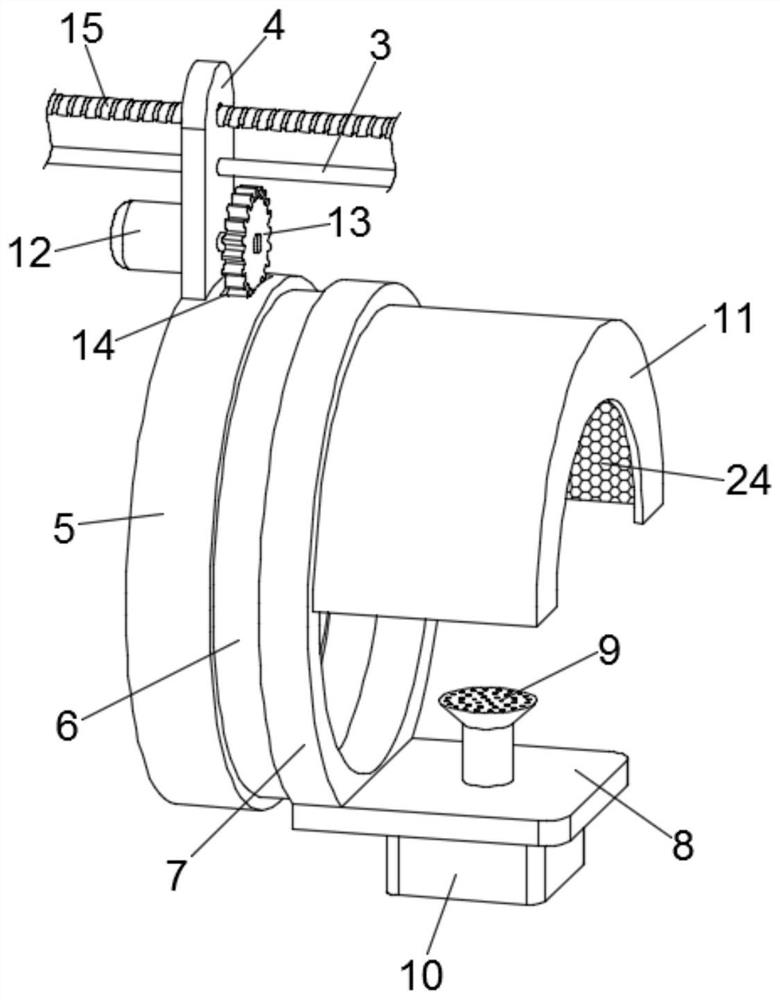

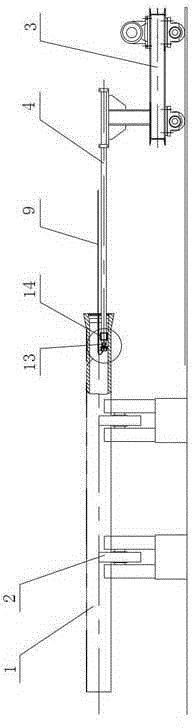

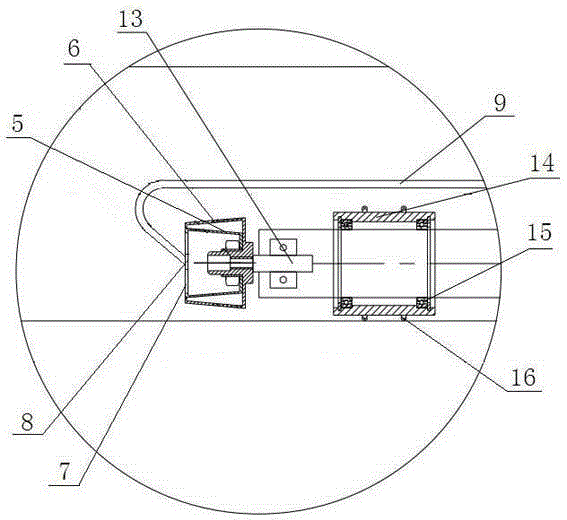

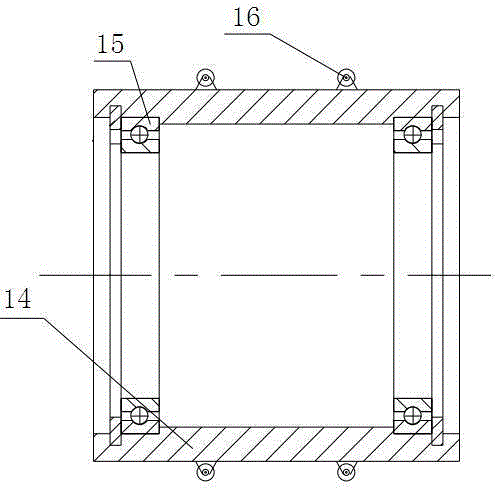

Steel structure paint spraying device

InactiveCN112138907AUniform spraying effectImprove spraying efficiencySpraying apparatusManufacturing engineeringSlide plate

The invention discloses a steel structure paint spraying device. The steel structure paint spraying device comprises a base, supporting frames are vertically fixed to the two ends of the base, a guidecolumn is horizontally fixed between the supporting frames, the guide column is slidably provided with a sliding plate in a sleeved mode, and horizontal-moving mechanisms are further installed on thesupporting frames; a fixed ring sleeve is connected to the lower end of the sliding plate, a rotating ring is rotationally arranged in the fixed ring sleeve in an embedded mode, a rotating motor is installed on the sliding plate, a gear is rotationally installed at the output end of the rotating motor, and a gear ring is arranged on the rotating ring; a mounting plate is fixed to the rotating ring, a spray head and a paint sprayer are arranged on the mounting plate, and a shielding cover is arranged on the opposite side of the spray head; and a plurality of sliding rails are fixed to the base, and supporting columns are slidably installed in the sliding rails. The spray head in the steel structure paint spraying device can rotate around a steel structure in the circumferential direction for spraying and horizontally move along the steel structure, so that omni-directional paint spraying of the steel structure is achieved, no dead angle exists in the paint spraying process, and the spraying effect is uniform and consistent; and the shielding cover is arranged on the opposite side of the spray head to block paint sprayed from the spray head, so that the paint is prevented from splashing everywhere.

Owner:冯剑茹

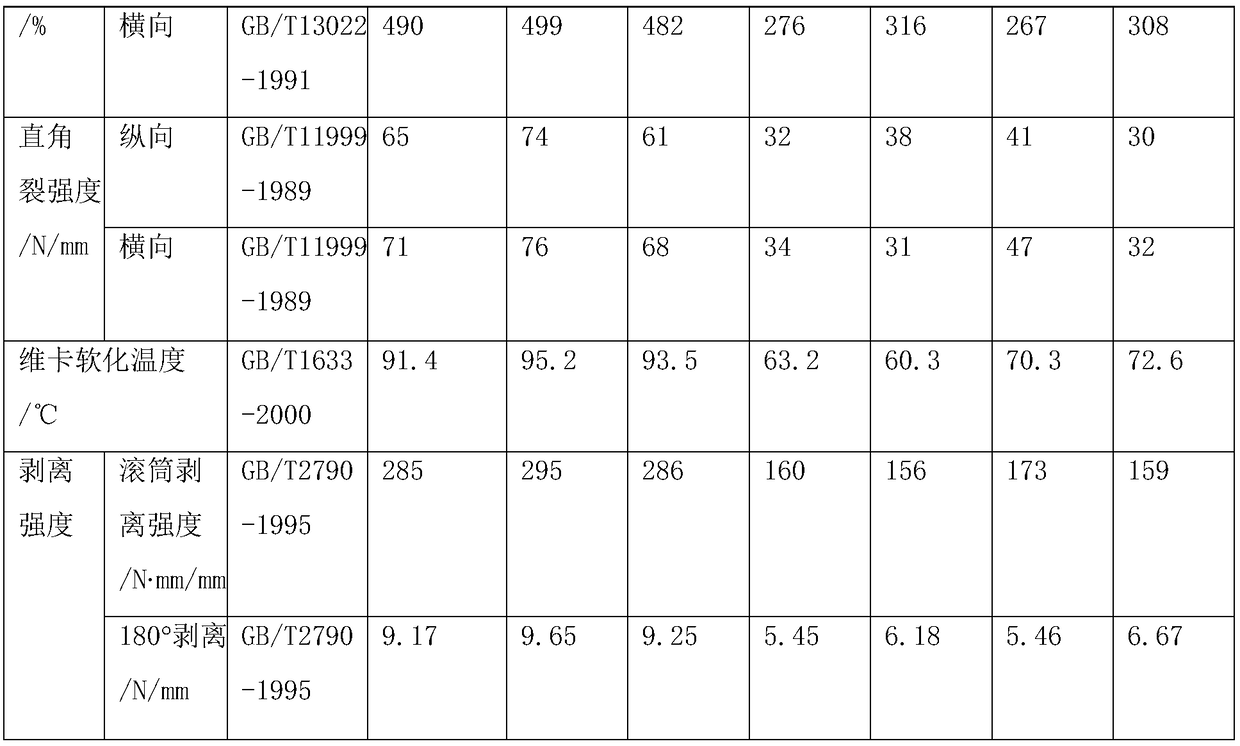

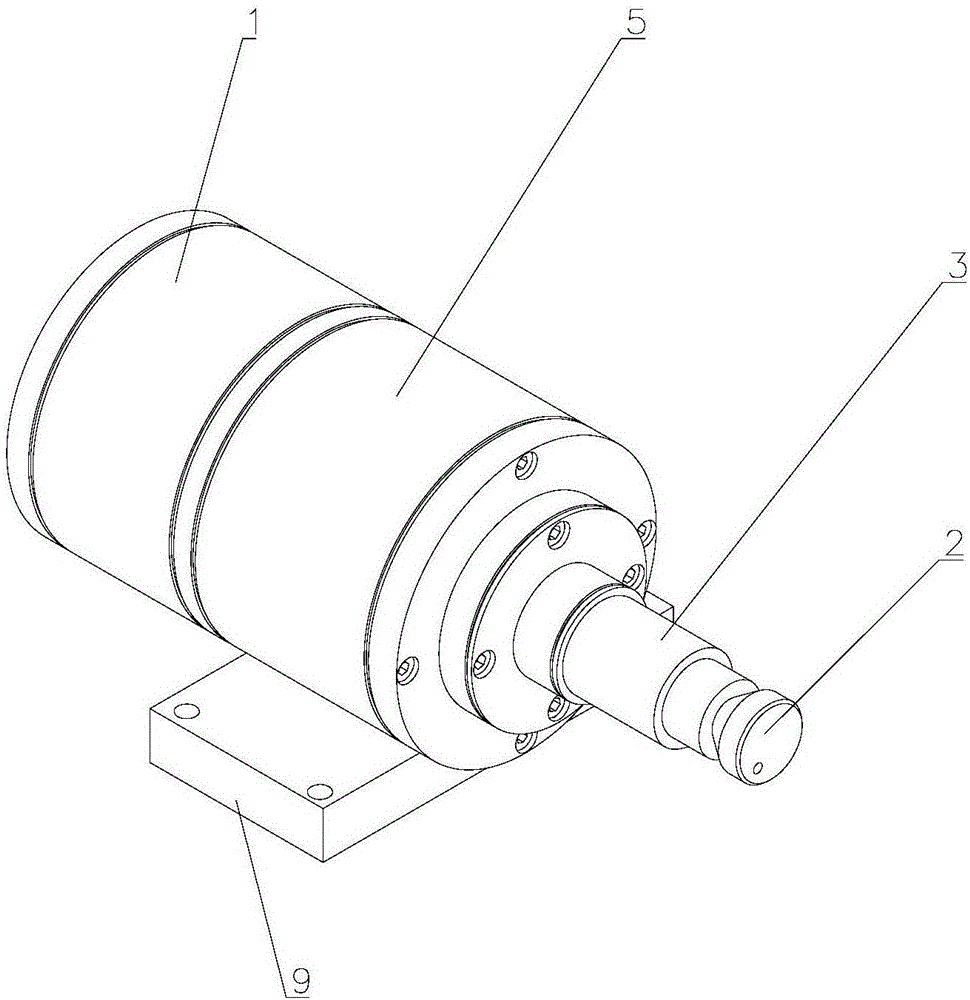

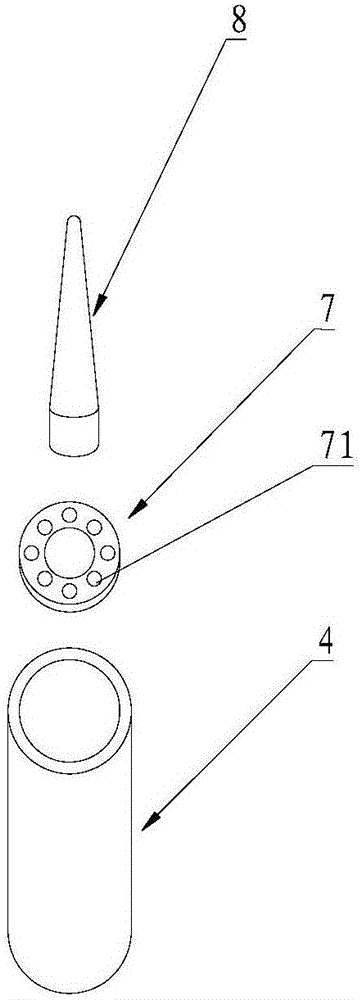

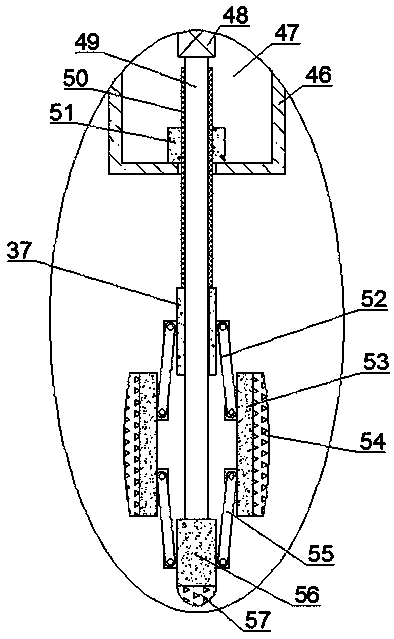

Multicomponent medium inner-wall spraying device for nodular cast iron pipes

InactiveCN104148227AGood for secondary fusionWell mixedSpraying apparatusCast iron pipeMaterials science

