Paint spraying device for machining of automobile parts and spraying method of paint spraying device

A technology for auto parts and paint spraying equipment, applied in spray booths, spraying devices, liquid spraying devices, etc., can solve the problems of large operation volume, inconvenient horizontal and vertical movement of workers, and small spraying range of paint spraying equipment, so as to improve operation efficiency. , Improve the effect of spraying range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

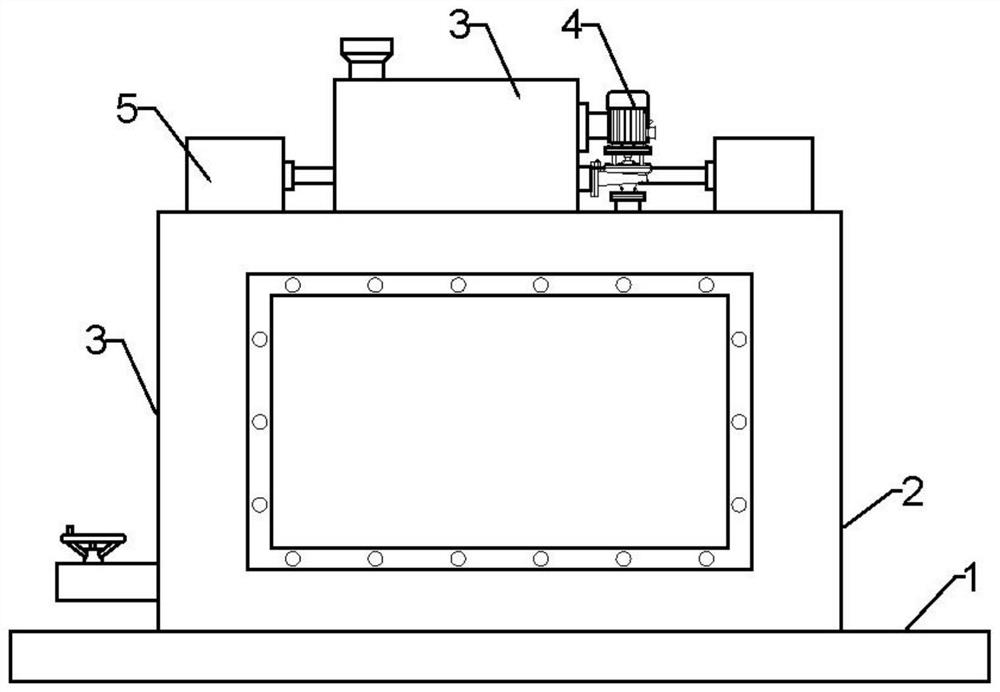

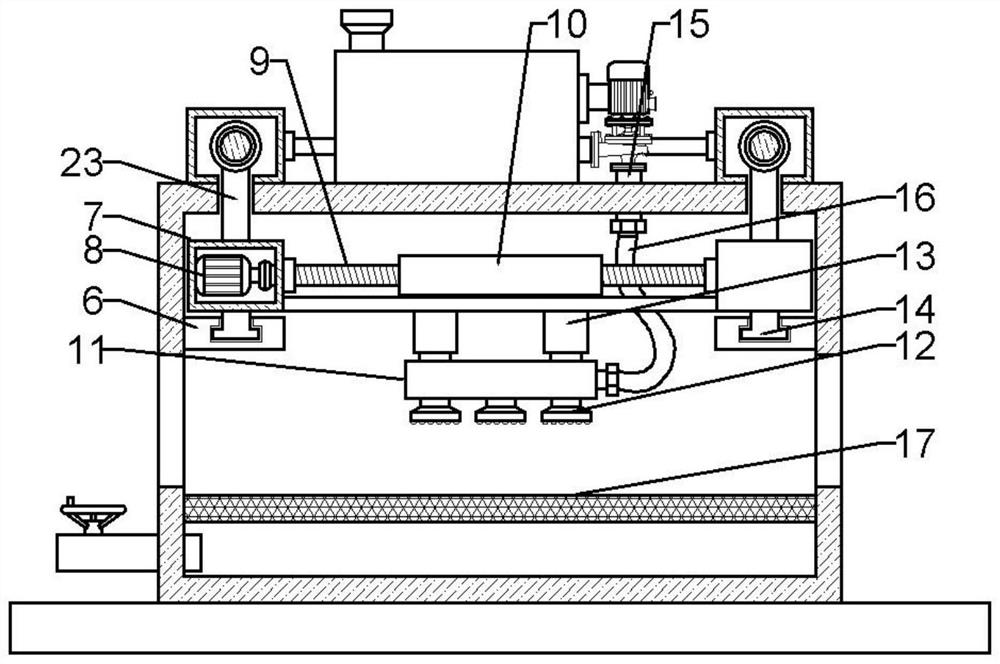

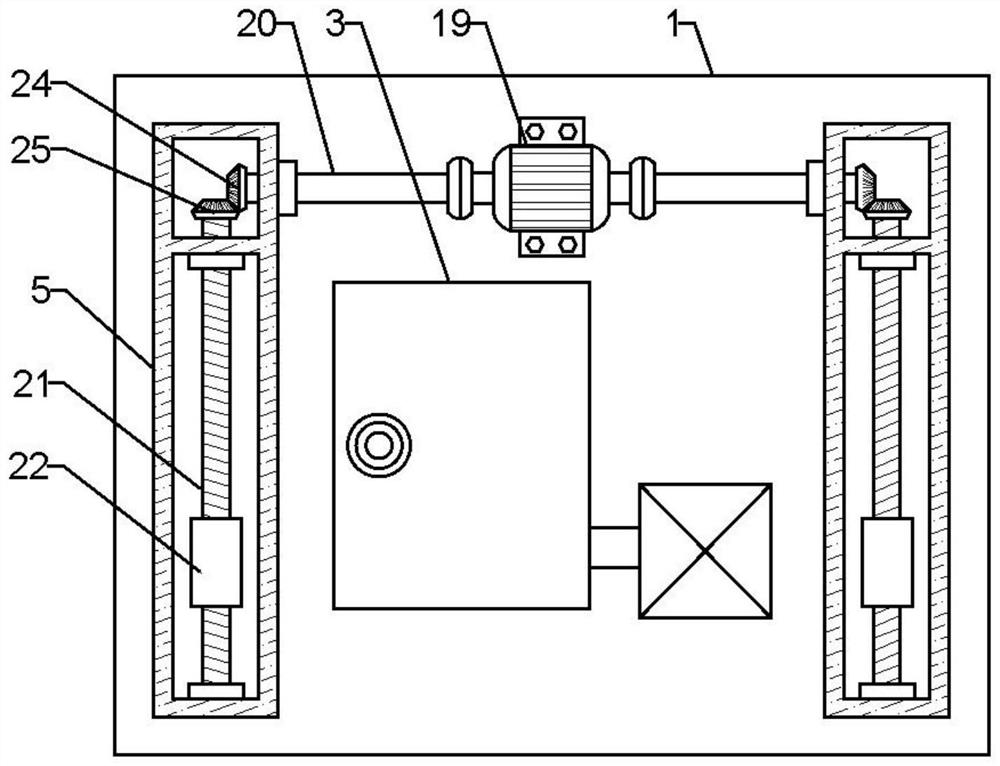

[0029] Embodiment 1: see Figure 1-4 , a kind of painting equipment for automobile parts processing, including a base 1, a protective box 2, a traverse assembly, a spray assembly, a longitudinal assembly and a transmission assembly, the top surface of the base 1 is fixed with a protective box 2, and the protective box The middle part of the top surface of 2 is fixed with a rectangular liquid storage tank 3, and the upper part of the other side of the liquid storage tank 3 is vertically fixed with a booster pump 4, and the model of the booster pump 4 is ISG50-125 ISW50-125. Both sides of the top surface of the protective box 2 are fixed horizontally and vertically with rectangular fixed beams 5, and the rear ends of each fixed beam 5 are provided with rectangular transmission chambers, and each transmission chamber is equipped with Transmission assembly; the fixed beam 5 at the front end of each transmission chamber is provided with a rectangular adjustment chamber longitudinal...

Embodiment 2

[0034] Example 2: see Figure 5 , in the present embodiment, the present invention also proposes a spraying method of a paint spraying equipment for automobile parts processing, comprising the following steps:

[0035] Step 1: First, the booster pump 4, the driving motor 8, the electric push cylinder 13 and the biaxial motor 19 are electrically connected to the external power supply through wires respectively; On the fixed net 17 inside;

[0036] Step 2: Control the expansion and contraction of the electric push cylinder 13 to drive the booster tank 11 to descend; control the booster pump 4 to extract the paint liquid from the liquid storage tank 3, and transport it into the booster tank through the connecting hose 16 at the bottom of the liquid inlet pipe 15 Inside 11; after being pressurized by the booster pump 4, the paint liquid is sprayed on the surface of the auto parts through the atomizing nozzle 12;

[0037] Step 3, by controlling the drive motor 8 to drive the thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com