Tool component for cutting touch screen protection film

A cutting tool assembly and protective film technology, which is applied in metal processing and other directions, can solve the problem that the protective film 16 cannot be cut off, and achieve the effects of precise pressure control, electrode protection, and weakened stab wounds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

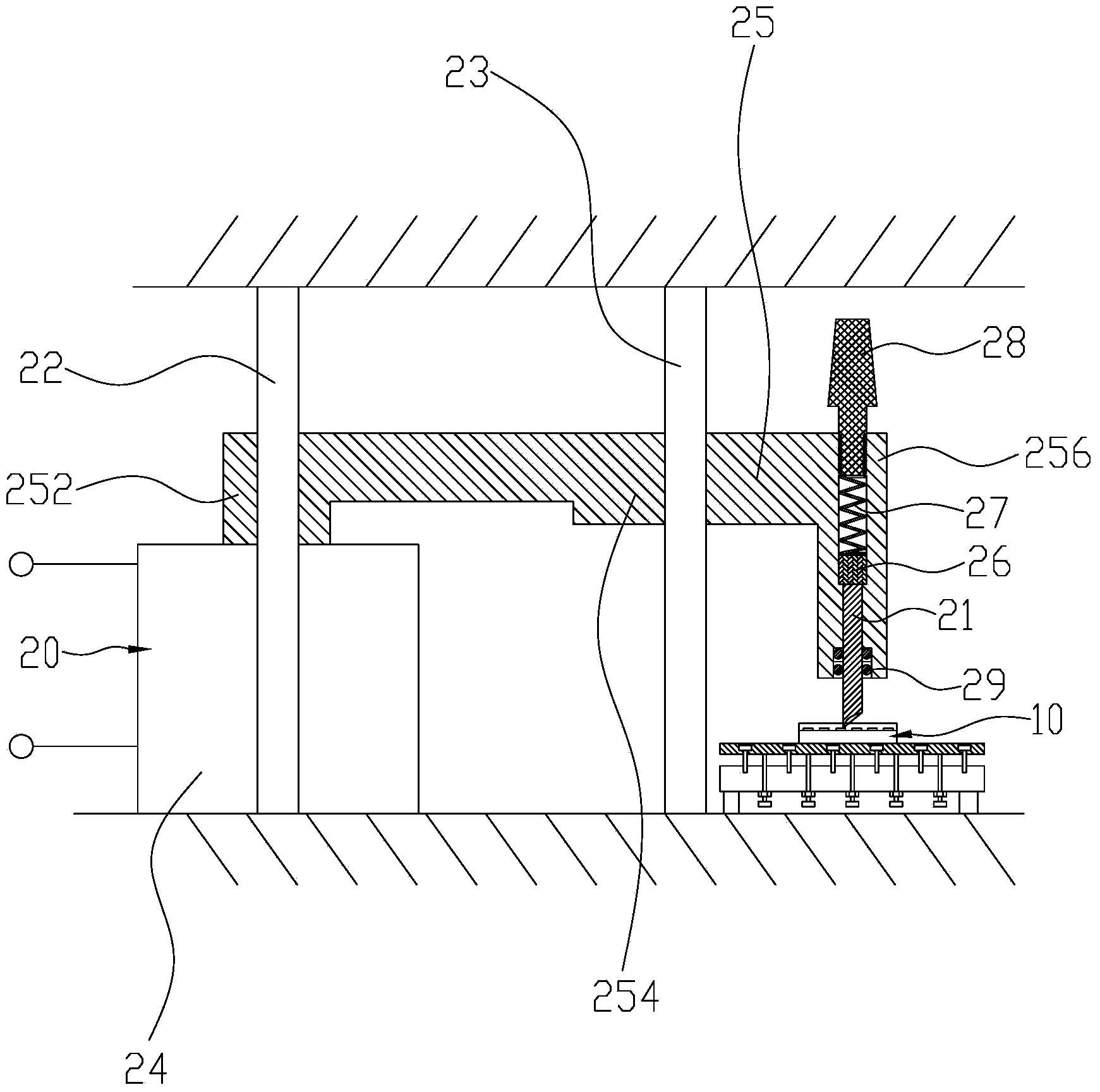

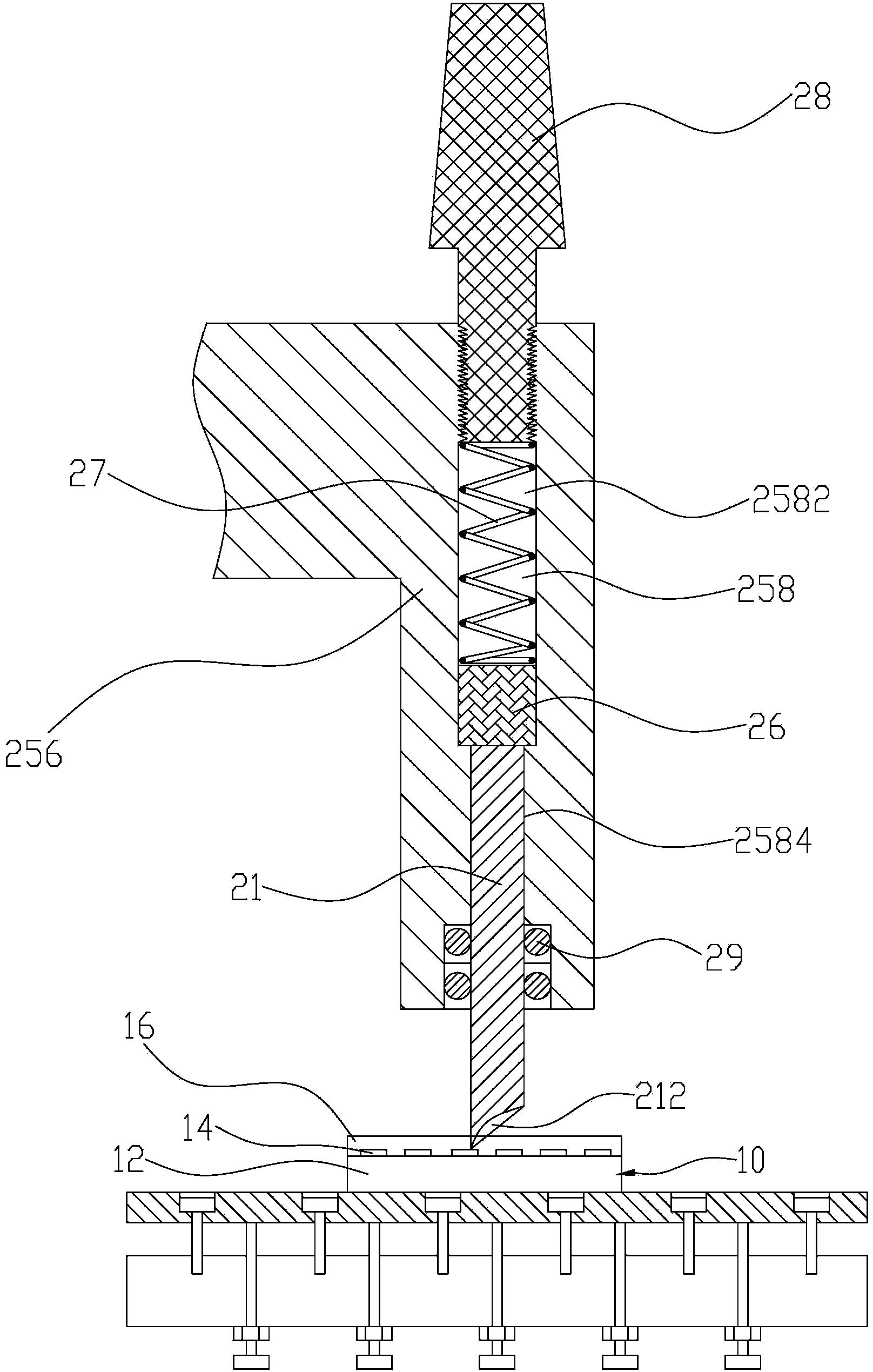

[0022] Please refer to figure 2 , a cutter assembly 20 for cutting the protective film of the touch screen of the present invention includes a cutter 21, a first guide post 22, a second guide post 23, an electromagnet 24, a knife seat 25, a magnetic block 26, An ejector 27 , a knob 28 and a bearing 29 . The cutter assembly 20 can precisely adjust the cutting pressure of the cutter 21 so that the cutting pressure of the cutter 21 is between 1-20 grams.