The invention discloses a multicomponent medium inner-wall spraying device for nodular cast iron pipes and relates to the technical field of spraying of the nodular cast iron pipes. The multicomponent medium inner-wall spraying device comprises a trolley, an extending rod and a spraying mechanism, the spraying mechanism comprises an inner rotary cup and an outer rotary cup which rotate coaxially, the inner rotary cup is arranged in the outer rotary cup, a cup rim of the outer rotary cup as well as a cup rim of the inner rotary cup faces the horizontal direction, the cup rim of the outer rotary cup is sealed, the cup rim of the inner rotary cup is provided with a seal cover with a circular opening, a feed pipe is arranged in the circular opening, and a secondary mixing cavity is arranged between the inner rotary cup and the outer rotary cup. The walls of the inner and outer rotary cups are provided with first holes and second holes respectively, the first holes and the second holes are communicated with the secondary mixing cavity, and the outer rotary cup is driven to rotate by a motor. During spraying, multicomponent medium coating is sufficiently and uniformly mixed, and in a porous mist type spraying manner, spraying quality is guaranteed and production efficiency is improved.

Owner:XINXING DUCTILE IRON PIPES CO LTD

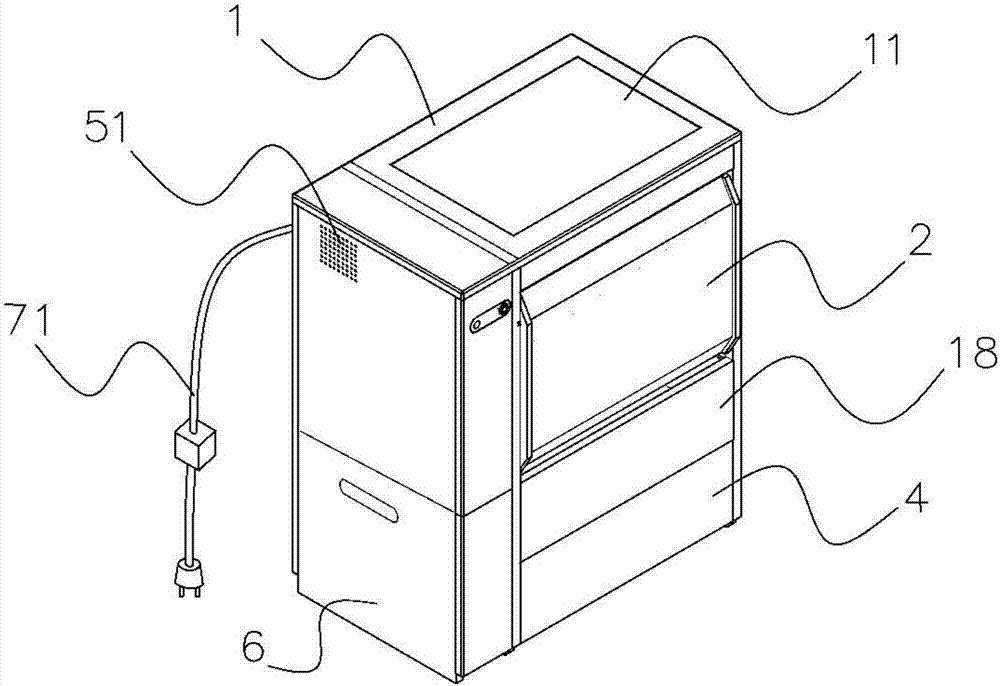

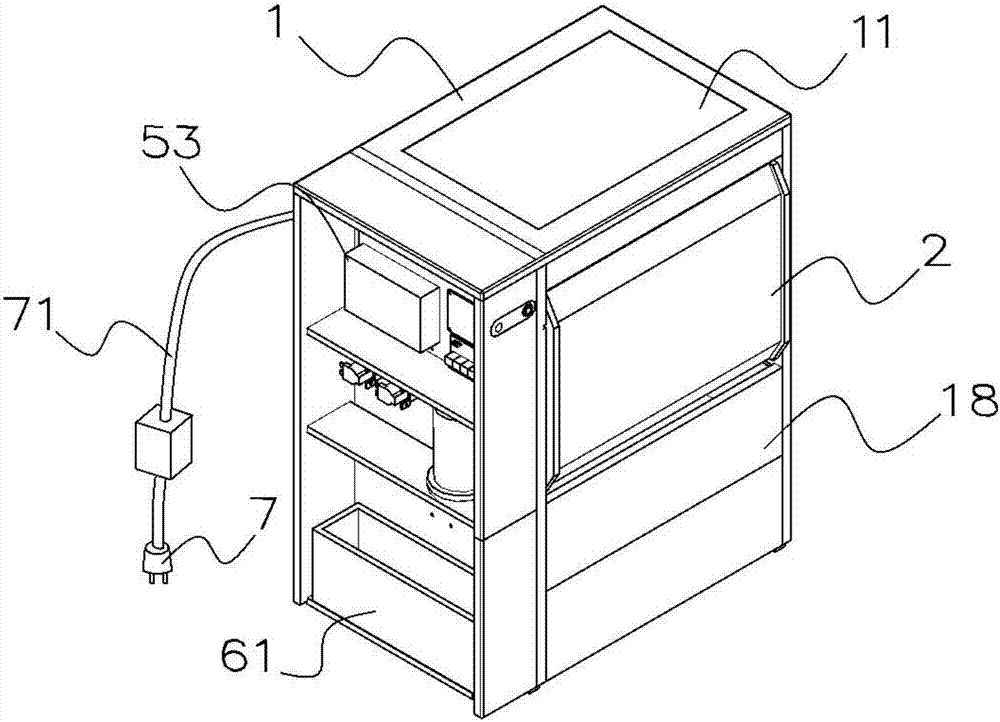

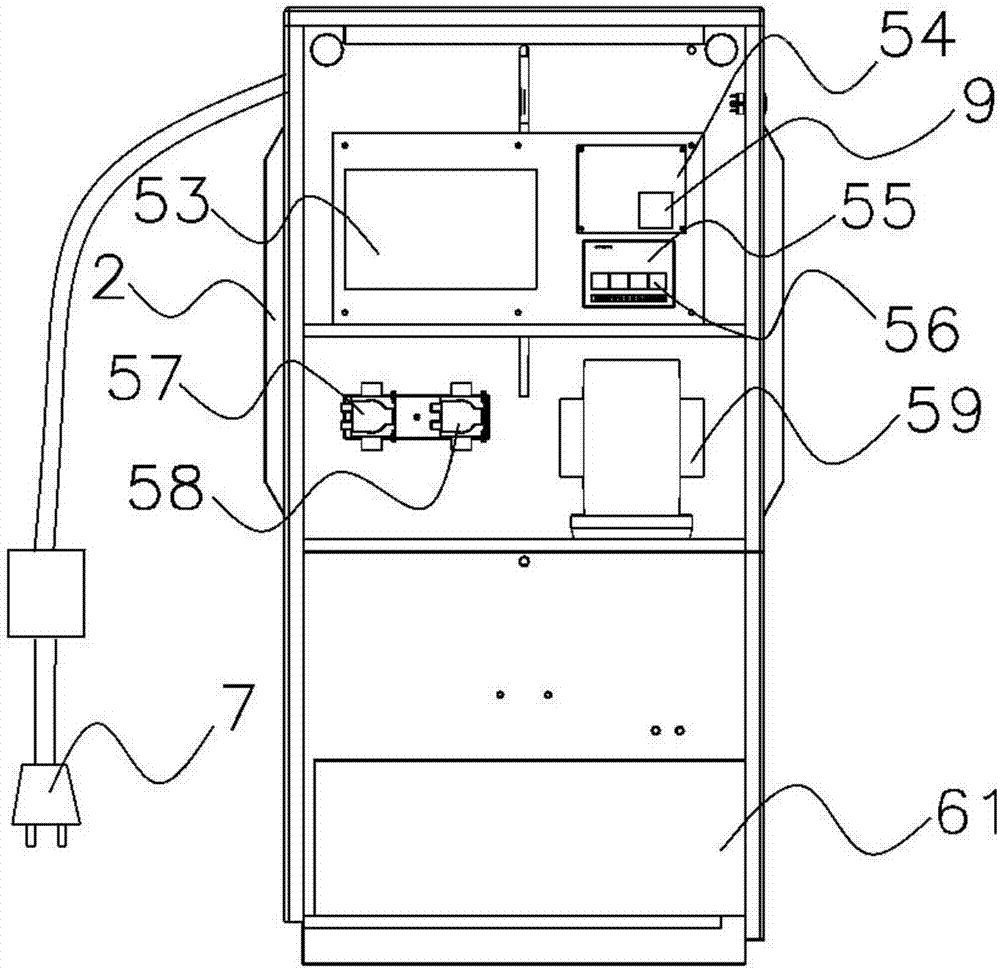

Intelligent-controlled vegetable cultivation plantation apparatus

InactiveCN106922419AFacilitate intelligent managementEfficient and rapid growthSelf-acting watering devicesSaving energy measuresMicrocomputerMicrocontroller

An intelligent-controlled vegetable cultivation plantation apparatus comprisesa growth tank, a control box, a data storage module, a mobile phone app terminal and a light intensity sensor, wherein a plantation groove is formed in the bottom of thegrowth tank; a power supply, a one-chip microcomputer and a relay are disposed in the control case; the power supply is respectively connected with the one-chip microcomputer and the relay; the one-chip microcomputer is connected with a control end of the relay; the power supply is further connected with a power supply plug via a power supply line outside the control box; a WiFi module is further disposed in the control box; the one-chip microcomputer is connected to the internet to be connected with the mobile phone app terminal via the WiFi module; the data storage module and the light intensity sensor are respectively connected with the one-chip microcomputer; an LED light-fill in lamp is arranged on the inner side of the growth tank; and a contact switch of the relay is further disposed in a power supplying circuit of the LED light-fill in lamp. By the use of theintelligent-controlled vegetable cultivation plantation apparatus, problems of low intelligence degree of household vegetable plantation and poor growth conditions can be solved; different optimal parameters required for various vegetables can be intelligently-managed via the mobile phone app and vegetables can be monitored in a remote way; and vegetables can quickly grow with high efficiency.

