Patents

Literature

37results about How to "Convenient painting operation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

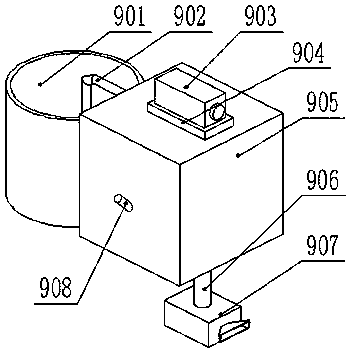

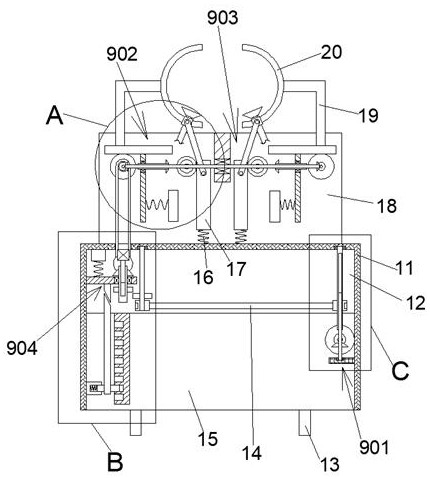

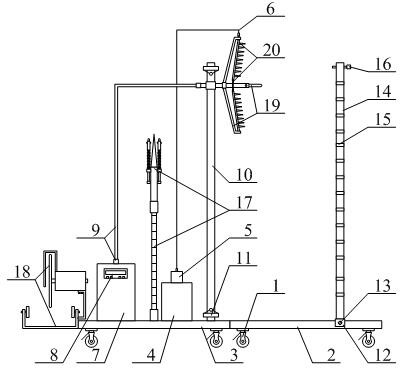

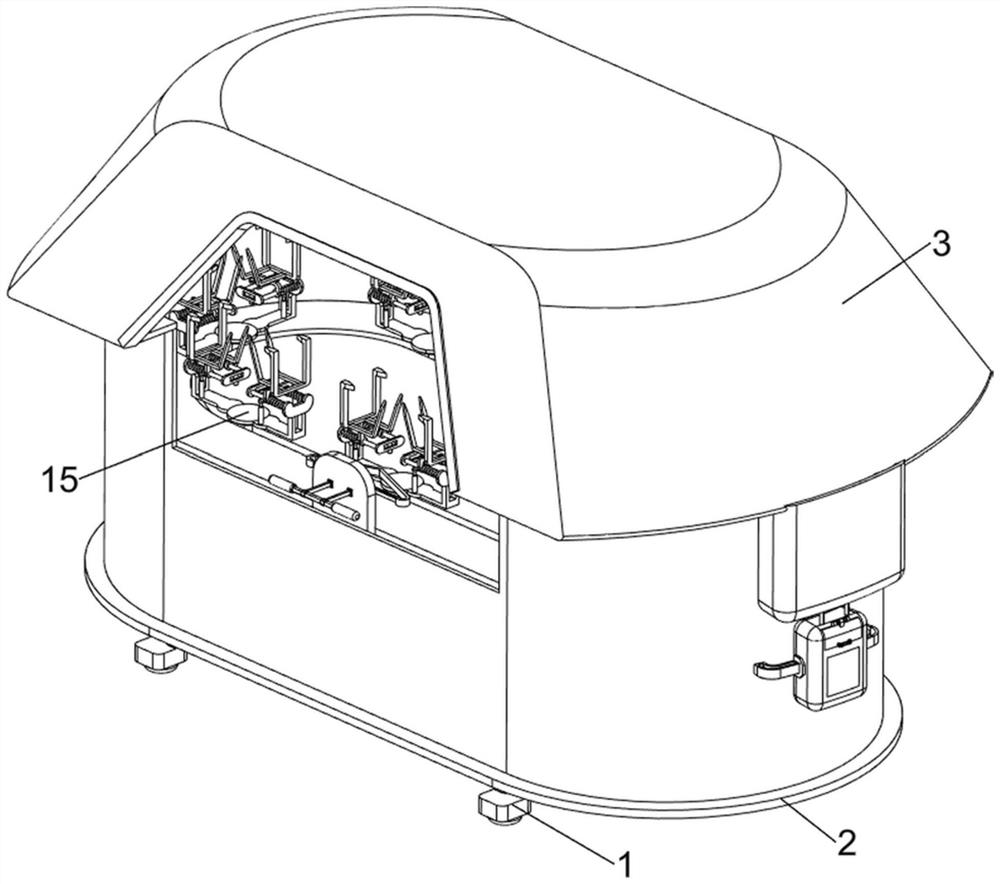

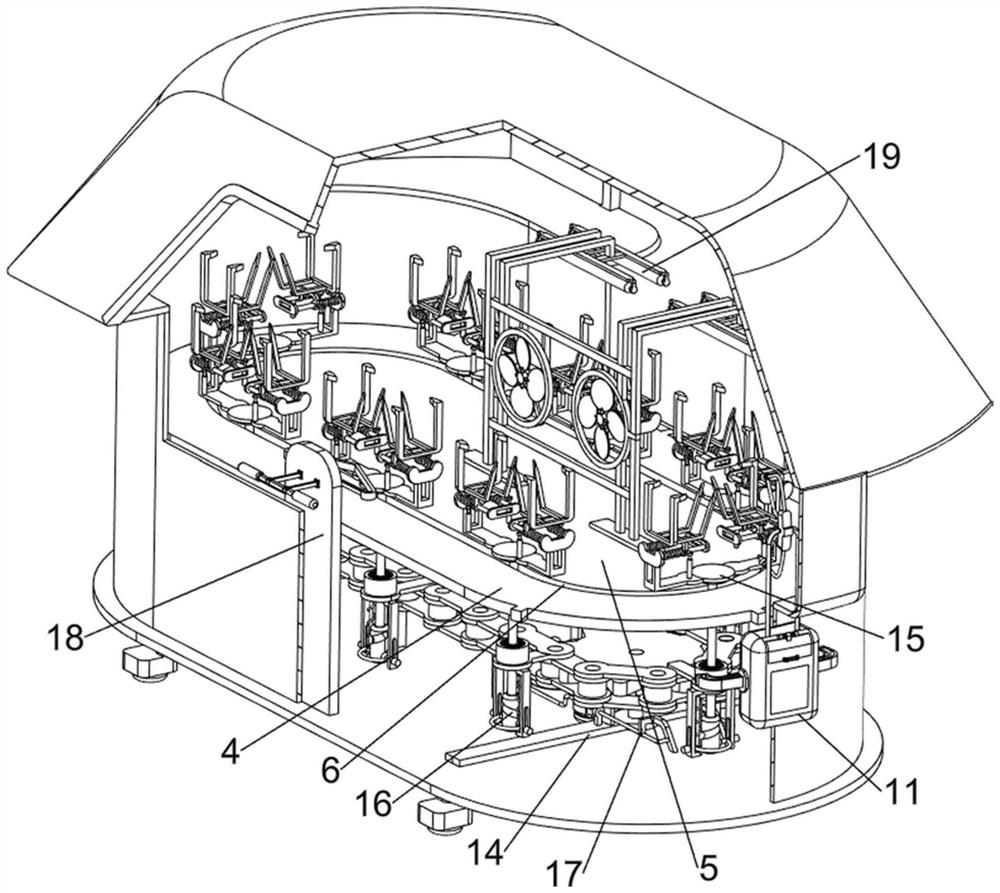

Automatic paint spraying machine

InactiveCN101185922ALow costTimely and pollution-free treatmentLiquid surface applicatorsSpraying apparatusControl systemEngineering

