Steel structure paint spraying device

A technology of steel structure and nozzle, applied in the direction of spraying device, etc., can solve the problems that it is difficult to ensure the uniform thickness of steel structure paint, affect the spraying effect and quality of spraying, and the spraying is not uniform enough, so as to achieve uniform spraying effect and ensure anti-rust Effect, the effect of ensuring the quality of spraying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

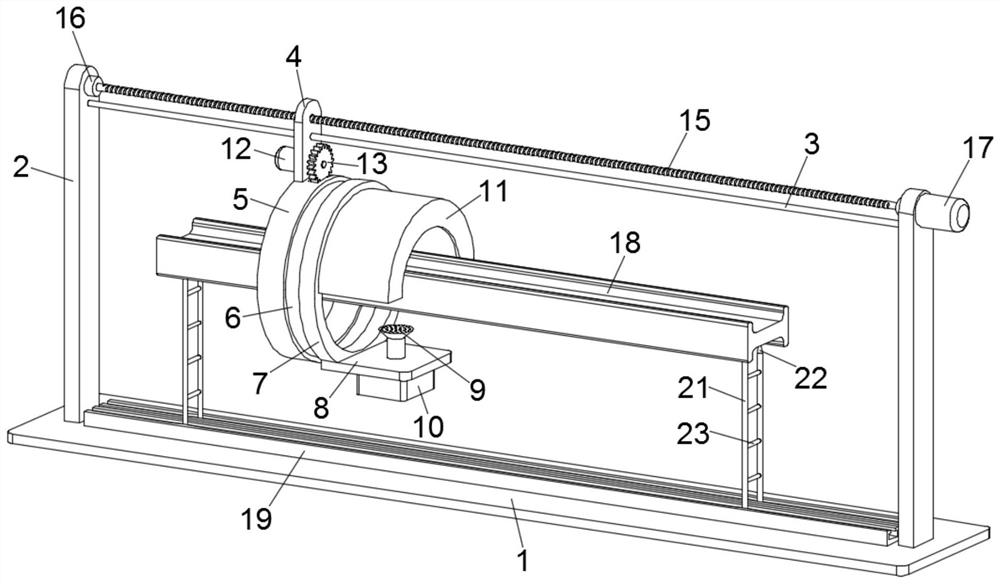

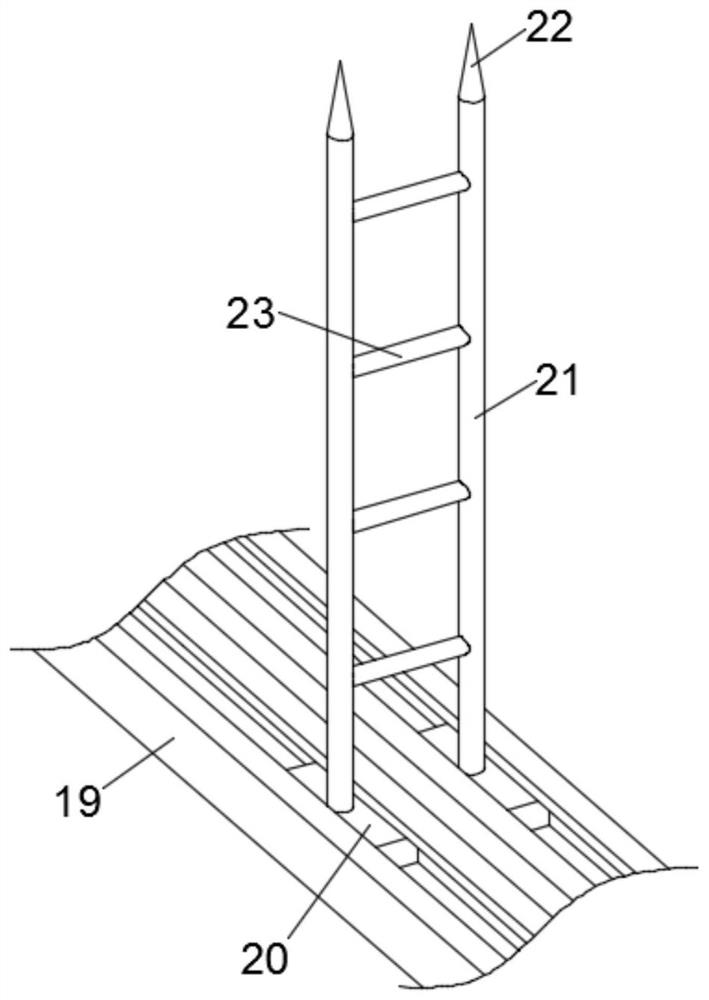

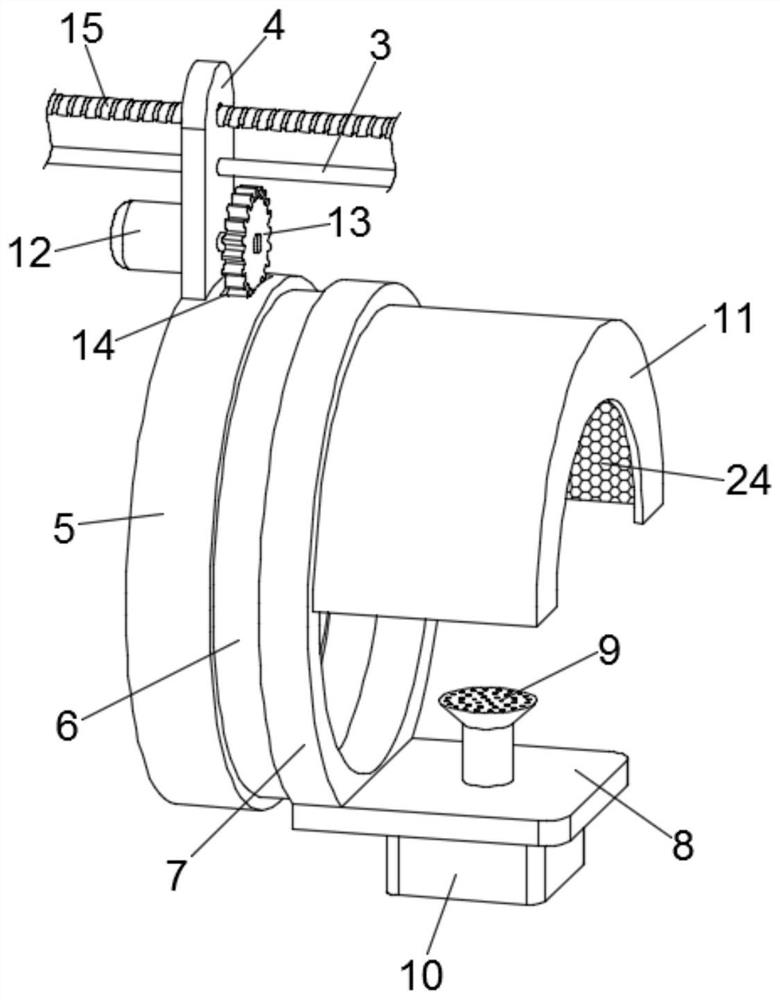

[0028] see figure 1 , a paint spraying device for a steel structure, comprising a base 1, two ends of the base 1 are vertically fixed with a support frame 2, a guide column 3 is fixedly connected horizontally between the two support frames 2, and a sliding sleeve on the guide column 3 is provided with The sliding plate 4, the support frame 2 is also equipped with a translation mechanism that drives the sliding plate 4 to move horizontally along the guide column 3; the lower end of the sliding plate 4 is connected with a fixed ring sleeve 5, and a rotating ring is embedded in the fixed ring sleeve 5 6. A rotary motor 12 is installed on the sliding plate 4, a gear 13 is rotatably installed on the output end of the rotary motor 12, a ring gear is provided on the rotary ring 6, and a slot 14 is provided on the fixed ring sleeve 5, The gear 13 is engaged with the ring gear through the slot 14;

[0029] A mounting ring 7 is fixed on the rotating ring 6 , and a mounting plate 8 is f...

Embodiment 2

[0041]A paint spraying device for a steel structure includes a base 1, a support frame 2 is vertically fixed at both ends of the base 1, a guide column 3 is horizontally fixedly connected between the two support frames 2, and a sliding plate is slidably sleeved on the guide column 3. 4. The support frame 2 is also provided with a translation mechanism that drives the sliding plate 4 to move horizontally along the guide column 3; , a rotary motor 12 is installed on the sliding plate 4, a gear 13 is installed on the output end of the rotary motor 12, a ring gear is provided on the rotary ring 6, and a slot 14 is provided on the fixed ring sleeve 5, so The gear 13 is meshed with the ring gear through the slot 14;

[0042] A mounting ring 7 is fixed on the rotating ring 6 , and a mounting plate 8 is fixed on the mounting ring 7 . The end face of the mounting plate 8 facing the center of the mounting ring 7 is provided with a spray head 9 , and the mounting plate 8 is away from the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com