Owner:上海蔬悦农业科技有限公司

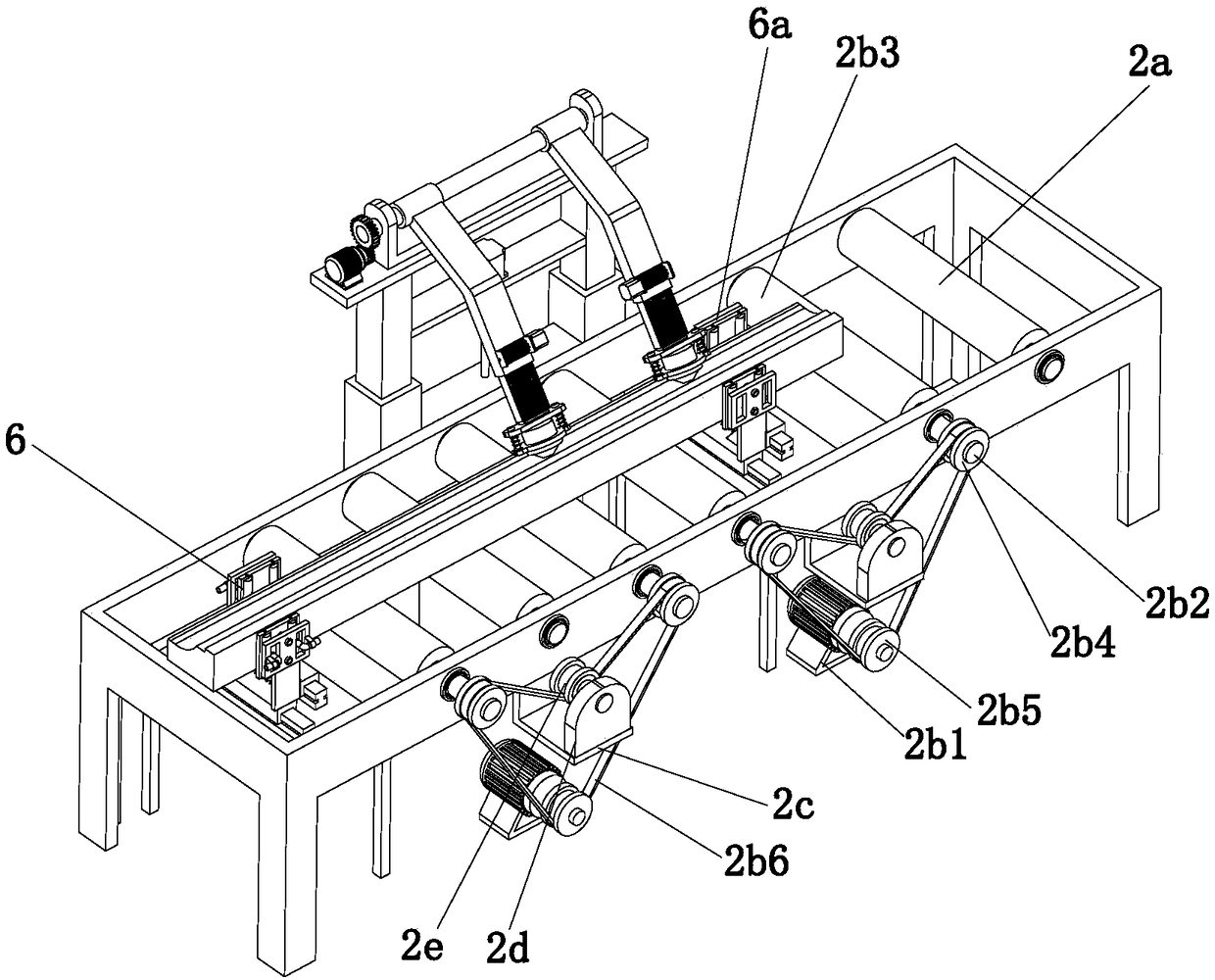

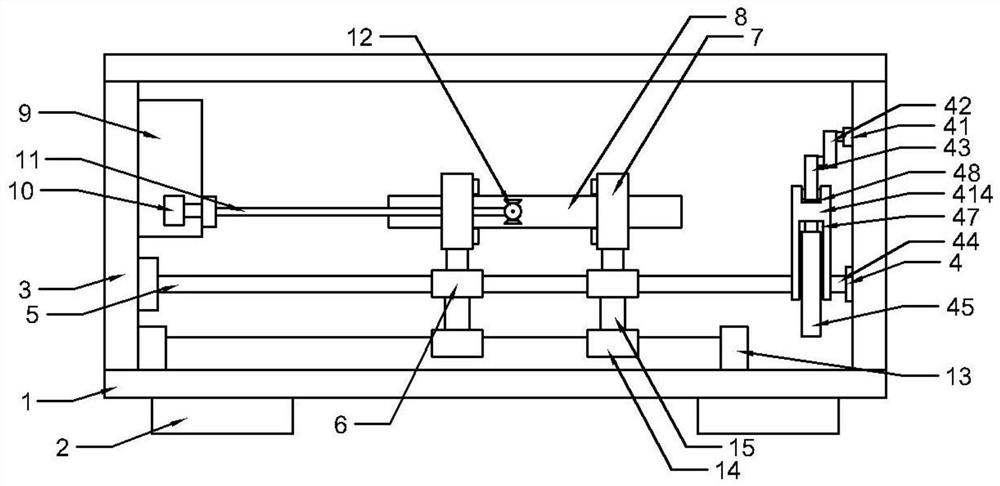

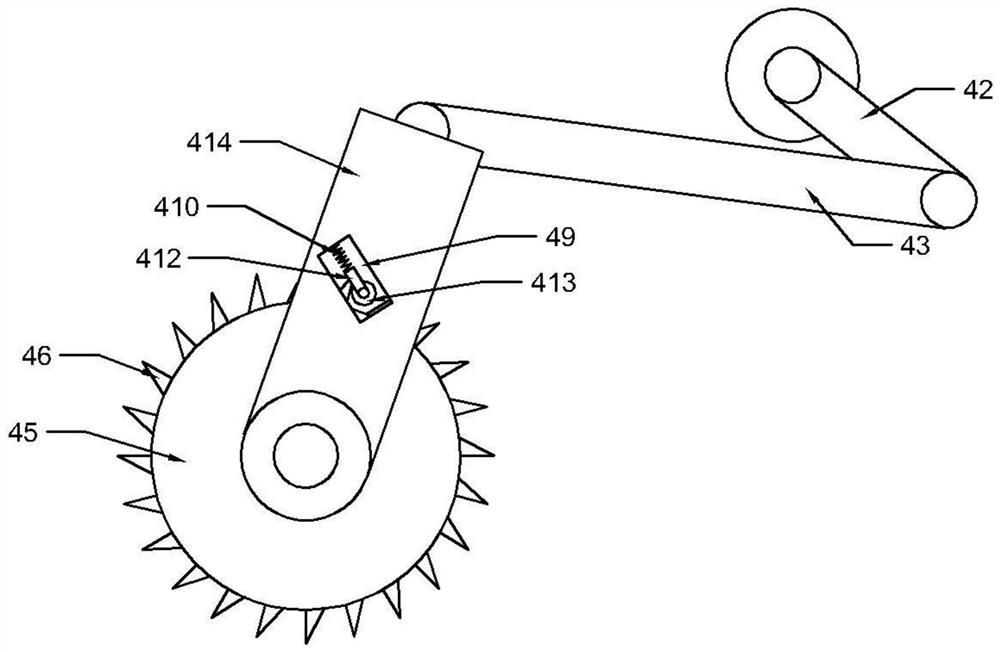

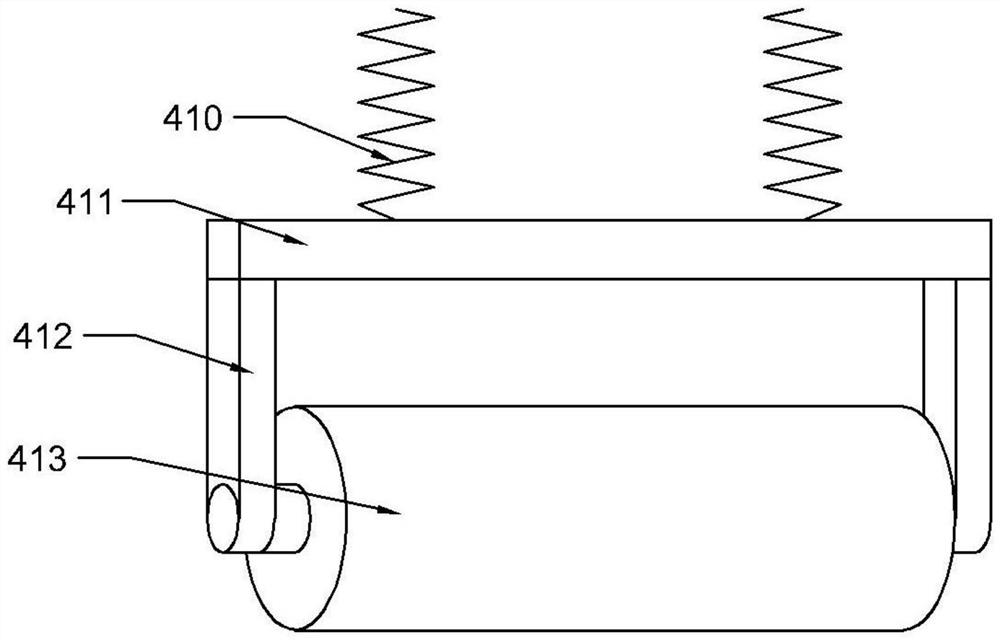

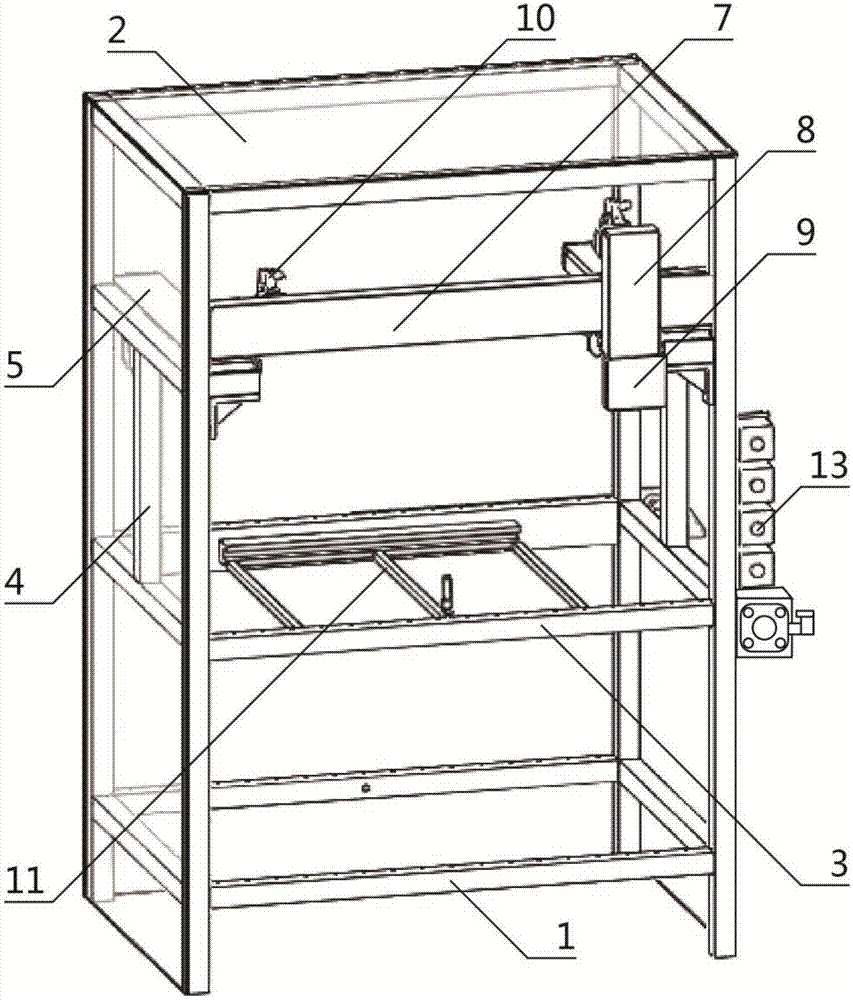

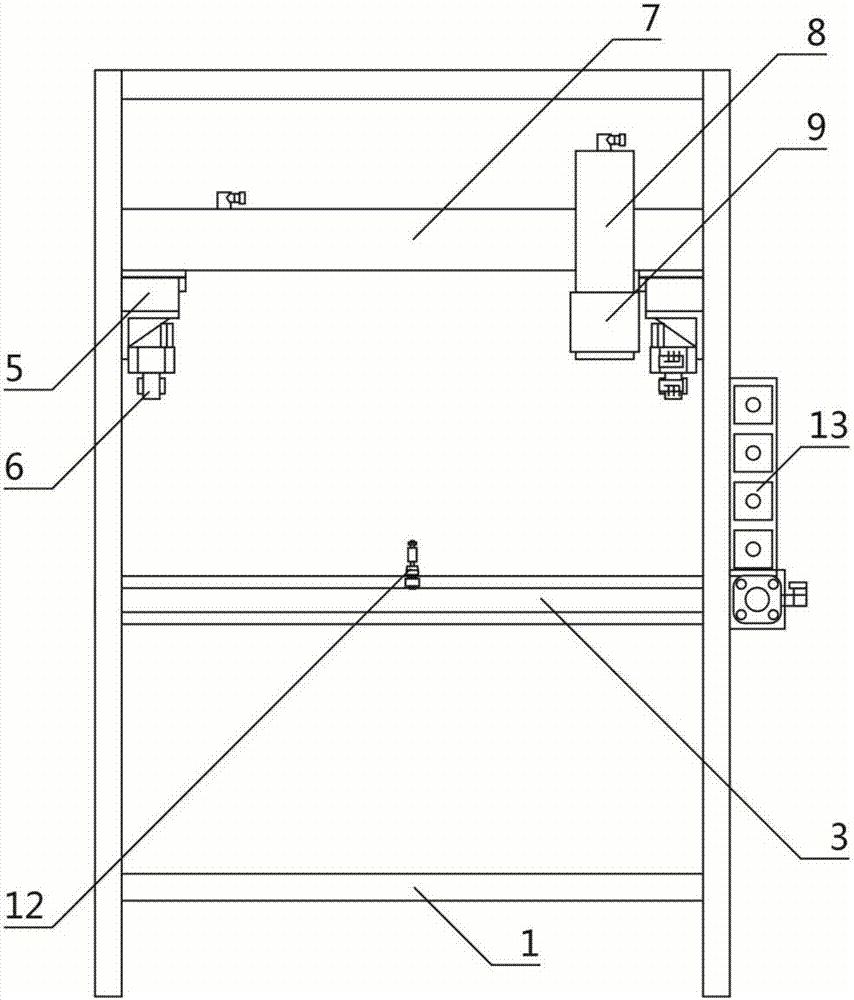

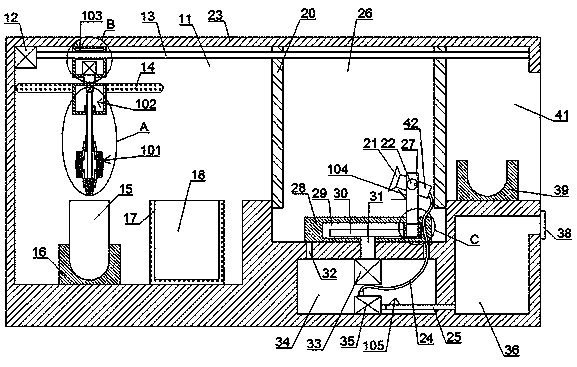

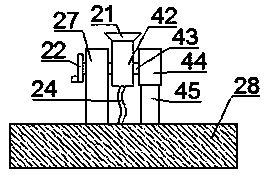

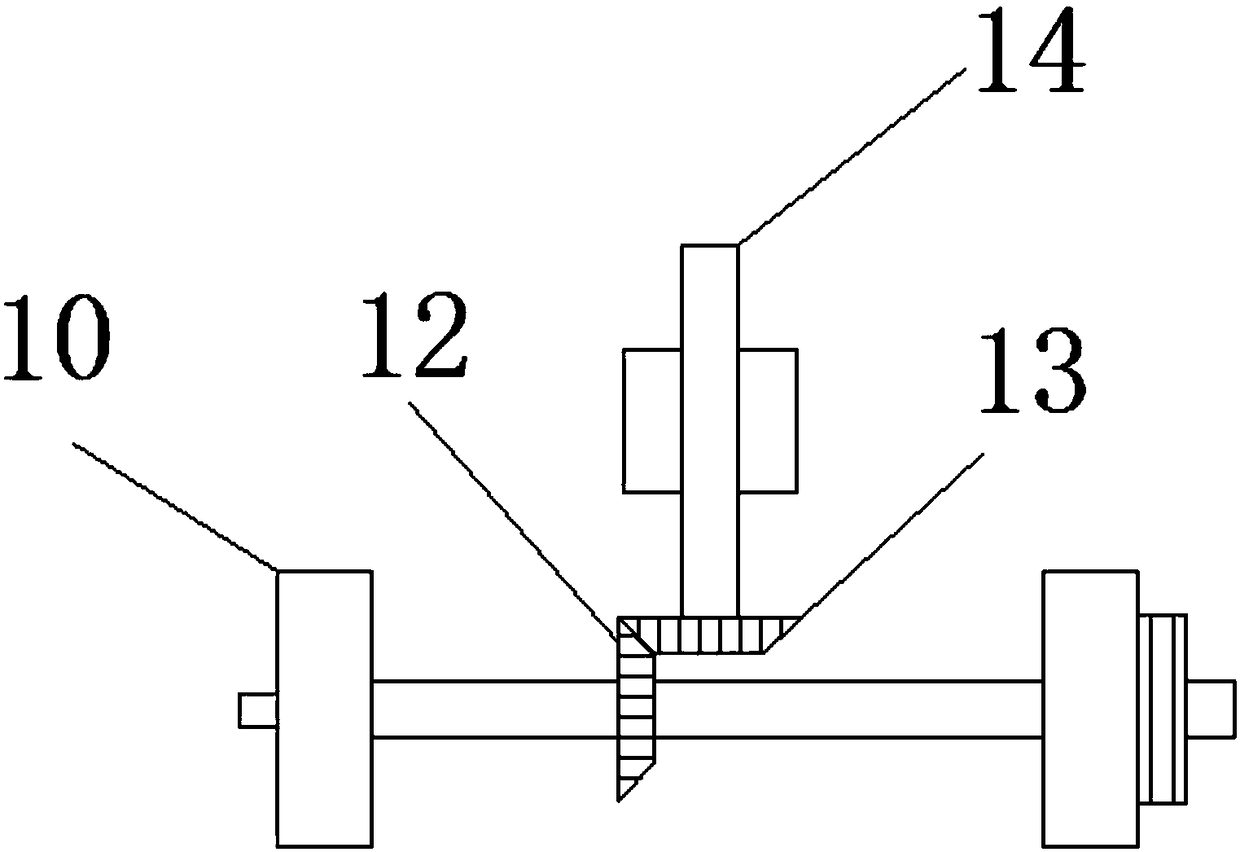

Automatic spraying equipment of architecture moldings

ActiveCN109453918AHigh degree of automationUniform spraying effectLiquid surface applicatorsSpraying apparatusMoving parts

The invention relates to the field of architecture decorative molding production equipment, in particular to automatic spraying equipment of architecture moldings. The automatic spraying equipment comprises a machine frame, a conveying mechanism, a molding limiting mechanism and an automatic spraying mechanism; the molding limiting mechanism comprises a vertical limiting assembly, a first positioning assembly and a second positioning assembly; the first positioning assembly and the second positioning assembly are arranged in a spaced mode and are the same in structure; and the first positioning assembly and the second positioning assembly each comprise a supporting frame, a material moving part and two abutting-contact parts, and the structures of the two abutting-contact parts are the same. The automatic spraying equipment of architecture moldings has the beneficial effects that spraying operation can be performed on the top surface and the side surfaces of a workpiece through the automatic spraying mechanism, a worker does not need to perform extra spraying operation on the side surfaces of the workpiece, the moldings which are different in size can be vertically limited and transversely limited through the molding limiting mechanism, spraying operation can be performed on the moldings which are different in size, and the hidden danger that the moldings deviate during transportation is avoided.