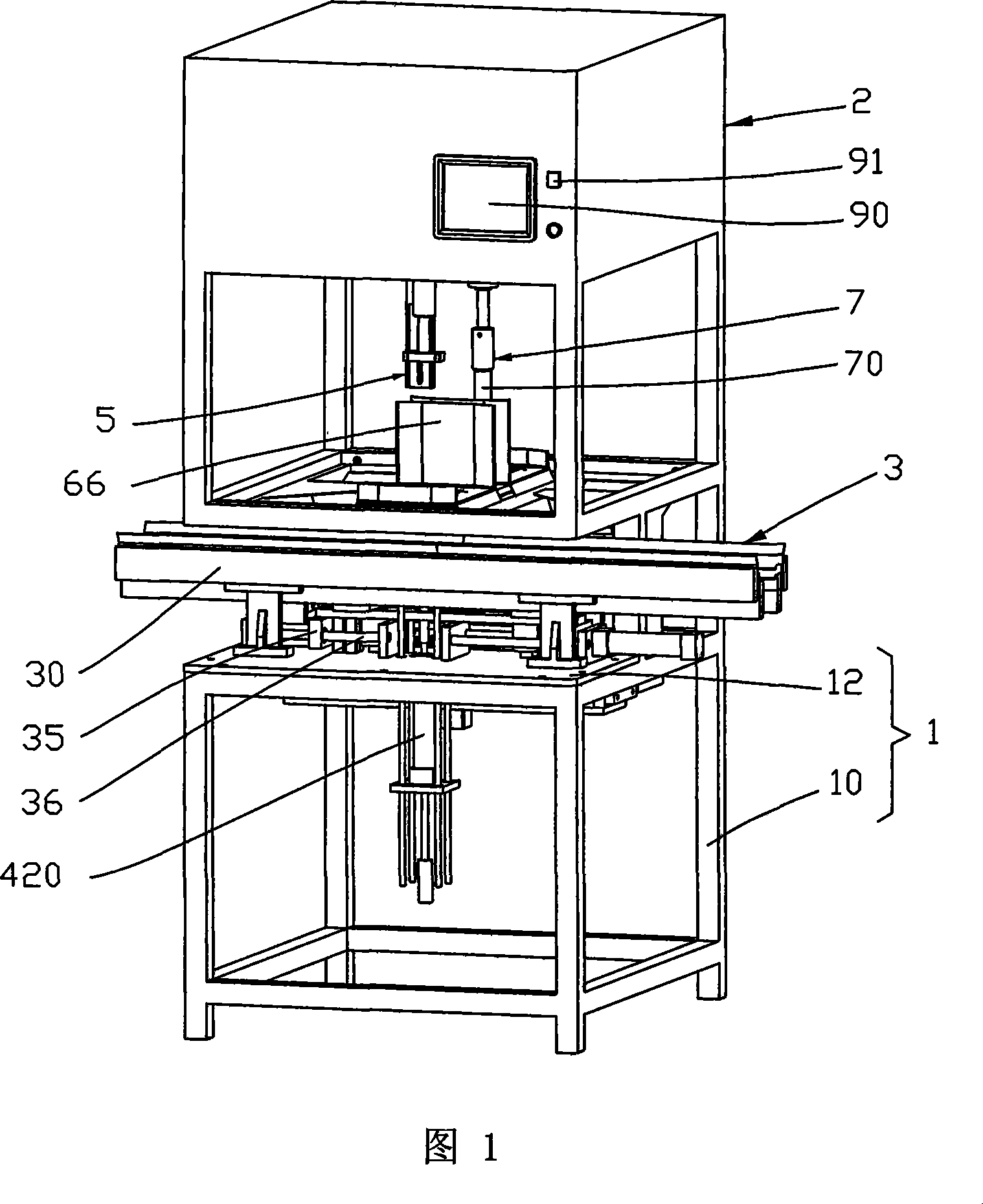

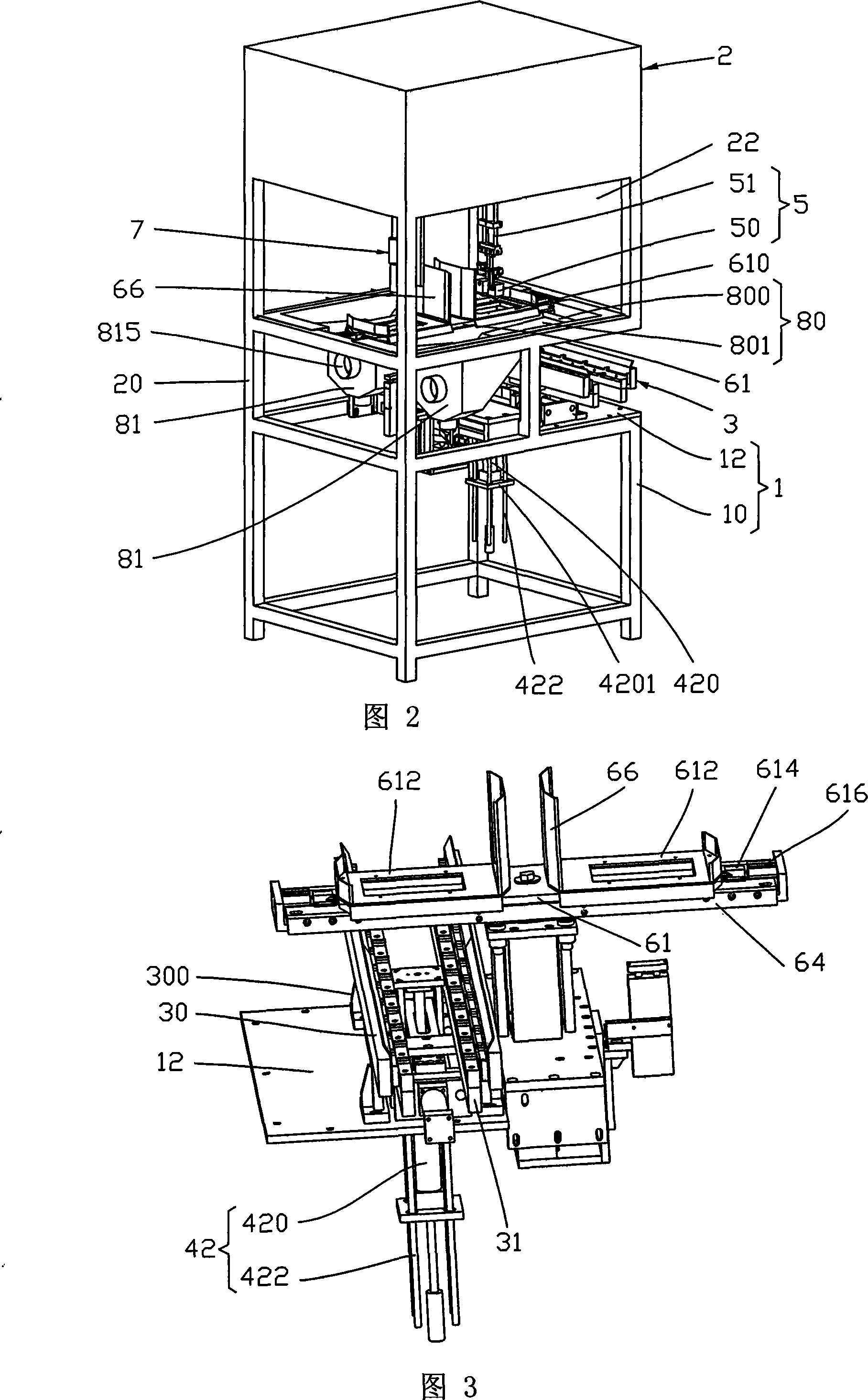

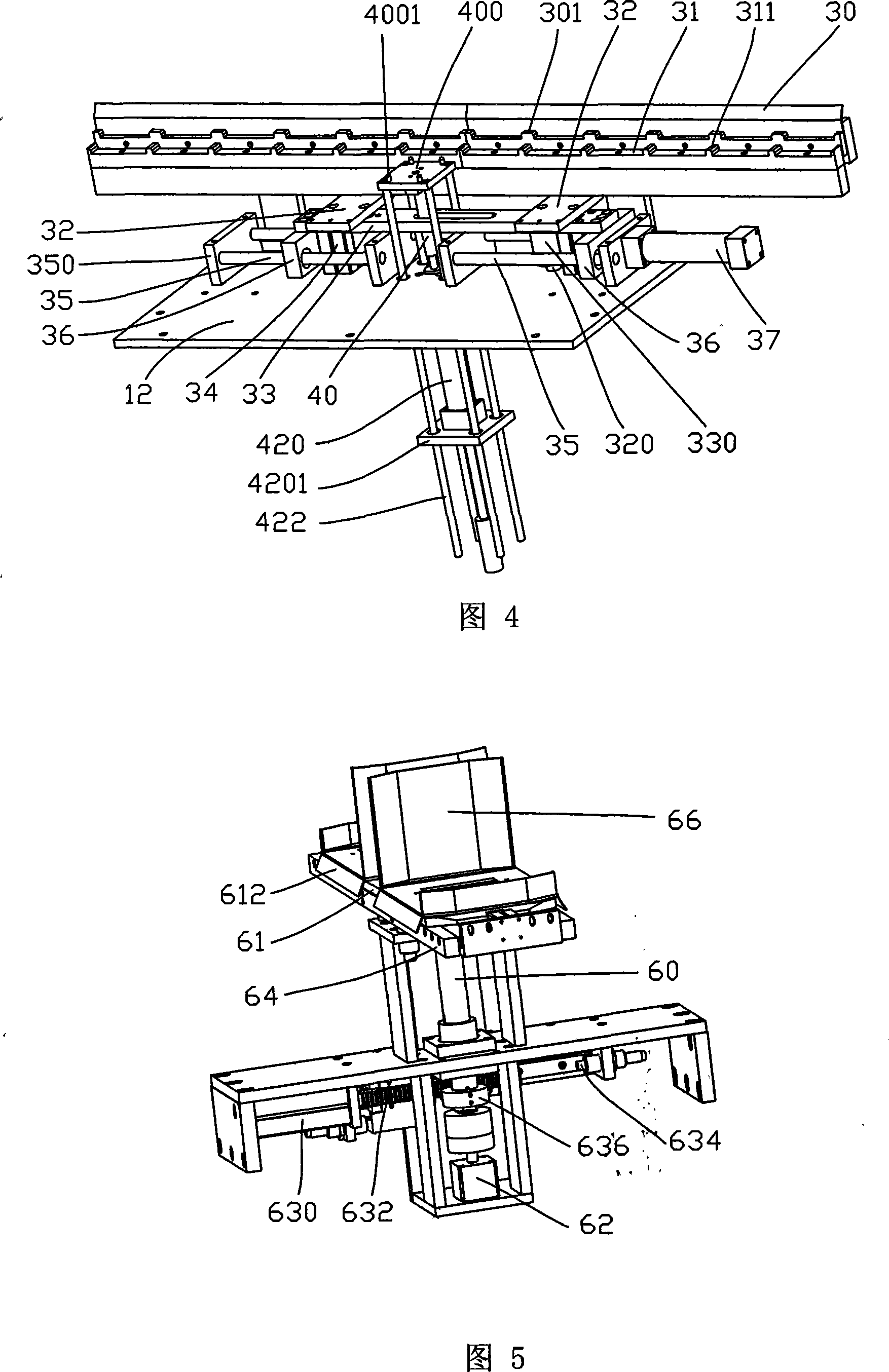

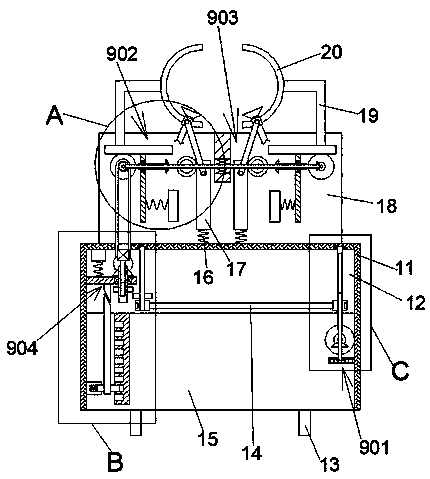

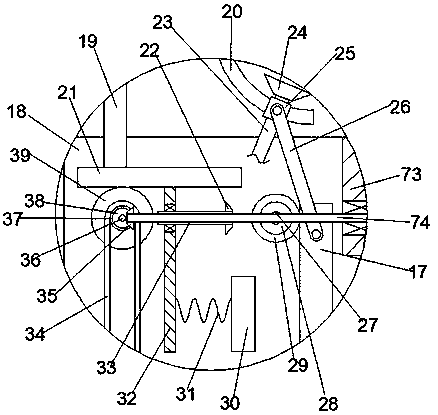

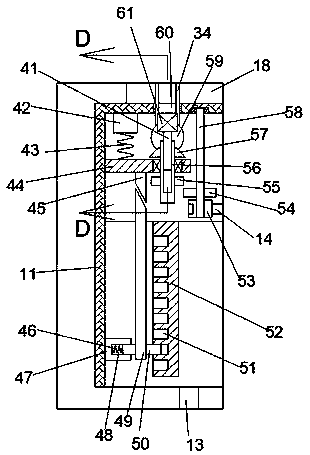

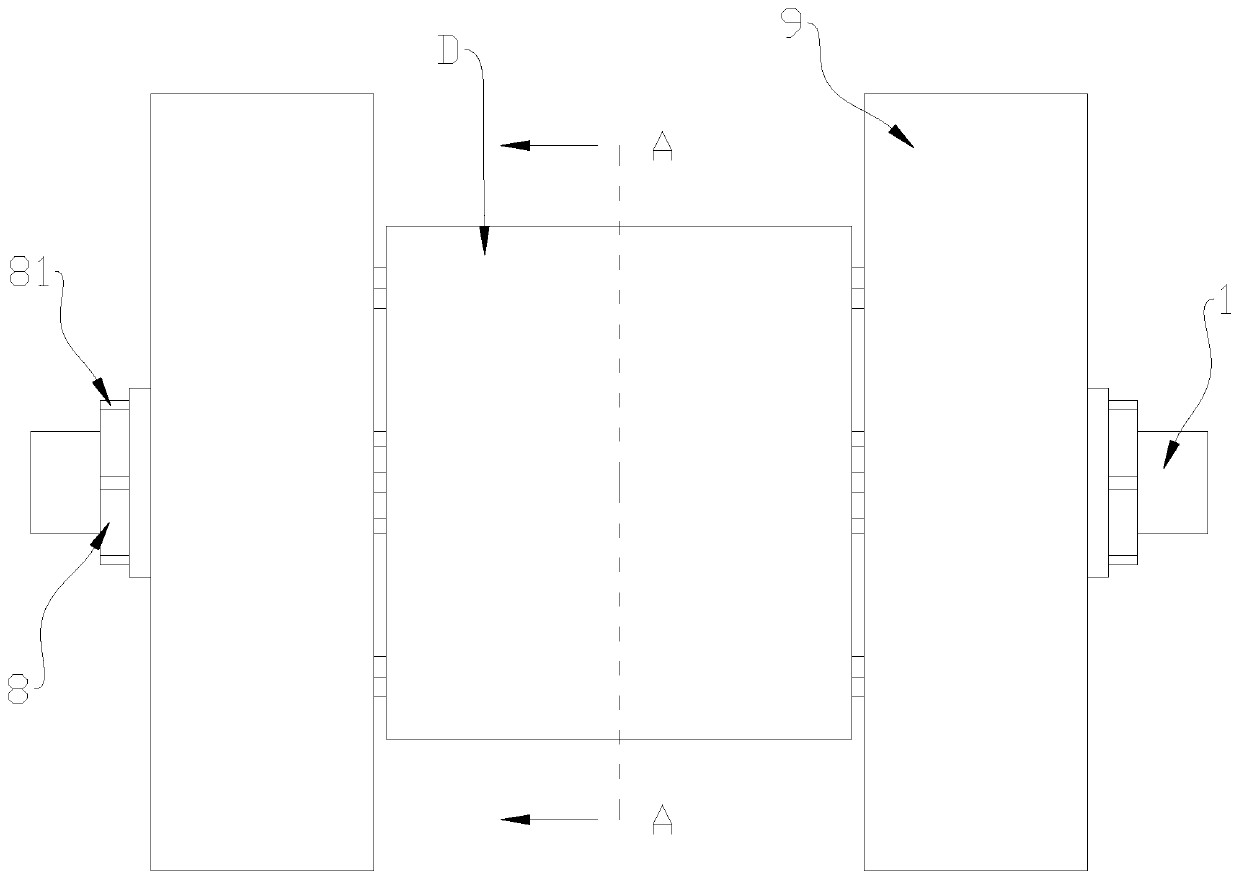

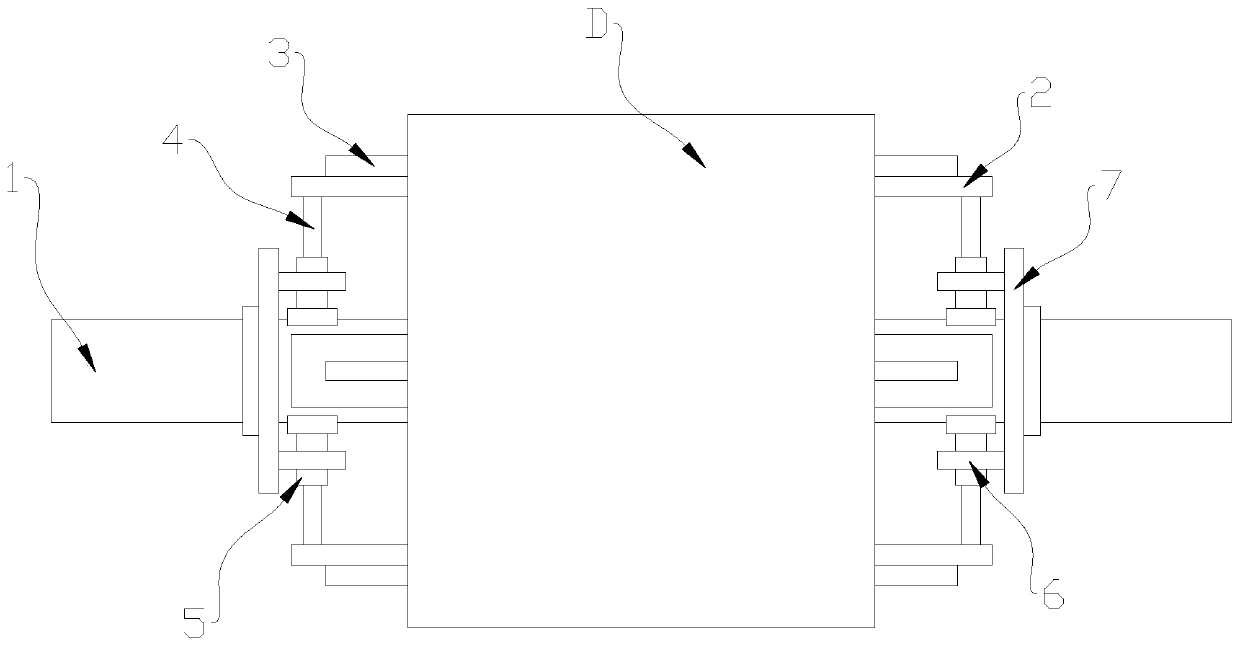

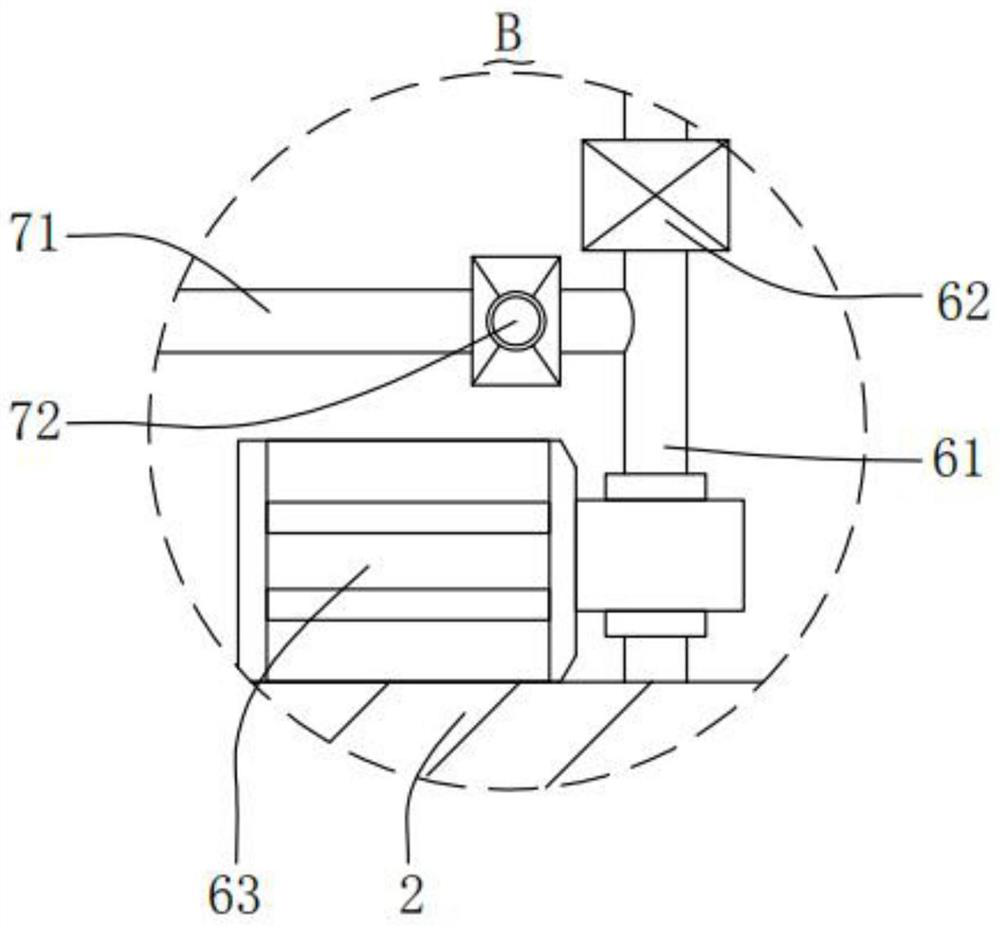

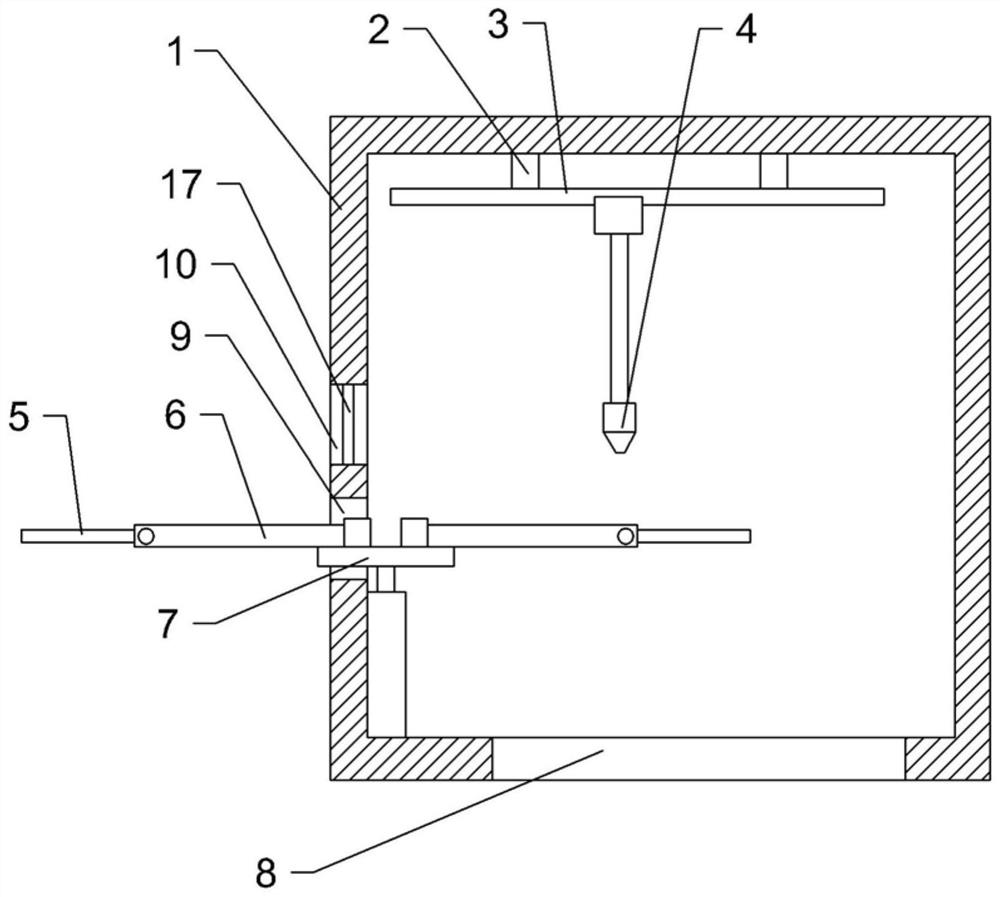

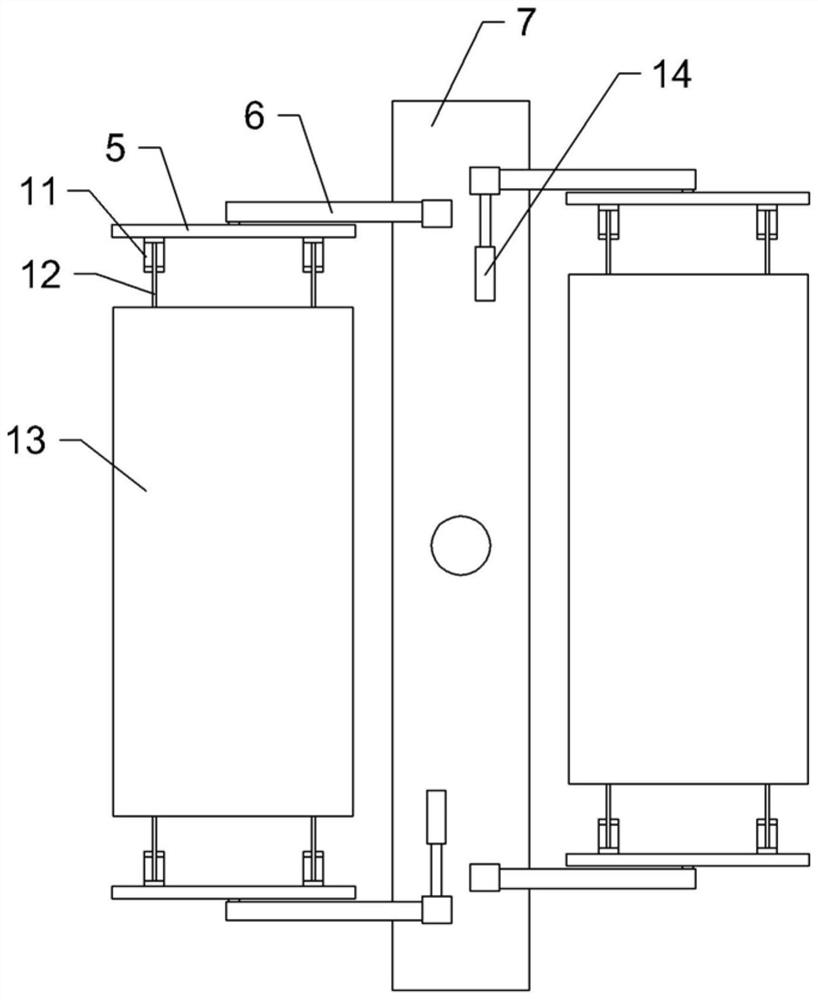

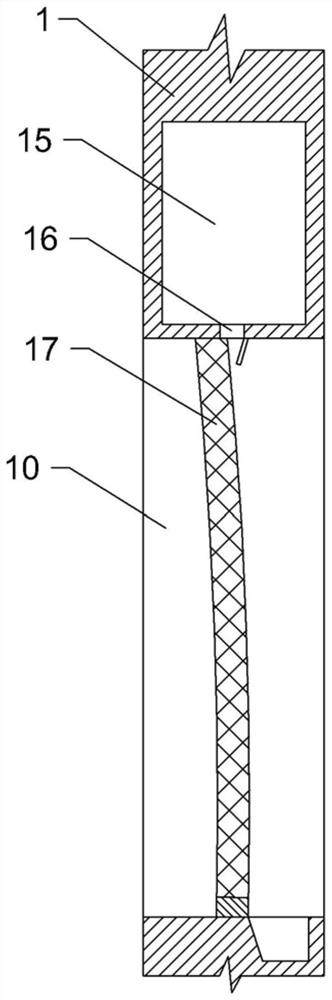

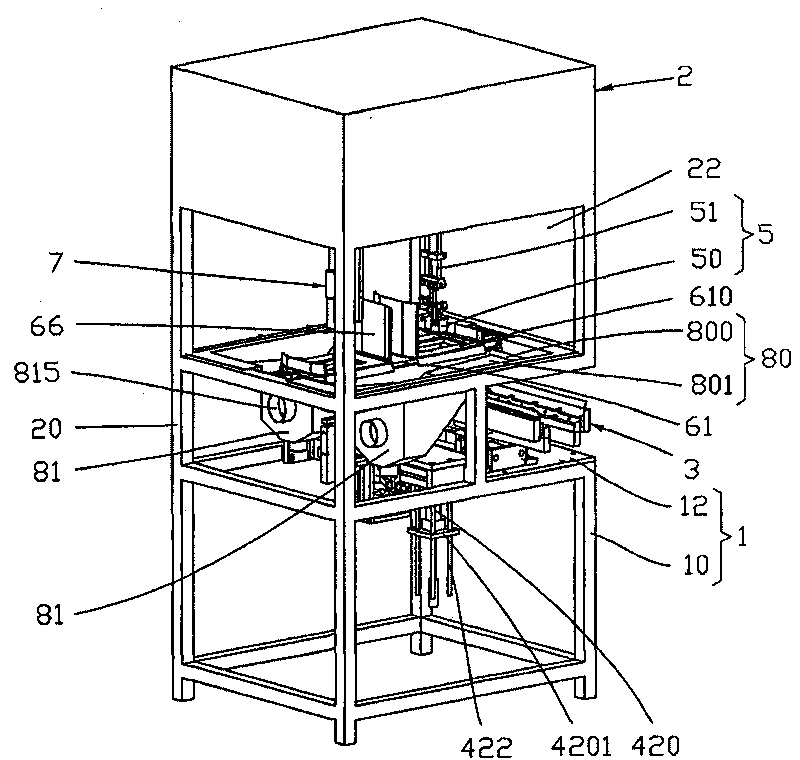

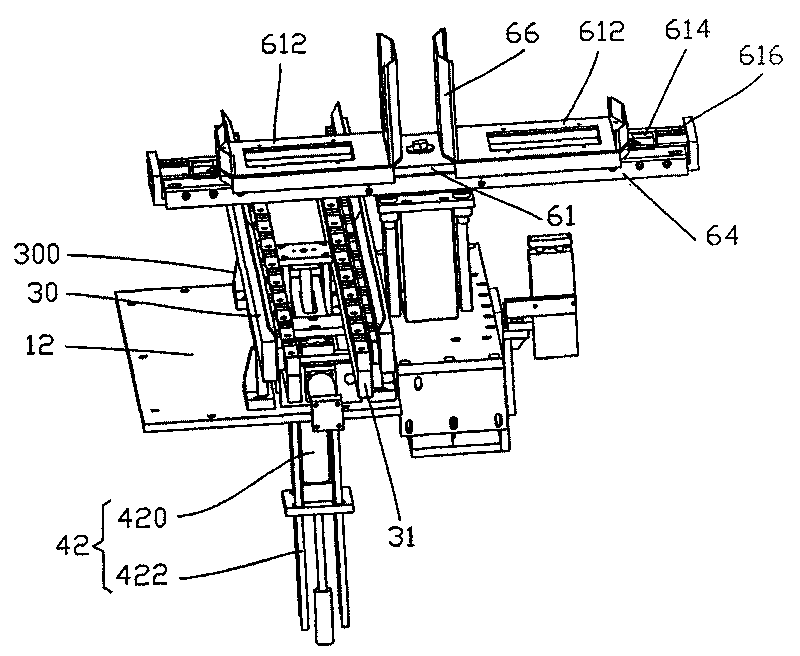

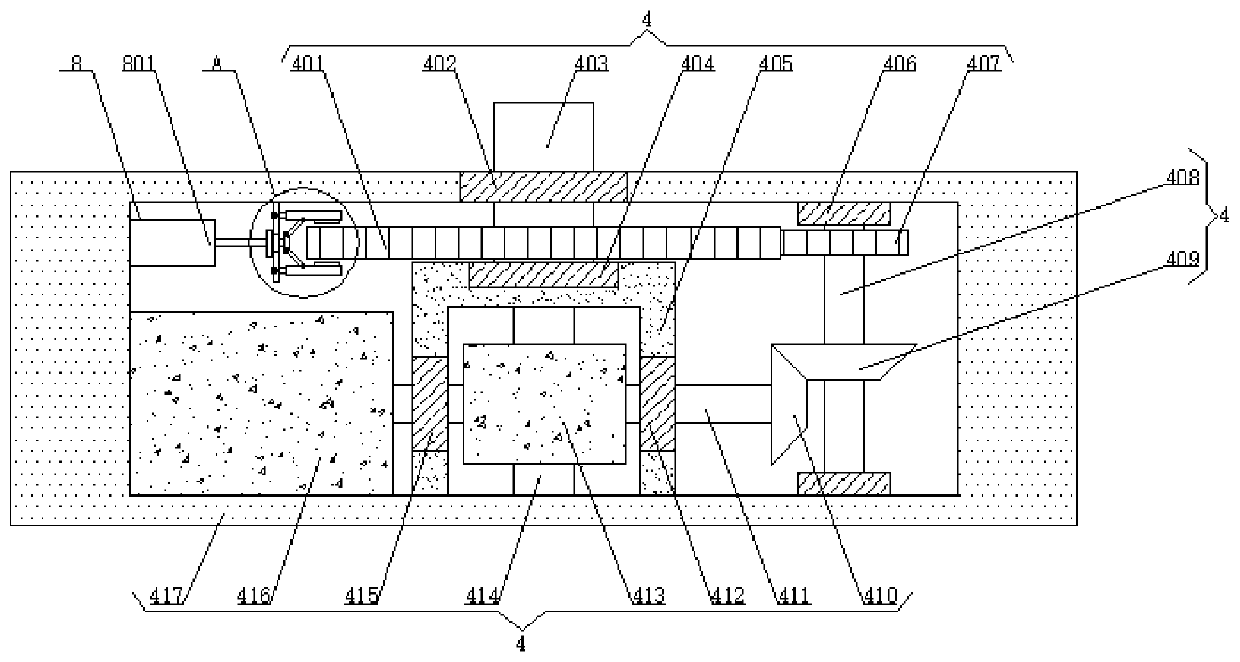

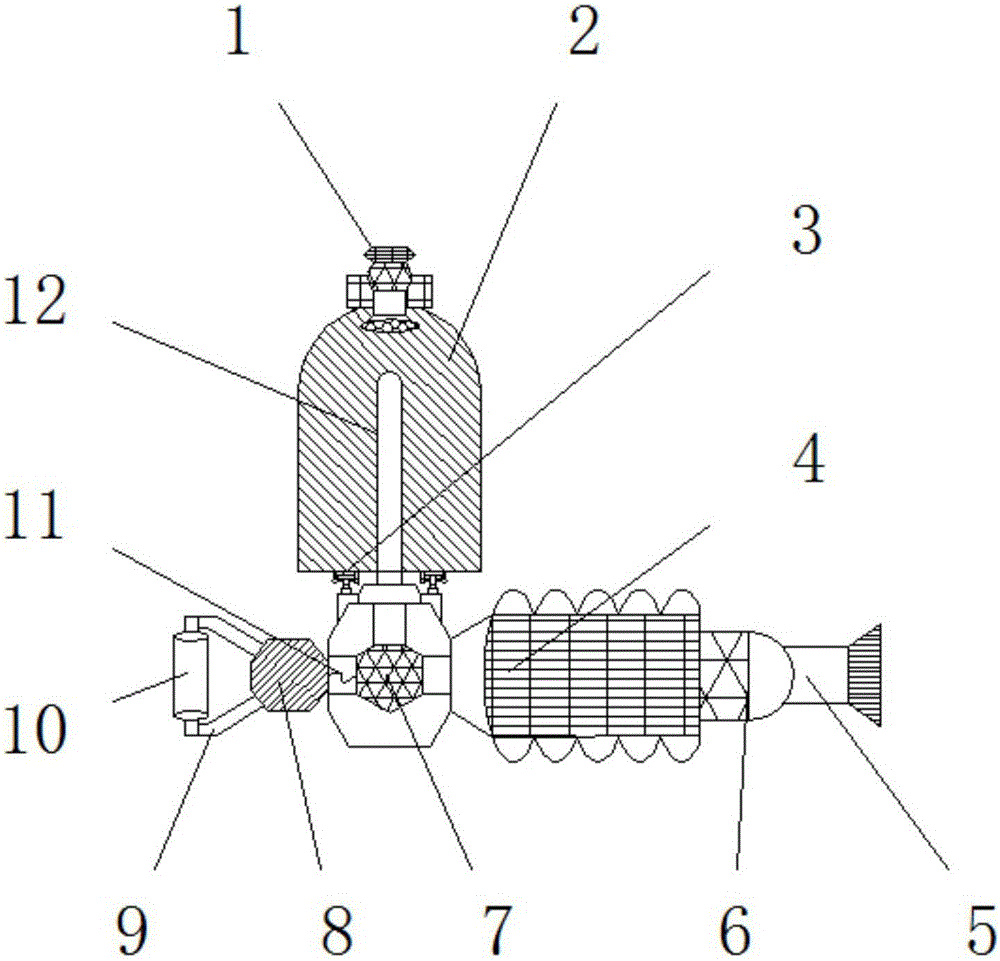

The invention relates to an automatic spray-painting machine, comprising a machine station, a spraying chamber, a work piece delivery device, a cover die device, a spraying device arranged in the spraying chamber, a rotating die device, a washing die device, a cleaning dirty device and a control system. The work piece delivery device is provided with a work piece loading plate; the cover die device comprises a cover die driving mechanism and an incremental launching column which can support the work piece loading plate and correspondingly lift and drop; the rotating die device comprises an upright column, a die base fixed on the top of the upright column, power elements for die base lifting and a rotating die driving mechanism. The die base is arranged in the spraying chamber and two ends of the die base are respectively positioned below the praying device and the washing die device. Two ends of the die base are respectively provided with dies and the middle part of the die base is provided with an isolation board. The invention can cover die automatically and do spraying and die washing work simultaneously. Only by rotating the die base, the position of the used die and the position of washed die can be exchanged, so as to realize high-speed and continual spraying process. The invention is high in automation degree and low in die cost. Due to the timely non-feculence treatment to the waste water and waster gas, the invention is also beneficial to environmental protection.

