Lineation positioning device and lineation method for throat width detection

A technology of positioning device and positioning piece, applied in the field of scribing positioning device and throat width detection, can solve the problem that the actual throat width cannot be obtained, the influence of the installation and welding of the diaphragm and the inspection of the manufacturing completion, and the inability to guarantee the manufacturing quality of the diaphragm, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

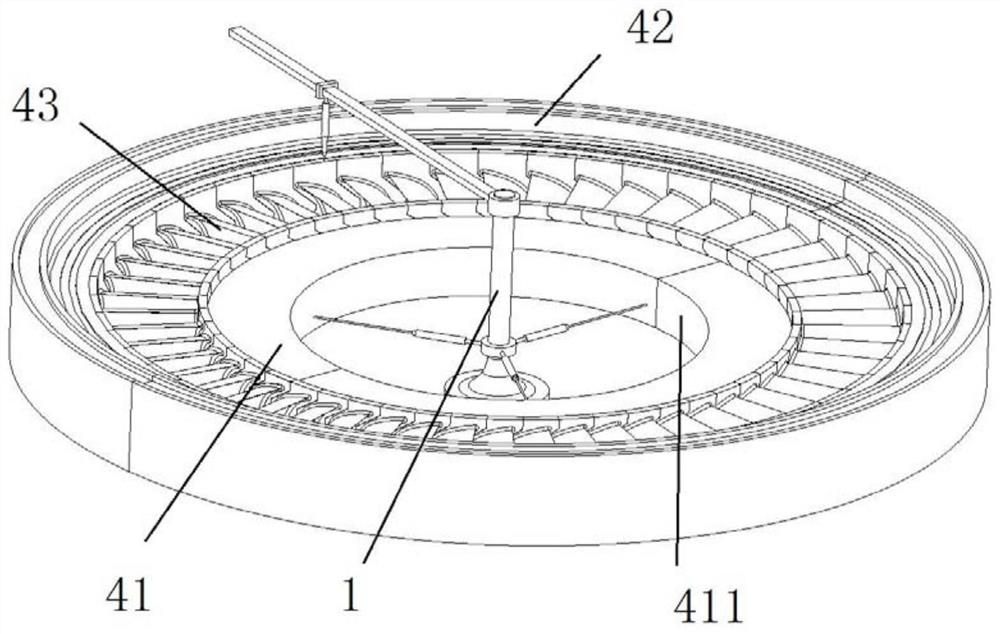

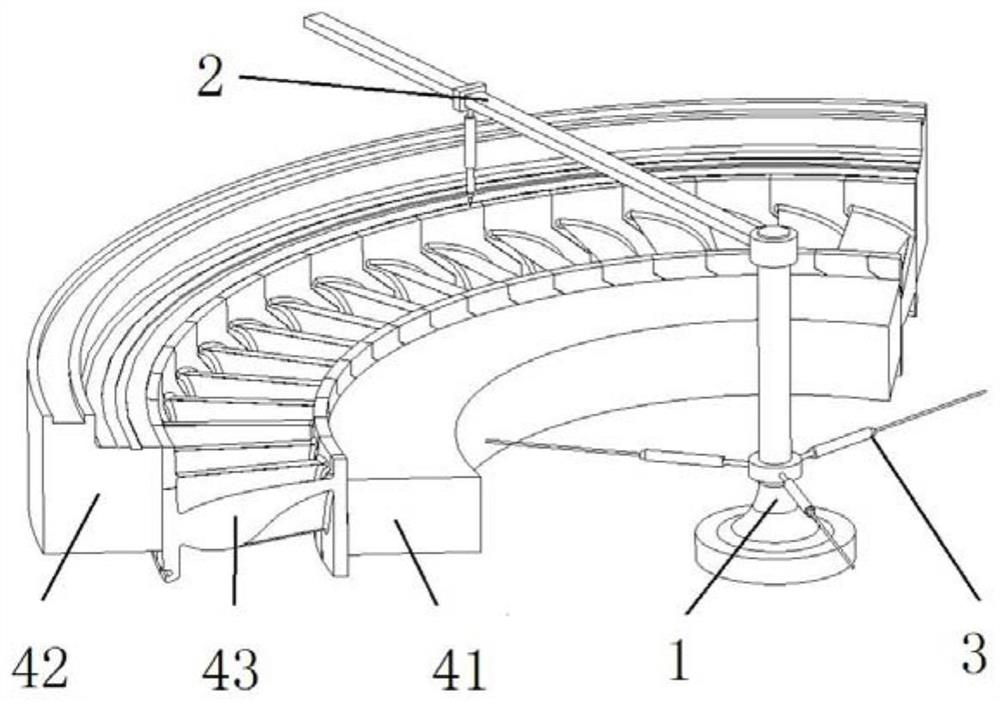

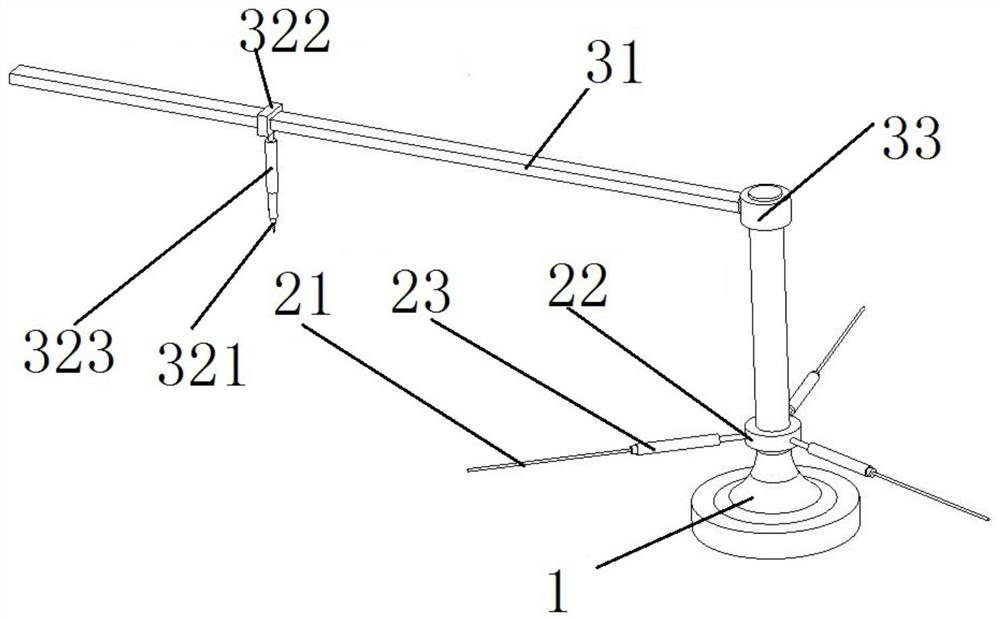

[0052] This embodiment provides a marking line positioning device, such as Figure 1 to Figure 7 As shown, it includes: a support 1 , a center positioning structure 2 and a rotary marking structure 3 . Wherein, the circle center positioning structure 2 is installed on the support member 1, and is used to carry out the circle center positioning of the inner circle 411 of the surface to be marked, and the rotary marking mechanism 32 is installed on the support member 1, and is positioned on the circle surface to be marked on the same radius size. A line mark is formed on the line surface.

[0053] Specifically, as figure 1 with figure 2 As shown, the partition in this embodiment includes a partition inner ring 41 and a partition outer ring 42, wherein the surface to be marked in this embodiment is a structure of several guide vanes 43, and the partition inner ring 41 is circular The inner circle 411 of the partition inner ring 41 has a cylindrical structure, and the central ...

Embodiment 2

[0064] This embodiment provides a scribing method for throat width detection, including the following steps:

[0065] S1: Fix the length of all radius positioning parts 21;

[0066] Adjust the third telescopic piece 231 and the fourth telescopic piece 232, thereby determine the distance that the radius positioning piece 21 protrudes relative to the second rotary piece 22, and ensure that the distance lengths that the three radius positioning pieces 21 protrude are equal. Specifically, you can pass The length scales on all the radius positioning members 21 are equal to ensure that the protruding lengths of the three radius positioning members 21 are equal;

[0067] S2: Determine the position of support 1:

[0068] The supporting member 1 is positioned at the center of the three radius positioning members 21 to determine the bottom placement position of the supporting member 1. Since the base area of the supporting member 1 is relatively large, the axial direction of the supp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com