Owner:浙江中乐建设有限公司

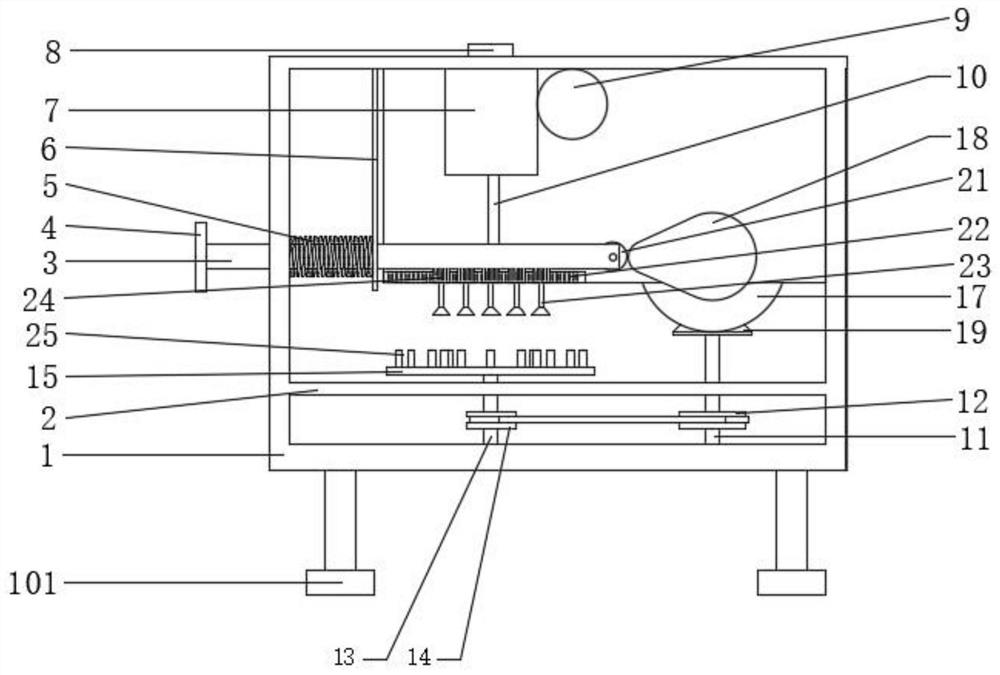

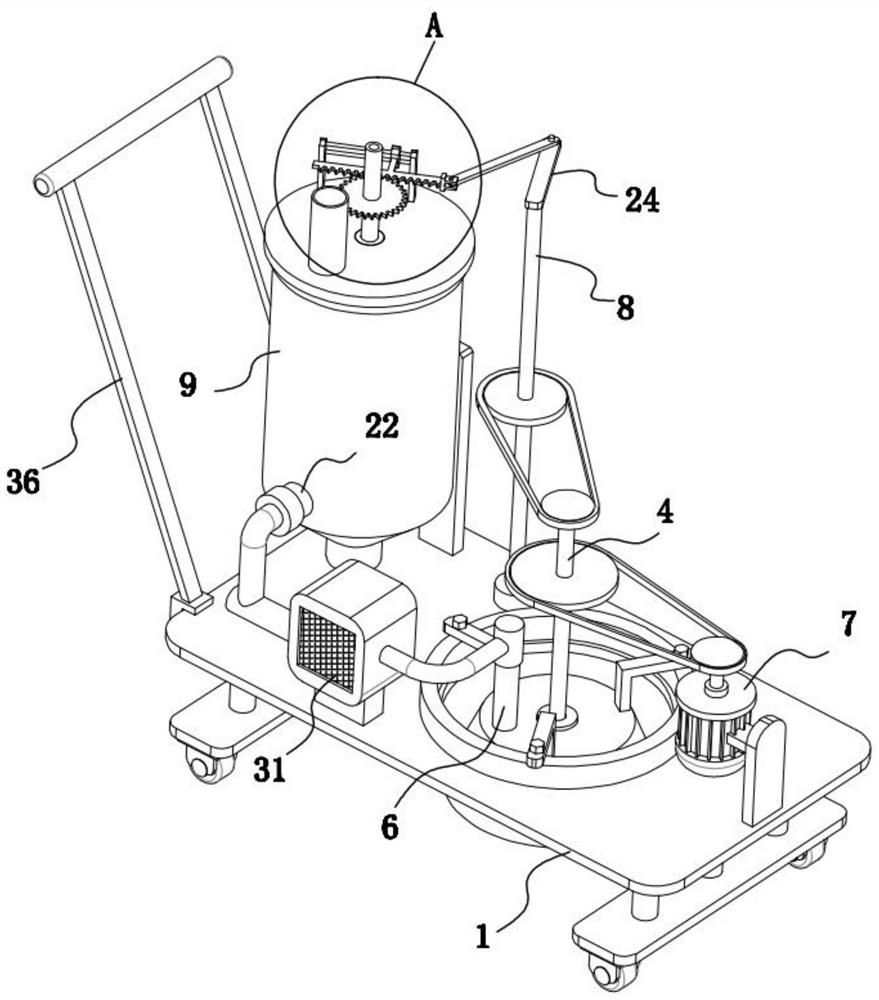

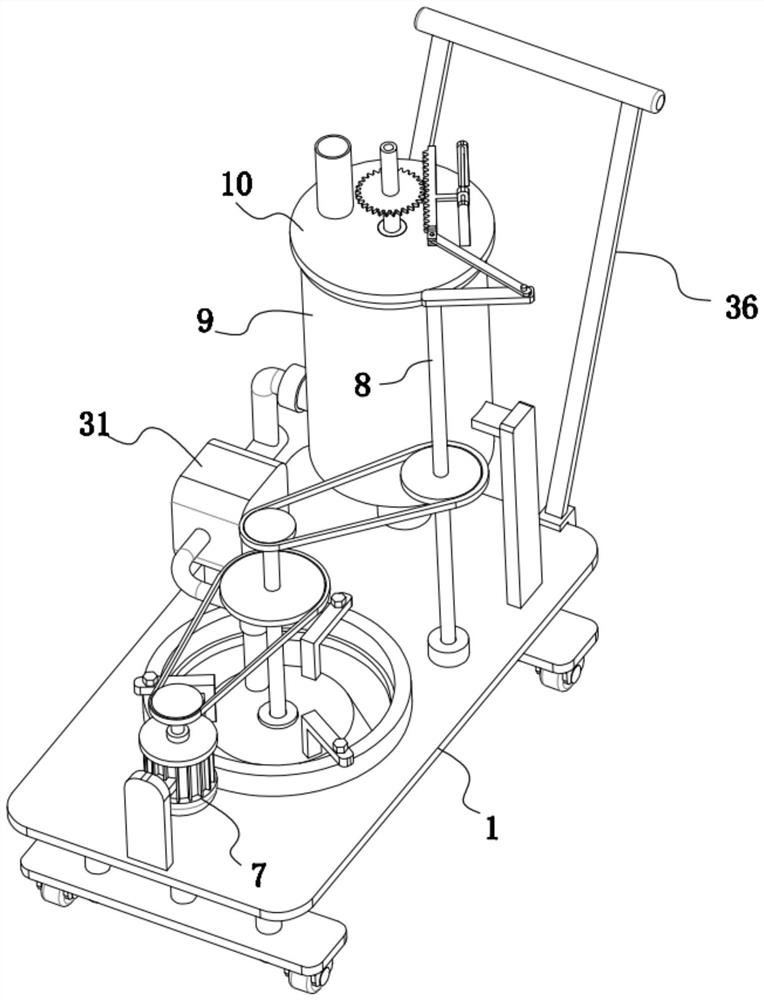

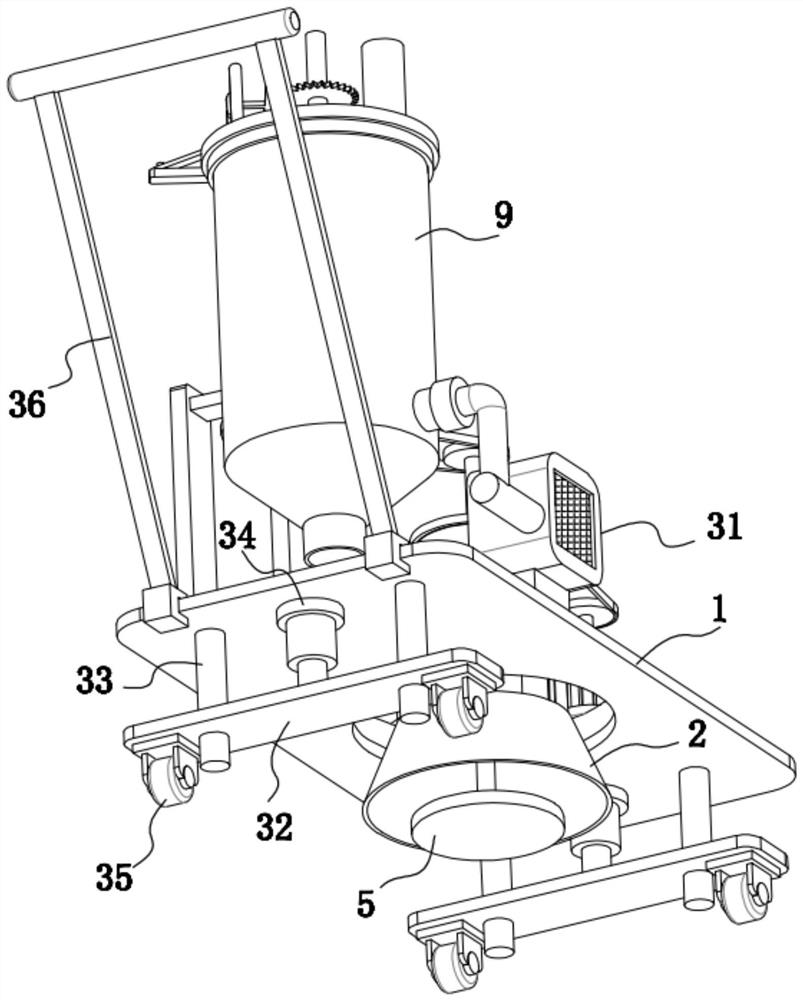

Spraying device in production system of hub bearing

InactiveCN111889260ASpray evenlyPrevent slipping outSpraying apparatusElectric machineryStructural engineering

The invention discloses a spraying device in a production system of a hub bearing, and belongs to the technical field of spraying. The spraying device in the production system of the hub bearing comprises a box body, wherein a motor is fixedly connected to the inner wall of the box body, the output end of the motor is fixedly connected with a first bevel gear and a cam, a first rotating shaft is rotationally connected to the inner wall of the box body, a first belt wheel and a second bevel gear are fixedly connected to the outer wall of the first rotating shaft, a second rotating shaft is rotationally connected to the inner wall of the box body, a second belt wheel and a discharging disc are fixedly connected to the outer wall of the second rotating shaft, a stabilizing plate is fixedly connected to the inner wall of the box body, a sliding rod is connected to the box body in a sliding mode, a spray head is rotationally connected to the outer wall of the sliding rod, a roller is rotationally connected to the sliding rod, the roller abuts against the cam, and a return spring is connected to the sliding rod in a sleeving mode. The spraying device in the production system of the hub bearing has the advantages that the spraying device is simple and convenient to operate, high in spraying efficiency and uniform in spraying effect, the labor cost is reduced, the time is saved, the production speed is increased, and the income of enterprises is increased.