Owner:SHENZHEN KUNHAN TECH

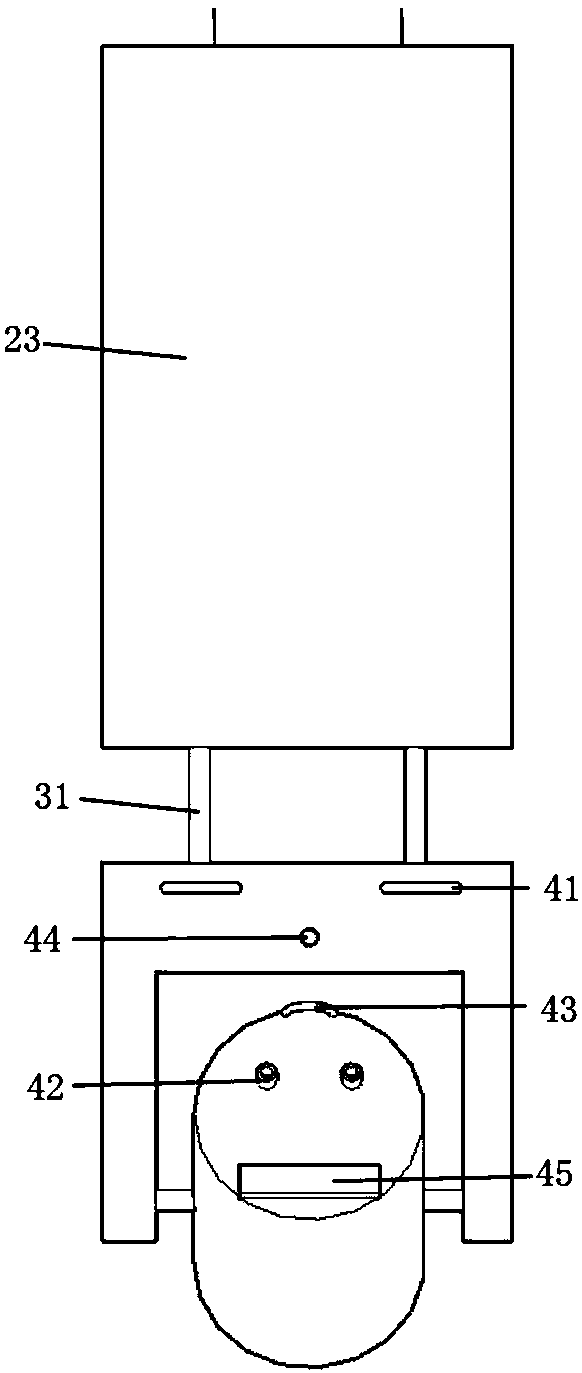

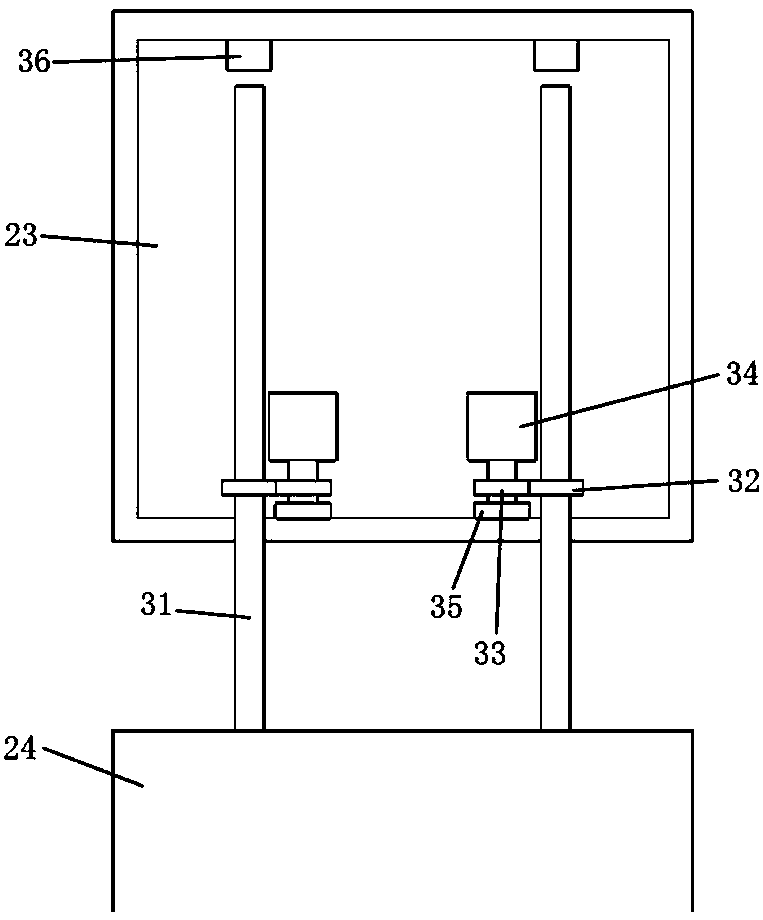

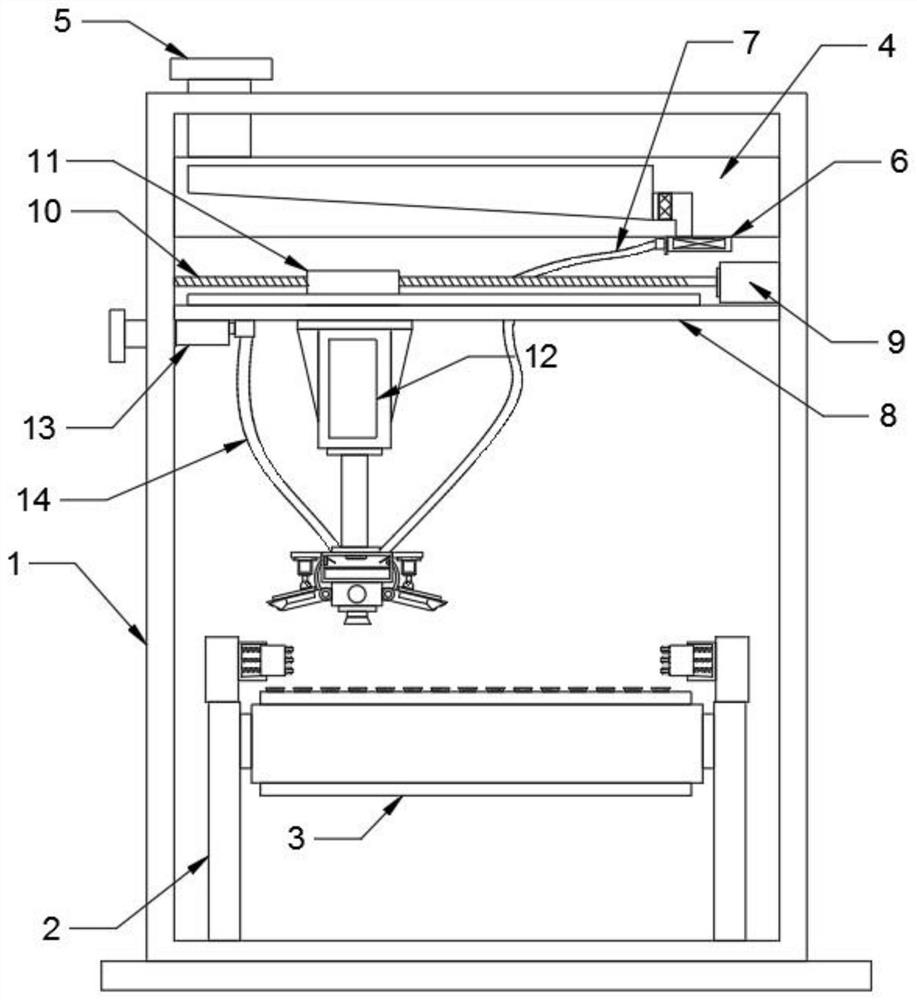

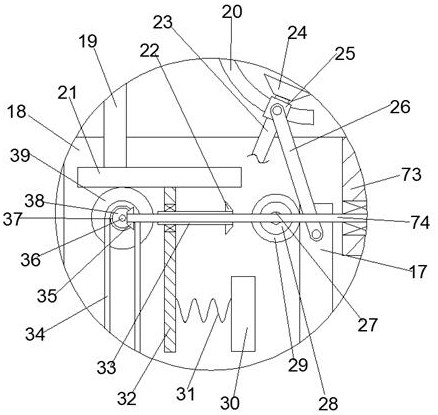

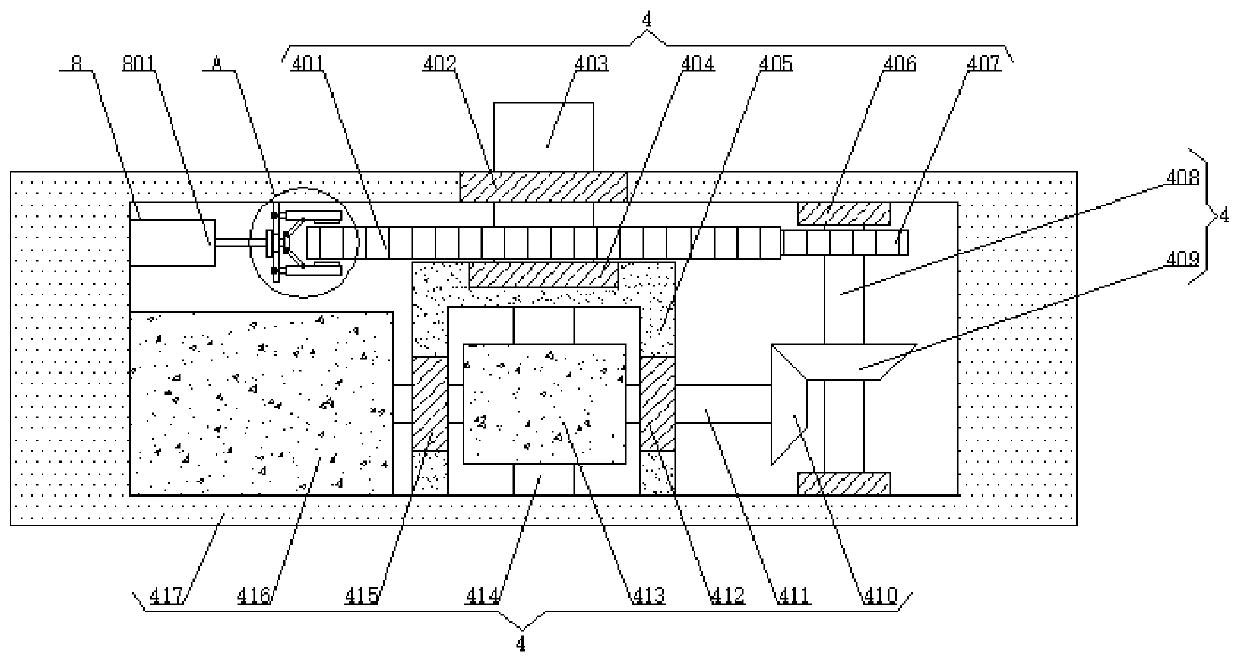

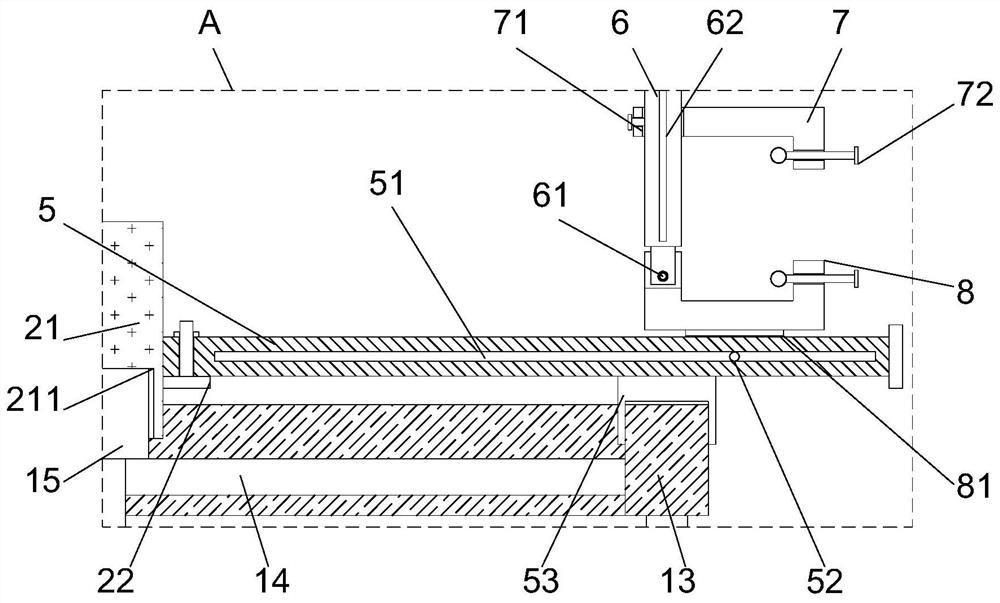

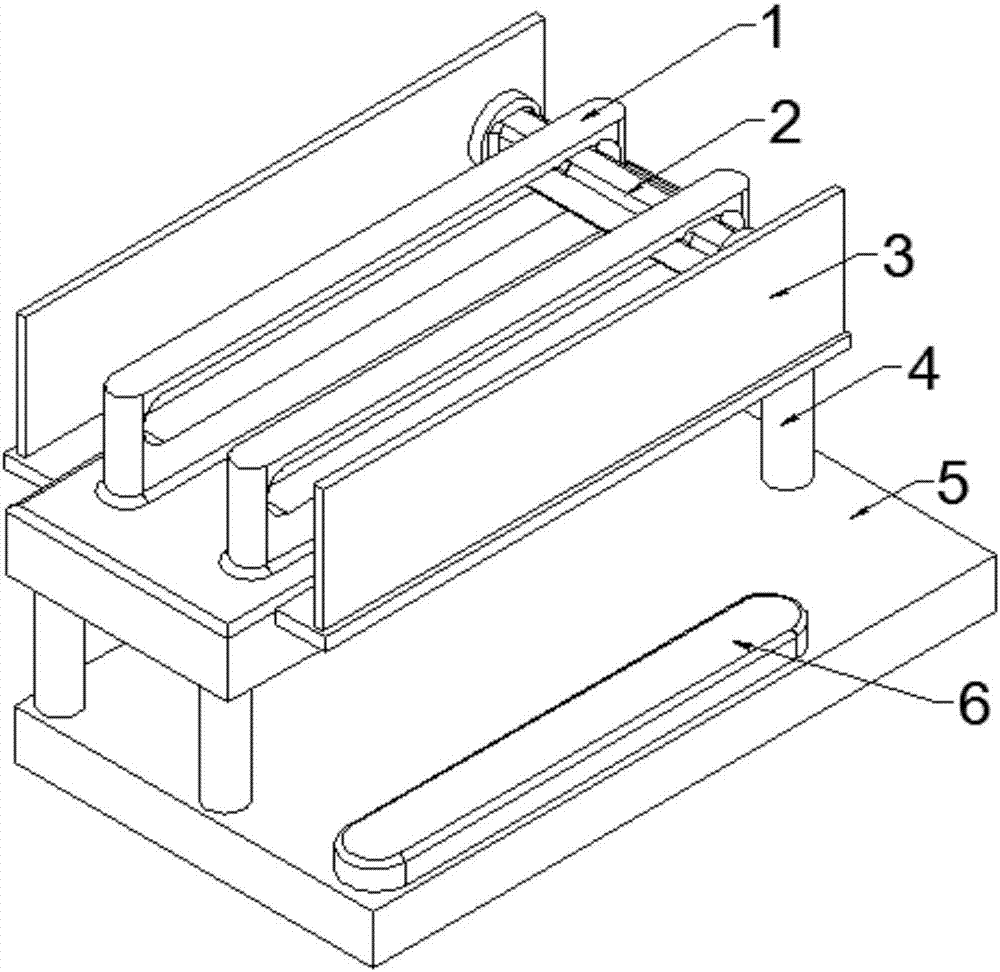

Flexible type paint spraying device for plate processing and using method thereof

ActiveCN110841831AAvoid misuseConvenient painting operationPretreated surfacesCoatingsEngineeringMaterials science

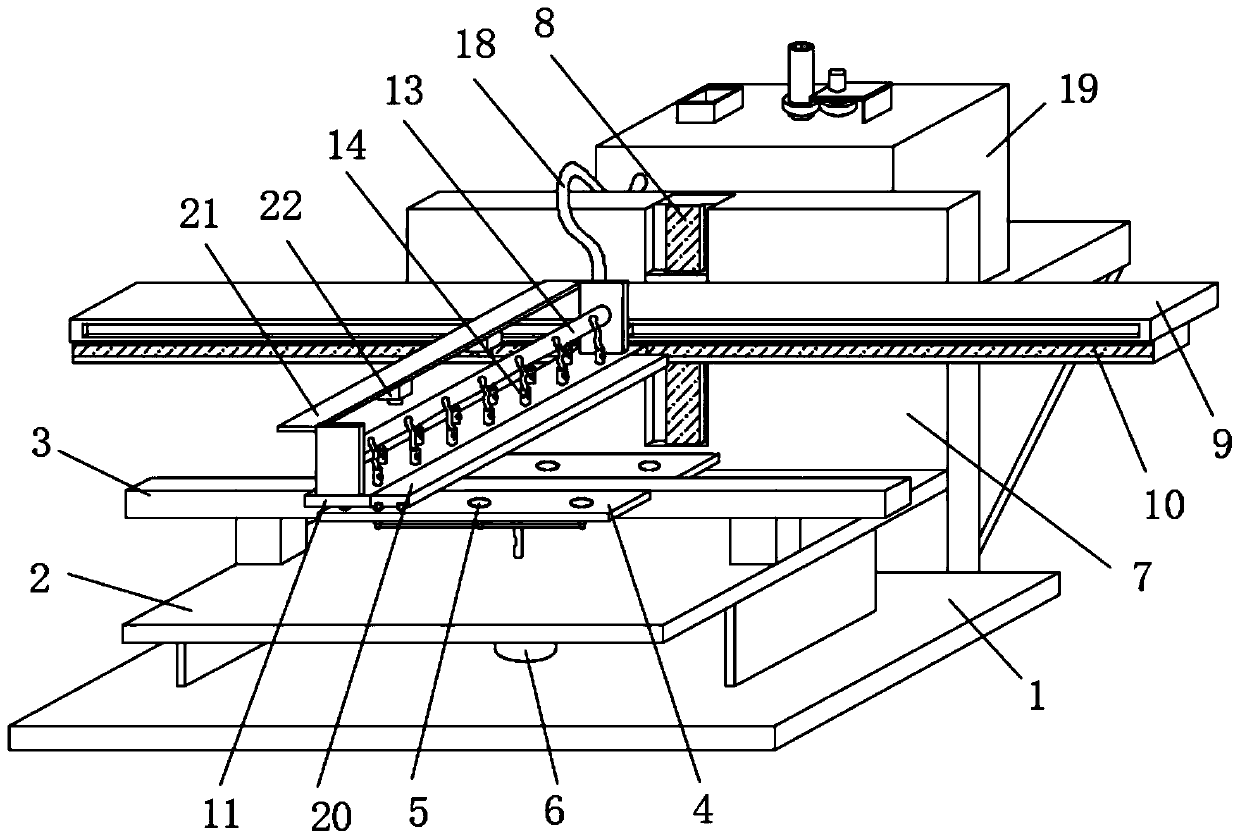

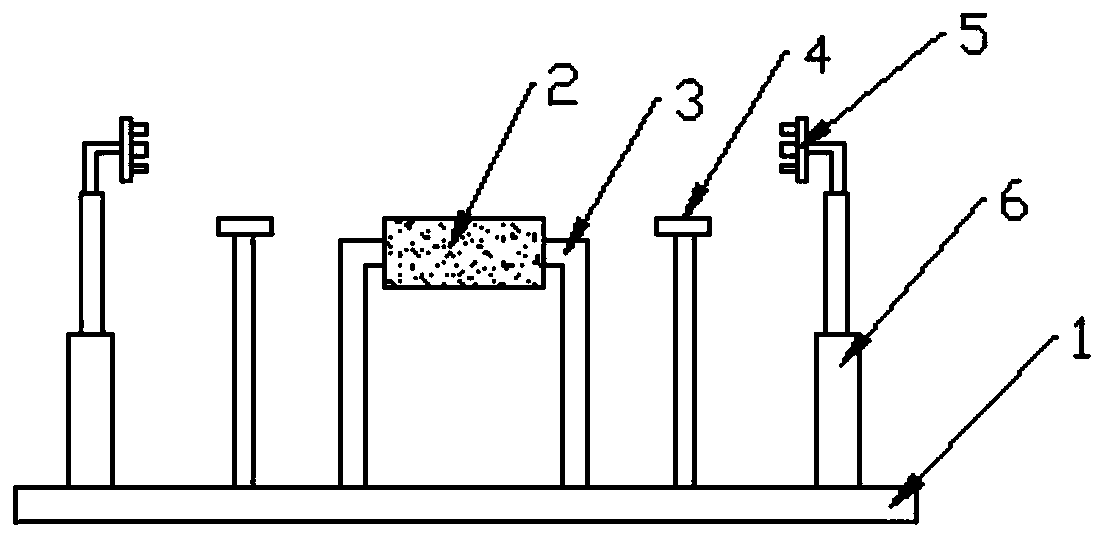

The invention discloses a flexible type paint spraying device for plate processing and a using method thereof, and belongs to the technical field of electromechanical machining. According to the flexible type paint spraying device for plate processing and the using method thereof disclosed by the invention, plate adsorbing mechanisms are arranged at the two sides of a bearing plate for placing plates for fixing the plates while the bottom surfaces of the plates are adsorbed and positioned, so that paint spraying operation on the upper end surfaces of the plates is not affected due to a positioning structure; a vertical electric slide rail is matched with a transverse electric slide rail, so that up, down, left and right motion of the paint spraying mechanism is realized, and therefore, flexible paint spraying operation is effectively improved; besides, a rotary stirring barrel is arranged in a paint box which communicates with the paint spraying mechanism, and the stirring barrel achieves the effect of stirring paint in a rotation process; a plurality of cavitation holes are formed outside the stirring barrel, and a special diluent is guided into the stirring barrel and is thrown into paint through the cavitation holes, so that the diluent is easily dissolved into the paint after cavitation is realized to generate gas bubbles, and therefore, the paint is not liable to condensate.

Owner:徐州达娇物资贸易有限公司

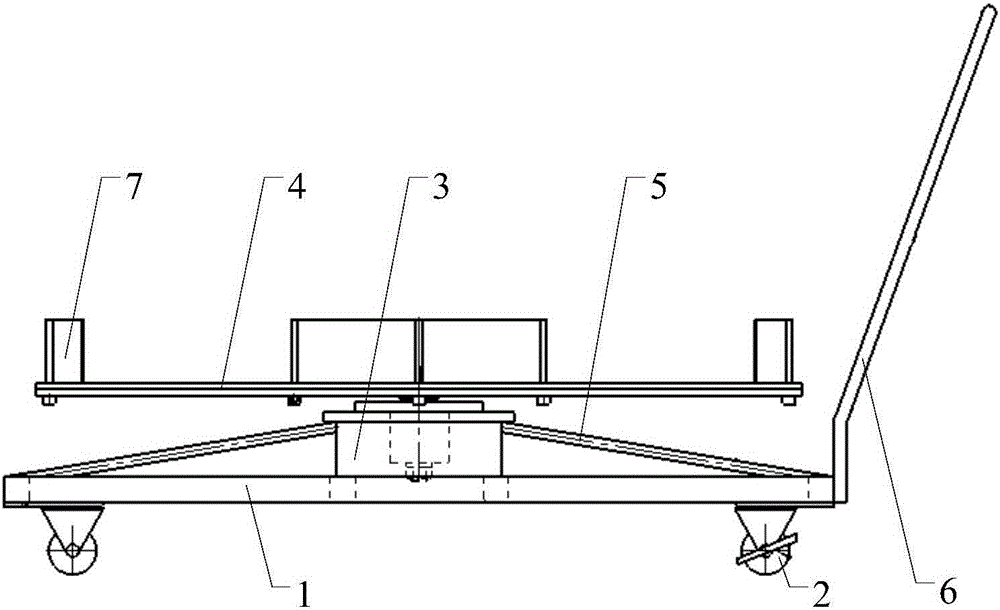

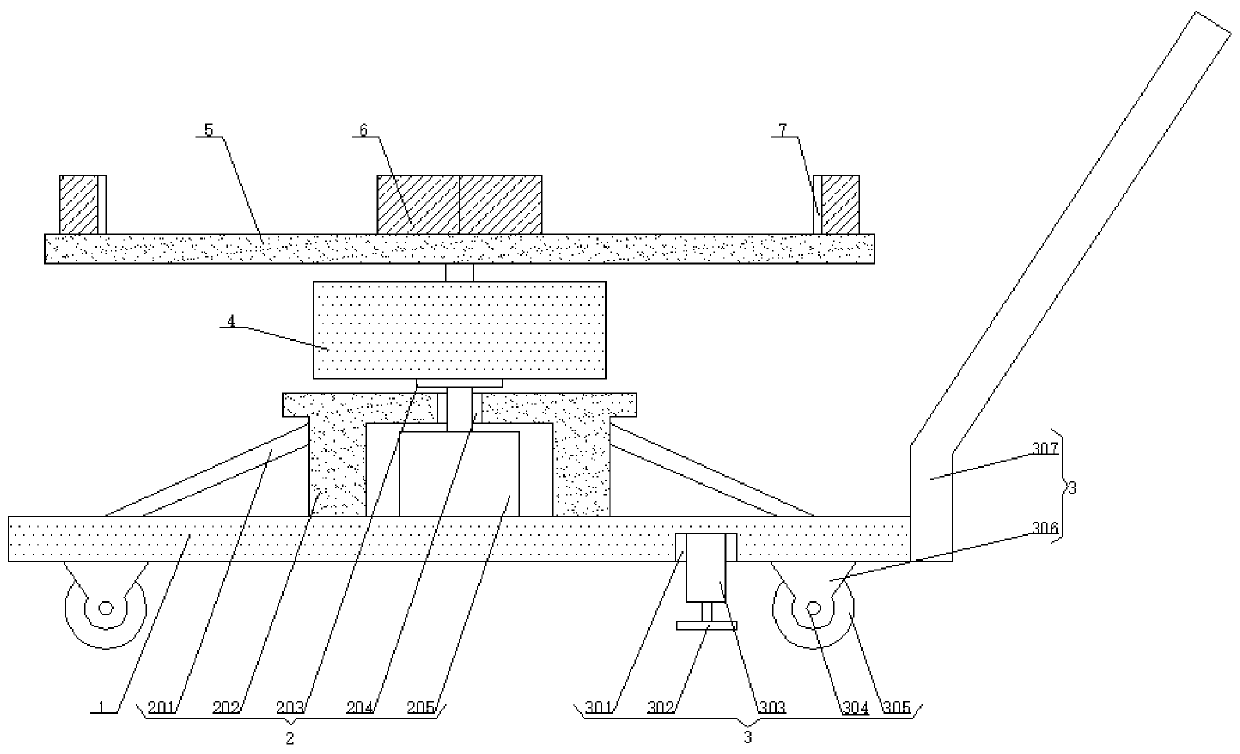

Paint transporter

InactiveCN106364536ACompact structureEasy to useSupporting partsHand carts with multiple axesVehicle frameEngineering

The invention discloses a paint transporter, comprising a frame provided with rollers at the bottom. The paint transporter also comprises a rotating lifting oil cylinder installed on the frame. A rotating plate used for bearing a paint storage device is fixedly connected to the top of the rotating lifting oil cylinder. The rotating plate used for bearing the paint storage device can perform lifting and rotating freely through the rotating lifting oil cylinder installed on the frame, when a workpiece in need of being painted is too high, the height of the rotating plate can be appropriately increased, so that workers can perform paint spraying conveniently, and when paint spraying is completed on one position and needs to be changed to the next position, the to-be-painted position of the workpiece can be aligned to again through rotating by a corresponding angle. The paint transporter has the advantages of compact structure, convenience in use and the like, the adjustment is convenient, so that the complex operation caused by the fact that workers need changing their positions constantly is decreased, the labour force of workers is decreased, and the efficiency is improved.