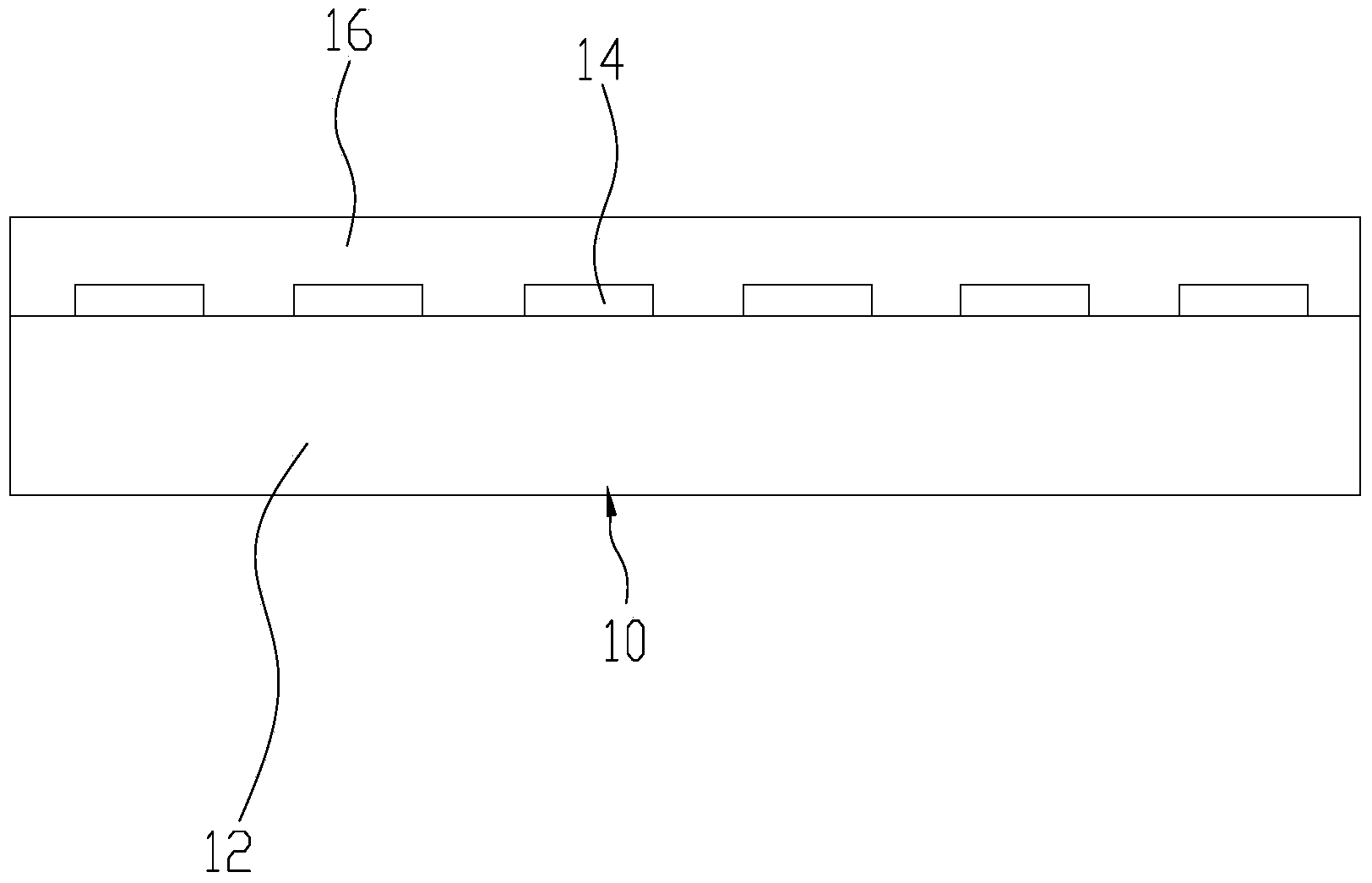

[0023] The head of the cutting knife 21 has a cutting edge 212 . The blade 212 is in the shape of an arc, such as Figure 4 shown.

[0024] The electromagnet 24 can generate a magnetic force for attracting the tool seat 25 when energized. The greater the current, the greater the magnetic force generated by the electromagnet 24.

[0025] The knife seat 25 includes a first guiding portion 252 , a second guiding portion 254 and a mounting portion 256 . The installation portion 256 defines a through hole 258 , the through ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com