Owner:彭珍

Production process of aluminum-plastic plate

The invention discloses a production process of an aluminum-plastic plate, and relates to the technical field of production and manufacturing of the aluminum-plastic plates. According to the technicalscheme, the production process is characterize by comprising the following steps that (1) mixing and stirring are performed; (2) extruding and piece making are performed; (3) aluminum plate degreasing is performed; (4) aluminum plate formation treatment is performed; (5) adhesive coating and compounding are performed; and (6) a protection film is compounded. According to the production process, the problem that the phenomenon of glue failure or falling off of an aluminum plate and a plastic core material due to poor bonding of the aluminum plate and the plastic core material is prone to occurrence during compounding of the aluminum plate and the plastic core material by using a polymer film is solved, the aluminum plate and the plastic core material are bonded and compounded by using adhesives, and air exhaust and dust removal operation is carried out so that the aluminum plate and the plastic core material can be tightly bonded, and glue failure or falling off of the aluminum plate and the plastic core material can be prevented.

Owner:台州市佳信新材料科技有限公司

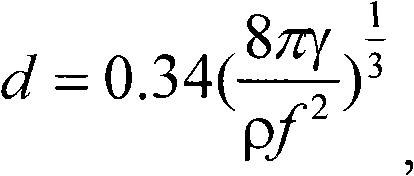

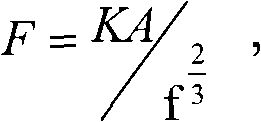

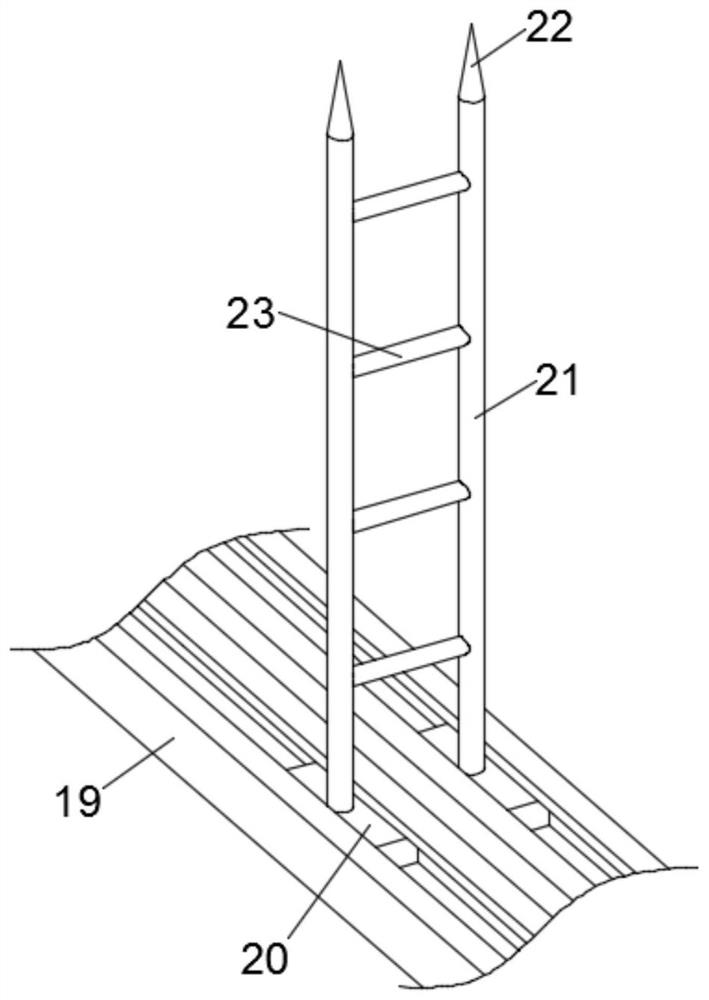

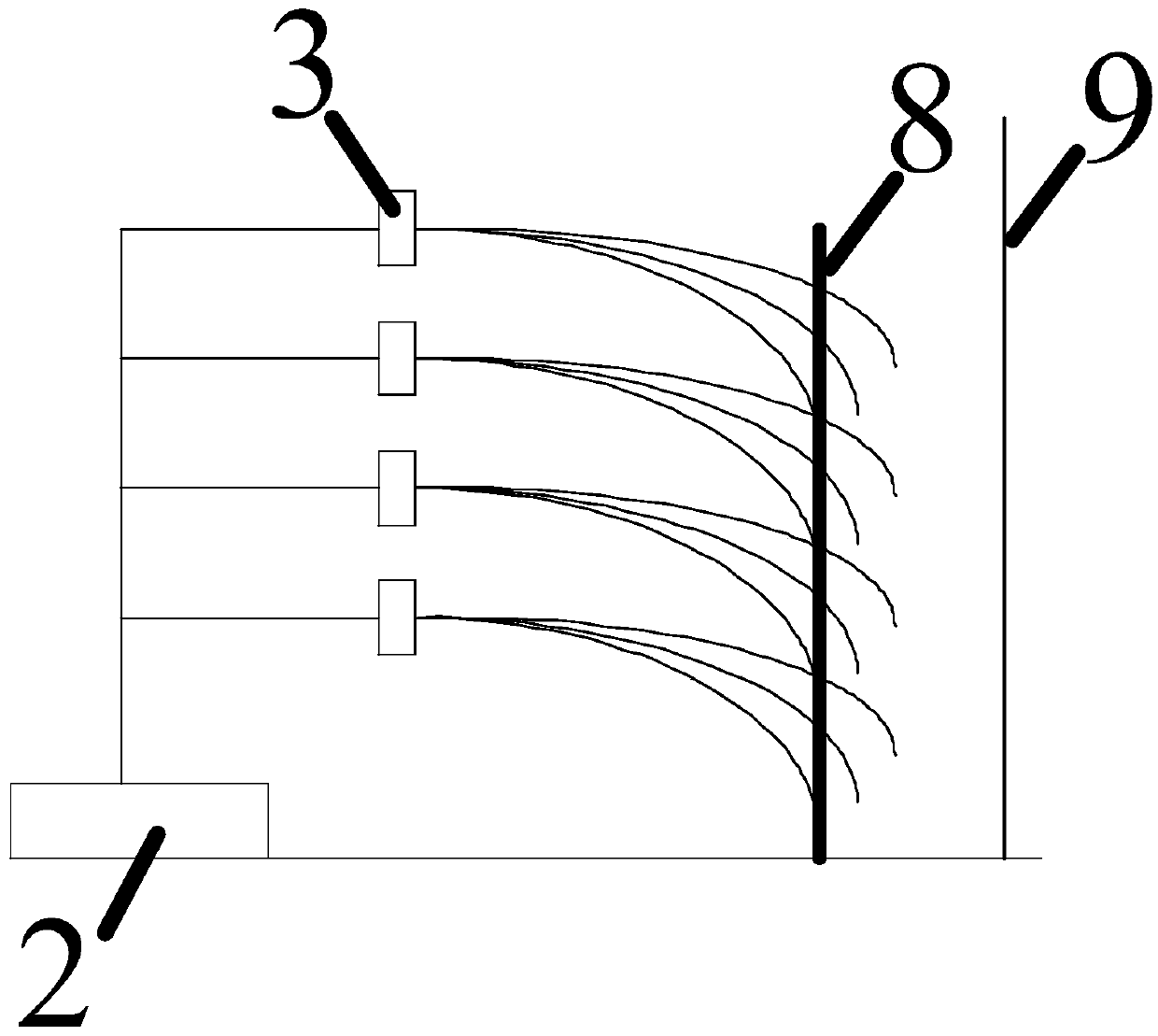

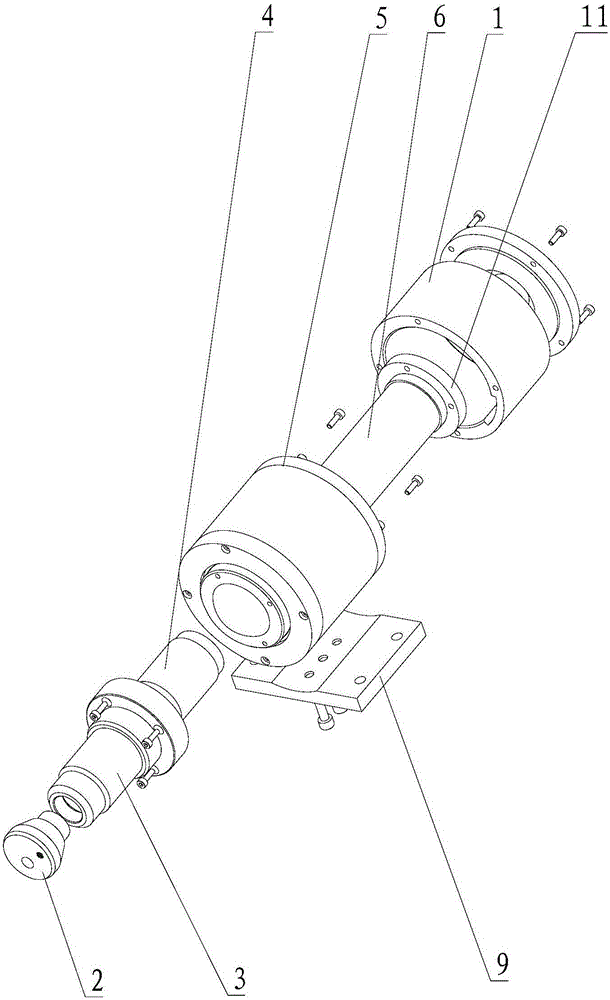

Thin and long inner hole workpiece spraying construction device and spraying method adopting same