Owner:JILIN INST OF CHEM TECH

Manual vacuum paint can and cup-free paint gun

InactiveCN101830319ASimple structureSave paintDispensing apparatusRemovable lids/coversLacquerEngineering

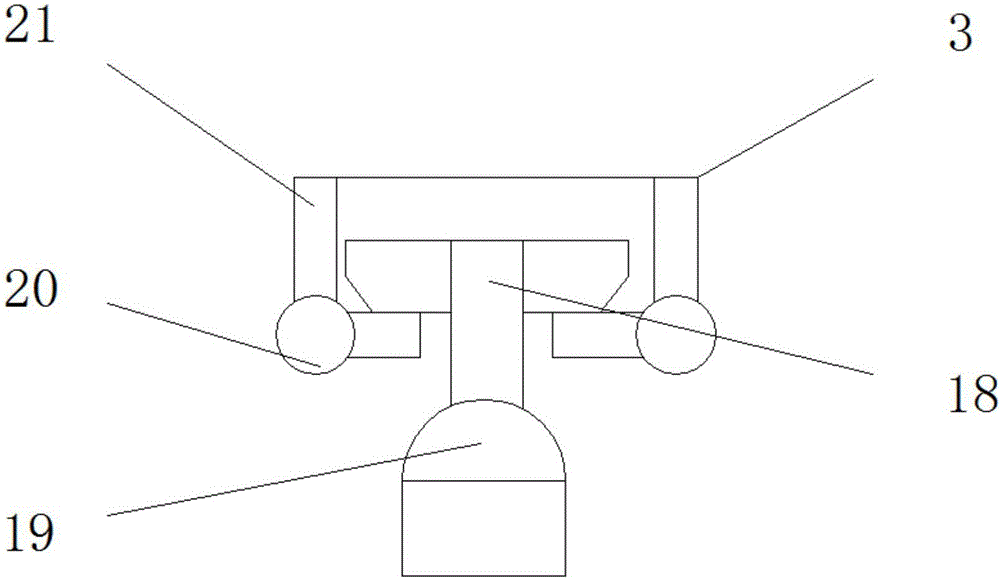

The invention discloses a manual vacuum paint can. A paint storage chamber and an airtight chamber are formed in a can body; a return gas connecting pipe, a paint conveying connecting pipe and a pouring port are arranged over the paint storage chamber; a manual vacuum is arranged at the pouring port; a cup-free paint gun is provided with a return gas pipe joint communicated with a high-pressure air inlet pipe and a paint conveying pipe joint communicated with a nozzle; a return gas pipe is connected with the return gas connecting pipe at the top of the paint storage chamber; and a paint conveying pipe is connected with the paint conveying connecting pipe. Paint spraying operation can be directly performed by connecting the paint conveying pipe and the paint conveying pipe joint of the cup-free paint gun and connecting the return gas pipe and the return gas pipe joint of the cup-free paint gun. Therefore, the paint gun does not need a spraying cup any more; the work of pouring paint into the spraying cup before paint spraying operation and washing the spraying cup after the paint spraying operation is eliminated; the working time can be saved; the labor intensity of operation workers is reduced; the working efficiency is improved; a thinner used for washing the spraying cup is saved; and pollution of the thinner which has washed the spraying cup to the environment is prevented.

Owner:夏延德

Board paint spraying process

InactiveCN105478328AFull accessConvenient painting operationPretreated surfacesCoatingsVarnishMaterials science

The invention provides a board paint spraying process, relating to the field of wood processing. The board paint spraying process comprises the following steps: (1) coarse grinding; (2) puttying; (3) fine grinding; (4) drying; (5) varnishing; (6) paint spraying. Through the multiple steps of operation processing, a board is not easily deformed, the sprayed paint adhered to the board surface is more uniform, the sprayed paint of the board surface is uniformly adhered, is not easy to shed and is bright in color, and the aesthetics is enhanced. The whole process is easy to operate, is reasonable in design, and is facilitated to be further promoted and applied.

Owner:GUANGDE CHANGFENG BAMBOO IND PROD CO LTD

Automatic paint spraying device for building steel

InactiveCN111570154AConvenient painting operationImprove efficiencySpraying apparatusStructural engineeringSpray painting

The invention discloses an automatic paint spraying device for building steel. The device comprises a vehicle body, a supporting support is in sliding connection to the outer surface of the vehicle body, a power cavity is formed in the supporting support, a lifting assembly is mounted in the power cavity, a supporting back plate is fixedly mounted on the upper end of the supporting support, a horizontal adjusting assembly is mounted on the front end of the supporting back plate, the distance between semi-ring rails can be changed, when the building steel is located between the semi-ring railson the left and right sides, the distance between the semi-ring rails on the left and right sides is reduced, subsequent paint spraying operation is facilitated, due to the semi-ring rails of two annular structures, sliding blocks for paint spraying sliding on the semi-ring rails can control nozzles through paint pipes to finish paint spraying operation on the building steel, due to the automationmanner, compared with a manual paint spraying manner, efficiency is improved, and the safety hidden danger existing during aerial work of a worker is eliminated.

Owner:中铝长城建设有限公司

Indoor decoration paint spraying device

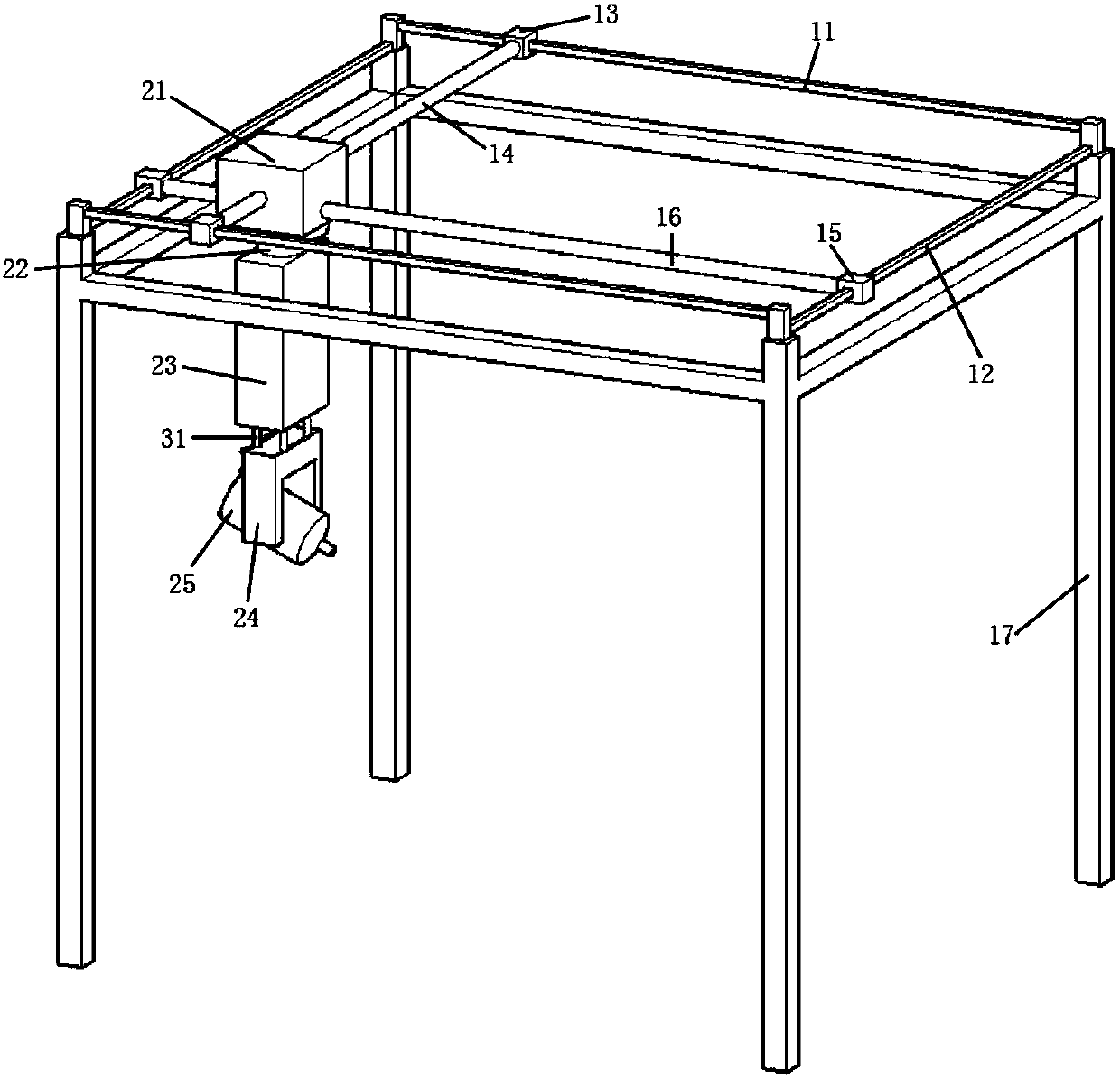

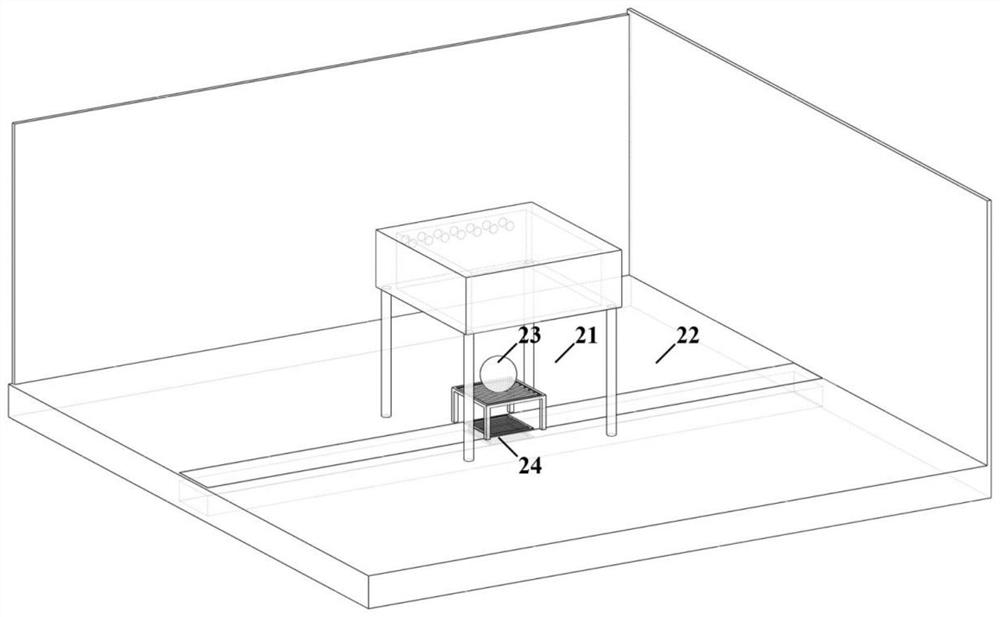

InactiveCN107700804AEasy to set up and install at one timeConvenient painting operationBuilding constructionsEngineeringInjector

The invention provides an indoor decoration paint spraying device. The indoor decoration paint spraying device comprises an injector, the injector is rotatably fixed to the bottom of a fixed block, the upper end of the fixed block is fixed to the position below a rotatable assembly, and the rotatable assembly is fixed to the position below a cross translation block. A transverse moving rod and a longitudinal moving rod are staggered in a cross shape to penetrate through the cross translation block, transverse moving blocks are fixed to the two ends of the transverse moving rod, and longitudinal moving blocks are fixed to the two ends of the longitudinal moving rod. The transverse moving blocks are movably fixed to a cross side frame, the longitudinal moving blocks are movably fixed to a longitudinal side frame, and the cross side frame and the longitudinal side frame form a square frame to be horizontally mounted at the top of a mounting frame. A stay rope through hole is formed in oneface, where the tail of the injector is located, of the fixed block, and the stay rope through hole communicates with the interior of the fixed block, and a limiting pull ring is arranged at the upper end of the tail of the injector. Through arrangement of the structures such as the cross translation block, one-time erecting and mounting are facilitated, and paint spraying operation on a high position can be achieved, thus the probability that dangers happen in the manual operation process can be reduced, and automated paint spraying operation is facilitated.

Owner:夏德银

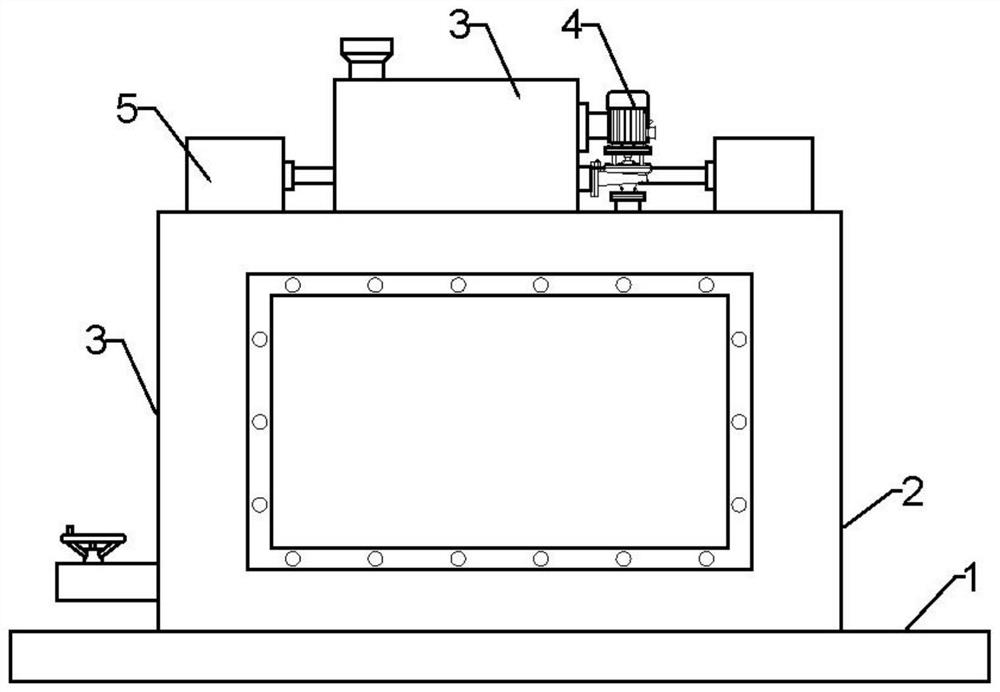

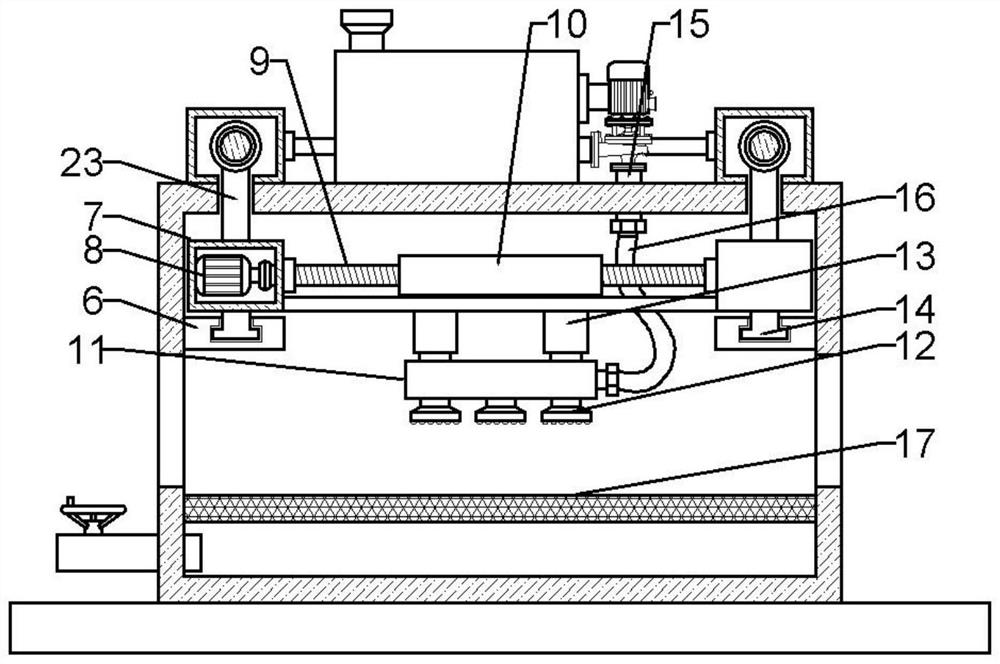

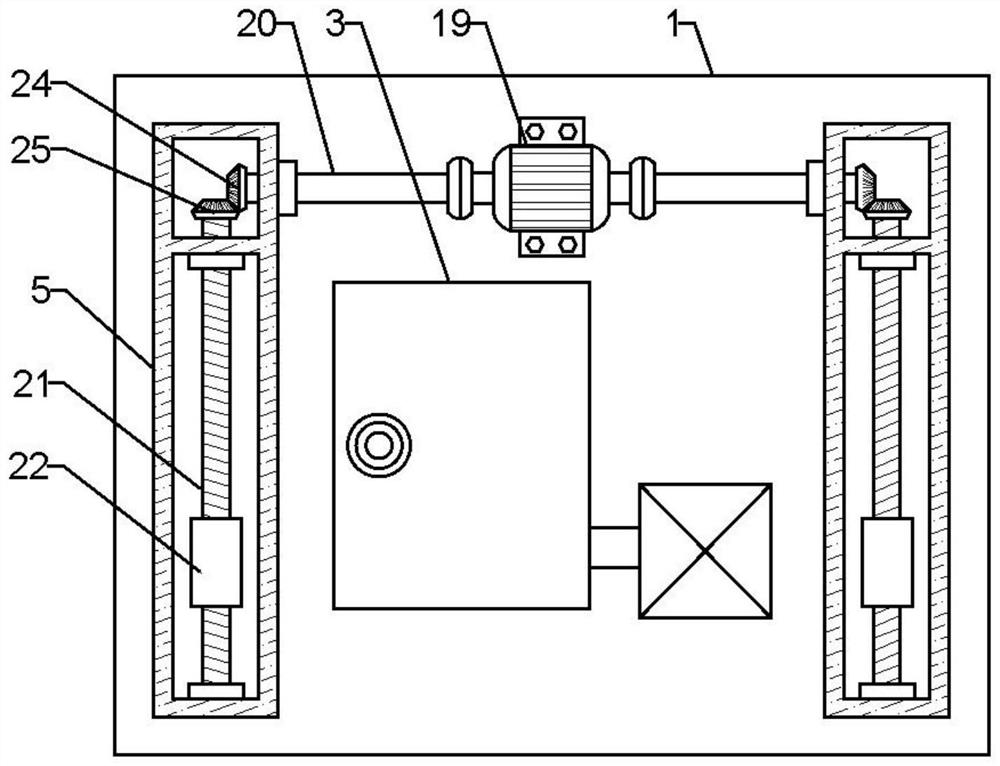

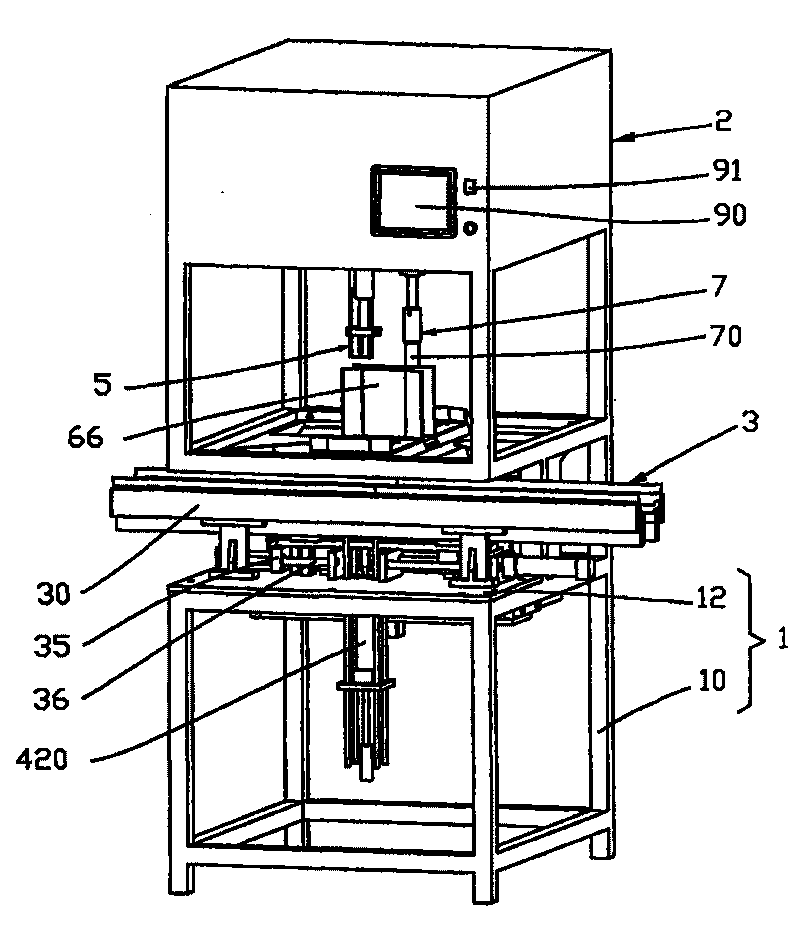

Paint spraying device for machining of automobile parts and spraying method of paint spraying device

InactiveCN112317220AEasy to traverseImprove operational efficiencyLiquid surface applicatorsLiquid spraying apparatusLiquid storage tankStructural engineering

The invention discloses a paint spraying device for machining of automobile parts. The paint spraying device comprises a base, a protection box, a horizontal moving assembly, a spraying assembly, vertical moving assemblies and transmission assemblies, wherein the protection box is fixedly arranged on the top surface of the base, a liquid storage tank is fixedly arranged in the middle of the top surface of the protection box, and the transmission assemblies are arranged in transmission cavities separately; an adjustment cavity is formed in a fixing beam at the front end of each transmission cavity, and the vertical sliding assemblies are arranged in the adjustment cavities separately; and a sliding block is movably arranged on the top surface of each fixing plate, and the spraying assemblyis arranged on a threaded rod in the horizontal moving assembly. The paint spraying device is convenient to operate, and the spraying assembly is driven by the horizontal moving assembly to move horizontally to spray paint, so that the problems that the stability is poor and the operation is complicated when an existing spraying device moves horizontally to carry out spraying are solved; and the transmission assemblies and the vertical moving assembly move, and the spraying assembly is driven by the vertical moving assembly to spray paint to the automobile parts vertically. so that the problemthat vertical paint spraying is inconvenient when an existing paint spraying device is operated is solved.

Owner:安徽淮星车体装备有限公司

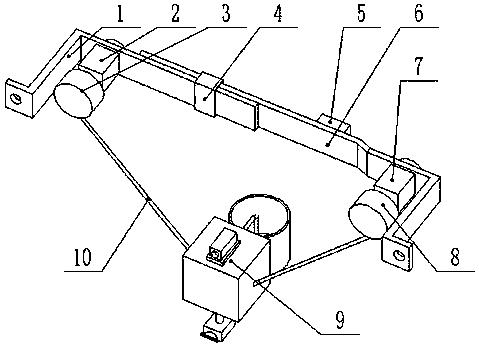

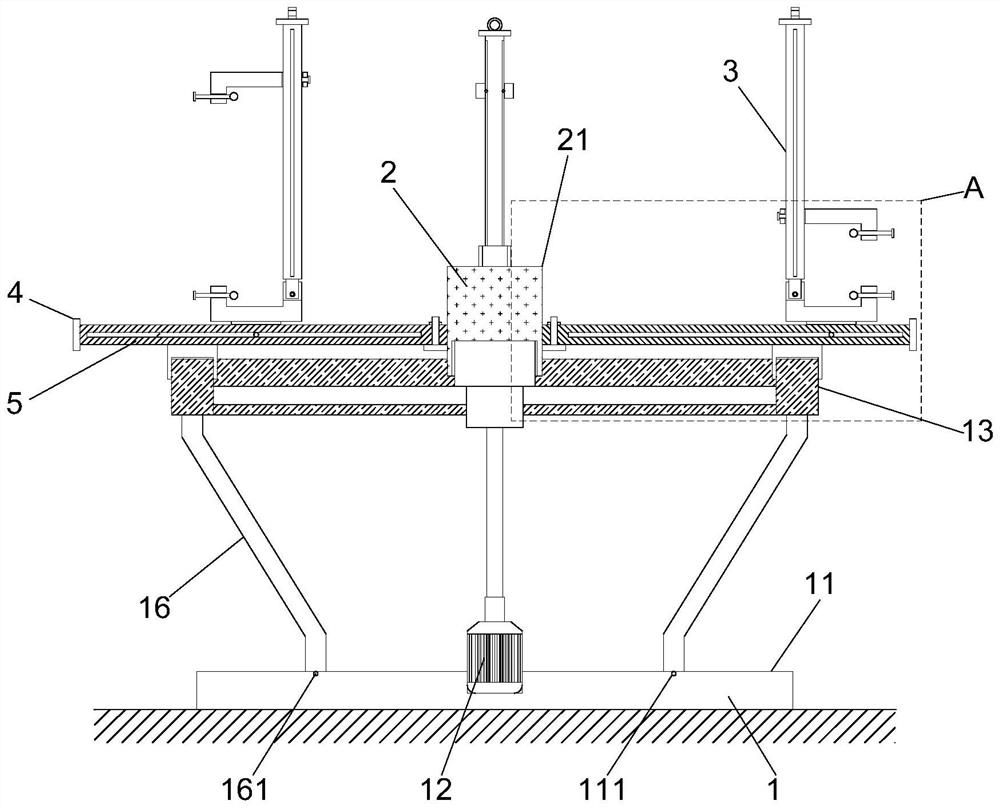

Decoration emulsion paint spray coating device based on polar coordinates

InactiveCN108212592AImprove utilizationAvoid causing different paint thicknessesBuilding constructionsLiquid spraying apparatusEmulsionMotor drive

The invention provides a decoration emulsion paint spray coating device based on polar coordinates and belongs to the field of constructional engineering devices. The support is in an L shape. A firstmotor is installed on the first support. A first wire reel is installed on the first motor. A support fixing frame is installed on the first support and a second support. A controller is installed onthe second support. The second motor is installed on the second support. The second wire reel is installed on the second motor. A spray coating device is hung on a nylon wire. A first coder is installed on the outer side of the first support. The fixing bolt is installed on the support fixing frame. The second coder is installed on the outer side of the second support. According to the decorationemulsion paint spray coating device based on the polar coordinates, the rotation angles of the motors are controlled through the controller, and the motors drive the wire reels to rotate to change the movement path of the spray coating device, so that emulsion paint spray coating is achieved; and in this way, the labor is saved, and the work efficiency is improved.

