Intelligent container welding production system

A production system and cargo box technology, applied in the field of intelligent cargo box welding production system, can solve problems such as inability to spray production, inability to weld marks, and easy occurrence of danger, to ensure the stability of marking lines, to avoid the danger of cutting and cutting, The effect of good protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

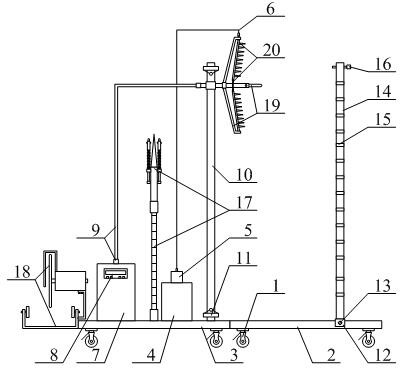

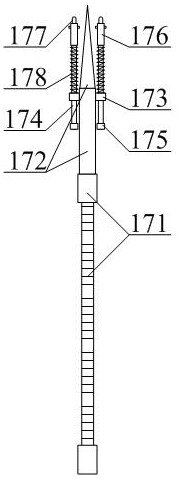

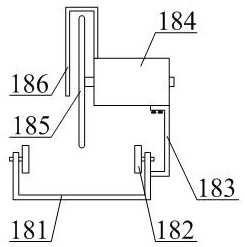

[0034] The present invention is described in detail below in conjunction with accompanying drawing, as shown in accompanying drawing 1 and accompanying drawing 2, a kind of intelligent container welding production system comprises mobile caster 1, welding support platform 2, welding processing mobile base 3, paint spraying box 4 , paint spray pump 5, soft paint tube 6, electric welding body 7, intelligent control panel 8, electric welding cable 9, linear slide rail 10, limit switch 11, U-shaped moving seat 12, adjusting bolt 13, support frame 14, fixed Holes 15, fixing bolts 16, bendable and adjustable marking needle roller structure 17, movable cutting support wheel structure 18, detachable welding splash guard structure 19 and double-row paint production nozzle structure 20, the The mobile casters 1 are respectively bolted to the bottom four corners of the welding support platform 2 and the bottom four corners of the welding processing mobile base 3; the lateral left end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com