PendingCN110216033AUniform sand productionMeet the requirements of different diameter inner holesSpraying apparatusEngineeringMechanical engineering

Owner:JIANGSU JIXIN WIND ENERGY TECH

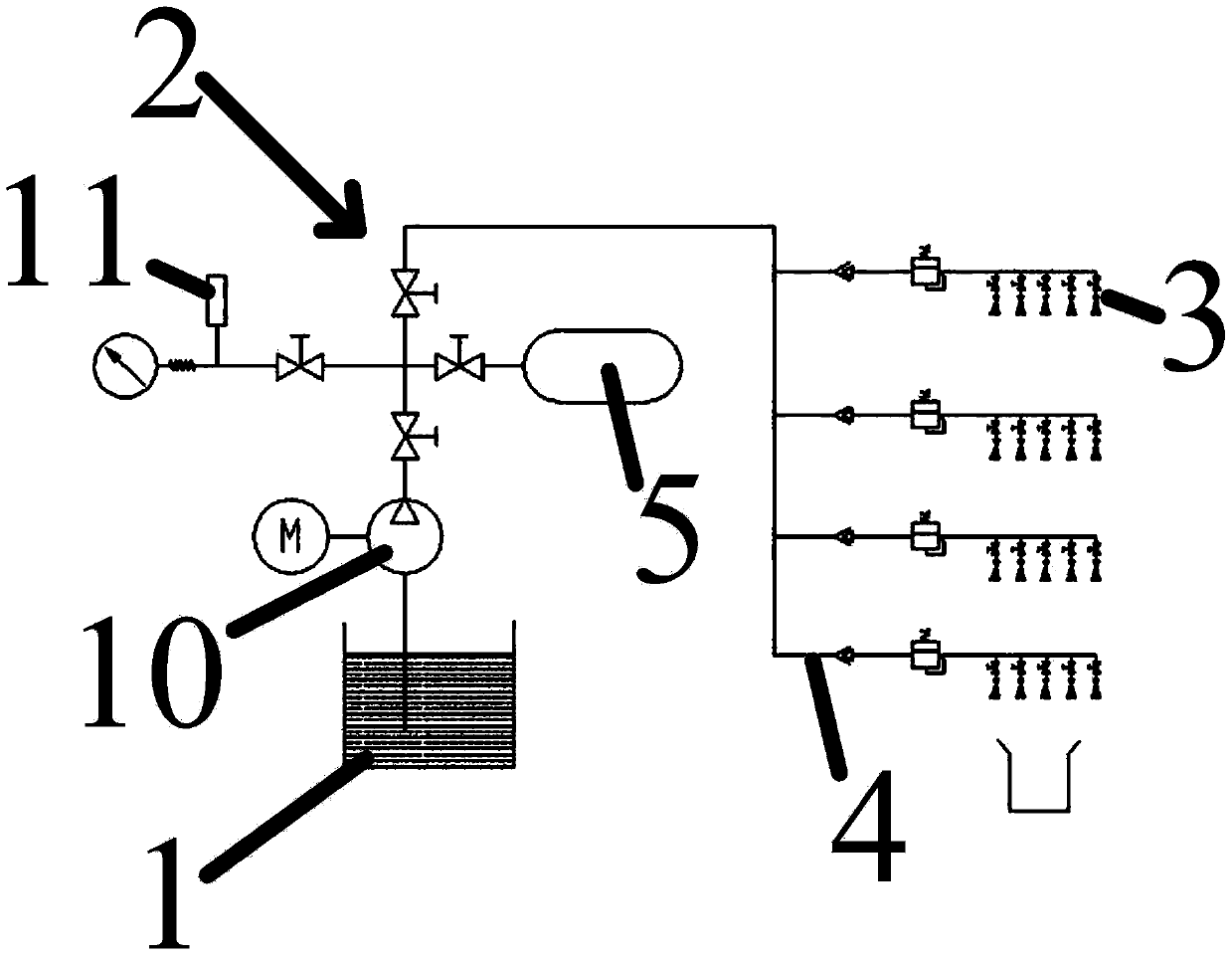

Simulation rainfall test device used for electric device

PendingCN105572497AImprove workabilityReduce wasteEnvironmental/reliability testsHigh pressureWater spray

The invention relates to a simulation rainfall test device used for an electric device. The test device comprises a water tank, a water transmission member and water spraying mechanisms, which are successively arranged. The water transmission member comprises a water pump and a buffering assembly. The water pump is connected with the water tank and parallel-connected water spraying branches. The buffering assembly is arranged between the water pump and the buffering assembly. Each of the water spraying members comprises a valve and a nozzle movably connected with a corresponding branch. According to the invention, it is ensured that a high-voltage electric device can get wet in the simulation rain satisfying requirements during an electric test in a rainfall state and reliability of the device in a natural rainfall condition is verified.

Owner:CHINA ELECTRIC POWER RES INST +1

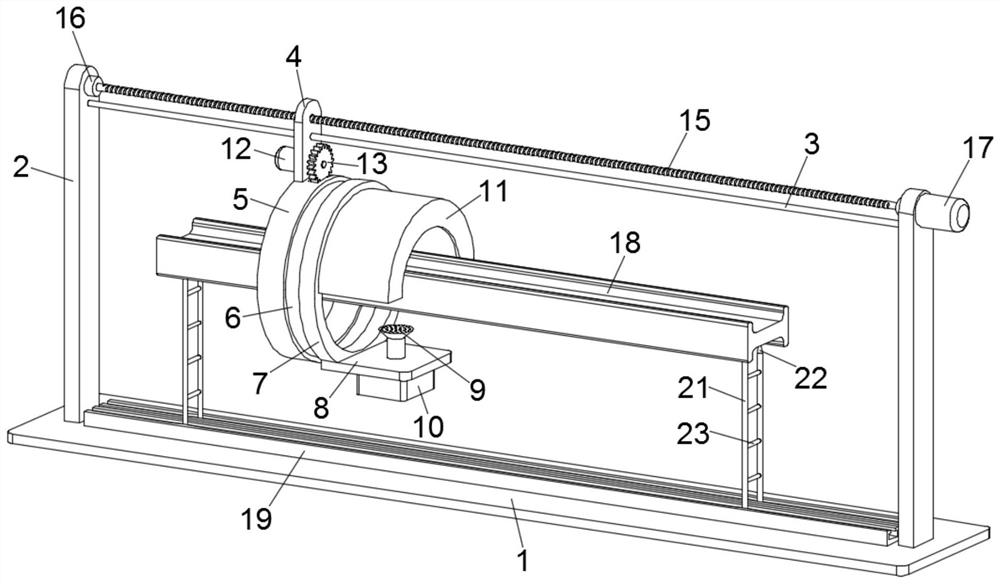

Adjustable pipe interior spraying device

InactiveCN112427195AUniform spraying effectWide applicabilitySpraying apparatusPipe fittingScrew thread

The invention is suitable for the field of pipe fitting spraying, and provides an adjustable pipe interior spraying device. The device comprises a bottom plate, wherein a supporting base is installedat the bottom of the bottom plate, a machine box is installed above the bottom plate, an intermittent rotating device is installed on the side portion of the machine box, a threaded rod is fixedly installed on the intermittent rotating device, the end, away from the intermittent rotating device, of the threaded rod is connected with the side wall of the side, away from the intermittent rotating device, of the machine box through a bearing, the threaded rod is sleeved with a threaded block, a fixing device is installed on the threaded block, and a pipe is arranged in the fixing device; and a coating box is fixedly installed on the side wall of the machine box, the fixing device is modified, so that the device can be suitable for various pipes of different specifications, the applicability of the device is wider, meanwhile, the pipes can be driven to advance at equal intervals through the intermittent rotating device, and the device can make the spraying effect in the pipe more uniform,and the spraying density is identical.

Owner:SUZHOU WABOTE INTELLIGENT TECH CO LTD

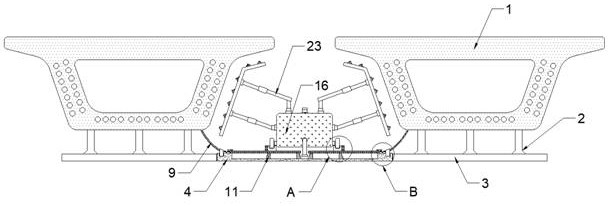

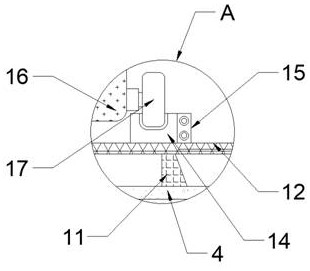

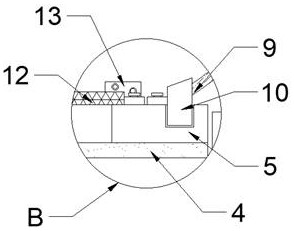

Energy-saving spraying system for precast beam maintenance

ActiveCN113211617AEfficient recyclingReduce wasteCeramic shaping apparatusDrive wheelWater resources

The invention discloses an energy-saving type spraying system for precast beam maintenance. The energy-saving type spraying system comprises precast beam bodies and water tanks; the lower ends of the precast beam bodies are placed on supporting plates through supporting legs, and the supporting plates are placed on the ground; a guide mechanism is arranged between every two supporting plates, and each guide mechanism is of an annular structure on the whole, wherein the two sides of each guide mechanism are parallel to the corresponding supporting plate, and the front end and the rear end of each guide mechanism are each of a semicircular structure; and each water tank is arranged at the position between every two precast beam bodies, and driving wheels used for walking are installed at the lower ends of the water tanks. According to the energy-saving type spraying system for precast beam maintenance, water resources can be effectively recycled and reused, waste of the water resources is reduced, spraying can be conducted on the side faces of two sets of precast beams at a time, and the spraying efficiency is improved; and the whole system is of a detachable structure, can be detached after being used, and is suitable for spraying of other precast beams.

Owner:黑龙江省铁投预制构件有限公司

Plasma surface treatment apparatus

ActiveCN106102296AIncrease speedGood adhesionElectric discharge tubesPlasma techniqueSpray nozzleEngineering

The invention relates to a plasma surface treatment device which comprises a shell, a plasma nozzle, a rotating neck, an insulator, a driving mechanism, an ionization mechanism, a metal member and an electrode. A power output shaft of the driving mechanism, the insulator and the ionization mechanism are respectively hollow structures. The metal member is arranged in the hollow structure of the insulator, and the metal member is a hollow annular structure. The electrode is arranged in the hollow portion of the metal member which is provided with two or more gas exhaust holes. The surfaces of the hole walls of the gas exhaust holes are disposed obliquely toward the direction of the plasma nozzle. The plasma surface treatment device of the present invention has the advantages of a more uniform spraying effect, less noises, effective reduction of loss and cost reduction.

Owner:深圳市诚峰智造有限公司

Oil spraying processing equipment for headphone cable

InactiveCN107971172ABetter and more uniform spraying effectSuppress splashSpraying apparatusProduct processingMoving frame

The invention aims to provide oil spraying processing equipment for a headphone cable. According to the technical scheme, the oil spraying processing equipment is composed of a frame body, a rotary fixing frame, horizontal spraying support frames, second horizontal displacement slide ways, a first horizontal displacement slide way, a spraying horizontal-moving frame, a spraying rotary frame and anelectric control device, wherein a spraying gun fixing frame is arranged on the spraying horizontal-moving frame, a rotary recognizer is arranged on the spraying rotary frame, and a spraying limitingdevice is arranged on each second horizontal displacement slide way. The oil spraying processing equipment is automatic processing equipment for carrying out turnover spraying on the mobile phone headphone cable, spraying of all angles in the spraying area at the horizontal position can be realized; the four side surfaces of the frame body are each provided with a protective layer, so that splashing of spraying sprays can be prevented, and therefore the operation environment can be protected; and the equipment has the advantages of being clear in structural idea, simple and convenient to operate, high in spraying precision, comprehensive in spraying area, capable of achieving the constant-speed turnover function and accurate in positioning, the product is not deformed, and the product processing quality can be improved.