Owner:平太宇

Anti-splashing spraying equipment

The invention discloses anti-splashing spraying equipment for the outer surface of an aluminum profile. The anti-splashing spraying equipment comprises a mounting frame, a paint spraying mechanism, and a conveying assembly located on the inner side of the mounting frame and used for supporting and conveying the profile. The paint spraying mechanism comprises a paint spraying piece, a displacement assembly connected with the paint spraying piece and used for driving the paint spraying piece to move and comprehensively spray the surface of the profile, a purification assembly located on the side face of the paint spraying piece and used for collecting splashing paint, and an angle adjusting assembly connected with the purification assembly and used for adjusting the included angle between the purification assembly and the paint spraying piece. The conveying assembly can move the profile, so that paint spraying operation is facilitated; and the displacement assembly in the paint spraying mechanism can drive the paint spraying piece to move, so that comprehensive paint spraying of the profile is achieved, and the paint spraying effect is effectively improved. The purification assembly is located on the outer side of the paint spraying piece and can effectively collect the splashing paint and reduce the diffusion of the splashing paint, so that the quality of the working environment is further improved, and use is facilitated.

Owner:江苏兴甬铝业科技有限公司

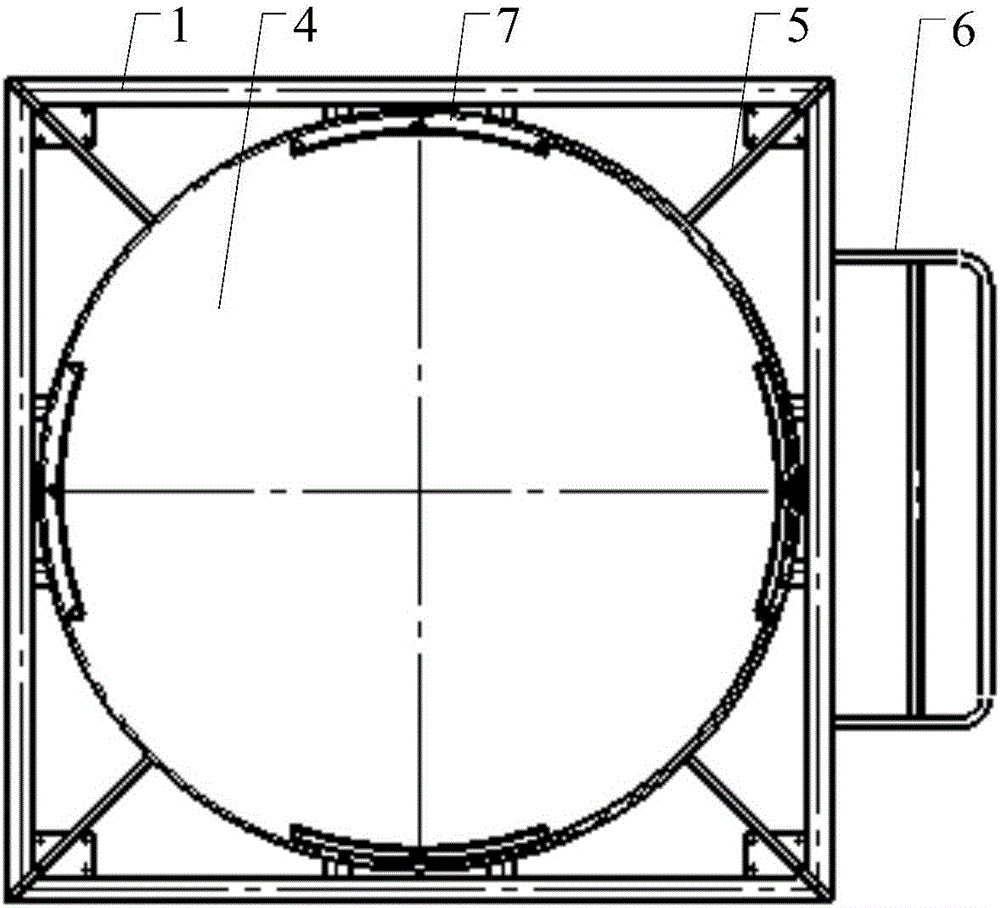

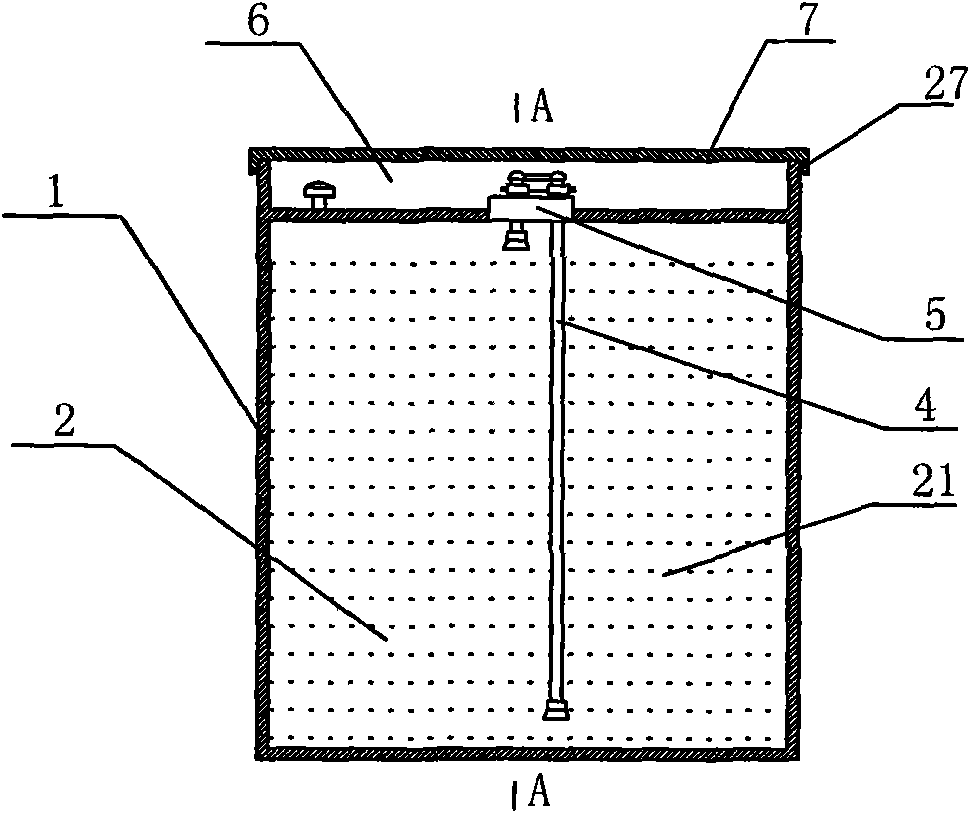

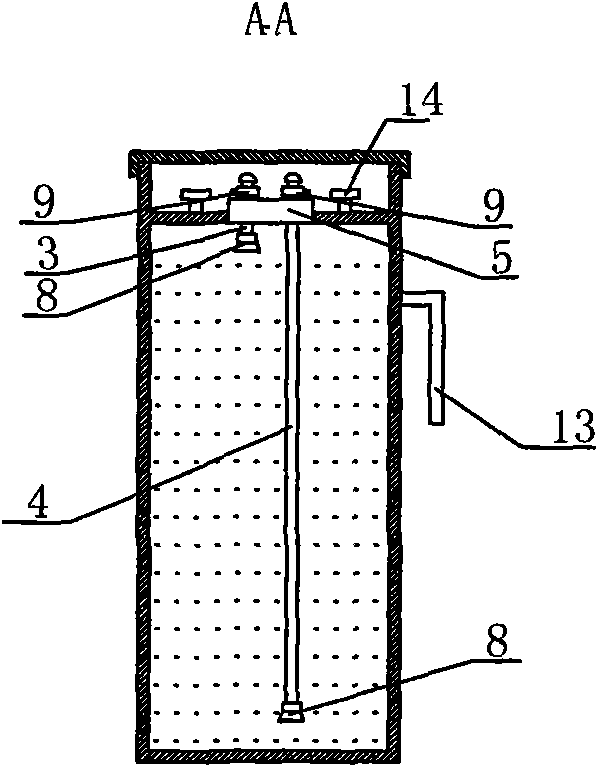

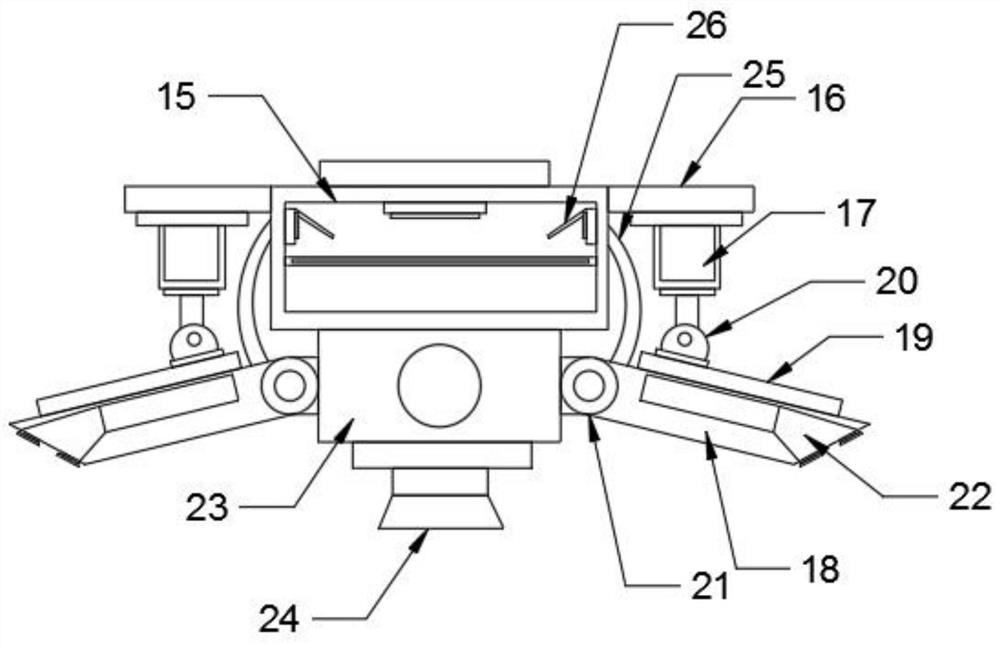

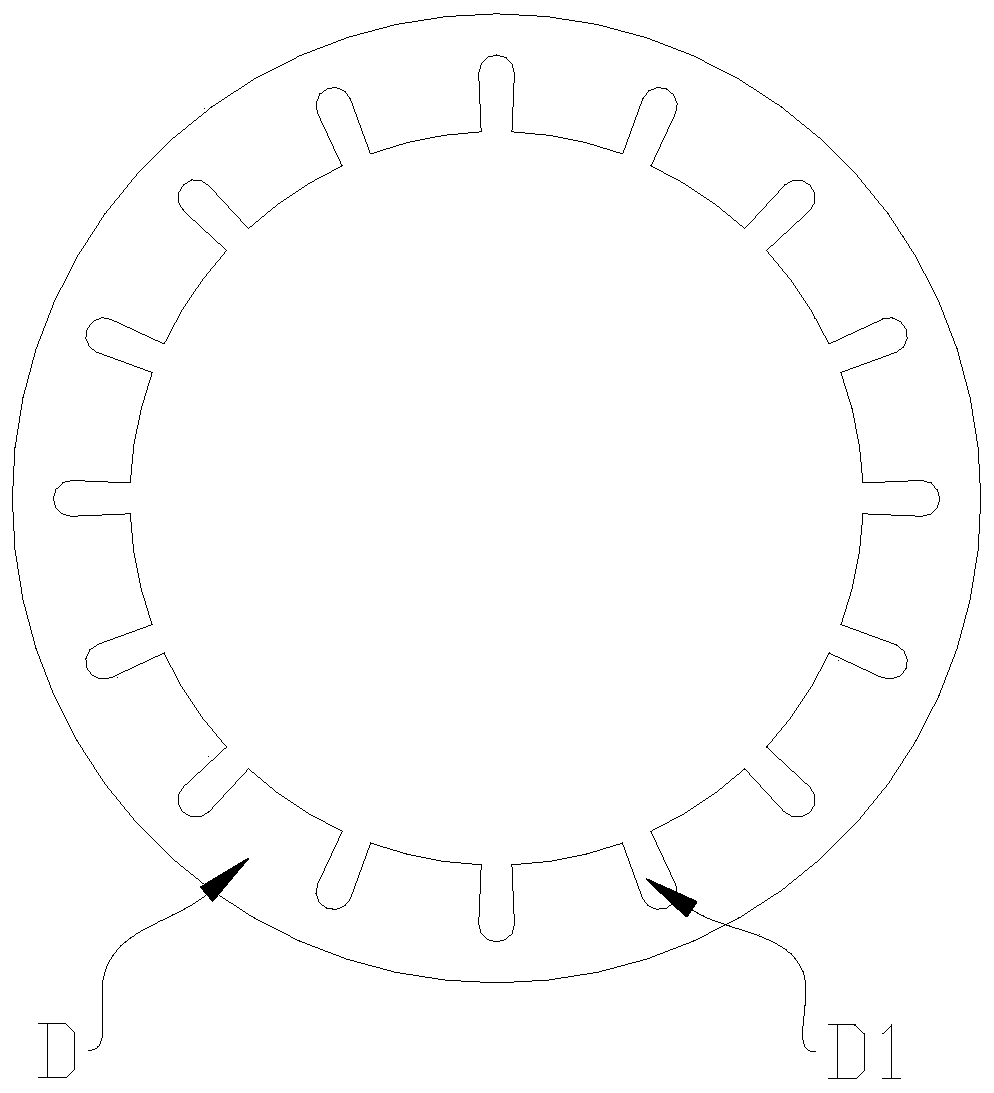

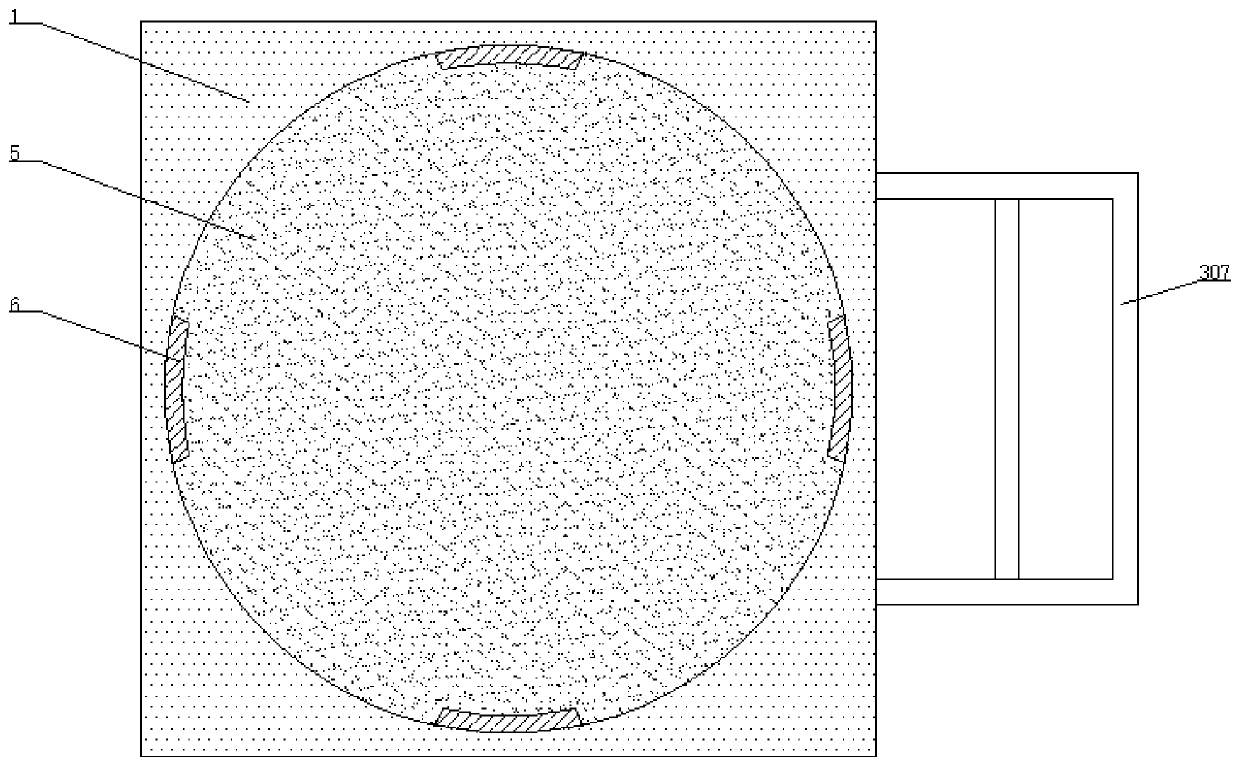

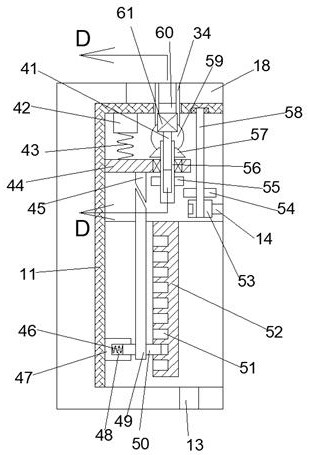

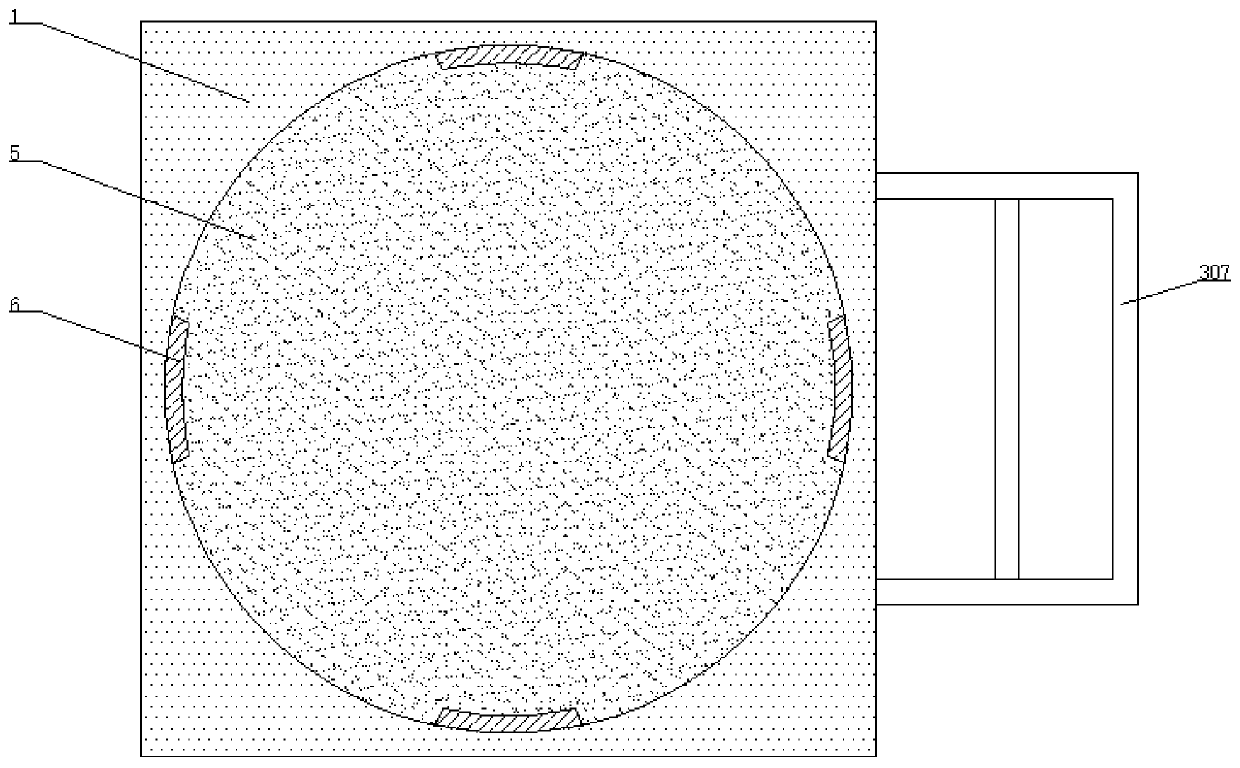

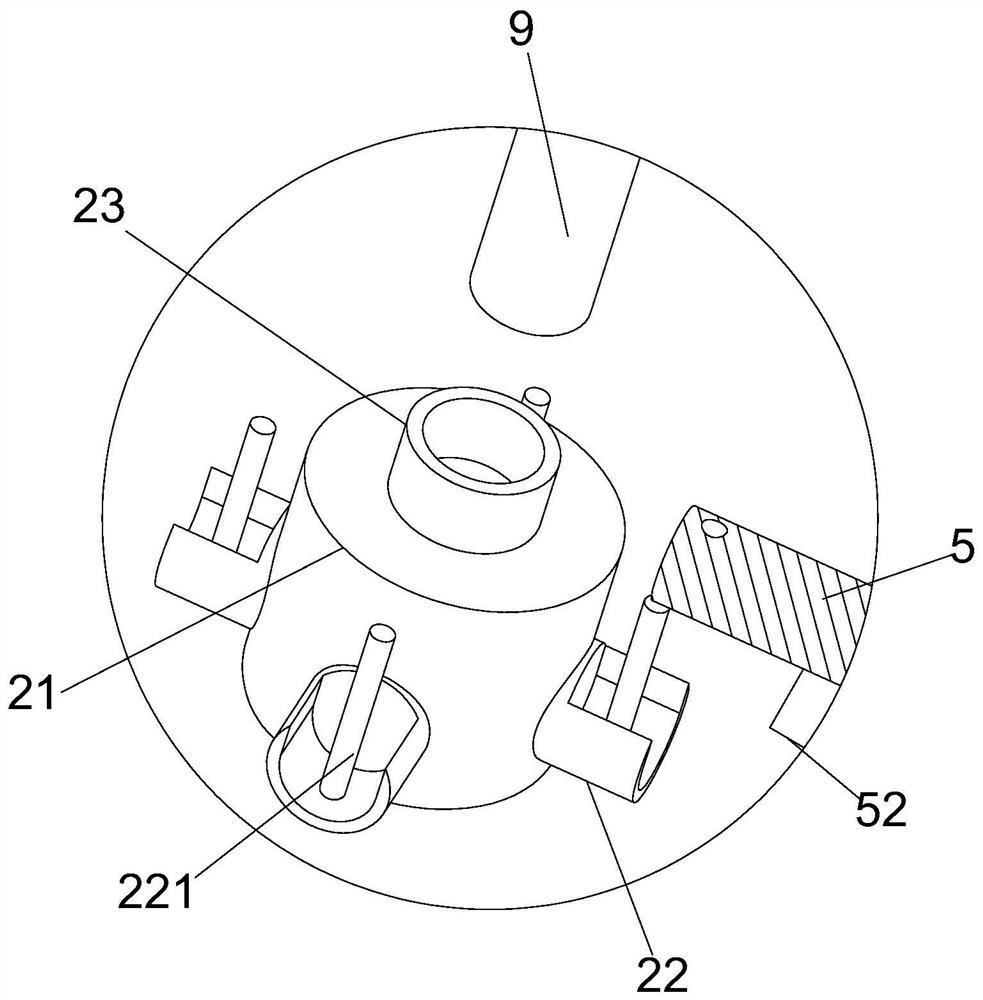

Processing treatment device for motor stator

InactiveCN111013864APrevent circumferential rotationEasy to installSpraying apparatusElectric machineEngineering

The invention discloses a processing treatment device for a motor stator. The device comprises a supporting piece, supporting plates, a limiting piece and at least one supporting part, wherein each supporting part comprises a plurality of supporting units, the plurality of supporting units are arranged in one-to-one correspondence with the supporting plates, the lengths of the supporting units canbe adjusted to change the distances between the supporting plates and the supporting piece, the adjustable structure can enable the device to clamp the stators with different inner diameters, and meanwhile, the assembly and the disassembly of the stator can be facilitated. In order to solve the problems that when the surface of the stator is painted, paint may be sprayed on the parts, which are not covered with the stator, of the supporting piece, the supporting plates, the limiting piece, and the supporting part, pollution is generated, and reuse of the device is influenced, the device is also provided with a shielding part, so that the occurrence of the above situation is effectively prevented. The device can effectively clamp the stator for processing, can make paint spraying more uniform during paint spraying operation of the stator, and improves the paint spraying effect.