Owner:SYNERGY HANIL PRECISION POLYMER TECH CO LTD

Paint spraying device for cutter base body of shield tunneling machine

PendingCN113769929AUniform spraying effectGood spray effectLiquid spraying plantsPretreated surfacesStructural engineeringShield tunneling

The invention discloses a paint spraying device for a cutter base body of a shield tunneling machine. The paint spraying device comprises a box body, a paint spraying chamber is arranged in the box body, a partition plate is arranged on the left side of the paint spraying chamber, a fixing mechanism is arranged on the partition plate, the cutter base body is fixed to the fixing mechanism, a rotating motor is arranged on the left side of the partition plate, the output end of the rotating motor penetrates through the partition plate and is connected with the fixing mechanism, an arc-shaped first sliding rail is fixed to the top of the paint spraying chamber through a vertical rod, a sliding block is mounted on the first sliding rail in a sliding mode, and an electrostatic spraying head is fixed to the bottom of the sliding block. The cutter base body is fixed through the fixing mechanism, and then the cutter base body is driven to rotate through the rotating motor, so that the spraying effect is more uniform; the electrostatic spraying head is arranged on the arc-shaped first sliding rail in a sliding mode and slides back and forth for spraying of the surface of the cutter base body, it can be guaranteed that all the surfaces can be evenly painted, the spraying effect is good, and the probability of later supplementary spraying is reduced.

Owner:浙江福仑德重工有限公司

Grinding machine for shipbuilding

InactiveCN112355898ASlow ascentImprove dust removal effectGrinding/polishing safety devicesDrive shaftDust control

The invention relates to the technical field of shipbuilding, in particular to a grinding machine for shipbuilding. A grinding disc coaxial with a driving shaft is fixedly installed at the bottom endof the driving shaft, a plurality of L-shaped fixing plates which are evenly distributed are fixedly installed on the surface of the top end of a dust hood in the circumferential direction, each L-shaped fixing plate is fixedly connected to a workbench through a bolt, a motor in transmission connection with the driving shaft is fixedly installed on a workbench, a communicating pipe communicating with the interior of the cover body is fixedly arranged at the top end of the dust hood, a spraying dust removal module in transmission connection with the driving shaft is fixedly installed on the workbench, an exhaust fan is further fixedly installed on the workbench, the air inlet end of the exhaust fan is connected with the communicating pipe through a pipeline, and the air outlet end of the exhaust fan is connected with the air inlet end of the spraying dust removal module through a pipeline. According to the grinding machine, air can be efficiently and sufficiently dedusted through the spraying dust removal module while grinding is conducted, the air quality in the working environment is effectively improved, and the body health of workers is guaranteed.

Owner:齐杰

Wall surface painting device

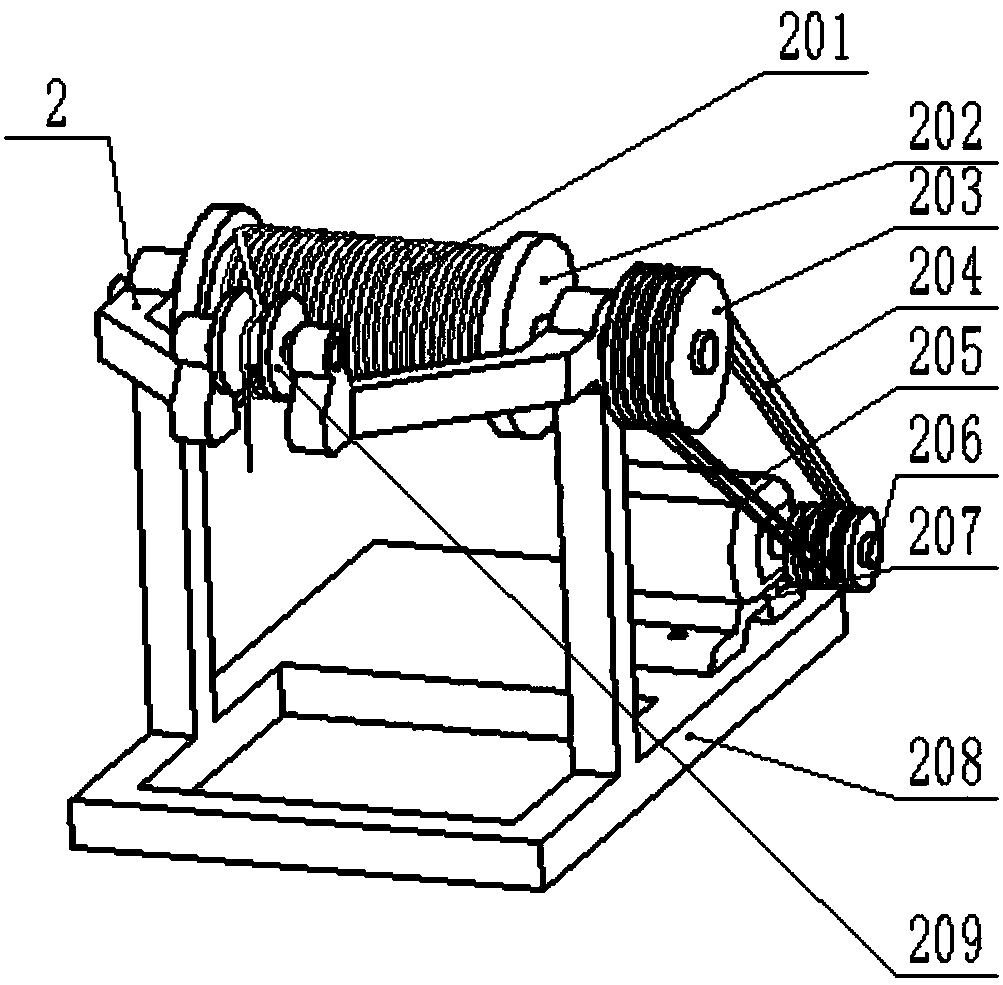

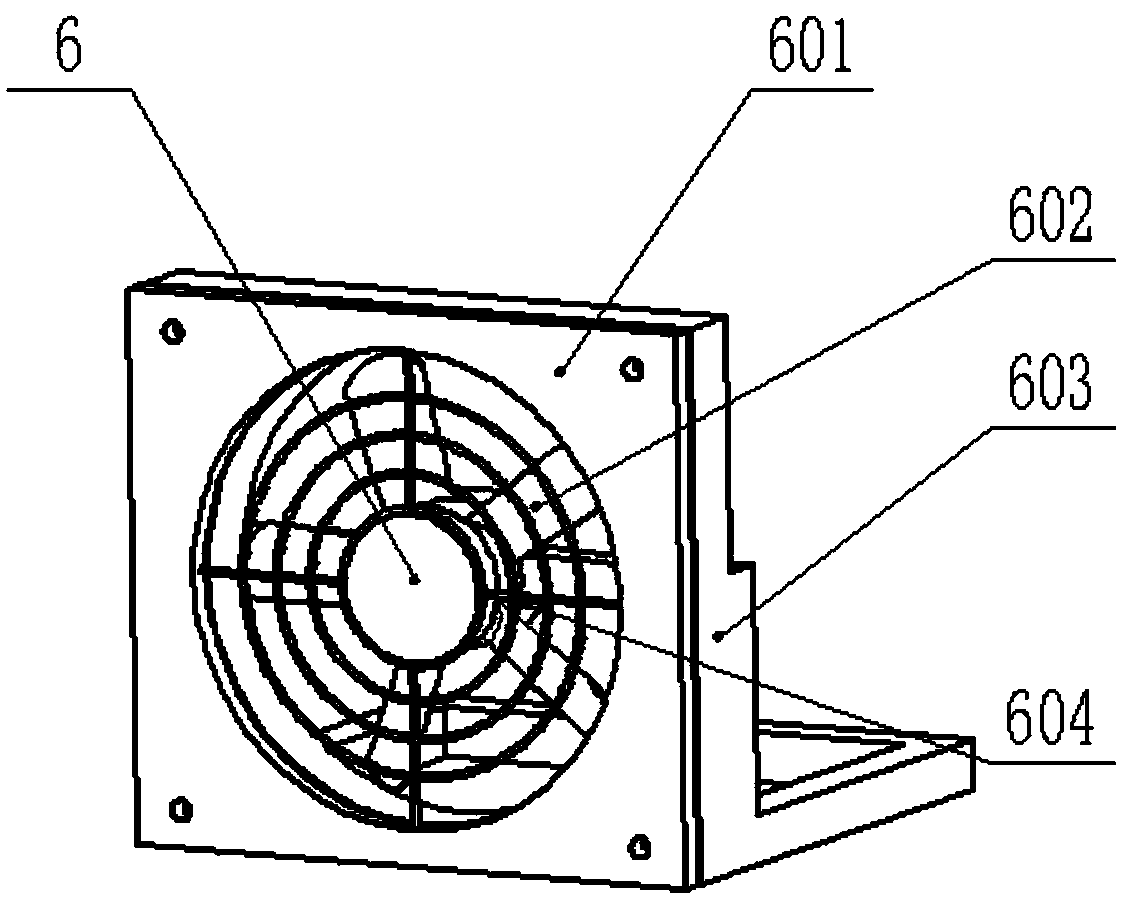

The invention relates to a wall surface painting device, and belongs to the field of high-rise building construction equipment. The device is composed of a rope winding device, a drying device, a painting device and a shell; when high-rise building outer wall surface painting operation is conducted, workers do not need to work at heights under bad working conditions, the work efficiency is improved compared with that of manual operation, operation is easy, and only few workers can complete wall surface painting operation; the painting device is provided with the drying device which can dry thewall surface obtained after painting, wheels are arranged at the upper end and the lower end of the painting device respectively, the painting device closely fits the wall surface to make the painting operation stable, the distance between a spray nozzle to the wall surface is controlled, the spraying effect is uniform, a charging basket of the painting device is internally provided with a stirring device and an air compression device, paint grains can be smaller, more uniform and easier to adhere to the wall surface, and the ground ash phenomenon is effectively reduced; the device is time saving and labor saving, and the risk of the painting operation can be greatly lowered.

Owner:杨晖

A spraying device based on solar vacuum tube heat-absorbing coating

ActiveCN110314805BStable clampingGuarantee personal safetyLiquid surface applicatorsCoatingsEngineeringMechanical engineering

The invention discloses a spraying device based on a heat-absorbing coating of a solar vacuum tube, which comprises a main body, the main body is provided with a gluing chamber with an opening forward, and a first placement is fixed on the bottom wall of the gluing chamber. Seat, the top surface of the first placement seat can place a vacuum tube, the first placement seat can slightly clamp the vacuum tube, and the upper side of the vacuum tube is provided with a clamping block that can press against the inner wall of the vacuum tube, so There are two groups of clamping blocks symmetrically arranged on the left and right. The invention can make the spraying process of the heat-absorbing coating on the outer periphery of the solar vacuum tube more convenient and easy. Just place the vacuum tube in the device, and the device can directly and automatically run the one-step forming spraying process. And the spraying effect is more uniform and perfect, and the whole inventive device makes the spraying process more green and environmentally friendly, ensuring the personal safety of operators.

Owner:磐安秀吉新能源科技有限公司

Multi-functional watering lorry

InactiveCN109220729ASave spaceReduce lossesWatering devicesRoad cleaningDrive wheelWater storage tank

The invention discloses a multi-functional watering lorry. The multi-functional watering lorry comprises a water storage tank and a lorry base, wherein a water conveying cylinder is vertically arranged on the bottom of the upper plane of the water storage tank, the front end and the rear end of the lorry base are provided with a front wheel axle and a rear wheel axle respectively, a piston plate is arranged in the water conveying cylinder, and the bottom of the piston plate is connected with a piston rod. The front wheel axle is connected with a second drive rod, the left end of a first driverod is connected with the bottom of the piston rod, a fixing plate is transversely installed in the middle of the left wall of the water storage tank, and the tail end of the fixing plate is providedwith a shaft sleeve. A rotary shaft penetrates through the shaft sleeve, the bottom of the rotary shaft is provided with a driven bevel gear, a drive bevel gear is installed in the middle of the rearwheel axle, and the driven bevel gear is in gear engagement with the drive bevel gear. According to the multi-functional watering lorry, through a linkage rod drive mechanism, transmission of a driving wheel axle and a spraying mechanism can be synchronously conducted, the space of a lorry body is saved, energy loss is reduced, and therefore, the energy-saving and environment-friendly effects areachieved.

Owner:孙冉冉

Board paint spraying process

InactiveCN105478328AFull accessConvenient painting operationPretreated surfacesCoatingsVarnishMaterials science

The invention provides a board paint spraying process, relating to the field of wood processing. The board paint spraying process comprises the following steps: (1) coarse grinding; (2) puttying; (3) fine grinding; (4) drying; (5) varnishing; (6) paint spraying. Through the multiple steps of operation processing, a board is not easily deformed, the sprayed paint adhered to the board surface is more uniform, the sprayed paint of the board surface is uniformly adhered, is not easy to shed and is bright in color, and the aesthetics is enhanced. The whole process is easy to operate, is reasonable in design, and is facilitated to be further promoted and applied.