Owner:宣城坚腾智能传动设备有限公司

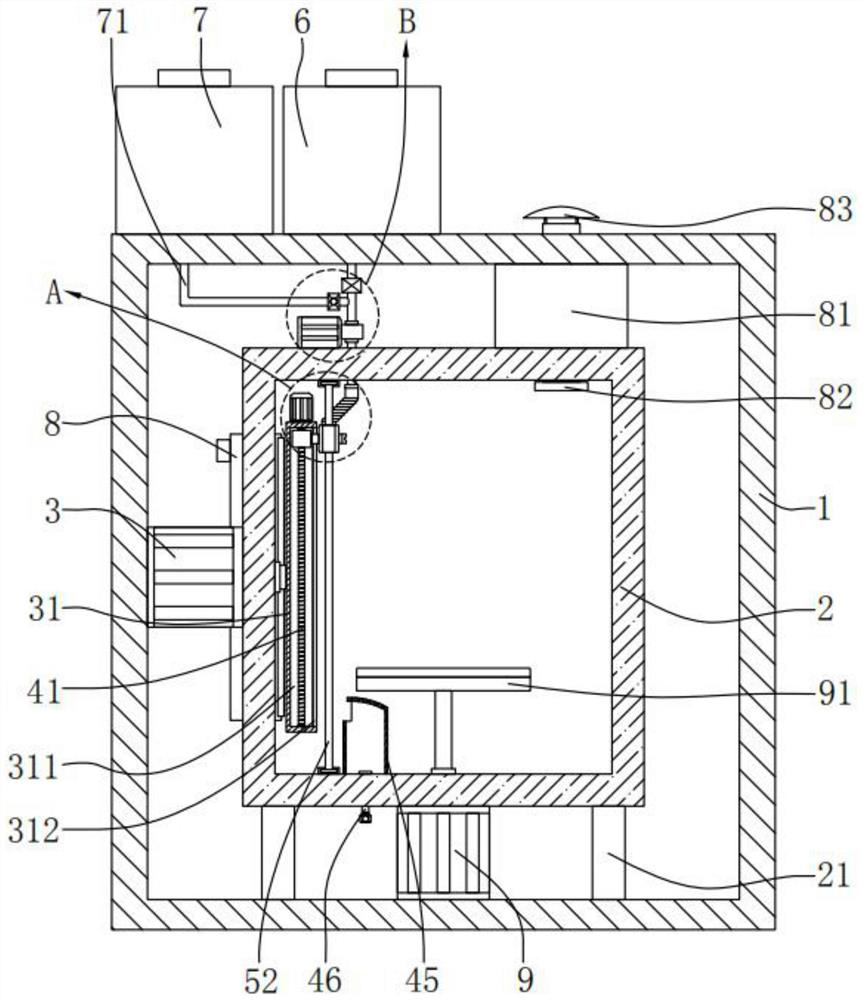

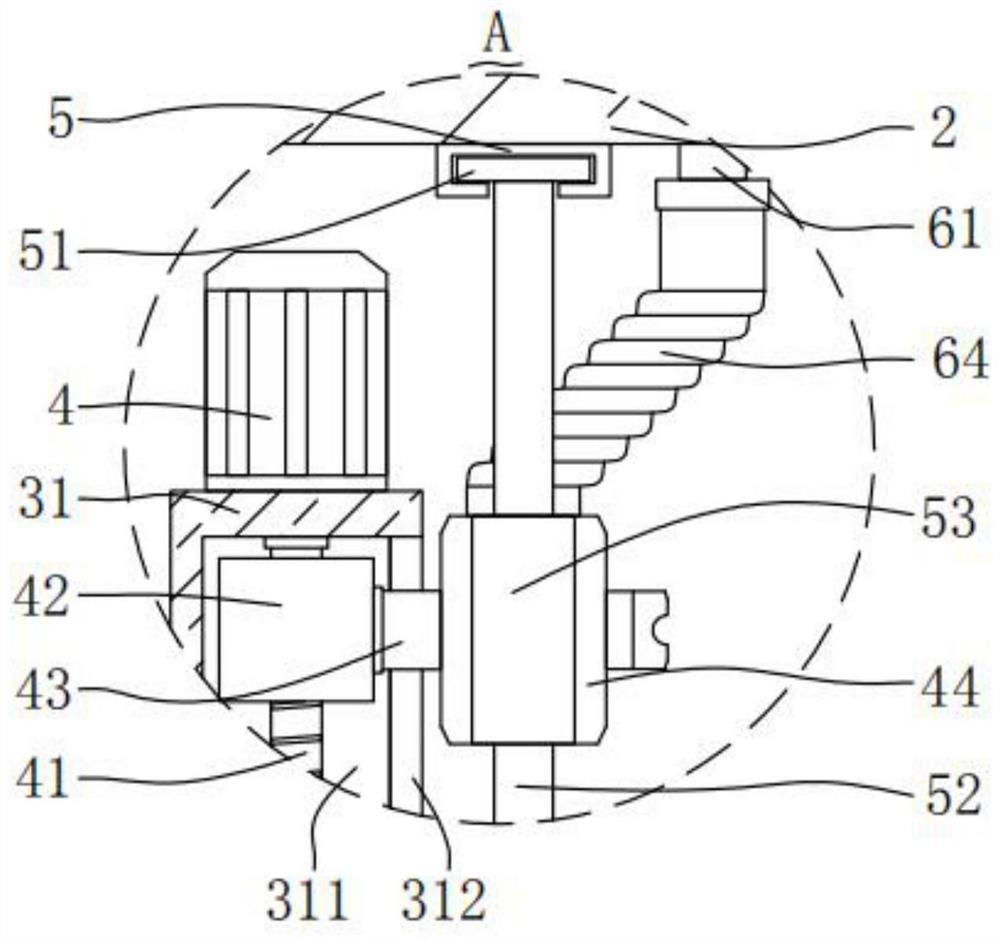

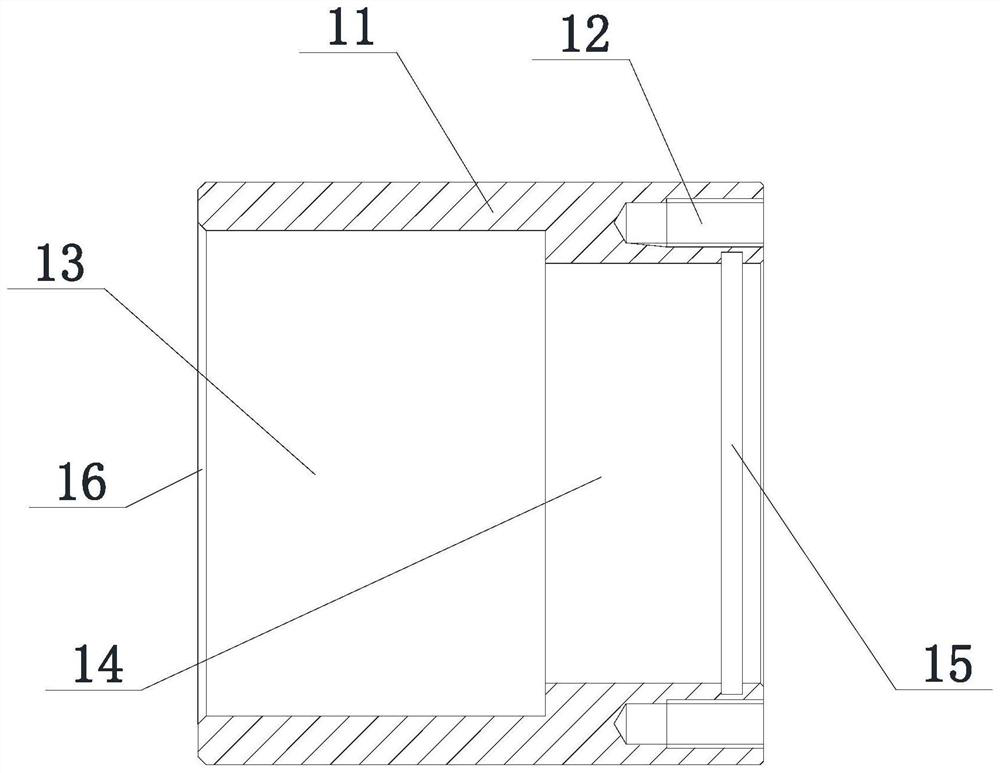

Paint spraying device with drying function used for wooden furniture processing

InactiveCN112337712AWith drying functionWork lessPretreated surfacesCoatingsElectric machineryIndustrial engineering

The invention provides a paint spraying device with a drying function used for wooden furniture processing. The paint spraying device with the drying function used for wooden furniture processing comprises a box body, an isolation box and an adjusting motor, wherein the bottom part of the isolation box is fixedly connected with supporting rods; one side of the adjusting motor is fixed to one sideof the inner wall of the box body. According to the paint spraying device with the drying function used for wooden furniture processing, a rotary adjusting way is employed to replace a threaded movingadjusting way of a moving screw rod, so that the working duration and the abrasion degree of the moving screw rod are reduced, the service life of the moving screw rod is prolonged, and the maintenance cost is reduced; a paint spraying pipe can meet different paint spraying ways of vertical paint spraying and horizontal paint spraying, so that the paint spraying requirements of different wooden furniture are met; and a cleaning solution flushes the interiors of a main pipeline, a telescopic hose and the paint spraying pipe after passing through a cleaning pipe, thereby avoiding that paint issolidified in the telescopic hose and the paint spraying pipe for fear of influencing the stability of equipment operation.

Owner:颍上县方圆新材料有限公司

Electric vehicle body machining process and special grinding tool

InactiveCN109531286AImprove balanceConvenient painting operationEdge grinding machinesGrinding carriagesEngineeringElectric vehicle

The invention discloses an electric vehicle body machining process and a special grinding tool thereof, and belongs to the technical field of electric vehicle machining. The machining process comprises the following steps that rough shape cutting is carried out, and specifically a pipe and a board are cut according to the machining sizes to obtain sheet metal part blanks; forming is carried out, and specifically stamping and bending are carried out on the sheet metal part blanks to obtain frame accessories; welding is carried out, and specifically the frame accessories are connected together to form a vehicle body through welding; grinding is carried out, and specifically all joints on the vehicle body are polished and leveled; spraying is carried out, and specifically paint is sprayed onthe surface of the vehicle body; and drying is carried out, and specifically the paint is dried. The tool comprises a base, wherein a grinding wheel, calipers and clamps are arranged on the base, thegrinding wheel is fixedly installed on the base through a support, the calipers are fixedly arranged on the two sides of the grinding wheel, the clamps are symmetrically distributed on the outer sidesof the calipers, and the grinding wheel and the clamps can rotate in situ. According to the technical scheme in the embodiment, a frame is more attractive, and the grinding effect is good.

Owner:湖南丽杰车业有限公司

Door panel spraying device

ActiveCN110665686BEasy to removeEasy to take off and put inSpray boothsStructural engineeringIndustrial engineering

Owner:重庆市佳禾家具制造有限公司

Automatic paint spraying machine

InactiveCN101185922BLow costTimely and pollution-free treatmentLiquid surface applicatorsSpraying apparatusControl systemEngineering

The invention relates to an automatic spray-painting machine, comprising a machine station, a spraying chamber, a work piece delivery device, a cover die device, a spraying device arranged in the spraying chamber, a rotating die device, a washing die device, a cleaning dirty device and a control system. The work piece delivery device is provided with a work piece loading plate; the cover die device comprises a cover die driving mechanism and an incremental launching column which can support the work piece loading plate and correspondingly lift and drop; the rotating die device comprises an upright column, a die base fixed on the top of the upright column, power elements for die base lifting and a rotating die driving mechanism. The die base is arranged in the spraying chamber and two endsof the die base are respectively positioned below the praying device and the washing die device. Two ends of the die base are respectively provided with dies and the middle part of the die base is provided with an isolation board. The invention can cover die automatically and do spraying and die washing work simultaneously. Only by rotating the die base, the position of the used die and the position of washed die can be exchanged, so as to realize high-speed and continual spraying process. The invention is high in automation degree and low in die cost. Due to the timely non-feculence treatmentto the waste water and waster gas, the invention is also beneficial to environmental protection.

Owner:SHENZHEN KUNHAN TECH

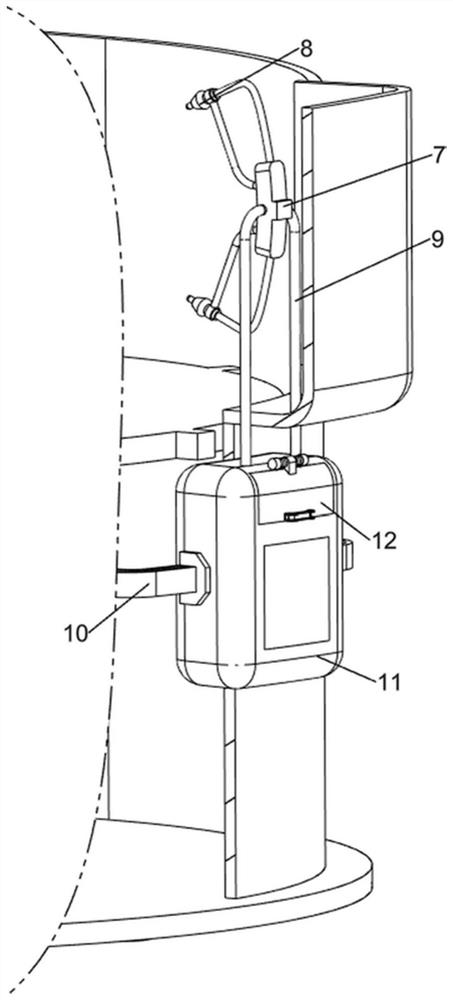

A Ventilation System for Containing Contaminant Escape from Open Paint Spaces

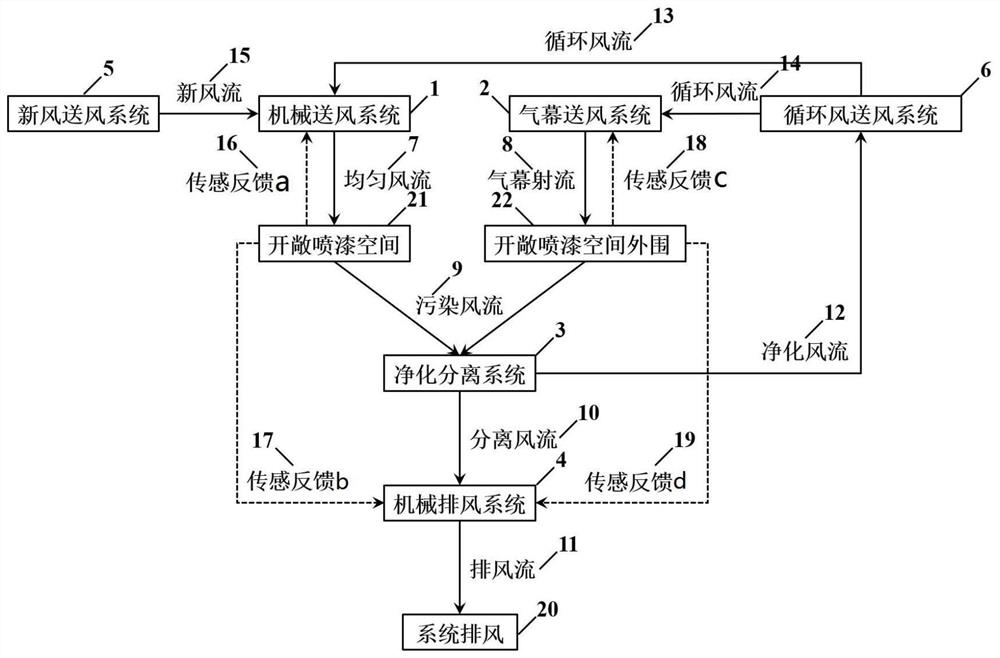

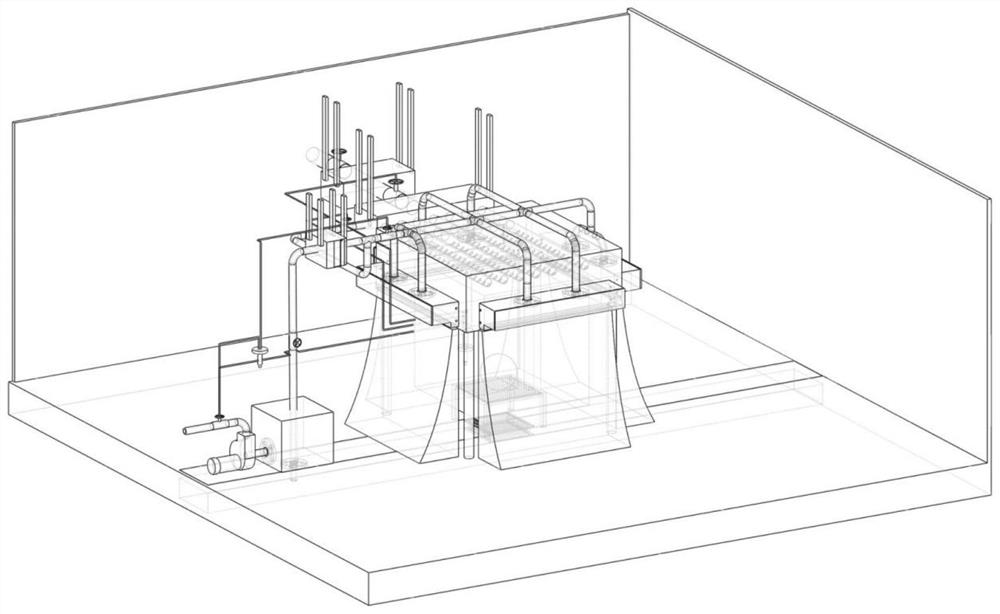

ActiveCN112902346BGuaranteed utilizationReduce power consumptionDucting arrangementsMechanical apparatusElectrical energy consumptionFresh air

The invention discloses a ventilation system for suppressing the escape of pollutants in an open paint spraying space. The periphery of the open painting space; the air flowing through the open painting space and the periphery of the open painting space forms a polluted airflow and enters the purification and separation system, in which the separation airflow with high pollutant concentration and the purification airflow with low pollutant concentration are formed. Air flow, the separated air flow with high pollutant concentration is discharged through the exhaust air flow through the mechanical exhaust system, and the purified air flow with low pollutant concentration is sent to the mechanical air supply system and the air curtain air supply system respectively by the circulating air supply system. The fresh air supply system described above forms a fresh air stream and sends it into the mechanical air supply system. The invention realizes the linkage between the operation of the ventilation system and the dynamic change of the concentration of pollutants in the environment, and reduces the power consumption and air consumption of the ventilation system during the painting process in an open space.

Owner:DALIAN UNIV OF TECH

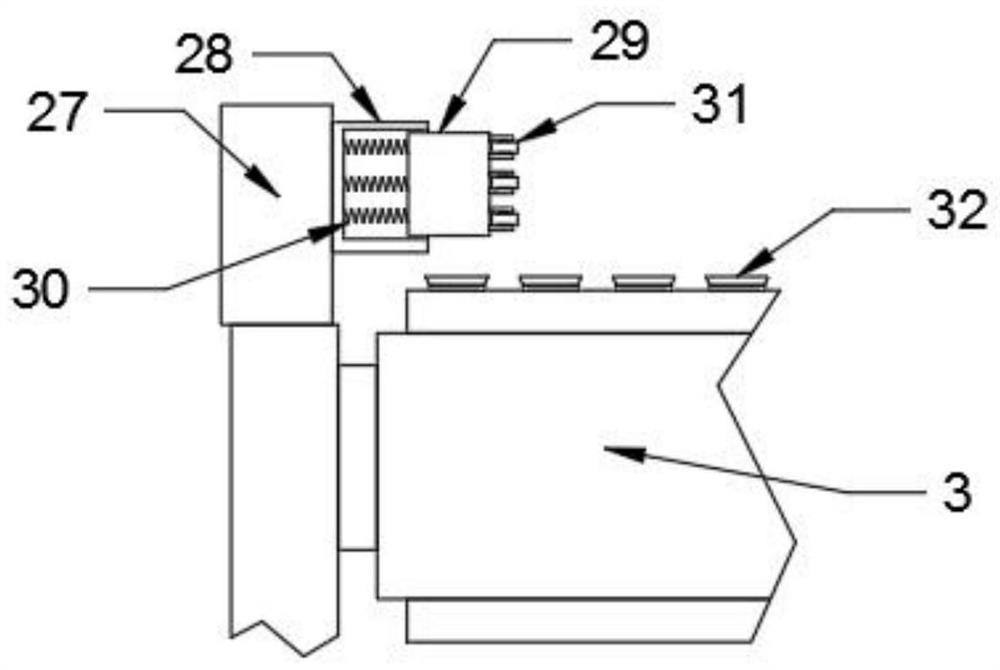

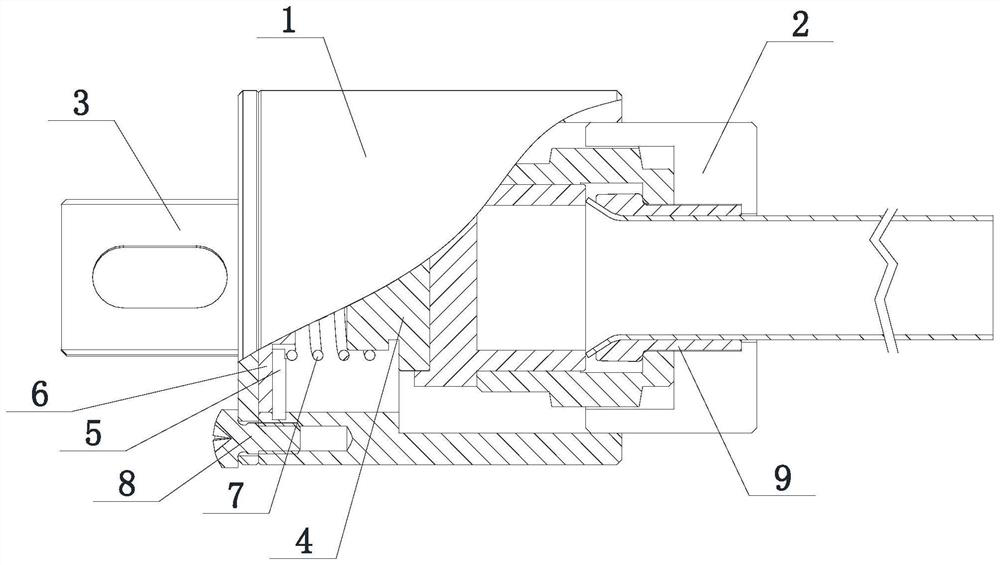

Protection cover for paint-spraying fixing assembly

The invention discloses a protection cover for a paint-spraying fixing assembly. The protection cover for the paint-spraying fixing assembly comprises a protection cover body, wherein a blanking cap assembly which is in threaded connection with the inner side wall of the protection cover body and capable of enabling the paint-spraying fixing assembly to pass through is arranged at one end of the protection cover body; an end cover in sealing connection with the inner part of the protection cover body is arranged at the other end of the protection cover body; a spring plug contacting the paint-spraying fixing assembly and tightly pressing the paint-spraying fixing assembly is arranged at one end, close to the paint-spraying fixing assembly, in the blanking cap assembly; a retainer ring fora hole is formed in one end, close to the end cover, on the inner side of the protection cover body; a spring washer is arranged on the inner side of the retainer ring for the hole; and a compressionspring is arranged between the spring washer and the spring plug. The protection cover for the paint-spraying fixing assembly provided by the invention can solve the problem so as to protect the paint-spraying fixing assembly in the paint spraying process.

Owner:成都长之琳航空制造有限公司

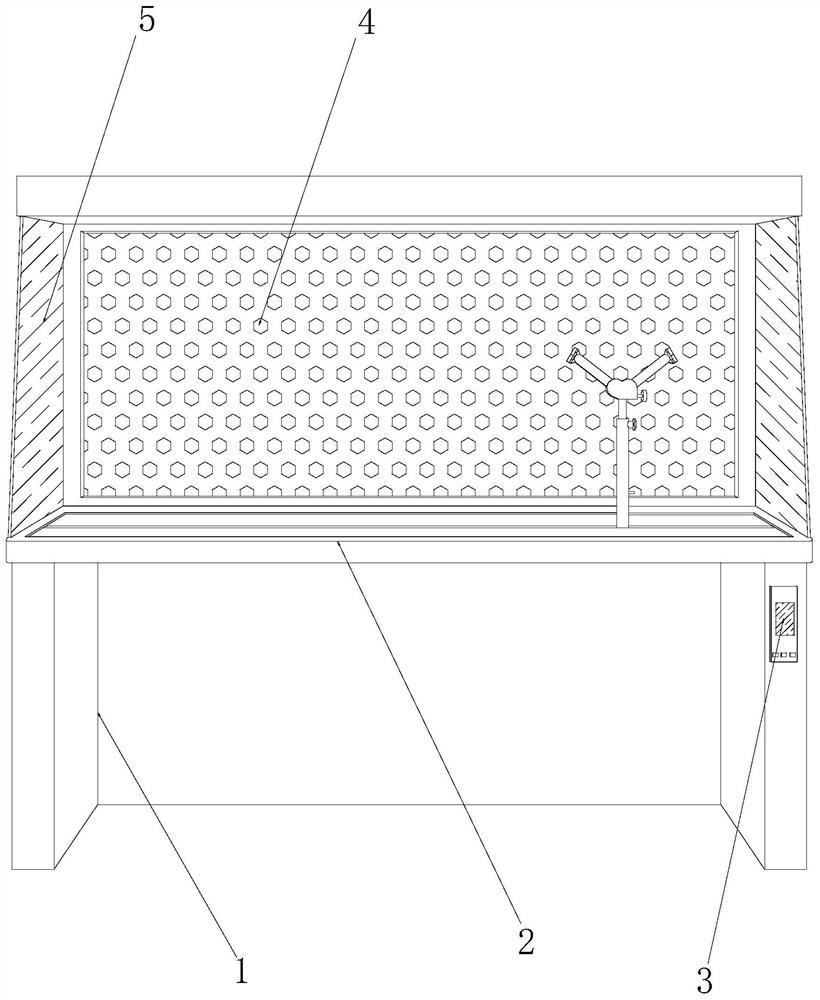

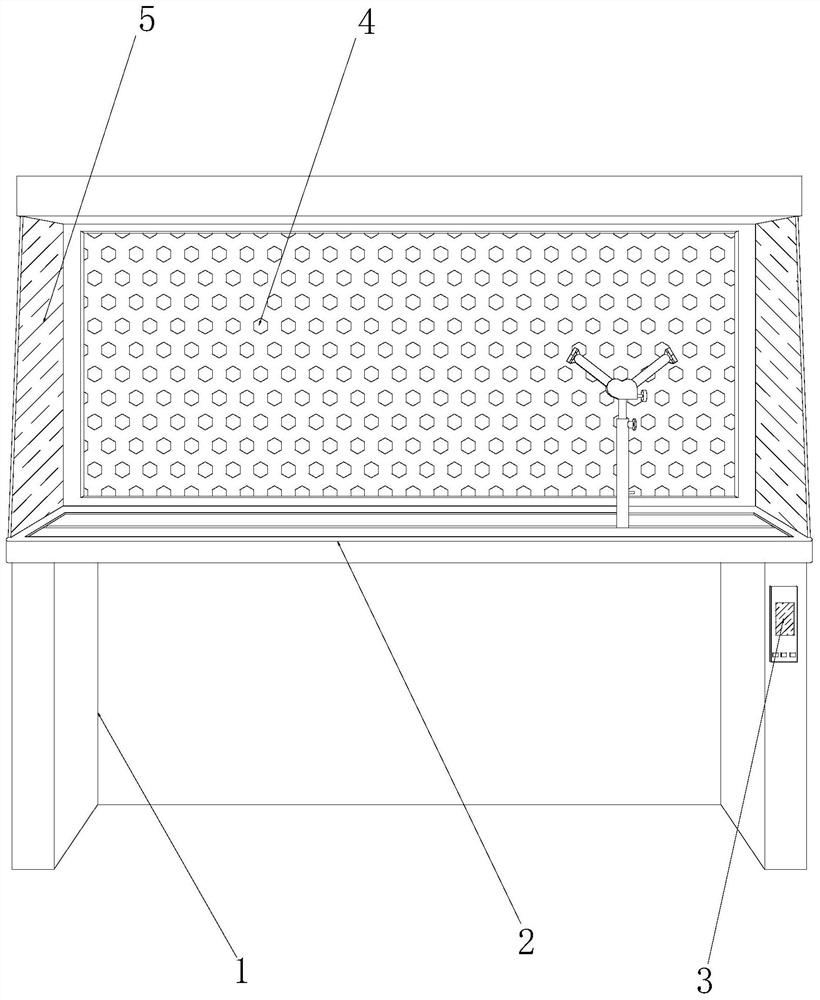

Hardware paint spraying workbench with clamping function

ActiveCN113171901AConvenient painting operationFull paint jobSpraying apparatusWorkbenchElectrical equipment

The invention discloses a hardware paint spraying workbench with a clamping function. The workbench structurally comprises a support, a containing table, a controller, an air suction device and partition plates; the containing table is connected with the upper portion of the support in a welded mode; the controller is installed at the right end of the front face of the support; the air suction device is fixedly connected with the rear end of the upper portion of the containing table in an embedded mode; and the partition plates are bonded to the upper portion of the containing table through a glue solution. According to the containing table of the hardware paint spraying workbench with the clamping function, a hollow metal electric appliance shell or handicrafts can be fixed in the air, and the height and the left-right position of a paint spraying part on the containing table can be stably adjusted, so that the paint spraying part can be painted more conveniently and comprehensively, the paint spraying part is formed through one-time operation, the workload is reduced, and the operation time is shortened. A fixer of the workbench can flexibly adapt to the inner walls of the various hollow metal electric appliance shells or the handicrafts, and is supported in the air through a magnetic force, so that the processing range of workbench is wider, and paint spraying parts with complex structures can be comprehensively painted.