Owner:GUANGDE CHANGFENG BAMBOO IND PROD CO LTD

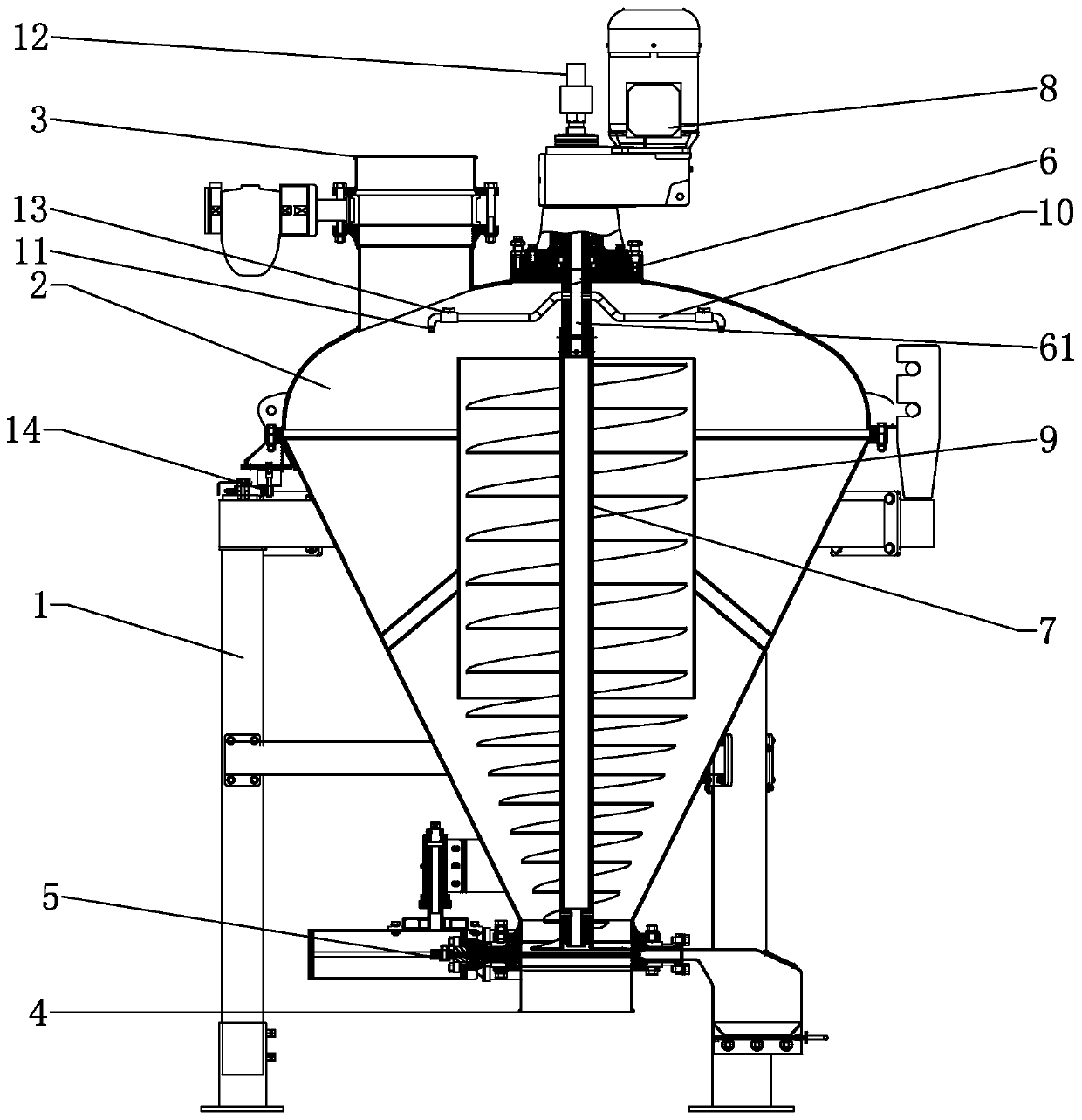

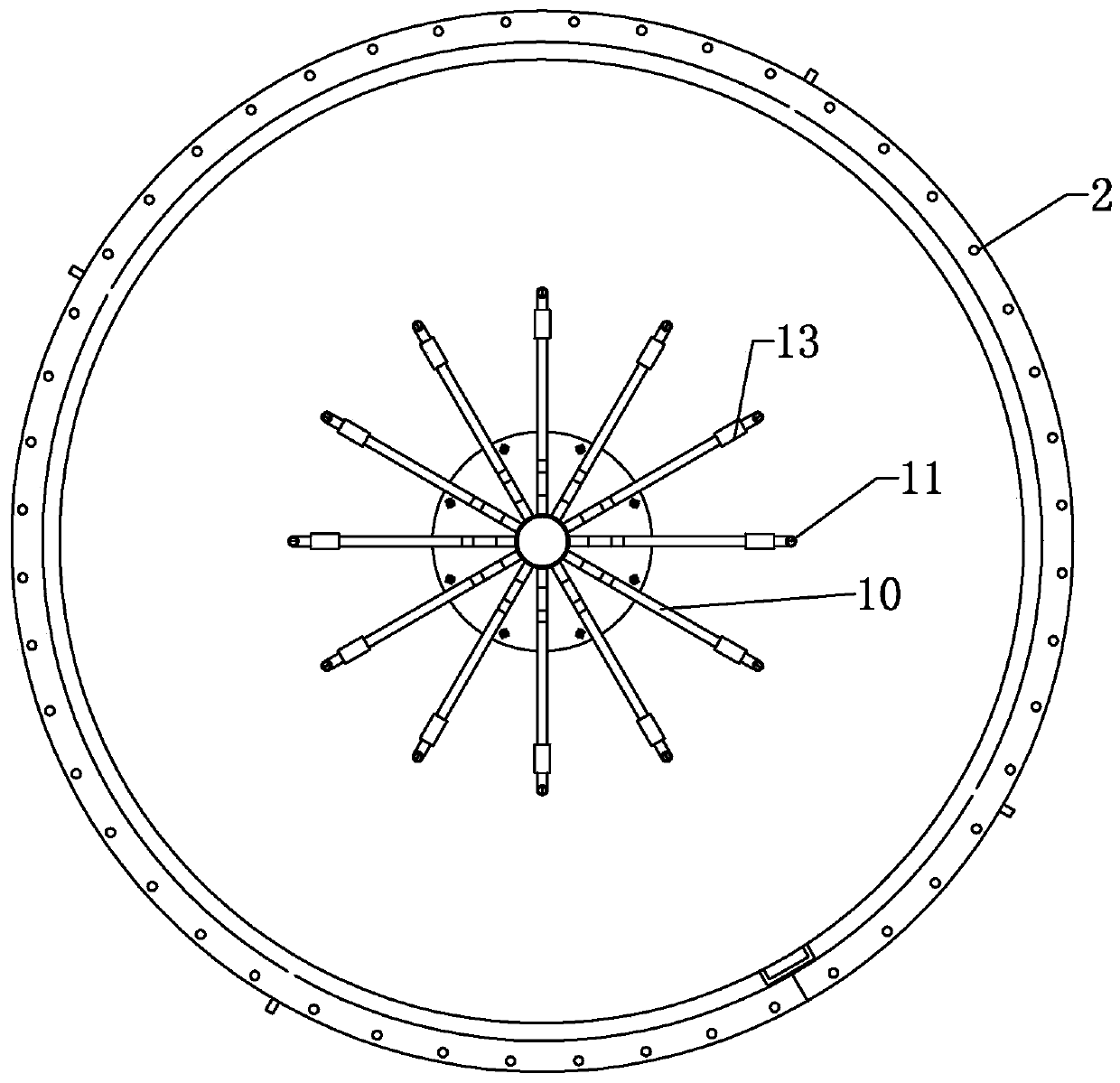

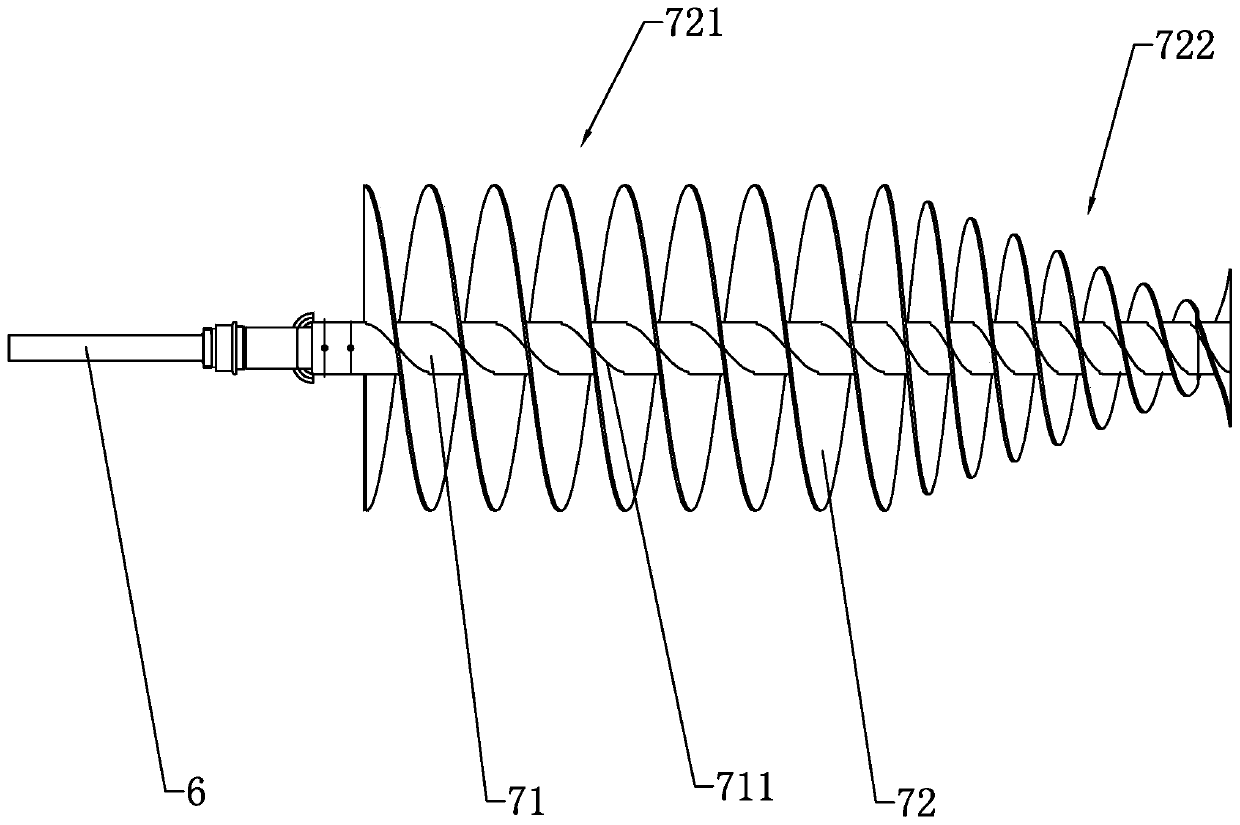

High-efficiency spraying device

PendingCN110665711AStrong spraying abilityUniform spraying effectSpraying apparatusPhysicsEngineering

The invention discloses a high-efficiency spraying device and belongs to the technical field of spraying equipment. The high-efficiency spraying device comprises a conical tank body, wherein the tankbody is provided with a feeding port and a discharging port, a pneumatic gate is arranged at the discharging port, an auger is arranged in the tank body, a distribution ring is fixed in the tank body,the auger is sleeved with the distribution ring, a linkage shaft is rotatably connected in the tank body, one end of the auger is connected with the linkage shaft, a spraying mechanism is arranged onthe linkage shaft, and a driving piece for driving the linkage shaft to rotate is arranged on the tank body. Compared with the prior art, combination of circulating throwing of the auger with dynamicrotary spraying of the spraying mechanism can show great spraying capability, and the spraying effect is extremely uniform.

Owner:广州百海工程机械有限公司

Stripable paint for laser impact treatment

This invention discloses a strippable coating for laser shock processing, which is composed of carbon powders 5-15 wt.%, bonding agent 50-70 wt.%, self-drying thinner 15-35 wt.% and additive 2-5 wt.%. The thickness of the coating layer is generally 60-150 mums. The strippable coating is manufactured by: (1) placing carbon powders in a reactor, and adding bonding agent, self-drying thinner and additive; and (2) stirring uniformly, and adjusting the pH value to 7.5 with 25% ammonia solution. The strippable coating can intimately adhere to the surface of metals, and cannot be stripped during continuous laser shock process, thus having a good shock effect.

Owner:JIANGSU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com