Owner:肇庆市广兴美金属制品有限公司

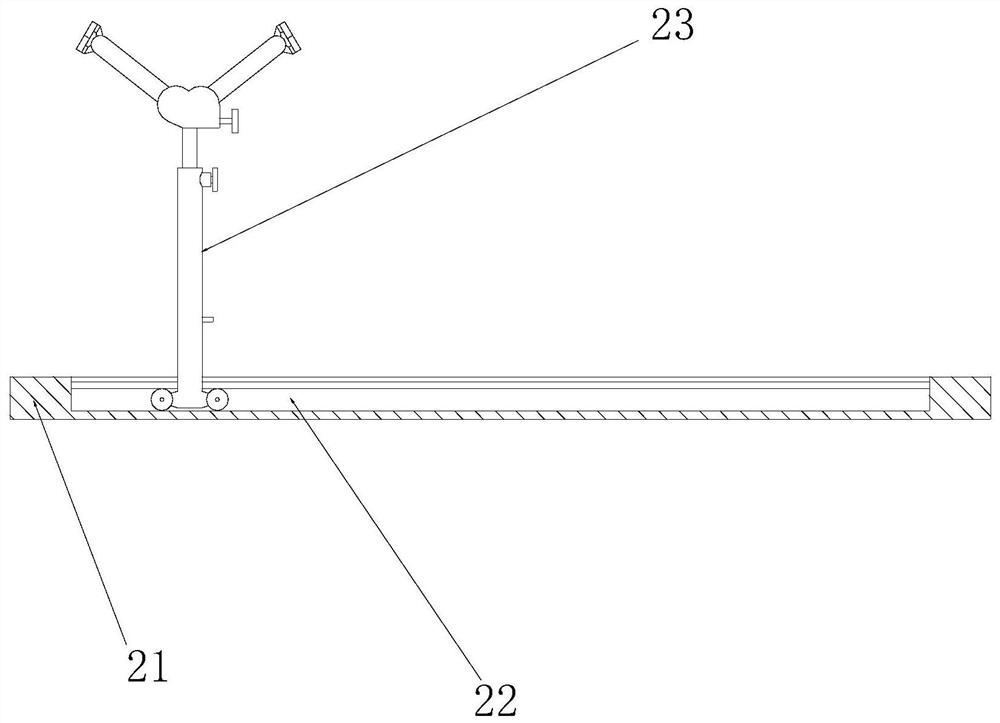

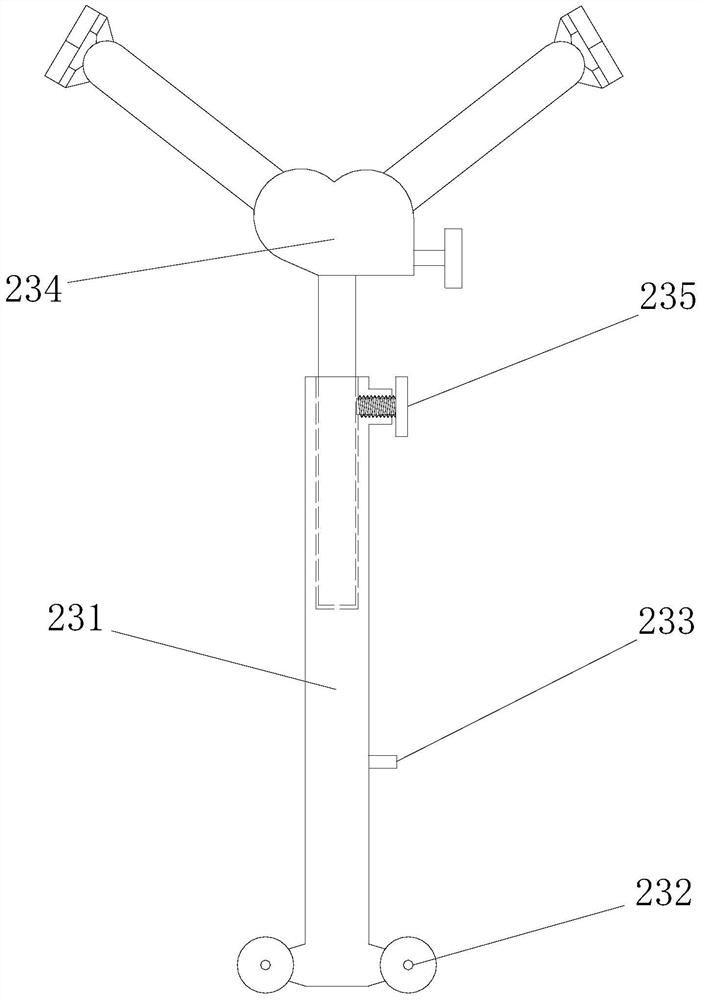

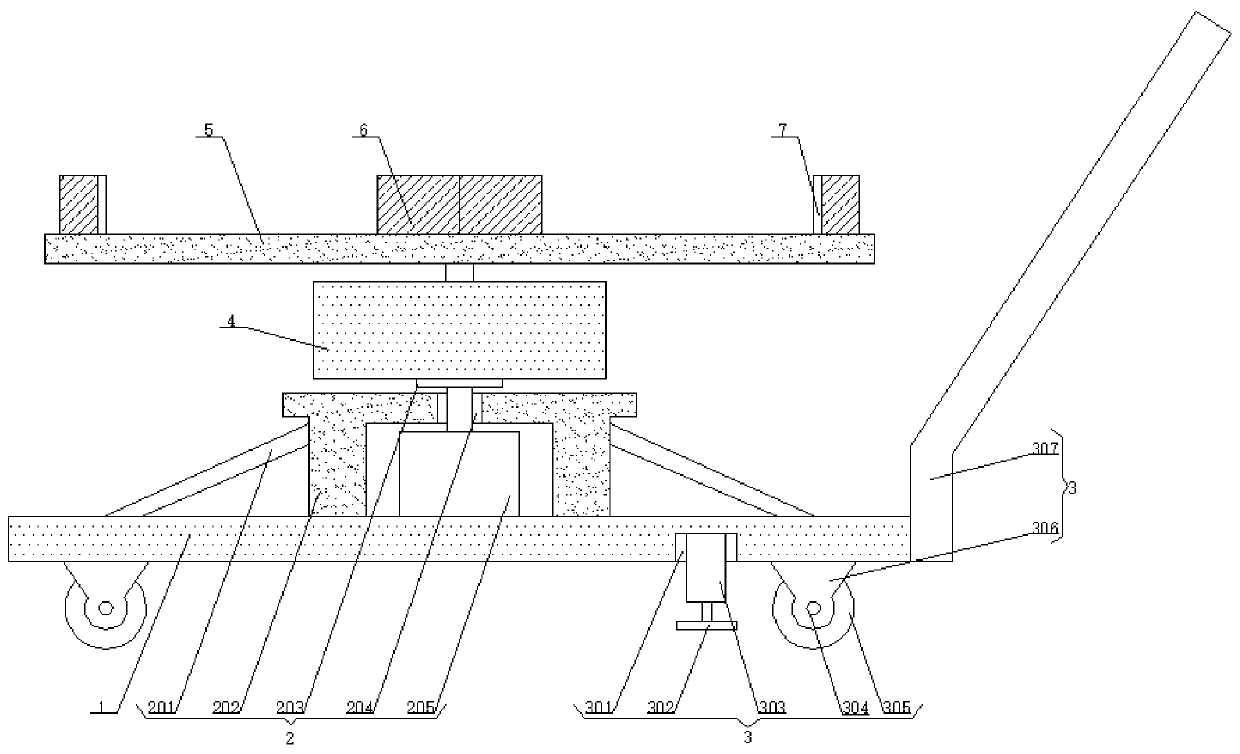

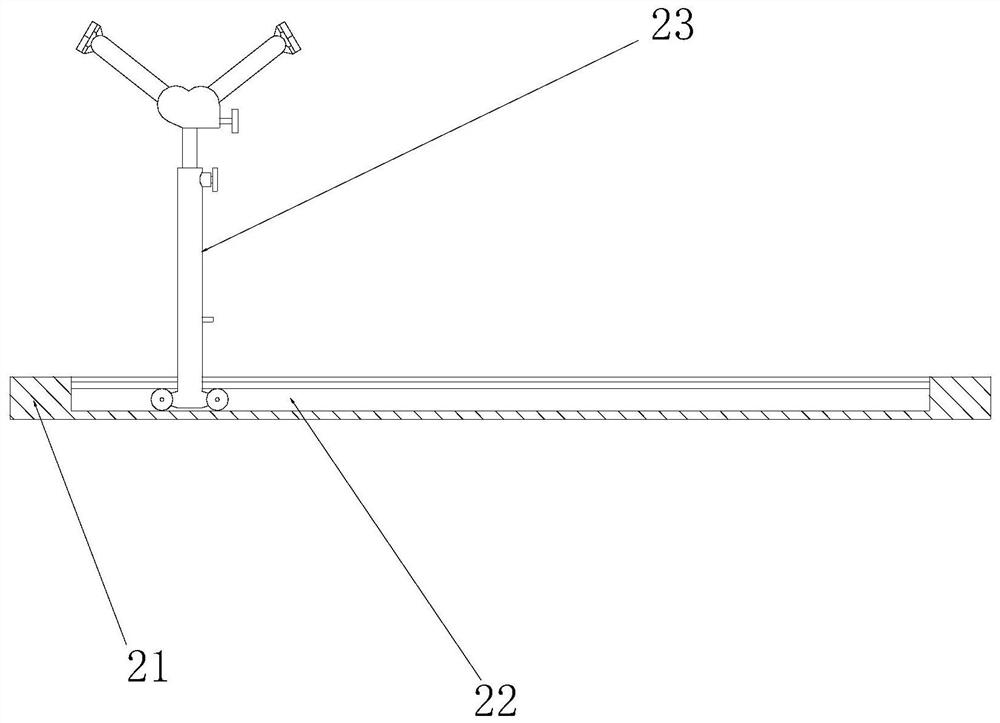

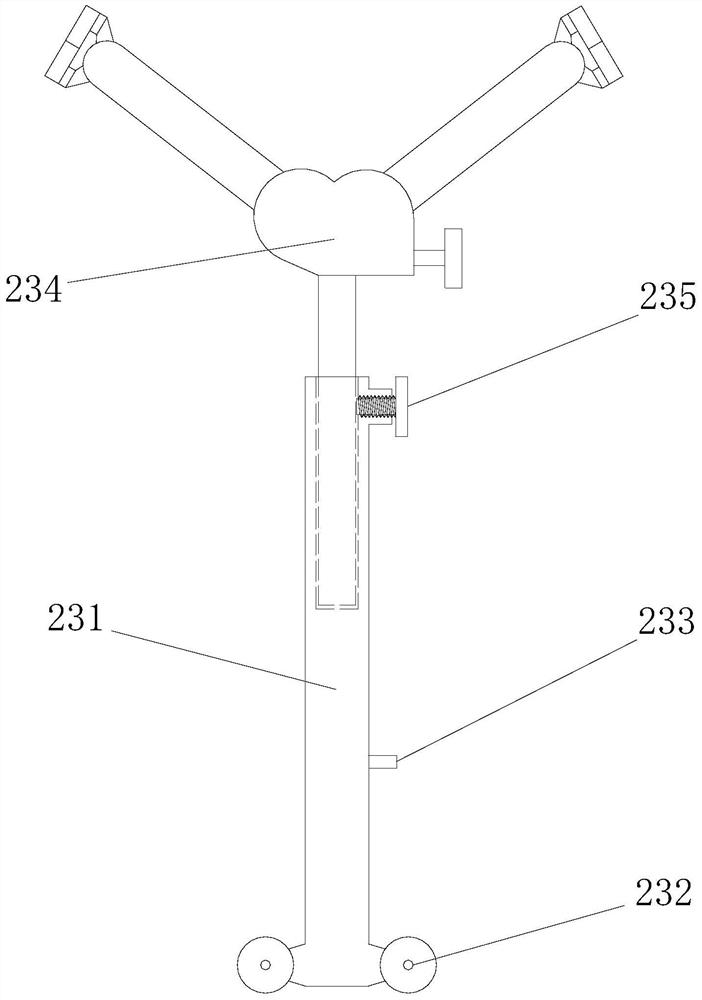

A high temperature resistant rotary lift paint transport vehicle

Owner:合肥龙智机电科技有限公司

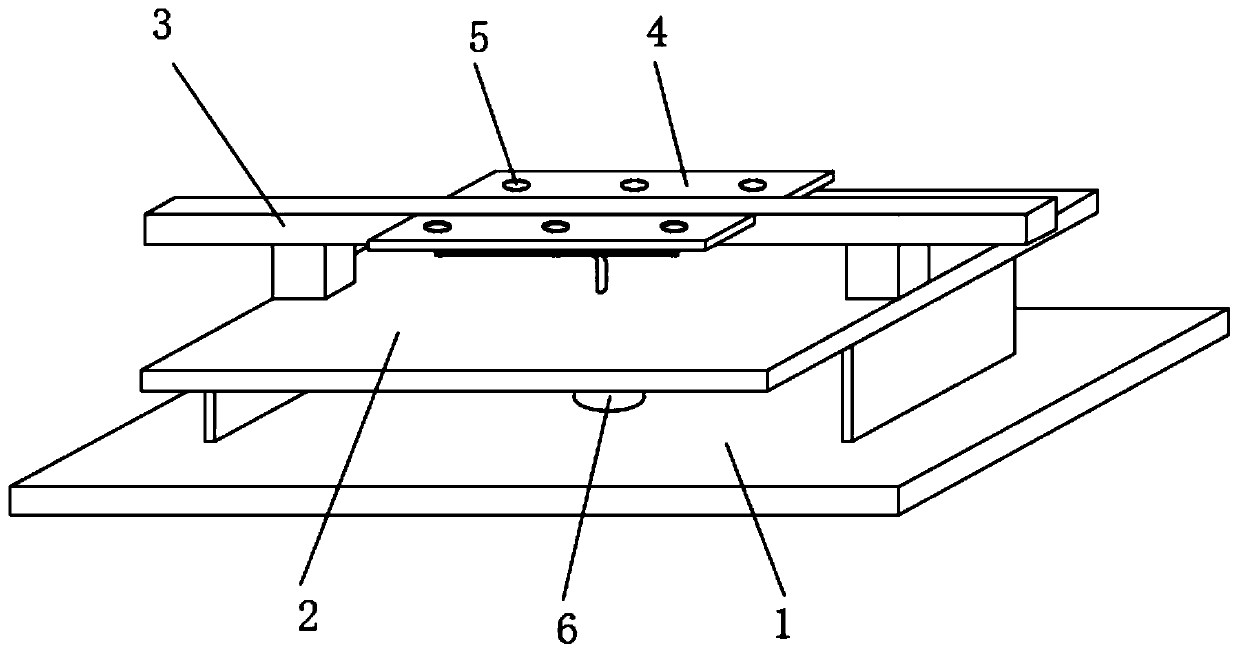

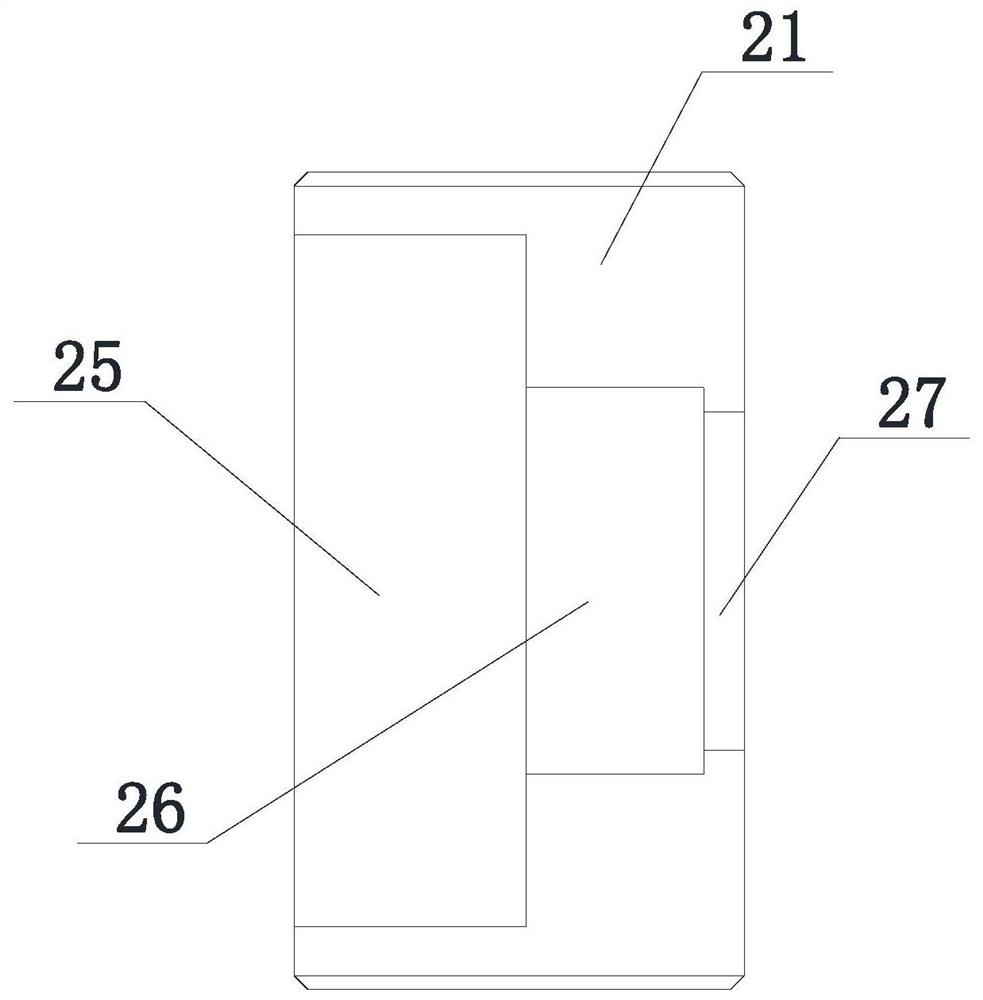

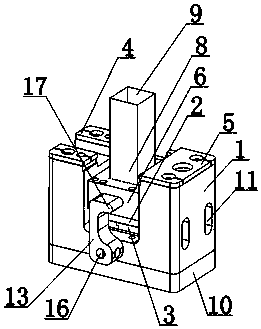

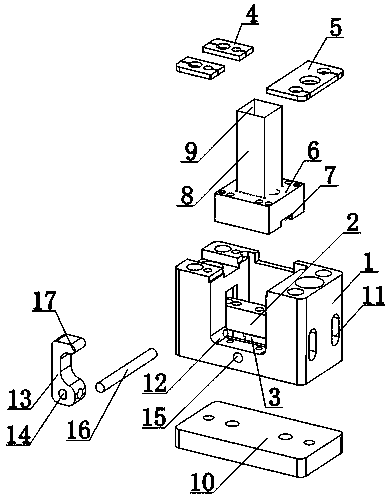

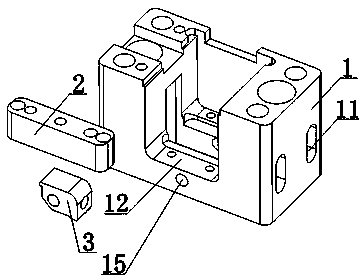

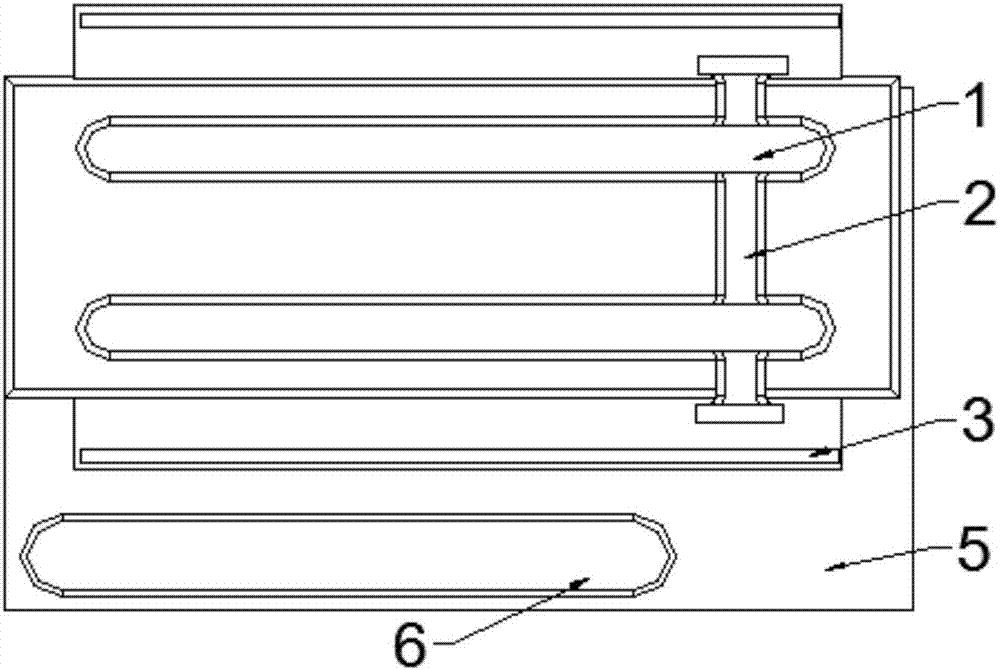

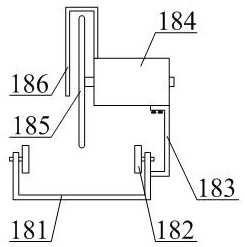

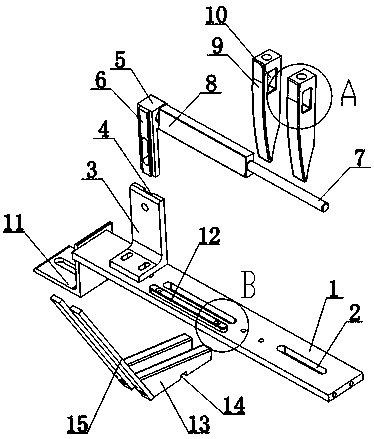

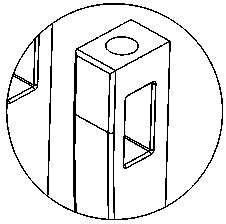

Seamless rectangular pipe sleeve device for paint spraying machine

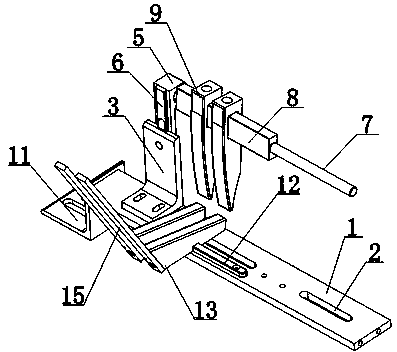

InactiveCN109201375AConvenient painting operationEasy to fixSpraying apparatusEngineeringMechanical engineering

The invention discloses a seamless rectangular pipe sleeve device for a paint spraying machine. The seamless rectangular pipe sleeve device comprises a base, wherein a positioning block is arranged atthe inner top of the base, and a fixing block is arranged between the positioning block and the inner top of the base; a first fixing plate is arranged on one side of the end part of the base, and asecond fixing plate is arranged on the other side of the end part of the base; a positioning seat is arranged in the base, a clamping groove is formed in the bottom of the positioning seat, and the positioning seat is clamped on the positioning block through the clamping groove; a positioning pipe is arranged on the positioning seat, the positioning pipe is vertically arranged, and a positioning groove is formed in the axial position of the positioning pipe; a bottom plate is arranged at the bottom of the base; and a sealing structure is arranged on one side of the base, and an opening is formed in the other side of the base. According to the seamless rectangular pipe sleeve device, the lower end of the seamless rectangular pipe can be conveniently sleeved through the positioning groove; and the end part of the base can be conveniently and fixedly installed through the fixing plate.

Owner:黄春梅

An automatic painting device for building steel

InactiveCN111570154BEliminate potential safety hazardsReduce distanceSpraying apparatusArchitectural engineeringStructural engineering

The invention discloses an automatic paint spraying device for building steel, which comprises a car body, the outer surface of the car body is slidably connected with a support bracket, a power chamber is arranged in the support bracket, a lifting assembly is arranged in the power chamber, and the support The upper end of the bracket is fixed with a support backboard, and the front end of the support backboard is provided with a horizontal adjustment assembly. The present invention can reduce the distance between the half-ring tracks when the building steel is located between the left and right half-ring tracks The distance between the left and right half-ring tracks is convenient for the subsequent painting operation; and the two ring-shaped half-ring tracks enable the sliders for painting that slide on the half-ring tracks to control the nozzles through the paint pipes to complete the construction of steel. Due to the automatic form of painting operation, compared with the manual painting method, it not only improves the efficiency, but also eliminates the safety hazards that exist when workers work at heights.

Owner:中铝长城建设有限公司

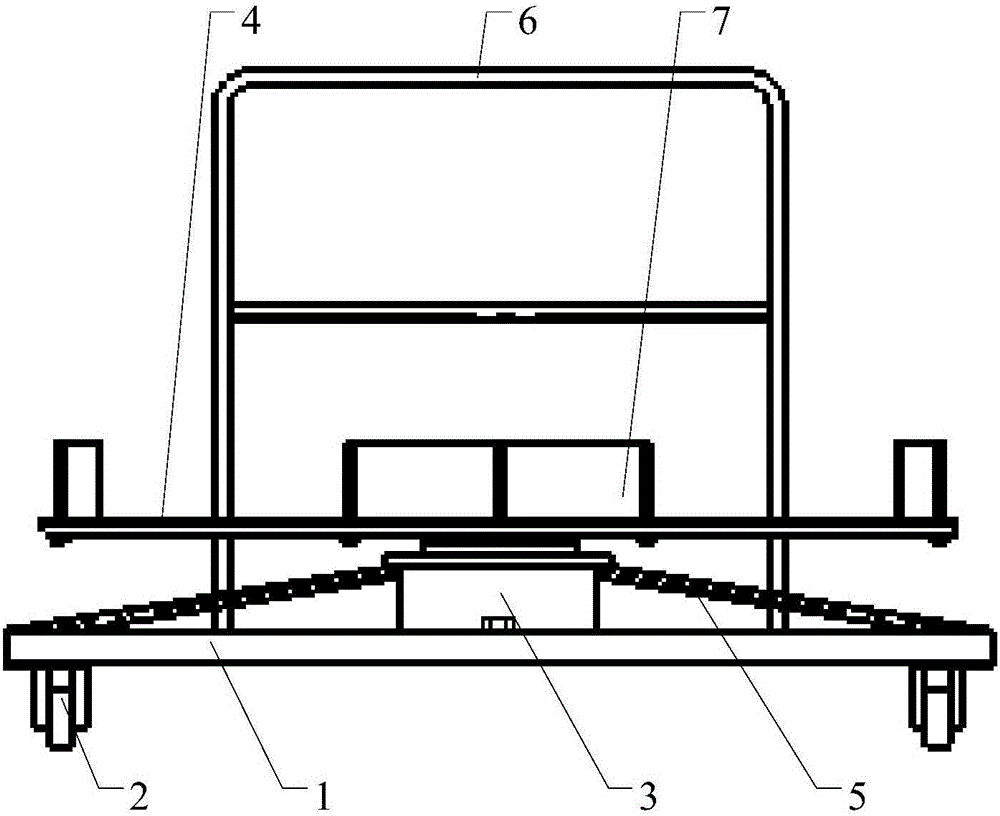

High-temperature-resistant rotary lifting paint spraying transport vehicle

ActiveCN109701785AGood painting operationImprove lifting effectSpraying apparatusSurface plateHot Temperature

Owner:合肥龙智机电科技有限公司

Fixing jig for vehicle door remanufacturing paint spraying

PendingCN114308453AConvenient painting operationQuick focusSpraying apparatusEngineeringIndustrial engineering

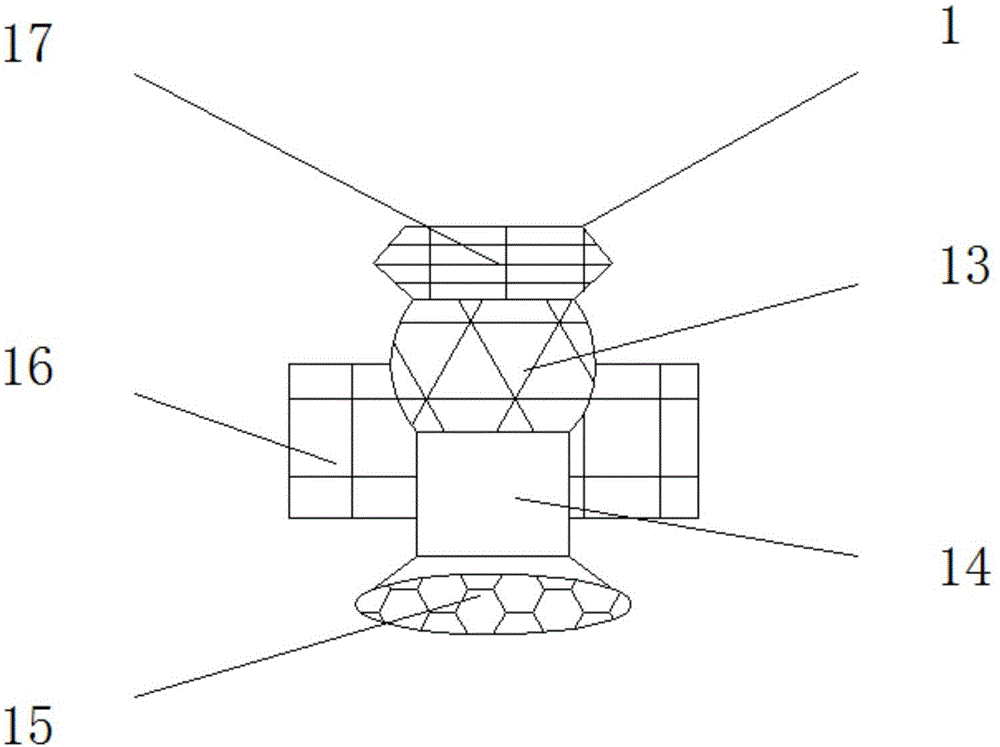

The invention discloses a vehicle door remanufacturing paint spraying fixing jig which comprises a support, a center piece, at least two fixing pieces and an extraction piece, the support is detachably connected with the center piece, the fixing pieces are detachably arranged on the center piece, the at least two fixing pieces are arranged on the periphery of the center piece, and the extraction piece is arranged on the center piece. The fixing piece comprises a fixing seat used for fixing a vehicle door and a mounting piece, the mounting piece is connected with the fixing seat in a sliding mode and used for adjusting the distance between the fixing seat and the center piece, and an extraction piece is further arranged on the center piece; according to the vehicle door remanufacturing paint spraying fixing jig, two or more vehicle doors can be fixed at the same time, the vehicle doors in different states can be replaced conveniently, the paint spraying efficiency of the vehicle doors is improved, and due to the fact that the extracting pieces are arranged, the multiple vehicle doors can be uniformly and conveniently installed for paint spraying operation; and a plurality of painted vehicle doors can be moved to the next working procedure at the same time.

Owner:中之捷(常州)汽车零部件再制造有限公司

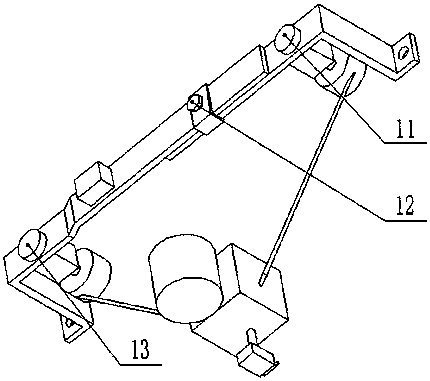

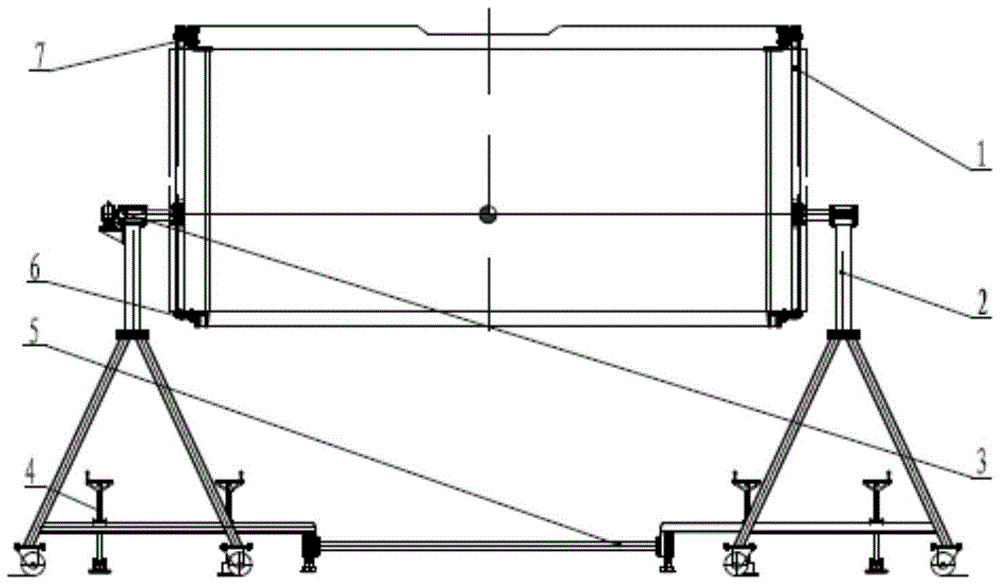

Large-scale satellite frame paint-spraying and overturning device

ActiveCN105032657AAdapt to painting operationFast painting operationSpraying apparatusSupporting systemSatellite

The invention discloses a large-scale satellite frame paint-spraying and overturning device. The device is mainly composed of a connecting frame, two A-shaped brackets, a connecting rod, support systems, rotating mechanisms, upper frame connecting rings and lower frame connecting rings, wherein the upper frame connecting rings and the lower frame connecting rings are fixed to a satellite, and the connecting frame is connected with the upper frame connecting rings and the lower frame connecting rings, so that connection with the satellite is achieved, the connecting frame is fixedly connected with revolving shafts on the A-shaped brackets, a product is supported through the A-shaped brackets, the rotating mechanisms are connected with the revolving shafts on the A-shaped brackets, the connecting frame is driven to rotate through the rotation of the rotating mechanisms, and the satellite rotating and overturning function is achieved. The device is an overturning tool which is capable of supporting the satellite to be placed and transferred horizontally and achieving the 360-degree rotation of the satellite, the problem of paint-spraying operation when the satellite is placed in two states, namely horizontally and vertically, is solved, and a novel approach for spraying the satellite in the two states subsequently is provided.

Owner:SHANGHAI INST OF SATELLITE EQUIP

A workbench for hardware spray painting with clamping function

ActiveCN113171901BConvenient painting operationFull paint jobSpraying apparatusWorkbenchElectrical equipment

The invention discloses a workbench for hardware spray painting with clamping function. , the suction device is embedded and fixed on the rear end above the placing table, and the partitions are respectively bonded on the top of the placing table through the glue solution; Stable adjustment of the height and the left and right positions of the painting parts on the placing table enables the painting parts to be painted more conveniently and comprehensively. It adapts to the inner wall of various hollow metal electrical enclosures or handicrafts, and supports it in mid-air by magnetic force, so that the processing range of the equipment is wider, and the painted parts with complex structures can also be fully painted.

Owner:肇庆市广兴美金属制品有限公司

Simple spraying device

The invention provides a simple spraying device, which includes a paint spraying pipe, and also includes a support frame for supporting the paint spraying pipe, and a track for connecting the paint spraying pipe is arranged in the support frame, and the paint spraying pipe and the rail For sliding connection, the end of the paint spraying pipe is provided with a blocking piece to prevent the paint spraying pipe from detaching from the track, and the lower end of the support frame is fixedly connected with an operating platform. The beneficial effect of the present invention is that by slidingly connecting the paint spraying pipe with the track of the support frame, it is beneficial to realize batch production.

Owner:天津优拓梦达科技有限公司

Intelligent container welding production system

PendingCN111774865AGuaranteed line stabilityGuaranteed cutting effectOther manufacturing equipments/toolsSmart controlLimit switch

The invention provides an intelligent container welding production system. The system comprises movable trundles, a welding supporting table, a welding machining movable base, a paint spraying box, apaint spraying pump, a soft paint pipe, an electric welding machine body, an intelligent control screen, an electric welding cable, a linear sliding rail, a limiting switch, a U-shaped movable base, an adjusting bolt, a supporting frame, a fixing hole and a fixing bolt, a bendable adjusting type scribing and marking roller pin structure, a movable cutting supporting wheel structure, a detachable welding splash-proof protective cover structure and a double-row paint spraying production nozzle structure, wherein the movable trundles are connected to the four corners of the bottom of the weldingsupporting table and the four corners of the bottom of a welding machining movable base through bolts respectively. Through the arrangement of a bendable metal flexible conduit, a scribing and markingpin, a connecting pipe, a buffer rod, a check ring, a wheel seat, a guide roller and a buffer spring, scribing and marking operation can be carried out on a to-be-cut container plate, and cutting operation is facilitated.

Owner:山东华海新材料有限公司

Hardware surface treatment device

ActiveCN114849956AImprove efficiency and effectivenessMultiple surface areaPretreated surfacesCoatingsElectric machineryElectrical and Electronics engineering

The invention relates to a treatment device, in particular to a hardware surface treatment device. According to the hardware surface treatment device, multiple pieces of hardware can be automatically and separately treated, the treatment efficiency is high, and the effect is ideal. The hardware surface treatment device comprises a supporting block, a fixing plate, an outer frame, a first positioning frame, a first fixing frame and the like. The bottom side of the outer frame is connected with the fixing plate, the left bottom side and the right bottom side of the fixing plate are connected with the supporting blocks in a front-back symmetry mode, and the supporting blocks are made of rubber and can play an anti-skid role. Hardware is clamped through the clamping frame, so that the superficial area of the hardware is more exposed, comprehensive paint spraying operation is facilitated, meanwhile, the multiple pieces of hardware can be separately treated, a chain is driven by a motor to rotate, the hardware is made to rotate, and then paint spraying treatment can be conducted on the hardware one by one through a spray head; and the paint spraying treatment effect is improved.

Owner:赣州嘉蓓乐实业发展有限公司

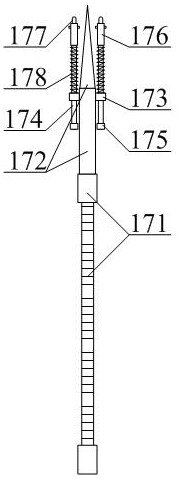

Full-automatic intelligent portable paint spraying brush

InactiveCN106140553AImprove aestheticsConvenient painting operationLiquid surface applicatorsCoatingsEngineeringData transmission

The invention discloses a full-automatic intelligent portable paint spraying brush. The full-automatic intelligent portable paint spraying brush comprises a spray paint extracting machine, a spray paint storage tank and a card slot machine, wherein the spray paint storage tank is mounted at the lower end of the spray paint extracting machine; the card slot machine is mounted at the lower end of the spray paint storage tank; an intelligent central controller is mounted under the card slot machine; a data transmission pipe is mounted at one end of the intelligent central controller; a paint compressor is mounted at the other end of the intelligent central controller; the intelligent central controller is connected to an automatic motor via the data transmission pipe; a fixing arm is mounted at one end of the automatic motor; an automatic regulator is mounted at one end of the paint compressor; an intelligent paint brush is mounted at one end of the automatic regulator; a paint sucking opening is mounted inside the paint extracting machine. Through the full-automatic intelligent portable paint spraying brush, the integrated full-automatic intelligent portable paint spraying brush technology is adopted, so that the effect of the full-automatic intelligent portable paint spraying brush can be achieved.

Owner:成都元始信息科技有限公司

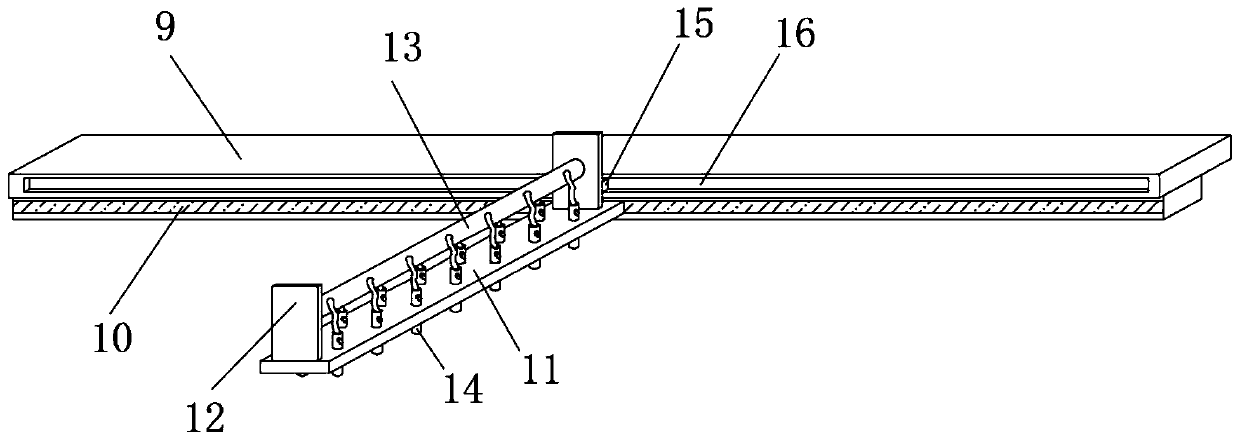

Sleeved mounting device used for painting inner-circular outer-square steel pipe

InactiveCN108722721AConvenience setConvenient painting operationSpraying apparatusAgricultural engineeringSteel tube

The invention discloses a sleeved mounting device used for painting an inner-circular outer-square steel pipe. The sleeved mounting device comprises a fixing plate; a supporting plate is arranged on the fixing plate, a clamping groove is formed in the back of the supporting plate, a fixing block is arranged on the back of the supporting block, a clamping block is arranged on the side wall of the fixing block and connected into the clamping groove in a clamped mode, and a positioning shaft is arranged at the end of the fixing block; on end of the positioning shaft is the free end, the other endof the positioning shaft is connected with the fixing block, and a sleeved mounting pipe is mounted on the outer peripheral surface of the positioning shaft in a sleeving mode; and an operating blockis mounted on the outer peripheral surface of the sleeved mounting pipe, a convex block is arranged on the fixing plate, an operating mechanism is arranged on the fixing plate and comprises the fixing block, a fixing groove is formed in the bottom of the fixing block, the convex block is mounted in the fixing groove, and an operating plate is arranged on the fixing block. By means of the sleevedmounting device, the inner-circular outer-square steel pipe can be conveniently mounted in a sleeved mode, and the sleeved mounting is more firm.

Owner:王玲芳

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com